Locking CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1479 of 2339

(24) Remove front carrier/rear annulus assembly

and #6 needle bearing (Fig. 38).

(25) Remove rear sun gear and #7 needle bearing

(Fig. 39).

NOTE: The number 7 needle bearing has three anti-

reversal tabs and is common with the number five

and number two position. The orientation should

allow the bearing to seat flat against the rear sun

gear (Fig. 40). A small amount of petrolatum can be

used to hold the bearing to the rear sun gear.(26) Setup tool 5058 as shown in (Fig. 41). Com-

press 2/4 clutch return spring (just enough to remove

snap ring) and remove snap ring.

NOTE: Verify that Tool 5058 is centered properly

over the 2/4 clutch retainer before compressing. If

necessary, fasten the 5058 bar to the bellhousing

flange with any combination of locking pliers and

bolts to center the tool properly.

Fig. 38 Remove Front Carrier/Rear Annulus

Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 39 Remove Rear Sun Gear

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 40 Number 7 Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 41 Remove 2/4 Clutch Retainer Snap Ring

1 - TOOL 5058

2 - SCREWDRIVER

3 - SNAP RING

4 - 2/4 CLUTCH RETAINER

21 - 18 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1589 of 2339

OPERATION

The converter impeller (Fig. 303) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impeller

blades strikes the blades of the turbine, some of the

energy and rotational force is transferred into the tur-

bine and the input shaft. This causes both of them (tur-

bine and input shaft) to rotate in a clockwise direction

following the impeller. As the fluid is leaving the trail-

ing edges of the turbine's blades it continues in a ªhin-

deringº direction back toward the impeller. If the fluid

is not redirected before it strikes the impeller, it will

strike the impeller in such a direction that it would

tend to slow it down.

STATOR

Torque multiplication is achieved by locking the sta-

tor's over-running clutch to its shaft (Fig. 304). Under

stall conditions (the turbine is stationary), the oil leaving

the turbine blades strikes the face of the stator blades

and tries to rotate them in a counterclockwise direction.

When this happens the over±running clutch of the stator

locks and holds the stator from rotating. With the stator

locked, the oil strikes the stator blades and is redirected

into a ªhelpingº direction before it enters the impeller.This circulation of oil from impeller to turbine, turbine to

stator, and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid that

was hitting the stator in such as way as to cause it to

lock±up is no longer doing so. In this condition of opera-

tion, the stator begins to free wheel and the converter

acts as a fluid coupling.

Fig. 303 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Fig. 304 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

21 - 128 40TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

Page 1624 of 2339

(24) Remove front carrier/rear annulus assembly

and #6 needle bearing (Fig. 38).

(25) Remove rear sun gear and #7 needle bearing

(Fig. 39).

NOTE: The number 7 needle bearing has three anti-

reversal tabs and is common with the number five

and number two position. The orientation should

allow the bearing to seat flat against the rear sun

gear (Fig. 40). A small amount of petrolatum can be

used to hold the bearing to the rear sun gear.(26) Setup tool 5058 as shown in (Fig. 41). Com-

press 2/4 clutch return spring (just enough to remove

snap ring) and remove snap ring.

NOTE: Verify that Tool 5058 is centered properly

over the 2/4 clutch retainer before compressing. If

necessary, fasten the 5058 bar to the bellhousing

flange with any combination of locking pliers and

bolts to center the tool properly.

Fig. 38 Remove Front Carrier and Rear Annulus

Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 39 Remove Rear Sun Gear

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 40 Number 7 Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 41 Remove 2/4 Clutch Retainer Snap Ring

1 - TOOL 5058

2 - SCREWDRIVER

3 - SNAP RING

4 - 2/4 CLUTCH RETAINER

RS41TE AUTOMATIC TRANSAXLE21 - 163

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1740 of 2339

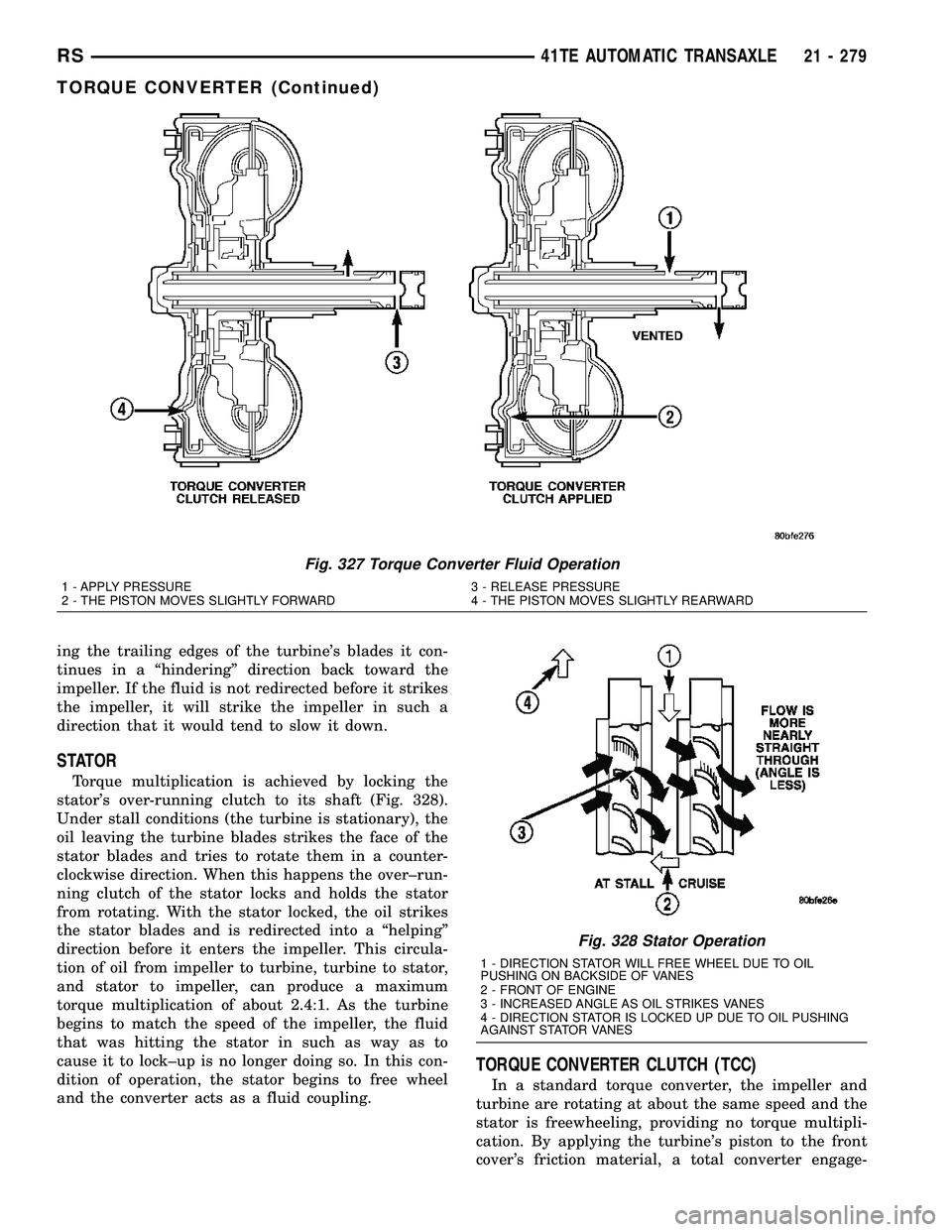

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 328).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over±run-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock±up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston to the front

cover's friction material, a total converter engage-

Fig. 327 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Fig. 328 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

RS41TE AUTOMATIC TRANSAXLE21 - 279

TORQUE CONVERTER (Continued)

Page 1806 of 2339

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Position latch/lock locking lever in unlocked

position.

(2) If equipped, engage wire connector into power

door lock motor (Fig. 4).

(3) Place latch/lock in position on door (Fig. 5).

CAUTION: REPLACE BOLTS IF INSTALLING NEW

LATCH.

(4) Insert bolt into slots in sliding door inner

panel.

(5) Tighten bolts attaching latch/lock assembly to

sliding door.

(6) Engage inside cable into latch/lock assembly.

(7) Install inside door handle assembly (Refer to

23 - BODY/DOORS - SLIDING/INSIDE LATCH

HANDLE - INSTALLATION).

(8) Install foam block.

(9) Engage external cable to latch/lock assembly.

(10) Engage link rod to bellcrank.

(11) Engage hold open latch cable from lower

hinge.

(12) Engage clip to hold bellcrank link to latch/lock

control.

(13) Verify sliding door operation.(14) Install latch/lock cover.

(15) Insure that enough adhesive remains to

securely retain the watershield. Replace as necessary.

(16) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(17) Install sliding door stop bumper.(Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(18) Install sliding door trim panel.(Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

INSIDE HANDLE ACTUATOR

REMOVAL

(1) Remove latch/lock assembly. (Refer to 23 -

BODY/DOORS - SLIDING/LATCH/LOCK CONTROL

- REMOVAL).

(2) Remove lock actuator three attaching screws

(Fig. 6).

(3) Remove lock actuator.

INSTALLATION

(1) Place lock actuator into position on latch/lock

assembly.

(2) Insall attaching screws (Fig. 6).

(3) Install latch/lock assembly. (Refer to 23 -

BODY/DOORS - SLIDING/LATCH / LOCK CON-

TROL - INSTALLATION).

Fig. 5 REMOVING SLIDING DOOR LATCH/LOCK

ASSEMBLY

1 - WIRE HARNESS

2 - LATCH/LOCK ASSEMBLY

3 - BELLCRANK LINK ROD

4 - LINK AND SLEEVE ASSEMBLY

Fig. 6 LOCK ACTUATOR

1 - INSIDE HANDLE ACTUATOR

2 - LATCH/LOCK ASSEMBLY

3 - THREE ATTACHING SCREWS

RSDOORS - SLIDING23-27

LATCH / LOCK ASSEMBLY (Continued)

Page 1814 of 2339

(6) Engage clip to hold cable end into release han-

dle mechanism.

(7) Place latch handle in position on sliding door.

(8) Install screw to hold top of inside release han-

dle to sliding door.

(9) Install screws to hold bottom of inside latch

handle to sliding door.

(10) Verify sliding door operation. Adjust as neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

(11) Install sliding door trim panel.(Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

BELLCRANK

REMOVAL

(1) Remove stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - REMOVAL).

(2) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel as necessary to gain

access to latch bellcrank.

(4) Disengage lock link (Fig. 23).

(5) Disengage link and sleeve

(6) Remove bellcrank by rotating bellcrank to

release it from door.

(7) Remove bellcrank from vehicle.

INSTALLATION

(1) Position bellcrank on vehicle.

(2) Rotate bellcrank into position.(3) Place lock link into position and engage clip

(Fig. 23).

(4) Place link and sleeve into position and engage

clip.

(5) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(6) Install sliding door trim panel (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION).

(7) Install stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - INSTALLA-

TION).

OUTSIDE HANDLE

REMOVAL

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel as necessary to access

outside release handle fasteners.

(4) Disengage clip attaching outside door handle

linkage to door cable.

(5) Remove linkage from outside door handle.

(6) Remove three nuts attaching outside door han-

dle to outer door panel (Fig. 24).

(7) Remove outside door handle from vehicle.

Fig. 22 RELEASE HANDLE CABLE

1 - ASSIST HANDLE MECHANISM

2 - SLIDING DOOR INSIDE ASSIST HANDLE

3 - RELEASE HANDLE CABLE

Fig. 23 BELLCRANK

1 - OUTSIDE HANDLE

2 - OUTSIDE HANDLE BRACKET ATTACHING NUT

3 - LOCK KNOB

4 - LATCH LINK

5 - LOCKING LINK

6 - DOOR LOCKING LEVER (BELLCRANK)

RSDOORS - SLIDING23-35

INSIDE LATCH HANDLE (Continued)

Page 1815 of 2339

INSTALLATION

(1) Position outside door handle on vehicle.

(2) Install nuts attaching outside door handle to

outer door panel.

(3) Engage clip attaching linkage to outside door

handle.

(4) Engage rigging cam to latch/lock control mech-

anism.

(5) Move clip on latch/lock control to bottom of slot

and engage linkage to latch/lock control.

(6) Verify sliding door operation. Adjust as neces-

sary.

(7) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(8) Install sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(9) Install sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

UPPER HINGE

REMOVAL

(1) Open sliding door, do not latch open.

(2) Remove screw attaching upper stop bracket to

upper roller bracket (Fig. 25).

(3) Remove stop bracket from vehicle.

(4) Place a padded block between the open sliding

door and the roof rail.(5) Mark outline of upper hinge bracket on sliding

door.

(6) Remove bolts attaching upper roller to sliding

door (Fig. 26).

(7) Remove upper hinge from door.

(8) Slide roller out of rear end of roof upper chan-

nel.

(9) Remove upper hinge from vehicle.INSTALLATION

(1) Place upper hinge in position on vehicle (Fig.

26).

(2) Slide roller into rear end of roof upper channel.

(3) Place upper hinge in position on door.

(4) Align outline marks on sliding door to upper

roller bracket

Fig. 24 SLIDING DOOR OUTSIDE LATCH RELEASE

HANDLE

1 - OUTSIDE HANDLE

2 - OUTSIDE HANDLE BRACKET ATTACHING NUT

3 - LOCK KNOB

4 - LATCH LINK

5 - LOCKING LINK

6 - DOOR LOCKING LEVER (BELLCRANK)

Fig. 25 SLIDING DOOR UPPER STOP

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

Fig. 26 SLIDING DOOR UPPER HINGE

1 - SLIDING DOOR UPPER HINGE

2 - SLIDING DOOR

23 - 36 DOORS - SLIDINGRS

OUTSIDE HANDLE (Continued)

Page 1842 of 2339

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts attaching

hood to hinge finger tight.

(2) Install top bolts attaching hood to hinge finger

tight.

(3) Position bolts at marks and tighten. Tighten

bolts to 13.5 N´m (120 in. lbs.) torque. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(4) Verify hood operation and alignment.

LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to radiator

closure panel crossmember (Fig. 3).

(3) Remove hood latch from crossmember.

(4) Disconnect hood release cable from hood latch

(Fig. 4).

(5) Remove hood latch from vehicle.

INSTALLATION

(1) Position hood latch on vehicle.

(2) Connect hood release cable from hood latch.

(3) Position hood latch on crossmember.

(4) Align hood latch by placing latch over net

pierced tabs. If alignment is required, flatten or

grind tabs.

(5) Verify hood operation and alignment. Adjust as

necessary.(6) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.

LATCH RELEASE CABLE

REMOVAL

(1) Remove hood latch.

(2) Disengage cable end from hood latch locking

mechanism.

(3) Slide cable case end sideways in keyhole slot of

hood latch while pinching barb on cable case closed.

(4) Remove cable from latch (Fig. 4).

(5) Remove hood release handle from instrument

panel.

(6) Disengage rubber grommet cable insulator

from hole in dash panel.

(7) Attach a suitable length of mechanic's wire to

latch end of cable to assist cable installation.

Fig. 2 HOOD

1 - HOOD

2 - HOOD LATCH STRIKER

3 - HOOD HALF OF HOOD HINGE

Fig. 3 HOOD LATCH

1 - HOOD RELEASE CABLE

2 - HOOD LATCH

3 - RADIATOR CLOSURE PANEL CROSSMEMBER

Fig. 4 HOOD

1 - RELEASE CABLE CASE

2 - HOOD LATCH

3 - RELEASE CABLE END

RSHOOD23-63

HOOD (Continued)

Page 1843 of 2339

(8) Route cable back from latch through engine

compartment toward dash panel near power brake

booster (Fig. 5).

(9) Remove attaching clips from cable case.

(10) From inside vehicle, pull cable through dash

panel until mechanic's wire is exposed.

(11) Disconnect cable from mechanic's wire.

(12) Remove hood release cable from vehicle.

INSTALLATION

(1) Place hood release cable in position under

instrument panel.

(2) Attach latch end of hood release cable to

mechanic's wire protruding through dash panel.

(3) Route cable forward through engine compart-

ment toward latch by pulling on mechanic's wire

(Fig. 5).(4) Disconnect mechanic's wire from cable.

(5) Engage rubber grommet cable insulator into

hole in dash panel.

(6) Install hood release handle into instrument

panel.

(7) Place cable in position on latch.

(8) Slide cable case end sideways into keyhole slot

of hood latch.

(9) Engage cable end into hood latch locking mech-

anism.

(10) Install hood latch.

(11) Install attaching clips to cable case and install

clips into original holes in strut tower, fender, head-

lamp area, and radiator closure panel crossmember.

LATCH STRIKER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching striker to inside of

hood.

(3) Remove hood latch striker from vehicle.

INSTALLATION

(1) Position hood latch striker on vehicle, aligning

with paint breaks.

(2) Install bolts attaching hood latch striker to

hood.

(3) Align hood latch striker to engage smoothly

into hood latch.

(4) Verify hood operation and alignment. Adjust as

necessary.

(5) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.Fig. 5 HOOD RELEASE CABLE ROUTING

1 - GROMMET

2 - HOOD RELEASE CABLE

3 - RADIATOR CLOSURE PANEL CROSSMEMBER

23 - 64 HOODRS

LATCH RELEASE CABLE (Continued)

Page 1870 of 2339

HEADLINER

REMOVAL

(1) Remove sun visors and vanity mirrors.

(2) Remove sun visor center supports.

(3) If equipped, remove coat hooks.

(4) If equipped, remove roof rail modules.

(5) Remove A-pillar trim covers. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - REMOVAL).

(6) Remove B-pillar upper trim covers (Fig. 20).

(Refer to 23 - BODY/INTERIOR/B-PILLAR UPPER

TRIM - REMOVAL).

(7) Remove C-pillar upper trim covers (Fig. 21).

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

REMOVAL).

(8) Remove D-pillar trim covers. (Refer to 23 -

BODY/INTERIOR/RIGHT D-PILLAR TRIM PANEL -

REMOVAL) and (Refer to 23 - BODY/INTERIOR/

LEFT D-PILLAR TRIM PANEL - REMOVAL).

(9) Remove liftgate opening header trim.

(10) If equipped, remove overhead console screws.

(11) If equipped, remove reading lamps.

(12) Remove dome lamp.

(13) Remove push in locking fasteners attaching

headlining to rear roof header and roof bows (Fig.

22).(14) Remove wiring connections.

(15) Remove headlining from roof (Fig. 23), (Fig.

24), (Fig. 25), and (Fig. 26).

(16) Extract headlining through liftgate opening.

Fig. 20 HEADLINER AT B-PILLAR

1 - FRONT AND SLIDING DOOR WEATHERSTRIP SEAL

2 - B-PILLAR UPPER TRIM PANEL

Fig. 21 HEADLINER AT C-PILLAR

1 - SLIDING DOOR WEATHERSTRIP

2 - C-PILLAR UPPER TRIM PANEL

3 - REAR QUARTER WINDOW OPENING WEATHERSTRIP

Fig. 22 HEADLINER PUSH PINS

RSINTERIOR23-91