lock CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1335 of 2339

(9) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(10) Install engine mount bracket (Fig. 137) and

tighten M10 to 54 N´m (40 ft. lbs.), M8 bolt to 28

N´m (21 ft. lb. lbs.).

(11) Install idler pulley on engine mount bracket

(Fig. 137).

(12) Install right side engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION)

(13) Install camshaft position sensor (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/CAMSHAFT

POSITION SENSOR - INSTALLATION).

(14) Connect the heater return hose at rear of tim-

ing chain cover (Fig. 135) or at water pump inlet

tube (if engine oil cooler equipped) (Fig. 136).

(15) Connect the radiator lower hose.

(16) Install A/C compressor.

Fig. 139 Timing Chain Cover and Gasket

1 - GASKET

2 - TIMING CHAIN COVER

Fig. 140 TIMING CHAIN COVER BOLT LOCATIONS

1 - BOLT - M8 x 1.25 x 95 4 - BOLT - M8 x 1.25 x 80

2 - BOLT - M10 x 1.5 x 100 5 - BOLT - M8 x 1.25 x 45

3 - BOLT - M10 x 1.5 x 85

9 - 158 ENGINE 3.3/3.8LRS

TIMING CHAIN COVER (Continued)

Page 1337 of 2339

INSTALLATION

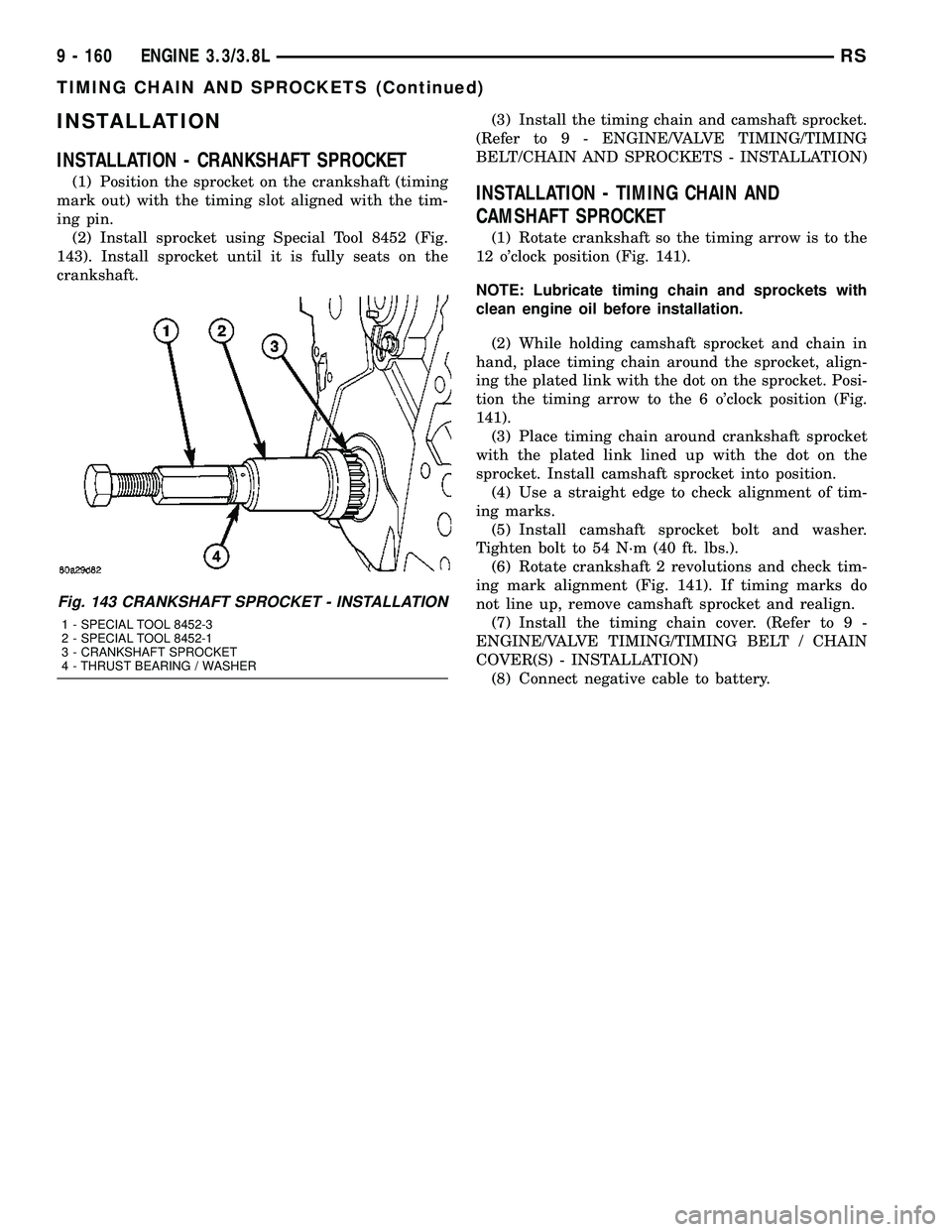

INSTALLATION - CRANKSHAFT SPROCKET

(1) Position the sprocket on the crankshaft (timing

mark out) with the timing slot aligned with the tim-

ing pin.

(2) Install sprocket using Special Tool 8452 (Fig.

143). Install sprocket until it is fully seats on the

crankshaft.(3) Install the timing chain and camshaft sprocket.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)INSTALLATION - TIMING CHAIN AND

CAMSHAFT SPROCKET

(1) Rotate crankshaft so the timing arrow is to the

12 o'clock position (Fig. 141).

NOTE: Lubricate timing chain and sprockets with

clean engine oil before installation.

(2) While holding camshaft sprocket and chain in

hand, place timing chain around the sprocket, align-

ing the plated link with the dot on the sprocket. Posi-

tion the timing arrow to the 6 o'clock position (Fig.

141).

(3) Place timing chain around crankshaft sprocket

with the plated link lined up with the dot on the

sprocket. Install camshaft sprocket into position.

(4) Use a straight edge to check alignment of tim-

ing marks.

(5) Install camshaft sprocket bolt and washer.

Tighten bolt to 54 N´m (40 ft. lbs.).

(6) Rotate crankshaft 2 revolutions and check tim-

ing mark alignment (Fig. 141). If timing marks do

not line up, remove camshaft sprocket and realign.

(7) Install the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(8) Connect negative cable to battery.

Fig. 143 CRANKSHAFT SPROCKET - INSTALLATION

1 - SPECIAL TOOL 8452-3

2 - SPECIAL TOOL 8452-1

3 - CRANKSHAFT SPROCKET

4 - THRUST BEARING / WASHER

9 - 160 ENGINE 3.3/3.8LRS

TIMING CHAIN AND SPROCKETS (Continued)

Page 1345 of 2339

CAUTION: When servicing the exhaust system, care

must be exercised not to dent or bend the bellows

of the flex-joint. Should this occur, the flex-joint will

eventually fail, requiring replacement of the cata-

lytic converter.

(3) Disconnect the right side axle half shaft from

the rear differential module (AWD equipped only).

(4) Loosen the band clamp (Fig. 10) at the muffler

to converter pipe connection.

(5) Remove the exhaust hangers to body screws

(Fig. 10).

(6) Separate muffler pipe from converter pipe.

(7) Remove muffler/resonator assembly by moving

assembly forward and guiding the resonator through

the rear axle to body opening.

(8) Clean ends of pipes or muffler to assure mat-

ing of all parts. Discard broken or worn insulators,

rusted clamps, supports and attaching parts.When

replacement is required on any component of

the exhaust system, it is important that original

equipment parts (or equivalent) be used for the

following conditions:²Ensure proper alignment with other components

in the system.

²Provide acceptable exhaust noise levels.

²Provide proper exhaust system back pressure for

maintaining emission and performance levels.

INSTALLATION

(1) Install the muffler/resonator assembly by guid-

ing resonator between the rear axle and body.

(2) Connect the muffler pipe to the converter pipe

but do not tighten band clamp (Fig. 10).

(3) Position hangers to body and install screws

starting at the resonator working forward (Fig. 10).

Tighten hanger screws to 28 N´m (250 in. lbs.).

(4) Insert muffler pipe into catalytic converter pipe

until the hangers are positioned as shown in (Fig. 11)

CAUTION: Band clamps should never be tightened

such that the two sides of the clamps are bottomed

out against the center hourglass shaped center

block. Once this occurs, the clamp band has been

stretched and has lost its clamping force and must

be replaced.

To replace the band clamp; remove the nut and peel

back the ends of the clamp until spot weld breaks.

Clean remaining spot weld from the pipe using a

file or grinder until surface is smooth.

Fig. 10 Exhaust System - Typical (All Vehicles)

1 - SCREW - RESONATOR HANGER TO BODY 3 - MUFFLER & RESONATOR ASSEMBLY

2 - SCREW - MUFFLER HANGER TO BODY 4 - CATALYTIC CONVERTER PIPE

11 - 8 EXHAUST SYSTEMRS

MUFFLER (Continued)

Page 1352 of 2339

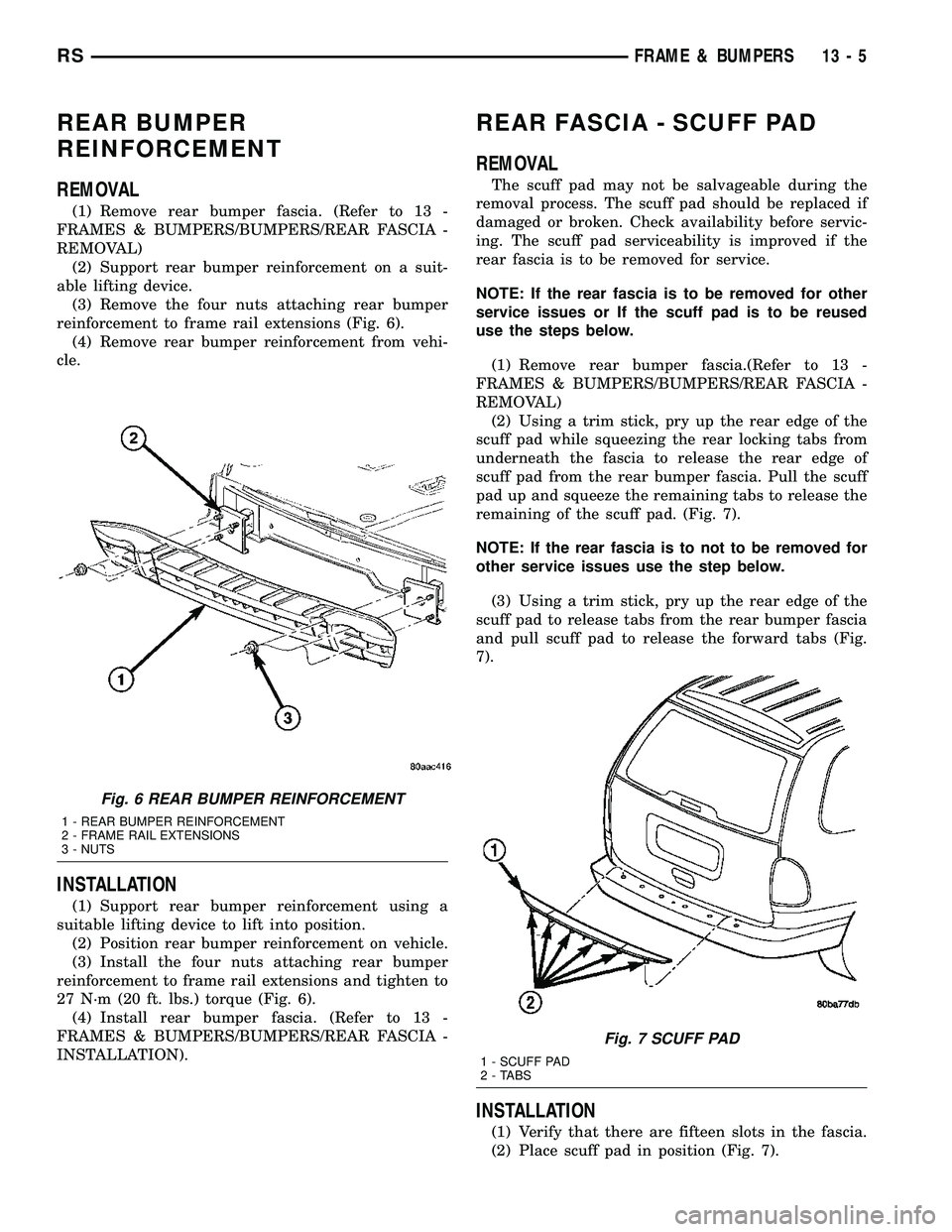

REAR BUMPER

REINFORCEMENT

REMOVAL

(1) Remove rear bumper fascia. (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/REAR FASCIA -

REMOVAL)

(2) Support rear bumper reinforcement on a suit-

able lifting device.

(3) Remove the four nuts attaching rear bumper

reinforcement to frame rail extensions (Fig. 6).

(4) Remove rear bumper reinforcement from vehi-

cle.

INSTALLATION

(1) Support rear bumper reinforcement using a

suitable lifting device to lift into position.

(2) Position rear bumper reinforcement on vehicle.

(3) Install the four nuts attaching rear bumper

reinforcement to frame rail extensions and tighten to

27 N´m (20 ft. lbs.) torque (Fig. 6).

(4) Install rear bumper fascia. (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/REAR FASCIA -

INSTALLATION).

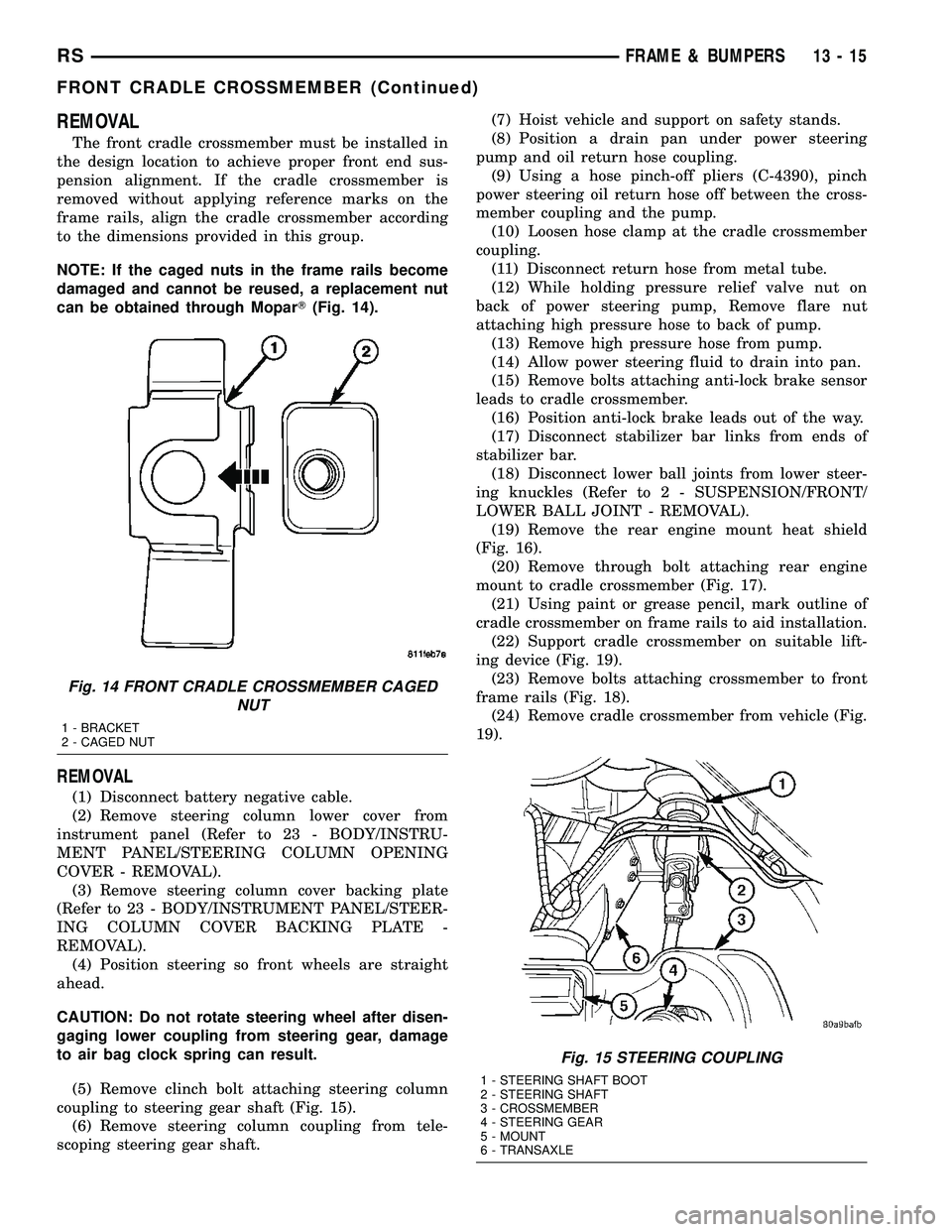

REAR FASCIA - SCUFF PAD

REMOVAL

The scuff pad may not be salvageable during the

removal process. The scuff pad should be replaced if

damaged or broken. Check availability before servic-

ing. The scuff pad serviceability is improved if the

rear fascia is to be removed for service.

NOTE: If the rear fascia is to be removed for other

service issues or If the scuff pad is to be reused

use the steps below.

(1) Remove rear bumper fascia.(Refer to 13 -

FRAMES & BUMPERS/BUMPERS/REAR FASCIA -

REMOVAL)

(2) Using a trim stick, pry up the rear edge of the

scuff pad while squeezing the rear locking tabs from

underneath the fascia to release the rear edge of

scuff pad from the rear bumper fascia. Pull the scuff

pad up and squeeze the remaining tabs to release the

remaining of the scuff pad. (Fig. 7).

NOTE: If the rear fascia is to not to be removed for

other service issues use the step below.

(3) Using a trim stick, pry up the rear edge of the

scuff pad to release tabs from the rear bumper fascia

and pull scuff pad to release the forward tabs (Fig.

7).

INSTALLATION

(1) Verify that there are fifteen slots in the fascia.

(2) Place scuff pad in position (Fig. 7).

Fig. 6 REAR BUMPER REINFORCEMENT

1 - REAR BUMPER REINFORCEMENT

2 - FRAME RAIL EXTENSIONS

3 - NUTS

Fig. 7 SCUFF PAD

1 - SCUFF PAD

2 - TABS

RSFRAME & BUMPERS13-5

Page 1362 of 2339

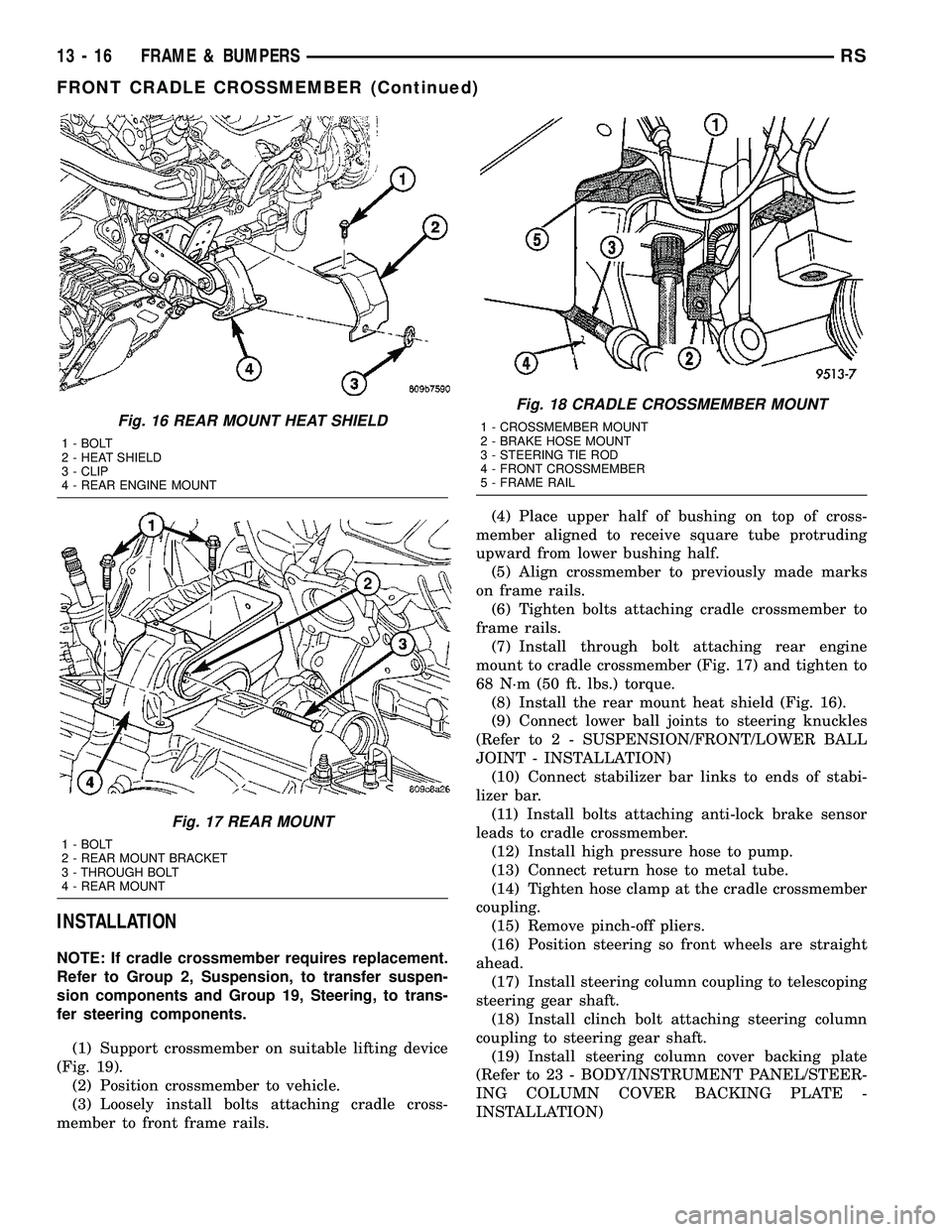

REMOVAL

The front cradle crossmember must be installed in

the design location to achieve proper front end sus-

pension alignment. If the cradle crossmember is

removed without applying reference marks on the

frame rails, align the cradle crossmember according

to the dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through MoparT(Fig. 14).

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - REMOVAL).

(3) Remove steering column cover backing plate

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN COVER BACKING PLATE -

REMOVAL).

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to air bag clock spring can result.

(5) Remove clinch bolt attaching steering column

coupling to steering gear shaft (Fig. 15).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.(7) Hoist vehicle and support on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the cradle crossmember

coupling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut

attaching high pressure hose to back of pump.

(13) Remove high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts attaching anti-lock brake sensor

leads to cradle crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar.

(18) Disconnect lower ball joints from lower steer-

ing knuckles (Refer to 2 - SUSPENSION/FRONT/

LOWER BALL JOINT - REMOVAL).

(19) Remove the rear engine mount heat shield

(Fig. 16).

(20) Remove through bolt attaching rear engine

mount to cradle crossmember (Fig. 17).

(21) Using paint or grease pencil, mark outline of

cradle crossmember on frame rails to aid installation.

(22) Support cradle crossmember on suitable lift-

ing device (Fig. 19).

(23) Remove bolts attaching crossmember to front

frame rails (Fig. 18).

(24) Remove cradle crossmember from vehicle (Fig.

19).

Fig. 14 FRONT CRADLE CROSSMEMBER CAGED

NUT

1 - BRACKET

2 - CAGED NUT

Fig. 15 STEERING COUPLING

1 - STEERING SHAFT BOOT

2 - STEERING SHAFT

3 - CROSSMEMBER

4 - STEERING GEAR

5 - MOUNT

6 - TRANSAXLE

RSFRAME & BUMPERS13-15

FRONT CRADLE CROSSMEMBER (Continued)

Page 1363 of 2339

INSTALLATION

NOTE: If cradle crossmember requires replacement.

Refer to Group 2, Suspension, to transfer suspen-

sion components and Group 19, Steering, to trans-

fer steering components.

(1) Support crossmember on suitable lifting device

(Fig. 19).

(2) Position crossmember to vehicle.

(3) Loosely install bolts attaching cradle cross-

member to front frame rails.(4) Place upper half of bushing on top of cross-

member aligned to receive square tube protruding

upward from lower bushing half.

(5) Align crossmember to previously made marks

on frame rails.

(6) Tighten bolts attaching cradle crossmember to

frame rails.

(7) Install through bolt attaching rear engine

mount to cradle crossmember (Fig. 17) and tighten to

68 N´m (50 ft. lbs.) torque.

(8) Install the rear mount heat shield (Fig. 16).

(9) Connect lower ball joints to steering knuckles

(Refer to 2 - SUSPENSION/FRONT/LOWER BALL

JOINT - INSTALLATION)

(10) Connect stabilizer bar links to ends of stabi-

lizer bar.

(11) Install bolts attaching anti-lock brake sensor

leads to cradle crossmember.

(12) Install high pressure hose to pump.

(13) Connect return hose to metal tube.

(14) Tighten hose clamp at the cradle crossmember

coupling.

(15) Remove pinch-off pliers.

(16) Position steering so front wheels are straight

ahead.

(17) Install steering column coupling to telescoping

steering gear shaft.

(18) Install clinch bolt attaching steering column

coupling to steering gear shaft.

(19) Install steering column cover backing plate

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN COVER BACKING PLATE -

INSTALLATION)

Fig. 16 REAR MOUNT HEAT SHIELD

1 - BOLT

2 - HEAT SHIELD

3 - CLIP

4 - REAR ENGINE MOUNT

Fig. 17 REAR MOUNT

1 - BOLT

2 - REAR MOUNT BRACKET

3 - THROUGH BOLT

4 - REAR MOUNT

Fig. 18 CRADLE CROSSMEMBER MOUNT

1 - CROSSMEMBER MOUNT

2 - BRAKE HOSE MOUNT

3 - STEERING TIE ROD

4 - FRONT CROSSMEMBER

5 - FRAME RAIL

13 - 16 FRAME & BUMPERSRS

FRONT CRADLE CROSSMEMBER (Continued)

Page 1369 of 2339

SPECIFICATIONS

FUEL SYSTEM PRESSURE

400 kpa 34 kpa (58 psi 5 psi)

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fuel Filler Neck Clamp 3.3 30

Fuel Rail 2.4L 22 195

Fuel Rail 3.3/3.8L 11.8 105

Fuel Tank Strap 54 40

Fuel Tank T Strap 28.2 250

Fuel Filter Bolt 4.5 40

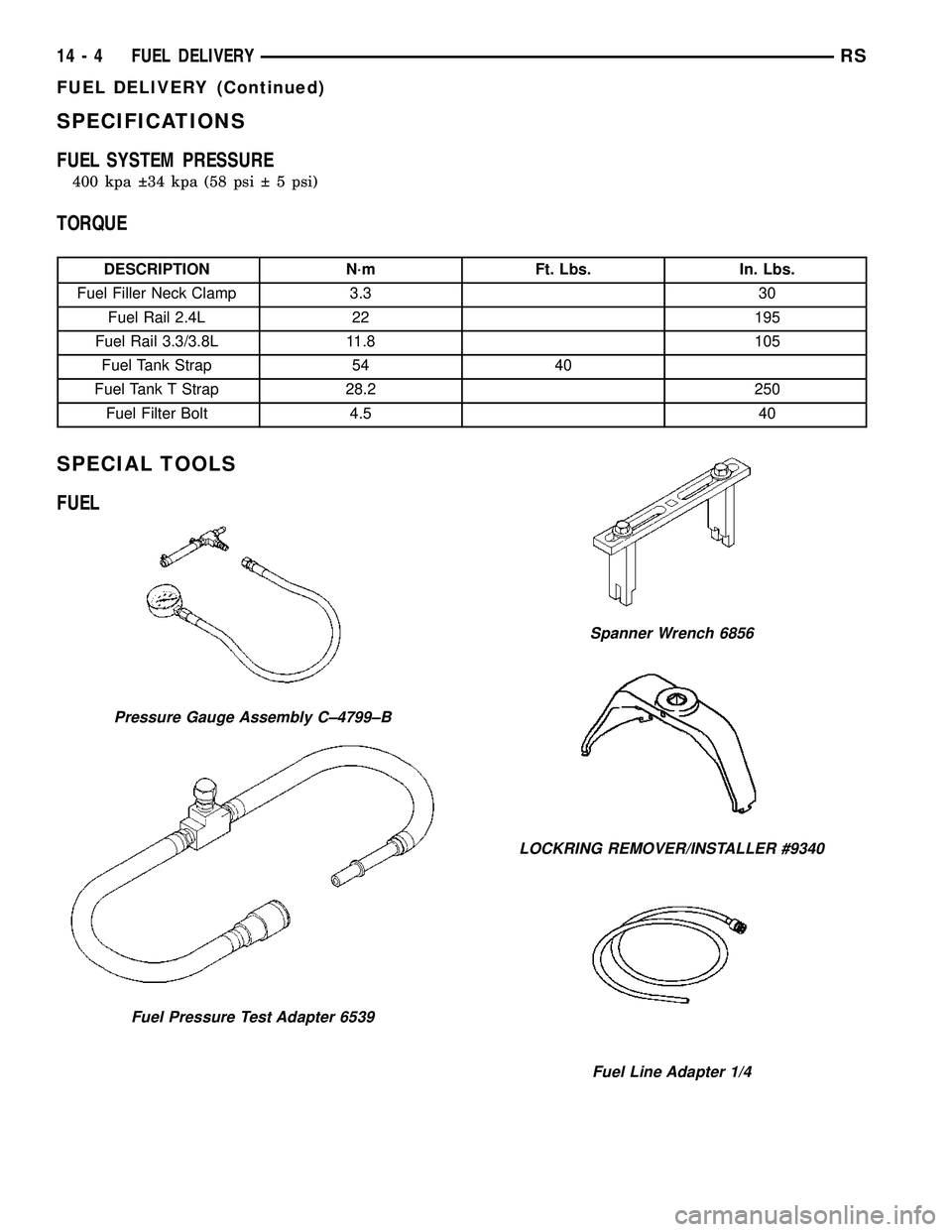

SPECIAL TOOLS

FUEL

Pressure Gauge Assembly C±4799±B

Fuel Pressure Test Adapter 6539

Spanner Wrench 6856

LOCKRING REMOVER/INSTALLER #9340

Fuel Line Adapter 1/4

14 - 4 FUEL DELIVERYRS

FUEL DELIVERY (Continued)

Page 1370 of 2339

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge level sending unit is attached to the

side of fuel pump module. The level sensor is a vari-

able resistor.

OPERATION

Its resistance changes with the amount of fuel in

the tank. The float arm attached to the sensor moves

as the fuel level changes.

The fuel level input is used as an input for OBD II.

If the fuel level is below 15% or above 85% of total

tank capacity several monitors are disabled. There

are diagnostics for the level circuit open and shorted.

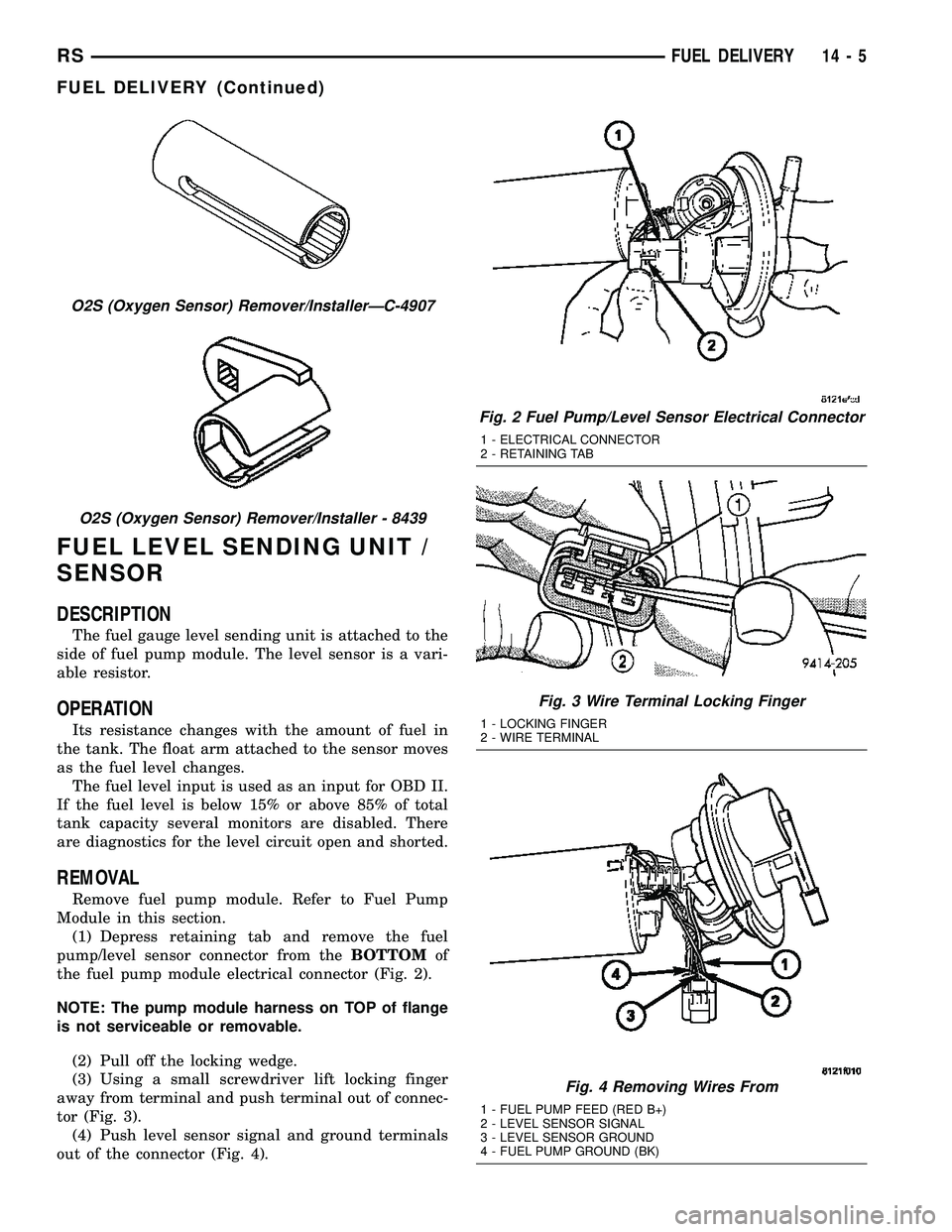

REMOVAL

Remove fuel pump module. Refer to Fuel Pump

Module in this section.

(1) Depress retaining tab and remove the fuel

pump/level sensor connector from theBOTTOMof

the fuel pump module electrical connector (Fig. 2).

NOTE: The pump module harness on TOP of flange

is not serviceable or removable.

(2) Pull off the locking wedge.

(3) Using a small screwdriver lift locking finger

away from terminal and push terminal out of connec-

tor (Fig. 3).

(4) Push level sensor signal and ground terminals

out of the connector (Fig. 4).

O2S (Oxygen Sensor) Remover/InstallerÐC-4907

O2S (Oxygen Sensor) Remover/Installer - 8439

Fig. 2 Fuel Pump/Level Sensor Electrical Connector

1 - ELECTRICAL CONNECTOR

2 - RETAINING TAB

Fig. 3 Wire Terminal Locking Finger

1 - LOCKING FINGER

2 - WIRE TERMINAL

Fig. 4 Removing Wires From

1 - FUEL PUMP FEED (RED B+)

2 - LEVEL SENSOR SIGNAL

3 - LEVEL SENSOR GROUND

4 - FUEL PUMP GROUND (BK)

RSFUEL DELIVERY14-5

FUEL DELIVERY (Continued)

Page 1371 of 2339

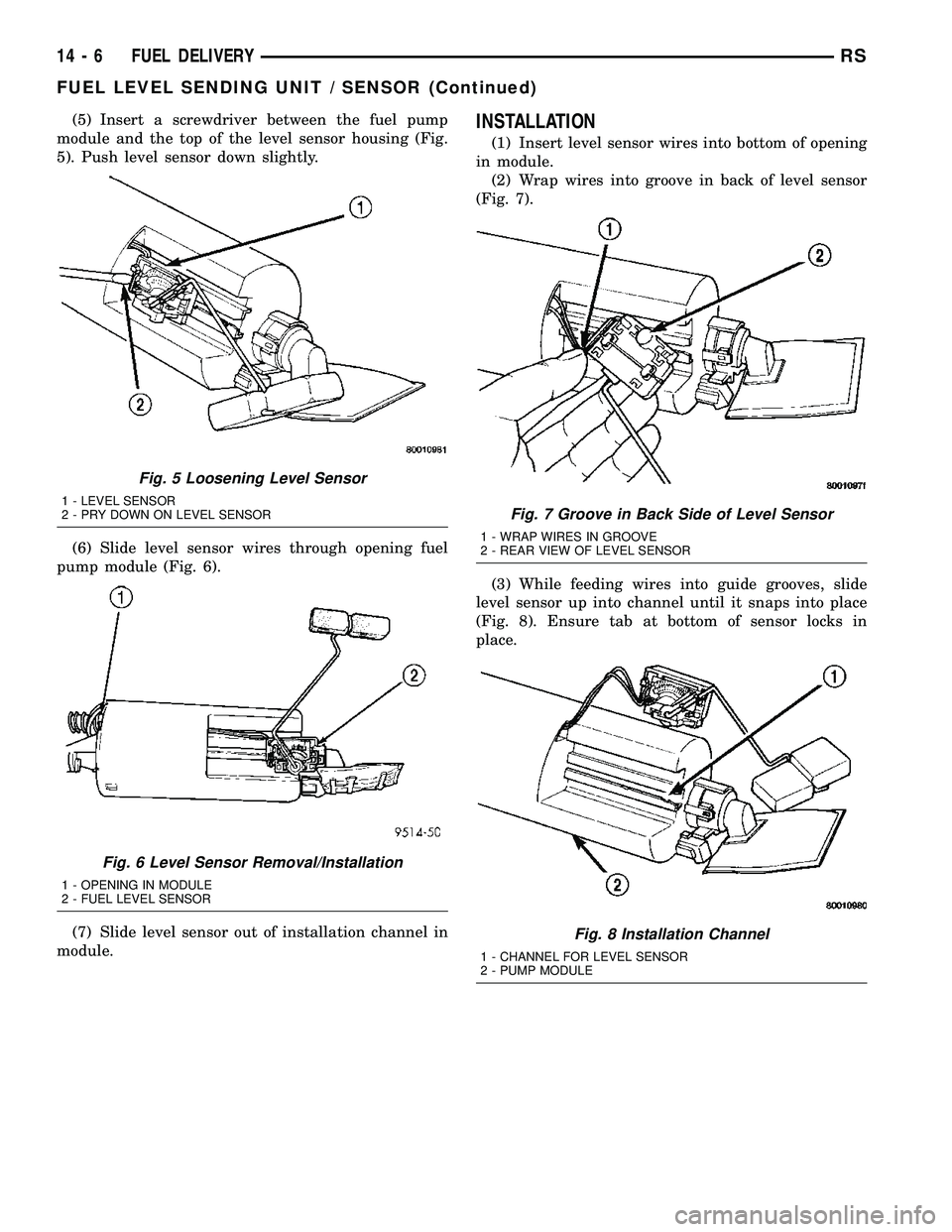

(5) Insert a screwdriver between the fuel pump

module and the top of the level sensor housing (Fig.

5). Push level sensor down slightly.

(6) Slide level sensor wires through opening fuel

pump module (Fig. 6).

(7) Slide level sensor out of installation channel in

module.INSTALLATION

(1) Insert level sensor wires into bottom of opening

in module.

(2) Wrap wires into groove in back of level sensor

(Fig. 7).

(3) While feeding wires into guide grooves, slide

level sensor up into channel until it snaps into place

(Fig. 8). Ensure tab at bottom of sensor locks in

place.

Fig. 5 Loosening Level Sensor

1 - LEVEL SENSOR

2 - PRY DOWN ON LEVEL SENSOR

Fig. 6 Level Sensor Removal/Installation

1 - OPENING IN MODULE

2 - FUEL LEVEL SENSOR

Fig. 7 Groove in Back Side of Level Sensor

1 - WRAP WIRES IN GROOVE

2 - REAR VIEW OF LEVEL SENSOR

Fig. 8 Installation Channel

1 - CHANNEL FOR LEVEL SENSOR

2 - PUMP MODULE

14 - 6 FUEL DELIVERYRS

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1372 of 2339

(4) Install level sensor wires in connector. Push

the wires up through the connector and then pull

them down until they lock in place. Ensure signal

and ground wires are installed in the correct posi-

tion.

(5) Install locking wedge on connector.

(6) Push connector up into bottom of fuel pump

module electrical connector.

(7) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL LINES

DESCRIPTION - FUEL LINES/HOSES AND

CLAMPS

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, use new original equipment

lines/tubes/hoses.

If equipped:The hose clamps used to secure rub-

ber hoses on vehicles are of a special rolled edge con-

struction. This construction is used to prevent the

edge of the clamp from cutting into the hose. Only

these rolled edge type clamps may be used in this

system. All other types of clamps may cut into the

hoses and cause leaks.

Use new original equipment type hose clamps.

STANDARD PROCEDURE - HOSES AND CLAMP

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that causeabrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (9 in. lbs.) torque.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes are

properly routed to prevent pinching and to avoid heat

sources.

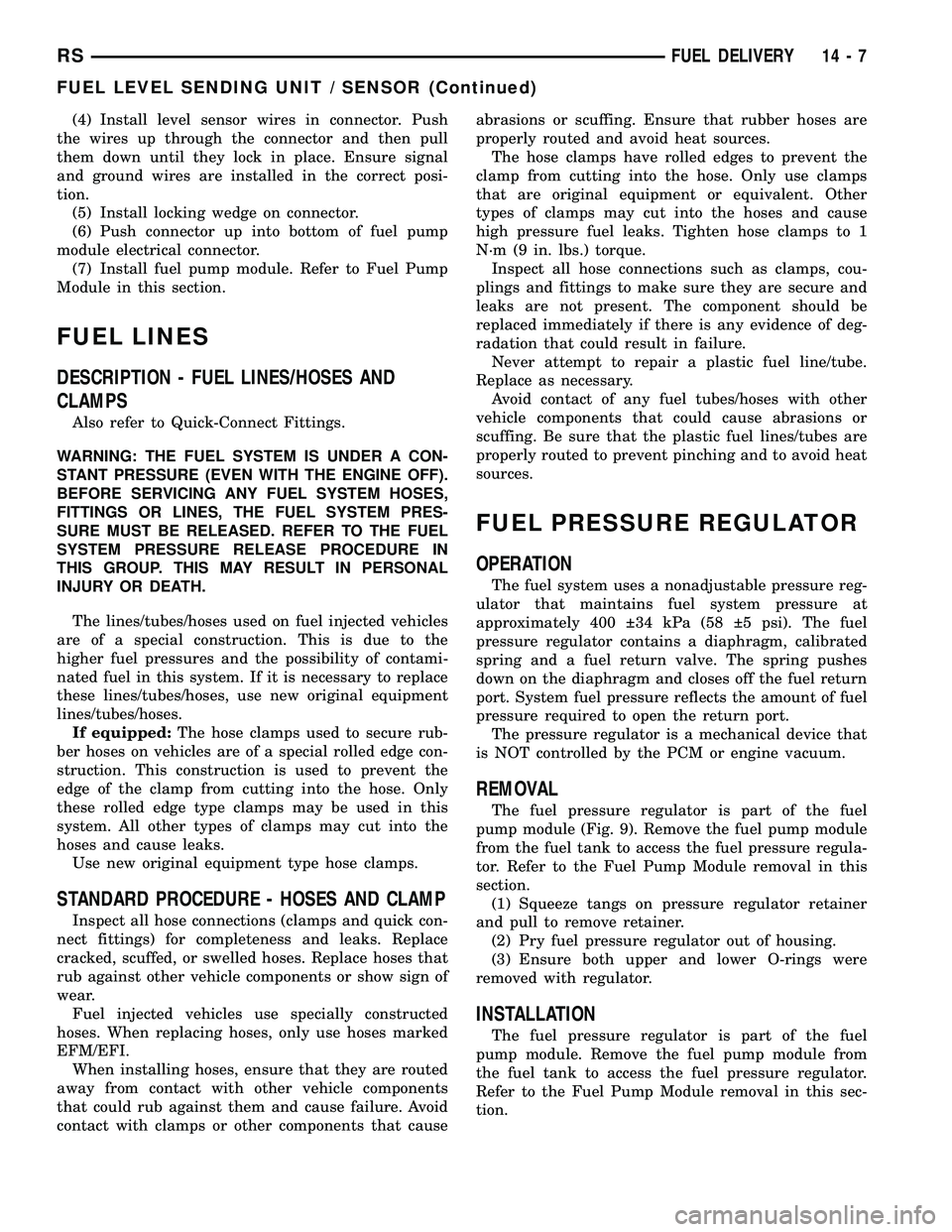

FUEL PRESSURE REGULATOR

OPERATION

The fuel system uses a nonadjustable pressure reg-

ulator that maintains fuel system pressure at

approximately 400 34 kPa (58 5 psi). The fuel

pressure regulator contains a diaphragm, calibrated

spring and a fuel return valve. The spring pushes

down on the diaphragm and closes off the fuel return

port. System fuel pressure reflects the amount of fuel

pressure required to open the return port.

The pressure regulator is a mechanical device that

is NOT controlled by the PCM or engine vacuum.

REMOVAL

The fuel pressure regulator is part of the fuel

pump module (Fig. 9). Remove the fuel pump module

from the fuel tank to access the fuel pressure regula-

tor. Refer to the Fuel Pump Module removal in this

section.

(1) Squeeze tangs on pressure regulator retainer

and pull to remove retainer.

(2) Pry fuel pressure regulator out of housing.

(3) Ensure both upper and lower O-rings were

removed with regulator.

INSTALLATION

The fuel pressure regulator is part of the fuel

pump module. Remove the fuel pump module from

the fuel tank to access the fuel pressure regulator.

Refer to the Fuel Pump Module removal in this sec-

tion.

RSFUEL DELIVERY14-7

FUEL LEVEL SENDING UNIT / SENSOR (Continued)