lock code CHRYSLER VOYAGER 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 492 of 2339

driver and the front seat passenger to the structure

of the instrument panel (Refer to 8 - ELECTRICAL/

RESTRAINTS/KNEE BLOCKER AIRBAG -

DESCRIPTION). The seat belt tensioners remove the

slack from the front seat belts to provide further

assurance that the driver and front seat passenger

are properly positioned and restrained for an airbag

deployment.

When the ORC monitors a problem in any of the

dual front airbag system circuits or components,

including the seat belt tensioners, it stores a Diag-

nostic Trouble Code (DTC) in its memory and sends

an electronic message to the EMIC to turn on the

airbag indicator. Proper testing of the supplemental

restraint system components, the Programmable

Communications Interface (PCI) data bus, the elec-

tronic message inputs to and outputs from the EMIC

or the ORC, as well as the retrieval or erasure of a

DTC from the ORC or the EMIC requires the use of

a scan tool. Refer to the appropriate diagnostic infor-

mation.

OCCUPANT CLASSIFICATION SYSTEM

The Occupant Classification System (OCS) auto-

matically suppresses or enables passenger airbag and

seat belt tensioner operation based upon whether or

not the passenger side front seat is occupied and, if

the seat is occupied, classifies the size of the occu-

pant and whether the seat is occupied by a child

seat.

The OCS has an Occupant Classification Module

(OCM) that monitors inputs from the seat weight

bladder pressure sensor under the passenger side

front seat cushion and from the belt tension sensor

on the passenger side front seat belt lower anchor.

Based upon those inputs the microprocessor within

the OCM classifies the occupant of the passenger

side front seat. The OCM then sends electronic occu-

pant classification messages to the ORC. The micro-

processor and programming of the ORC uses these

occupant classification messages to determine

whether to enable or disable the deployment circuits

for the passenger airbag and seat belt tensioner.

The OCS electrical circuits and components are

continuously monitored by the OCM, and the OCM is

continuously monitored by the ORC. A passenger air-

bag ON/OFF indicator is located in the instrument

panel center stack area. This indicator receives bat-

tery current whenever the ignition switch is in the

ON or START positions, and illuminates only when

the ORC pulls the indicator control circuit to ground.

The indicator illuminates for about seven seconds as

a bulb test each time the ignition switch is turned to

the ON or START positions. Following the bulb test,

the indicator is turned ON or OFF by the ORC based

upon the electronic occupant classification messagesreceived from the OCM. This indicator is illuminated

whenever the passenger airbag and seat belt ten-

sioner operation has been suppressed, and is turned

OFF whenever they are enabled or when the passen-

ger seat is classified as empty.

When the OCM monitors a problem in any of the

OCS circuits or components, it stores a fault code or

DTC in its memory circuit and sends an electronic

message to the ORC. The ORC then sends an elec-

tronic message to the EMIC to turn ON the airbag

indicator. If for any reason the OCM is unable to

classify the occupant it sends an electronic message

to the ORC, and the ORC suppresses passenger air-

bag and seat belt tensioner operation. Proper testing

of the OCS components, the Programmable Commu-

nications Interface (PCI) data bus, the electronic

message inputs to and outputs from the OCM, the

EMIC or the ORC, as well as the retrieval or erasure

of a DTC's, requires the use of a scan tool. Refer to

the appropriate diagnostic information.

WARNING

WARNINGS

Disconnect and isolate the battery negative

cable before beginning any airbag system com-

ponent diagnosis, testing, removal, or installa-

tion procedures. Allow system capacitor to

discharge for two minutes before beginning any

component testing or service. This will disable

the airbag system. Failure to disconnect the

battery negative cable may result in accidental

airbag deployment, personal injury, or death.

Do not place an intact undeployed airbag

face down on a solid surface. The airbag will

propel into the air if accidentally deployed and

may result in personal injury or death.

When carrying or handling an undeployed

airbag, the trim side (face) of the airbag should

be pointing towards the body to minimize pos-

sibility of injury if accidental deployment

occurs. Failure to do this may result in per-

sonal injury or death.

Replace airbag system components with

Mopartreplacement parts. Substitute parts

may appear interchangeable, but internal dif-

ferences may result in inferior occupant protec-

tion. Failure to do so may result in occupant

personal injury or death.

Wear safety glasses, rubber gloves, and long

sleeved clothing when cleaning powder residue

from vehicle after airbag deployment. Sodium

hydroxide powder residue emitted from a

deployed airbag can cause skin irritation.

Flush affected area with cool water if irritation

is experienced. If nasal or throat irritation is

RSRESTRAINTS8O-5

RESTRAINTS (Continued)

Page 493 of 2339

experienced, exit the vehicle for fresh air until

the irritation ceases. If irritation continues, see

a physician.

Do not use a replacement airbag that is not in

the original packaging. This may result in

improper deployment, personal injury, or

death.

The factory installed fasteners, screws and

bolts used to fasten airbag components have a

special coating and are specifically designed

for the airbag system. Do not use substitute fas-

teners. Use only original equipment fasteners

listed in the parts catalog when fastener

replacement is required.

During, and following, any child restraint

anchor service, due to impact event or vehicle

repair, carefully inspect all mounting hard-

ware, tether straps, and anchors for proper

installation, operation, or damage. If a child

restraint anchor is found damaged in any way,

the anchor must be replaced. Failure to do this

may result in personal injury or death.

Deployed and nondeployed airbags may or

may not have live pyrotechnic material within

the airbag inflator. Do not dispose of driver/

passenger/seat/curtain/knee blocker airbags or

seat belt tensioners unless you are sure of com-

plete deployment. Refer to the Hazardous Sub-

stance Control System for proper disposal.

Dispose of deployed airbags and tensioners

consistent with state, provincial, local, and fed-

eral regulations.

After any airbag component testing or ser-

vice, do not connect the battery negative cable

(Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM).

Personal injury or death may result if the sys-

tem test is not performed first.

If the vehicle is equipped with the Occupant

Classification System (OCS), do not connect the

battery negative cable before performing the

OCS Verification Test using the scan tool and

the appropriate diagnostic information. Per-

sonal injury or death may result if the system

test is not performed properly.

Never replace both the Occupant Restraint

Controller (ORC) and the Occupant Classifica-

tion Module (OCM) at the same time. If both

require replacement, replace one, then perform

the Airbag System test (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - DIAGNOSIS AND TESTING

- AIRBAG SYSTEM) before replacing the other.

Both the ORC and the OCM store Occupant

Classification System (OCS) calibration data,

which they transfer to one another when one of

them is replaced. If both are replaced at thesame time, an irreversible fault will be set in

both modules and the OCS may malfunction

and cause personal injury or death.

DIAGNOSIS AND TESTING - AIRBAG SYSTEM

(1) With the battery negative remote cable discon-

nected, connect the scan tool to the Data Link Con-

nector (DLC).

(2) Turn the ignition key to the ON position, then

exit vehicle with the scan tool.

(3) After checking that no one is inside the vehicle,

connect the battery negative remote terminal.

(4) Read and record theACTIVEDiagnostic Trou-

ble Code (DTC) data.

(5) Read and record anySTOREDDTC's.

(6) Refer to the proper diagnostic information if

any DTC's are found in Step 4 and Step 5.

(7) If the airbag warning lamp either fails to light,

or goes ON and stays ON, there is a system malfunc-

tion. To test the airbag warning lamp (bulb) opera-

tion in the cluster (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Refer to the proper diagnostic informa-

tion for any other system problems.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

AIRBAGS

DEPLOYED AIRBAG

WARNING: The vehicle interior may contain a very

small amount of powder, a by-product of airbag

deployment. This powder can irritate the skin, eyes,

nose and throat. Wear safety glasses, rubber

gloves, and long sleeved clothing when cleaning

any of the powder residue from the vehicle. If you

find that the cleanup is irritating your skin, run cool

water over the affected area. Also, if you experience

nasal or throat irritation, exit the vehicle for fresh

air until the irritation ceases. If irritation continues,

see a physician.

8O - 6 RESTRAINTSRS

RESTRAINTS (Continued)

Page 503 of 2339

INSTALLATION

(1) Position curtain airbag over retaining holes in

roof rail and firmly snap into place (Fig. 17).

(2) Install the curtain airbag retaining bolts (Fig.

17).

(3) Engage the side curtain airbag front tether in

the A-pillar and install retaining bolt (Fig. 16).

(4) Install the bolt in the curtain airbag inflator

mounting bracket (Fig. 18).

(5) Install the retaining bolts at the d-pillar (Fig.

19).

(6) Connect the curtain airbag squib connector

(Fig. 15).

(7) Install the headliner into the vehicle (Refer to

23 - BODY/INTERIOR/HEADLINER - INSTALLA-

TION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(8) Verify vehicle and system operation.

(9) Close hood.

DRIVER AIRBAG

DESCRIPTION

The injection molded, thermoplastic driver airbag

protective trim cover is the most visible part of the

driver airbag. The driver airbag is located in the cen-

ter of the steering wheel, where it is secured to the

steering wheel armature. Concealed beneath the

driver airbag trim cover are the horn switch, thefolded airbag cushion, the airbag cushion retainer,

the airbag housing, the airbag inflator, and the

retainers that secure the inflator to the airbag hous-

ing. The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover.

The resistive membrane-type horn switch is

secured with heat stakes to the inside surface of the

driver airbag trim cover, between the trim cover and

the folded airbag cushion. The horn switch ground

pigtail wire has a female spade terminal connector

that receives a path to ground through a male spade

terminal that is integral to the driver airbag housing

stamping and is located near the upper right corner

on the back of the housing. The horn switch feed pig-

tail wire has a white, molded plastic insulator that is

secured by an integral retainer to a mounting hole

located near the lower left corner on the back of the

housing, and is connected to the vehicle electrical

system through a take out and connector of the steer-

ing wheel wire harness.

The airbag is a multistage unit that deploys with

less force than those previously used. The airbag

inflator is a dual-initiator, non-azide, pyrotechnic-

type unit with four mounting studs and is secured to

the stamped metal airbag housing using four hex

nuts with washers. Two keyed and color-coded con-

nector receptacles on the driver airbag inflator con-

nect the two inflator initiators to the vehicle

electrical system through two yellow or black-jack-

eted, two-wire pigtail harnesses of the clockspring.

The driver airbag, trim cover, and horn switch unit

cannot be repaired, and must be replaced if deployed

or in any way damaged.

OPERATION

The Driver Airbag Trim Cover contains the horn

switch, inflator device, and a fabric bag. The driver

airbag trim cover/horn switch is not serviced sepa-

rately from the driver airbag components.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly

²Lower Steering Column Coupler

²Steering Wheel.

²Clockspring.

²Driver Airbag

²Passenger Airbag

²Knee Blocker Airbag

²Upper Instrument Panel with Pad

²Front Seat Belt Buckles, both driver and passen-

ger with integral tensioners.

Fig. 19 CURTAIN AIRBAG D-PILLAR ATTACHMENT

1 - CURTAIN AIRBAG D-PILLAR ATTACHMENT LOCATIONS

2 - D-PILLAR

3 - ROOF RAIL AT REAR QUARTER GLASS

8O - 16 RESTRAINTSRS

CURTAIN AIRBAG (Continued)

Page 513 of 2339

anchor. The OCM then monitors the return voltage

from each of the sensors. The bladder pressure sen-

sor input allows the OCM to determine whether the

passenger front seat is occupied and the relative size

of the occupant by providing a weight-sensing refer-

ence to the load on the seat cushion. The belt tension

sensor provides an additional logic input to the OCM

microprocessor that allows it to distinguish between

the lower seat belt cinch loads of a belted occupant

and the higher loads associated with a belted child

seat.

Pre-programmed decision algorithms and OCS cal-

ibration allow the OCM microprocessor to determine

when the seat cushion load as signaled by the blad-

der pressure sensor and the seat belt cinch load as

signaled by the belt tension sensor indicate that pas-

senger airbag protection is appropriate. When the

programmed conditions are met, the OCM sends the

proper electronic occupant classification messages

over the PCI data bus to the Occupant Restraint

Controller (ORC), and the ORC enables or disables

the deployment circuits for the passenger front sup-

plemental restraints. The ORC also provides a con-

trol output for the Passenger Airbag Disabled (PAD)

indicator in the instrument panel center stack, based

upon the electronic occupant classification messages

it receives from the OCM.

The OCM microprocessor continuously monitors all

of the OCS electrical circuits and components to

determine the system readiness. If the OCM detects

a monitored system fault, it sets an active and stored

Diagnostic Trouble Code (DTC) and sends the appro-

priate electronic messages to the ORC over the PCI

data bus. Then the ORC sets a DTC and sends mes-

sages to control the airbag indicator operation

accordingly. An active fault only remains for the

duration of the fault, or in some cases for the dura-

tion of the current ignition switch cycle, while a

stored fault causes a DTC to be stored in memory by

the OCM and the ORC. For some DTC's, if a fault

does not recur for a number of ignition cycles, the

OCM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

The OCM receives battery current from an IPM

high side driver (Run/Start). The OCM receives

ground through a ground circuit of the body wire

harness, which it shares with the ORC. These con-

nections allow the OCM to be operational whenever

the ignition switch is in the Start or ON positions.

To diagnose and test the OCS, use a scan tool and

the appropriate diagnostic information.

REMOVAL

Once any of the original factory-installed compo-

nents except the Occupant Classification Module(OCM) have been replaced with the service replace-

ment package components, the OCM can only be ser-

viced by replacing the entire passenger front seat

cushion unit with another complete service replace-

ment package (Refer to 23 - BODY/SEATS/SEAT

CUSHION - FRONT - REMOVAL).

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Disconnect and isolate the battery negative

cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(3) Reach under the front edge of the passenger

side front seat cushion to access and remove the lock

pin from the connector lock tower on the Occupant

Classification Module (OCM) (Fig. 36).

(4) Disconnect the passenger front seat wire har-

ness connector for the OCM.

(5) Remove the two screws that secure the OCM to

the OCM bracket.

(6) Remove the OCM from under the passenger

front seat.

INSTALLATION

WARNING: To avoid personal injury or death on

vehicles equipped with the Occupant Classification

System (OCS), only the Occupant Classification

Module (OCM) and the seat cushion trim may be

serviced separately. All other components of the

passenger front seat cushion must be serviced only

as a complete factory-calibrated, assembled and

tamper-evident service replacement package.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

8O - 26 RESTRAINTSRS

OCCUPANT CLASSIFICATION MODULE (Continued)

Page 515 of 2339

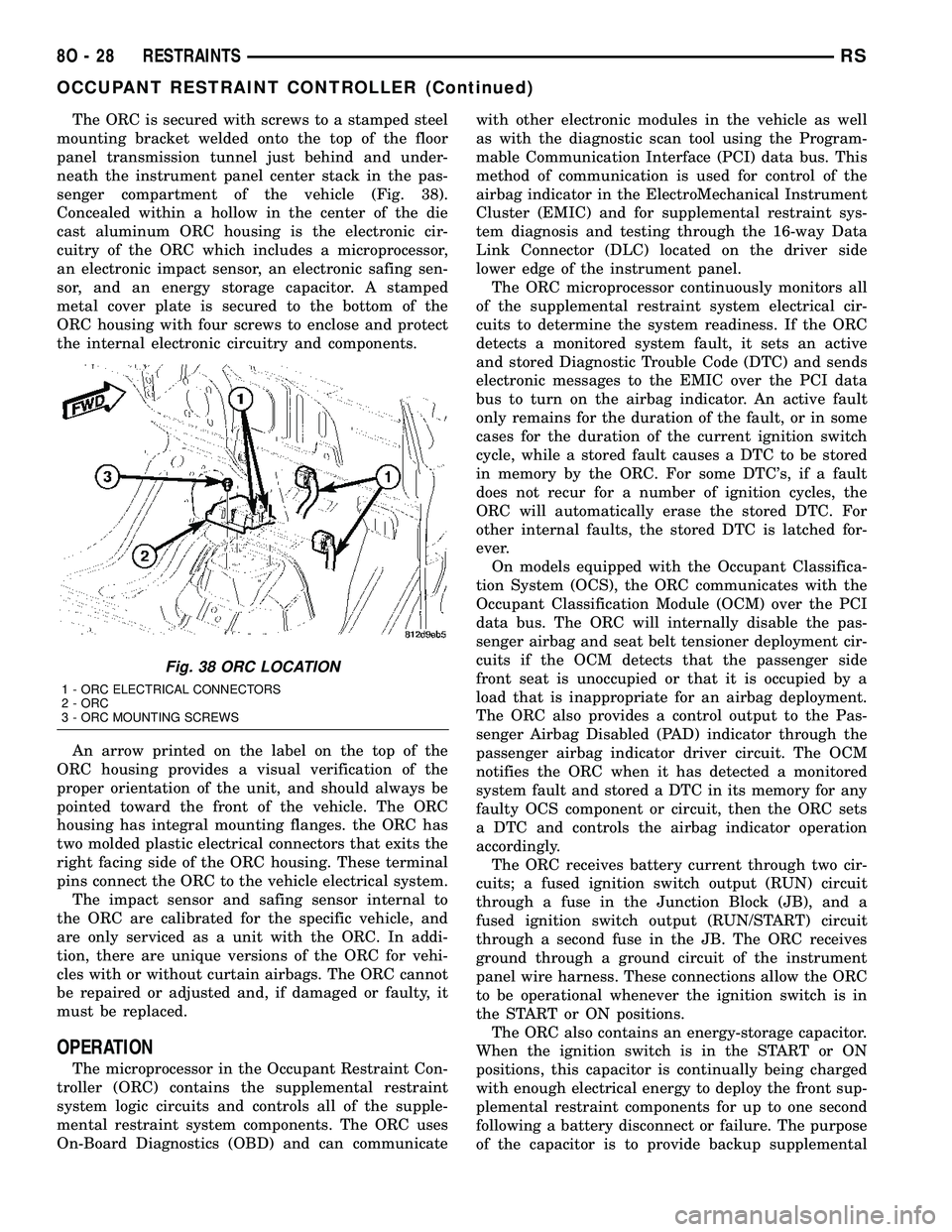

The ORC is secured with screws to a stamped steel

mounting bracket welded onto the top of the floor

panel transmission tunnel just behind and under-

neath the instrument panel center stack in the pas-

senger compartment of the vehicle (Fig. 38).

Concealed within a hollow in the center of the die

cast aluminum ORC housing is the electronic cir-

cuitry of the ORC which includes a microprocessor,

an electronic impact sensor, an electronic safing sen-

sor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ORC housing with four screws to enclose and protect

the internal electronic circuitry and components.

An arrow printed on the label on the top of the

ORC housing provides a visual verification of the

proper orientation of the unit, and should always be

pointed toward the front of the vehicle. The ORC

housing has integral mounting flanges. the ORC has

two molded plastic electrical connectors that exits the

right facing side of the ORC housing. These terminal

pins connect the ORC to the vehicle electrical system.

The impact sensor and safing sensor internal to

the ORC are calibrated for the specific vehicle, and

are only serviced as a unit with the ORC. In addi-

tion, there are unique versions of the ORC for vehi-

cles with or without curtain airbags. The ORC cannot

be repaired or adjusted and, if damaged or faulty, it

must be replaced.

OPERATION

The microprocessor in the Occupant Restraint Con-

troller (ORC) contains the supplemental restraint

system logic circuits and controls all of the supple-

mental restraint system components. The ORC uses

On-Board Diagnostics (OBD) and can communicatewith other electronic modules in the vehicle as well

as with the diagnostic scan tool using the Program-

mable Communication Interface (PCI) data bus. This

method of communication is used for control of the

airbag indicator in the ElectroMechanical Instrument

Cluster (EMIC) and for supplemental restraint sys-

tem diagnosis and testing through the 16-way Data

Link Connector (DLC) located on the driver side

lower edge of the instrument panel.

The ORC microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ORC

detects a monitored system fault, it sets an active

and stored Diagnostic Trouble Code (DTC) and sends

electronic messages to the EMIC over the PCI data

bus to turn on the airbag indicator. An active fault

only remains for the duration of the fault, or in some

cases for the duration of the current ignition switch

cycle, while a stored fault causes a DTC to be stored

in memory by the ORC. For some DTC's, if a fault

does not recur for a number of ignition cycles, the

ORC will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

On models equipped with the Occupant Classifica-

tion System (OCS), the ORC communicates with the

Occupant Classification Module (OCM) over the PCI

data bus. The ORC will internally disable the pas-

senger airbag and seat belt tensioner deployment cir-

cuits if the OCM detects that the passenger side

front seat is unoccupied or that it is occupied by a

load that is inappropriate for an airbag deployment.

The ORC also provides a control output to the Pas-

senger Airbag Disabled (PAD) indicator through the

passenger airbag indicator driver circuit. The OCM

notifies the ORC when it has detected a monitored

system fault and stored a DTC in its memory for any

faulty OCS component or circuit, then the ORC sets

a DTC and controls the airbag indicator operation

accordingly.

The ORC receives battery current through two cir-

cuits; a fused ignition switch output (RUN) circuit

through a fuse in the Junction Block (JB), and a

fused ignition switch output (RUN/START) circuit

through a second fuse in the JB. The ORC receives

ground through a ground circuit of the instrument

panel wire harness. These connections allow the ORC

to be operational whenever the ignition switch is in

the START or ON positions.

The ORC also contains an energy-storage capacitor.

When the ignition switch is in the START or ON

positions, this capacitor is continually being charged

with enough electrical energy to deploy the front sup-

plemental restraint components for up to one second

following a battery disconnect or failure. The purpose

of the capacitor is to provide backup supplemental

Fig. 38 ORC LOCATION

1 - ORC ELECTRICAL CONNECTORS

2 - ORC

3 - ORC MOUNTING SCREWS

8O - 28 RESTRAINTSRS

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 539 of 2339

RG Only- If fault is detected on the driver key

cylinder input, the indicator LED will remain solid

during the arming process, although the system will

still arm.

If the indicator LED does not illuminate at all

upon door closing it indicates that the system is not

arming.

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the remote trans-

mitter (RG - ignition key or remote transmitter). This

disarming will also halt the alarm once it has been

activated.

A tamper alert exists to notify the driver that the

VTSS had been activated. This alert consists of 3

horn pulses when the vehicle is disarmed.

NOTE: The VTSS will not arm by pushing down the

door lock mechanism. This will manually override

the system.

RG Only- For Door Cylinder Lock Switch

Removal and Installation, refer to Electrical, Power

Locks, Door Cylinder Lock Switch.

If the VTSS is triggered, the horn will pulse, head-

lamps/marker lamps will flash, and the VTSS warn-

ing lamp will flash. If BCM determines the threat to

be false and the VTSS is not triggered again, the sys-

tem will shut down and rearm itself after three min-

utes. If a trigger is still active, the alarm will

continue for an additional 15 minutes without the

horn. The VTSS monitors the passenger compart-

ment (for RG - Export it also monitors the engine

compartment. If a malfunction occurs in the engine

compartment, the passenger compartment would still

arm and function normally).

NOTE: System will not arm if passenger compart-

ment is not secure.

NOTE: (RG - Export - If hood is not secure during

the arming sequence, the lamp will stay lit and not

flash. The system will arm with hood not secured

and the liftgate open).

ARMING THE VTSS - METHOD A

(1) With the key removed from the ignition lock

and any door open (excluding liftgate), actuate one of

the following:

²Power door lock button to LOCK,

²Key fob LOCK button

²Driver door lock key cylinder to locked position

(RG Only).

(2) Close all opened doors. Liftgate can remain

open.(3) After the last door is closed, an arming time-

out period of sixteen seconds will start, then the

VTSS will become armed.

ARMING THE VTSS - METHOD B

Actuating the key fob transmitter LOCK button,

key locking the front doors with the doors closed and

the ignition locked will begin the arming time-out

period. If method A, 16 second time-out sequence was

in process when method B was actuated, the 16 sec-

ond time-out will restart from the time of the second

actuation.

If the security lamp does not illuminate at all upon

final door closure, it indicates that the system is not

arming.

The current VTSS status armed or disarmed shall

be maintained in memory to prevent battery discon-

nects from disarming the system.

TRIGGERING THE VTSS

After the VTSS is armed, the following actions will

trigger the alarm:

²Opening any door (liftgate - only if opening via

liftgate button on key fob).

²Opening the hood (RG - Export)

²Turning the ignition to the RUN position.

NOTE: When the VTSS is ARMED, the interior

power door lock switch ªUNLOCKº will be disabled

until the vehicle is disarmed.

CAUTION: The VTSS indicator LED will trigger and

engine will continue to run if the vehicle is

equipped with SKREES and the proper key is used

to start the vehicle. This condition will occur if the

VTSS has been triggered. If valid key is used, VTSS

will disarm

SENTRY KEY REMOTE ENTRY SYSTEM

The SKREES includes keys from the factory which

are pre-programmed. Each SKREEM will recognize a

maximum of eight Sentry Keys. If the customer

would like to own additional keys other than those

provided with the vehicle, they can be purchased

from any authorized dealer. These keys must be pro-

grammed to the SKREEM on the vehicle in order for

the system to recognize them as valid keys. This can

be done by the dealer with a DRBllltscan tool or by

a customer if this feature is available in their market

and they have two (2) valid keys already available to

them. Refer to the Service Procedures portion of this

system for additional details. The SKREES performs

a self-test each time the ignition switch is turned to

the ON position and will store Diagnostic Trouble

Codes (DTC's) if a system malfunction is detected.

8Q - 2 VEHICLE THEFT SECURITYRS

VEHICLE THEFT SECURITY (Continued)

Page 541 of 2339

(PCM) based upon the results. The ªVALID/INVALID

KEYº message communication is performed using a

rolling code algorithm via the Programmable Com-

munication Interface (PCI) data bus. A ªVALID KEYº

message must be sent to the Powertrain Control

Module (PCM) within two seconds of ignition ON to

free the engine from immobilization.

The SKREEM contains a Radio Frequency (RF)

transceiver and a microprocessor. The SKREEM

retains in memory the ID numbers of any Sentry Key

that is programmed to it. The maximum number of

keys that may be programmed to each module is

eight (8). The SKREEM also communicates over the

Programmable Communication Interface (PCI) data

bus with the Powertrain Control Module (PCM), the

Body Control Module (BCM), the Mechanical Instru-

ment Cluster (MIC), and the DRB IIItscan tool. The

SKREEM transmits and receives RF signals through

a tuned antenna enclosed within a molded plastic

ring formation that is integral to the SKREEM hous-

ing. When the SKREEM is properly installed on the

steering column, the antenna ring fits snugly around

the circumference of the ignition lock cylinder hous-

ing. If this ring is not mounted properly, communica-

tion problems may arise in the form of transponder-

related faults.

For added system security, each SKREEM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKREEM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKREEM for service. The SKREEM also stores in its

memory the Vehicle Identification Number (VIN),

which it learns through a bus message from the

assembly plant tester. The SKIS scrambles the infor-

mation that is communicated between its components

in order to reduce the possibility of unauthorized

SKREEM access and/or disabling.

REMOTE KEYLESS ENTRY (RKE)

The RKE transmitter uses radio frequency signals

to communicate with the SKREEM. The SKREEM is

on the PCI bus. When the operator presses a buttonon the transmitter, it sends a specific request to the

SKREEM. In turn the SKREEM sends the appropri-

ate request over the PCI Bus to the:

²Body Control Module (BCM) to control the door

lock and unlock functions, the liftgate lock and

unlock functions, the arming and disarming of the

Vehicle Theft Security System (VTSS) (if equipped),

and the activation of illuminated entry.

²Integrated Power Module (IPM) to activate the

park lamps, the headlamps, and the horn for horn

chirp. If requested, the BCM sends a request over

the PCI Bus to the:

TIRE PRESSURE MONITORING (TPM)

If equipped with the Tire Pressure Monitoring

(TPM) System, each of the vehicles four wheels will

have a valve stem with a pressure sensor and radio

transmitter built in. Signals from the tire pressure

sensor/transmitter are received and interpreted by

the SKREEM.

A sensor/transmitter in a mounted wheel will

broadcast its detected pressure once per minute

when the vehicle is moving faster than 15 mph (24

km/h). Each sensor/transmitter's broadcast is

uniquely coded so that the SKREEM can determine

the location.

OPERATION

SENTRY KEY IMMOBILIZER

The Sentry Key Remote Entry Module (SKREEM)

receives an encrypted Radio Frequency (RF) signal

from the transponder key. The SKREEM then

decrypts the signal and broadcasts the requested

remote commands to the appropriate modules in the

vehicle over the Programmable Communication

Interface (PCI) data bus. A valid transponder key ID

must be incorporated into the RF signal in order for

the SKREEM to pass the message on to the appro-

priate modules.

Automatic transponder key synchronization is done

by the SKREEM if a valid transponder key is

inserted into the ignition cylinder, and the ignition is

turned ON. This provides a maximum operation win-

dow for RKE functions.

Each Sentry Key Remote Entry System (SKREES)

consists of a SKREEM and a transponder key. Each

system has a secret key code unique to that system.

The secret key is electronically coded in the

SKREEM and in all programmed transponder keys.

It is used for immobilization and RKE functions for

data security. In addition, each transponder key will

have a unique identification. For North America, the

options are a 3-button or 6 button integrated keys.

For Export, the options are 2-button or 5 button key

fobs. (Export does not get the integrated key).

8Q - 4 VEHICLE THEFT SECURITYRS

SENTRY KEY REMOTE ENTRY MODULE (Continued)

Page 542 of 2339

When the ignition switch is moved to the RUN

position, the SKREEM transmits an Radio Frequency

(RF) signal to the transponder in the ignition key.

The SKREEM then waits for a response RF signal

from the transponder in the key. If the response

received identifies the key as valid, the SKREEM

sends a9valid key9message to the Powertrain Con-

trol Module (PCM) over the Programmable Commu-

nication Interface (PCI) data bus. If the response

received identifies the key as invalid or no response

is received from the transponder in the ignition key,

the SKREEM sends an9invalid key9message to the

PCM. The PCM will enable or disable engine opera-

tion based upon the status of the SKREEM mes-

sages. It is important to note that the default

condition in the PCM is9invalid key.9Therefore, if no

response is received by the PCM, the engine will be

immobilized after two (2) seconds of running.

The SKREEM also sends indicator light status

messages to the Mechanical Instrument Cluster

(MIC) to operate the light. This is the method used to

turn the light ON solid or to flash it after the indi-

cator light test is complete to signify a fault in the

SKREES. If the light comes ON and stays ON solid

after the indicator light test, this signifies that the

SKREEM has detected a system malfunction and/or

that the SKREES has become inoperative. If the

SKREEM detects an invalid keyORa key-related

fault exists, the indicator light will flash following

the indicator light test. The SKREEM may also

request an audible chime if the customer key pro-

gramming feature is available and the procedure is

being utilized (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY/TRANSPONDER KEY - STAN-

DARD PROCEDURE).

REMOTE KEYLESS ENTRY (RKE)

After pressing the lock button on the RKE trans-

mitter, all of the door locks will lock, the illuminated

entry will turn off (providing all doors are closed),

and the VTSS (if equipped) will arm. After pressing

the unlock button, on the RKE transmitter, one time,

the driver door lock will unlock, the illuminated

entry will turn on the courtesy lamps, and the VTSS

(if equipped) will disarm. After pressing the unlock

button a second time, the remaining door locks will

unlock. The Electronic Vehicle Information Center

(EVIC) or the DRBIIItscan tool can reprogram this

feature to unlock all of the door locks with one press

of the unlock button. If the vehicle is equipped with

the memory system, the memory message will iden-

tify which transmitter (1 or 2) sent the signal.The SKREEM is capable of retaining up to 8 indi-

vidual access codes (8 transmitters). If the PRNDL is

in any position except park, the SKREEM will dis-

able the RKE. The 4 button transmitter uses

1-CR2032 battery. The minimum battery life is

approximately 4.7 years based on 20 transmissions a

day at 84ÉF (25ÉC). Use the DRBIIItscan tool or the

Miller Tool 9001 RF Detector to test the RKE trans-

mitter. Use the DRBIIItor the customer program-

ming method to program the RKE system. However,

the SKREEM will only allow RKE programming

when the ignition is in the ON position, the PRNDL

is in park position, and the VTSS (if equipped) is dis-

armed.

TIRE PRESSURE MONITORING (TPM)

The SKREEM monitors the signals from the tire

pressure sensor/transmitters and determines if any

tire has gone below the low pressure threshold LOW

TIRE PRESSURE THRESHOLDS table.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 193 kPa (28 PSI)

OFF 227 kPa (33 PSI)

CRITICAL AND NON-CRITICAL SYSTEM ALERTS

CRITICAL:A critical alert will be triggered when

a tire pressure has gone below a set threshold pres-

sure. The EVIC display will display ªX TIRE(S) LOW

PRESSUREº. ªXº will be the number of tires report-

ing low pressure. The message will display for the

duration of the current ignition cycle or until an

EVIC button is pressed. If the display is removed

without correcting the condition, it will reappear 300

seconds to warn the driver of the low pressure condi-

tion.

NON-CRITICAL:A non-critical alert will be trig-

gered when no signal is received from a sensor/trans-

mitter. The EVIC display in the cluster will display

ªSERVICE TIRE SYSTEM SOON.º

DIAGNOSIS AND TESTING - SENTRY KEY

REMOTE ENTRY MODULE

For proper diagnosis and testing of the Sentry Key

Remote Entry Module (SKREEM), use a DRBllltand

refer to the proper Body Diagnostic Procedures infor-

mation.

RSVEHICLE THEFT SECURITY8Q-5

SENTRY KEY REMOTE ENTRY MODULE (Continued)

Page 543 of 2339

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Steering Column Opening Cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(3) Remove the steering column upper and lower

shrouds (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - REMOVAL) and (Refer to 19 - STEER-

ING/COLUMN/LOWER SHROUD - REMOVAL).

(4) Disengage the steering column wire harness

from the Sentry Key Remote Entry Module

(SKREEM).

(5) Remove the one screws securing the SKREEM

to the steering column.

(6) Rotate the SKREEM upwards and then to the

side away from the steering column to slide the

SKREEM antenna ring from around the ignition

switch lock cylinder housing.

(7) Remove the SKREEM from the vehicle.

INSTALLATION

(1) Slip the Sentry Key Remote Entry Module

(SKREEM) antenna ring around the ignition switch

lock cylinder housing. Rotate the SKREEM down-

wards and then towards the steering column.

(2) Install the one screws securing the SKREEM to

the steering column.

(3) Connect the steering column wire harness to

the SKREEM.

(4) Install the steering column upper and lower

shrouds (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - INSTALLATION) and (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(5) Install the Steering Column Opening Cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

(6) Connect the battery negative cable.

TRANSPONDER KEY

DESCRIPTION

The Sentry Key Remote Entry System (SKREES)

uses a transponder chip that is integral to the circuit

board of the integrated ignition key (SKREES and

RKE incorporated) to communicate with the Sentry

Key Remote Entry Module (SKREEM). Ignition keys

are supplied with the vehicle when it is shipped from

the factory.

For export vehicles equipped with SKREES, the

transponder chip is undermolded within the head of

the key.

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the Sentry Key Remote

Entry Module (SKREEM) has a unique9Secret Key9

code programmed into it by the manufacturer as

well. When a Sentry Key is programmed into the

memory of the SKREEM, the SKREEM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKREEM. Once the Sentry Key learns the

9Secret Key9code of the SKREEM, it is also perma-

nently programmed into the transponder's memory.

Therefore, blank keys for the Sentry Key Remote

Entry System (SKREES) must be programmed by

the SKREEM in addition to being cut to match the

mechanical coding of the ignition lock cylinder. Refer

to Electrical, Vehicle Theft Security, Transponder

Key, Standard Procedure - Transponder Program-

ming.

The Sentry Key's transponder is within the range

of the SKREEM's transceiver antenna ring when it is

inserted into the ignition lock cylinder. When the

ignition switch is turned to the ON position, the

SKREEM communicates with the Sentry Key via a

radio frequency (RF) signal. The SKREEM deter-

mines if a valid key is present based on the informa-

tion it receives from the Sentry Key. If a valid key is

detected, that fact is communicated to the PCM via

the PCI bus and the vehicle is allowed to continue

running. If an invalid key is received by the PCM or

no status at all is communicated, the vehicle will

stall after two (2) seconds of running. The indicator

light will be flashing at this point. The Sentry Key's

transponder can not be repaired. If it is faulty or

damaged, it must be replaced.

Common communication problems:

²Two transponder keys too close together.

²Speed Pass too close to transponder key.

Solid indicator that there is a system failure.

²Loss of PCM communication.

²Failed antenna circuit.

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING

USING A DRBIIITSCAN TOOL

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Remote

Entry System (SKREES) when it is shipped from the

factory. The Sentry Key Remote Entry Module

(SKREEM) can be programmed to recognize up to a

total of eight Sentry Keys. When programming a

blank Sentry Key transponder, the key must first be

cut to match the ignition lock cylinder of the vehicle

for which it will be used. The vehicle's four digit PIN

8Q - 6 VEHICLE THEFT SECURITYRS

SENTRY KEY REMOTE ENTRY MODULE (Continued)

Page 544 of 2339

code will be required to complete this task since you

will need it to enter the Secured Access Mode in the

SKREEM. The following steps must be completed

using a DRBIIItscan tool:

(1) Insert the blank key into the ignition and turn

it to the RUN position.

(2) Using a DRBIIItscan tool, select9Theft

Alarm,99SKREEM,99Miscellaneous,9and then9Pro-

gram New Key.9

(3) Enter the four digit PIN code using the

DRBIIItscan tool. When programming is completed,

the SKREEM will exit Secured Access Mode and the

DRBIIItscan tool will display the results of your

attempt to program the key. One of five distinct

results may be displayed. All five are listed below:

²(Programming Successful(is displayed if the

Sentry Key programming is successful.

²(Learned Key in Ignition(is displayed if the

key in the ignition has already been programmed

into that vehicle's SKREEM.

²(Eight Keys Already Learned (At The Maxi-

mum) Programming Not Done(is displayed if

eight keys have already been programmed into the

SKREEM. In this case, if a new key needs to be

added due to a lost or defective key, the9Erase All

Keys9command (which requires entering the Secured

Access Mode) has to be performed. Following the

9Erase All Keys9command, all keys that will be used

to operate the vehicleMUSTbe reprogrammed to

the SKREEM.

²(Programming Not Attempted(is displayed

after an9Erase All Keys9function is executed.

²(Programming Key Failed(is displayed if fur-

ther diagnosis is required.

To learn additional keys, turn the ignition OFF,

remove the learned key, insert the next new blank

key, and repeat the steps from the beginning.

ªCUSTOMER LEARNº MODE

This feature is only available on domestic vehicles

or those which have a U.S. country code designator.

This procedure requires access to at least two valid

Sentry Keys. If two valid Sentry Keys are not avail-

able, Sentry Key programming will require the use of

a DRBIIItscan tool.

The steps required to program Sentry Keys with

two valid Sentry Keys follows:

(1) Obtain the blank Sentry Key(s) that need to be

programmed. Cut the keys to match the ignition lock

cylinder mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

ON position.

(3) After the ignition switch has been in the ON

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back tothe OFF position. Replace the first valid Sentry Key

in the ignition lock cylinder with the second valid

Sentry Key and turn the ignition switch back to the

ON position. The second valid Sentry Key must be

inserted within 15 seconds of removing the first valid

Sentry key.

(4) About ten seconds after the completion of Step

3, the indicator light will start to flash and a single

audible chime tone will sound to indicate that the

system has entered the9Customer Learn9program-

ming mode.

(5) Within sixty seconds of entering the9Customer

Learn9programming mode, turn the ignition switch

to the OFF position, replace the valid Sentry Key

with a blank Sentry Key transponder, and turn the

ignition switch back to the ON position.

(6) About ten seconds after the completion of Step

5, a single audible chime tone will sound and the

indicator light will stop flashing and stay on solid for

three seconds and then turn off to indicate that the

blank Sentry Key has been successfully programmed.

The SKREES will immediately exit the9Customer

Learn9programming mode and the vehicle may be

started using the newly programmed Sentry Key.

NOTE: The Remote Keyless Entry (RKE) Transmitter

will also be programmed during this procedure.

These steps must be completed in their entirety for

each additional Sentry Key to be programmed. If any

of the above steps are not completed in the given

sequence, or within the allotted time, the SKREES

will exit the9Customer Learn9programming mode

and the programming will be unsuccessful. The

SKREES will also automatically exit the9Customer

Learn9programming mode if:

²It sees a non-blank Sentry Key when it should

see a blank.

²If it has already programmed four (4) valid Sen-

try Keys.

²If the ignition switch is turned to the OFF posi-

tion for more than about fifty (50) seconds.

NOTE: If you attempt to start the vehicle while in

ªCustomer Learnº mode (LED flashing), the vehicle

will behave as though an invalid key is being used

(i.e. the engine will stall after two (2) seconds of

running). No faults will be logged.

NOTE: Once a Sentry Key has been programmed to

a particular vehicle, it cannot be used on any other

vehicle.

RSVEHICLE THEFT SECURITY8Q-7

TRANSPONDER KEY (Continued)