Locking CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1871 of 2339

INSTALLATION

(1) Insert headlining through liftgate opening (Fig.

23), (Fig. 24), (Fig. 25), and (Fig. 26).

(2) Place headlining in position on roof.

(3) Connect wire connectors.

(4) Install left sun visor support.

(5) Install push in locking fasteners attaching

headlining to rear roof header and bows (Fig. 22).

(6) Install right sun visor support.

(7) Install sun visors and vanity mirrors.

(8) If equipped, install roof rail modules.

(9) If equipped, install coat hooks.

(10) Install dome lamp.

(11) If equipped, install reading lamp.

(12) If equipped, install overhead console.

(13) Install liftgate opening header trim.

(14) Install D-pillar trim covers. (Refer to 23 -

BODY/INTERIOR/LEFT D-PILLAR TRIM PANEL -

INSTALLATION), and (Refer to 23 - BODY/INTERI-

OR/RIGHT D-PILLAR TRIM PANEL - INSTALLA-

TION).(15) Install C-pillar upper trim covers. (Refer to 23

- BODY/INTERIOR/C-PILLAR TRIM - INSTALLA-

TION).

(16) Install B-pillar upper trim covers. (Refer to 23

- BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION).

(17) Install A-pillar trim covers. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - INSTALLA-

TION).

Fig. 23 HEADLINER WITH SIDE CURTAINS

1 - 4-WAY LOCATOR AT FRONT OF HEADLINER

2 - PUSH IN CLIPS ON SUN VISOR RETAINER RACKET AND

TWO SCREWS IN SUN VISOR SWIVEL BRACKET

3 - ONE SCREW IN OVER HEAD CONSOLE

4 - PUSH PINS ATTACHING HEADLINER TO OVERHEAD5-2WAYLOCATOR AT REAR OF HEADLINER

6 - COAT HANGER HOOKS

7 - 2-WAY LOCATORS

8 - WIRE HARNESS

23 - 92 INTERIORRS

HEADLINER (Continued)

Page 1882 of 2339

SEAT BASE RISER - SECOND ROW - FOLD-IN-

FLOOR

REMOVAL............................134

INSTALLATION........................135

SEAT CUSHION COVER/FOAM -SECOND ROW

- FOLD-IN-FLOOR

REMOVAL............................136

INSTALLATION........................136

SEAT RECLINER/FORWARD FOLDING

MECHANISM -SECOND ROW -FOLD-IN-

FLOOR

REMOVAL............................137

INSTALLATION........................137

SEAT CUSHION SIDE SHIELD - SECOND ROW

- FOLD-IN-FLOOR

REMOVAL............................138

INSTALLATION........................138

SEAT GAS STRUT - SECOND ROW - FOLD-IN-

FLOOR

REMOVAL............................138

INSTALLATION........................139

SEAT PROP ROD - SECOND ROW - FOLD-IN-

FLOOR

REMOVAL............................139

INSTALLATION........................140

BUCKET SEAT BACK - QUAD BUCKET

REMOVAL............................140

INSTALLATION........................141

QUAD SEAT CUSHION

REMOVAL............................141

INSTALLATION........................141

QUAD BUCKET SEAT SIDE SHIELD/CUP

HOLDER

REMOVAL............................141

INSTALLATION........................142

QUAD BUCKET SEAT SIDE SHIELD - NO CUP

HOLDER

REMOVAL............................143

INSTALLATION........................143

QUAD BUCKET SEAT RISER

REMOVAL............................143

INSTALLATION........................143

BENCH SEAT BACK PANEL

REMOVAL............................143

INSTALLATION........................144

SEAT CUSHION COVER - QUAD BUCKET,

50/50 SPLIT, BENCH

REMOVAL............................144

INSTALLATION........................144

BENCH SEAT RISER - 50/50 SPLIT

REMOVAL............................145

INSTALLATION........................145

BENCH SEAT RISER - SECOND ROW

REMOVAL............................145

INSTALLATION........................145BENCH SEAT RISER - THIRD ROW

REMOVAL............................145

INSTALLATION........................145

SEAT BACK HINGE COVERS - QUAD BUCKET,

50/50 SPLIT, BENCH

REMOVAL............................146

INSTALLATION........................146

BENCH SEAT BACK HINGE

REMOVAL............................146

INSTALLATION

INSTALLATION......................146

SYNCHRONIZING CABLE ADJUSTMENT . . 147

BENCH SEAT BACK

REMOVAL............................147

INSTALLATION........................147

BENCH SEAT BACK COVER

REMOVAL............................148

INSTALLATION........................148

BENCH SEAT TRACK

REMOVAL............................148

INSTALLATION........................148

PLASTIC GROCERY BAG RETAINER

REMOVAL............................149

INSTALLATION........................149

UNDER SEAT STORAGE BIN

REMOVAL............................149

INSTALLATION........................149

UNDER SEAT STORAGE BIN GUIDE

REMOVAL............................150

INSTALLATION........................150

UNDER SEAT STORAGE BIN LOCK/LATCH

REMOVAL............................150

INSTALLATION........................150

LUMBAR SUPPORT

REMOVAL............................150

INSTALLATION........................150

SEAT RISER LATCH LOCKING LINK

REMOVAL............................151

INSTALLATION........................151

QUAD BUCKET SEAT SIDE SHIELD/CUP

HOLDER - FLAP AND SPRING ASSEMBLY

REMOVAL............................151

INSTALLATION........................151

BOTTOM OF SEAT CUSHION PAN PANEL-

THIRD ROW - FOLD-IN-FLOOR

REMOVAL............................152

INSTALLATION........................152

HEADREST SLEEVE - THIRD ROW - FOLD-IN-

FLOOR

REMOVAL............................152

INSTALLATION........................153

SEAT - THIRD ROW - FOLD-IN-FLOOR

REMOVAL............................153

INSTALLATION........................154

RSSEATS23 - 103

Page 1884 of 2339

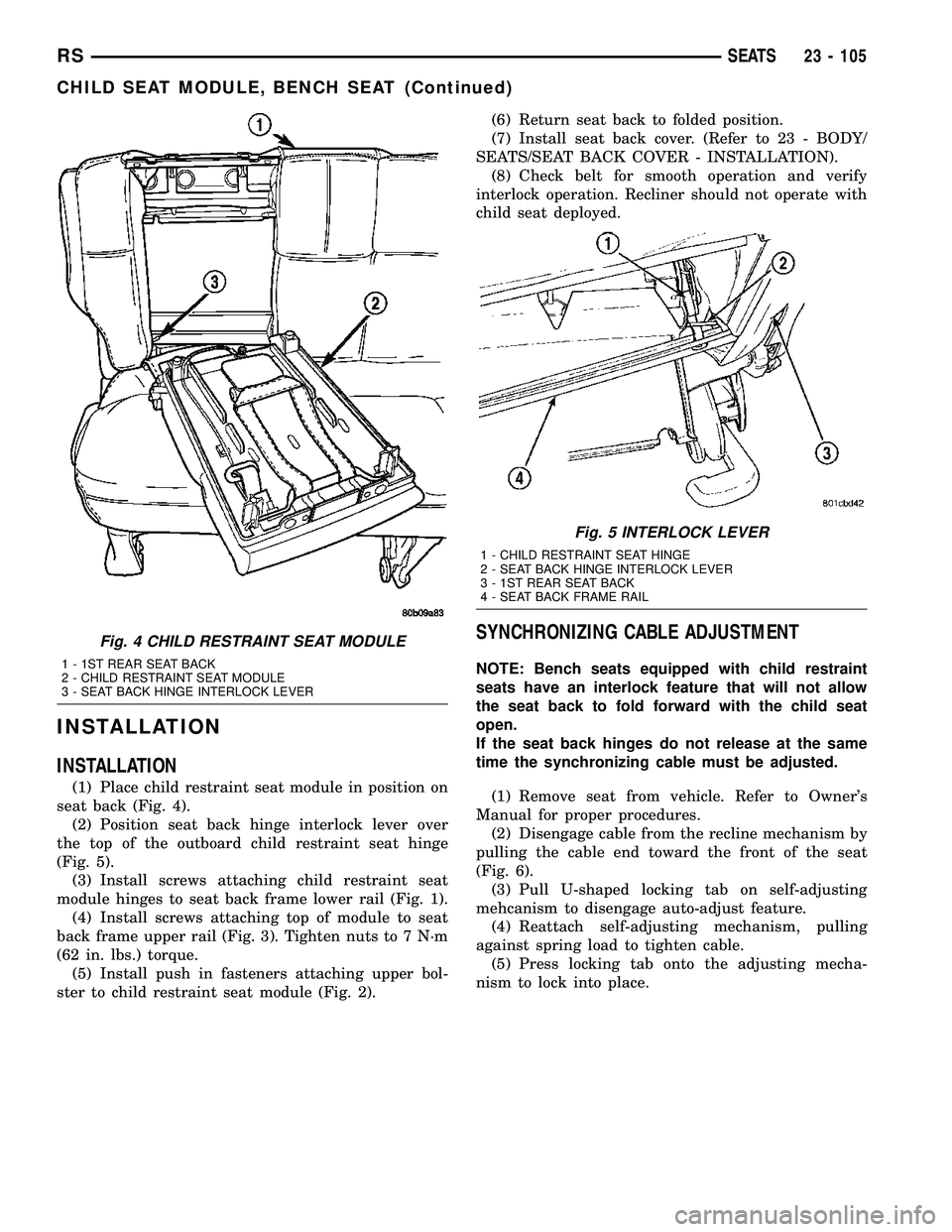

INSTALLATION

INSTALLATION

(1) Place child restraint seat module in position on

seat back (Fig. 4).

(2) Position seat back hinge interlock lever over

the top of the outboard child restraint seat hinge

(Fig. 5).

(3) Install screws attaching child restraint seat

module hinges to seat back frame lower rail (Fig. 1).

(4) Install screws attaching top of module to seat

back frame upper rail (Fig. 3). Tighten nuts to 7 N´m

(62 in. lbs.) torque.

(5) Install push in fasteners attaching upper bol-

ster to child restraint seat module (Fig. 2).(6) Return seat back to folded position.

(7) Install seat back cover. (Refer to 23 - BODY/

SEATS/SEAT BACK COVER - INSTALLATION).

(8) Check belt for smooth operation and verify

interlock operation. Recliner should not operate with

child seat deployed.

SYNCHRONIZING CABLE ADJUSTMENT

NOTE: Bench seats equipped with child restraint

seats have an interlock feature that will not allow

the seat back to fold forward with the child seat

open.

If the seat back hinges do not release at the same

time the synchronizing cable must be adjusted.

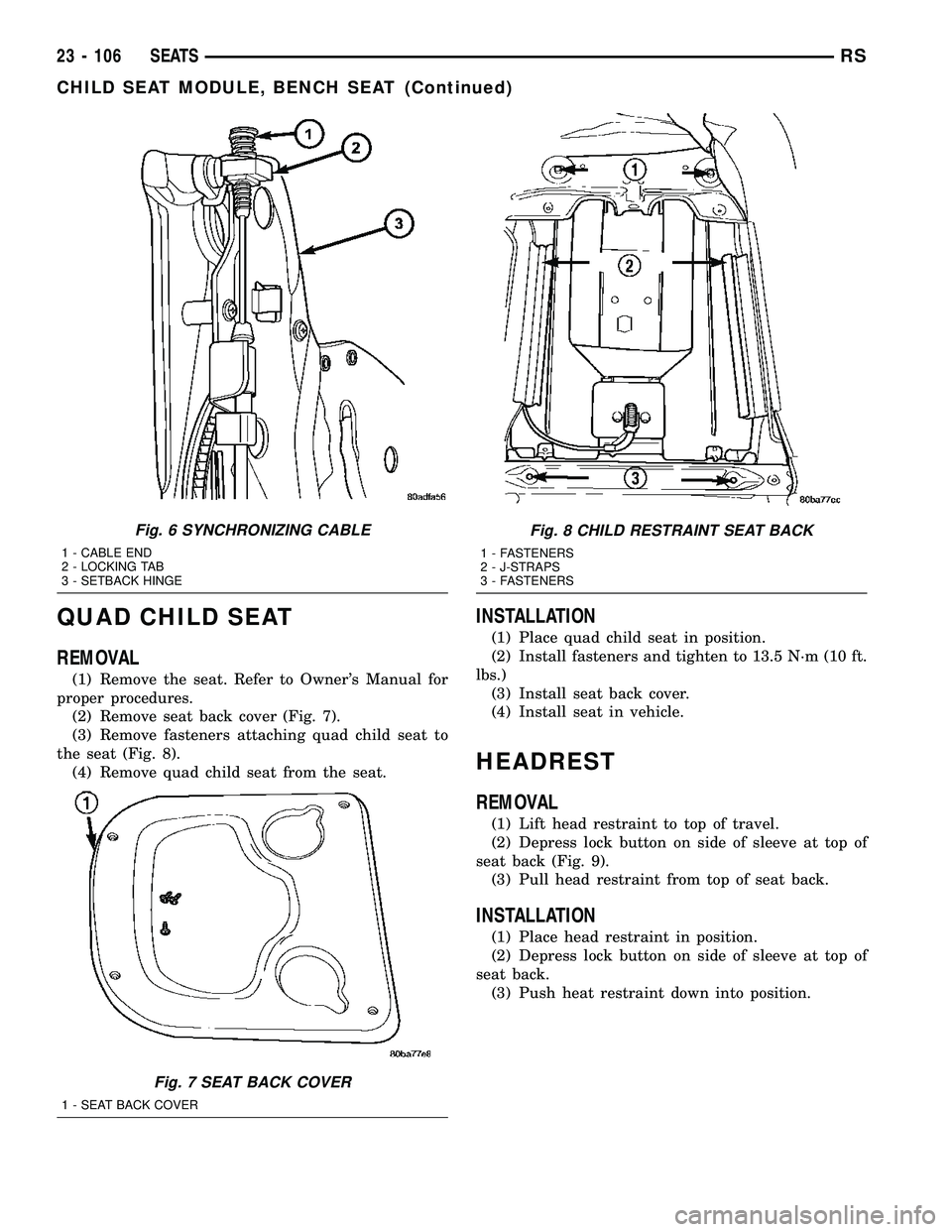

(1) Remove seat from vehicle. Refer to Owner's

Manual for proper procedures.

(2) Disengage cable from the recline mechanism by

pulling the cable end toward the front of the seat

(Fig. 6).

(3) Pull U-shaped locking tab on self-adjusting

mehcanism to disengage auto-adjust feature.

(4) Reattach self-adjusting mechanism, pulling

against spring load to tighten cable.

(5) Press locking tab onto the adjusting mecha-

nism to lock into place.

Fig. 4 CHILD RESTRAINT SEAT MODULE

1 - 1ST REAR SEAT BACK

2 - CHILD RESTRAINT SEAT MODULE

3 - SEAT BACK HINGE INTERLOCK LEVER

Fig. 5 INTERLOCK LEVER

1 - CHILD RESTRAINT SEAT HINGE

2 - SEAT BACK HINGE INTERLOCK LEVER

3 - 1ST REAR SEAT BACK

4 - SEAT BACK FRAME RAIL

RSSEATS23 - 105

CHILD SEAT MODULE, BENCH SEAT (Continued)

Page 1885 of 2339

QUAD CHILD SEAT

REMOVAL

(1) Remove the seat. Refer to Owner's Manual for

proper procedures.

(2) Remove seat back cover (Fig. 7).

(3) Remove fasteners attaching quad child seat to

the seat (Fig. 8).

(4) Remove quad child seat from the seat.

INSTALLATION

(1) Place quad child seat in position.

(2) Install fasteners and tighten to 13.5 N´m (10 ft.

lbs.)

(3) Install seat back cover.

(4) Install seat in vehicle.

HEADREST

REMOVAL

(1) Lift head restraint to top of travel.

(2) Depress lock button on side of sleeve at top of

seat back (Fig. 9).

(3) Pull head restraint from top of seat back.

INSTALLATION

(1) Place head restraint in position.

(2) Depress lock button on side of sleeve at top of

seat back.

(3) Push heat restraint down into position.

Fig. 6 SYNCHRONIZING CABLE

1 - CABLE END

2 - LOCKING TAB

3 - SETBACK HINGE

Fig. 7 SEAT BACK COVER

1 - SEAT BACK COVER

Fig. 8 CHILD RESTRAINT SEAT BACK

1 - FASTENERS

2 - J-STRAPS

3 - FASTENERS

23 - 106 SEATSRS

CHILD SEAT MODULE, BENCH SEAT (Continued)

Page 1895 of 2339

(9) Separate seat back cover from the foam by sid-

ing the locking strips through the keepers (Fig. 29)

and (Fig. 30).

(10) Remove seat back cover from vehicle.INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Place seat back cover on to the foam and push

locking strip into the keepers to lock seat back cover

into position (Fig. 29) and (Fig. 30).

(2) Fit seat back cover and foam on to seat back

frame (Fig. 28).

(3) Place seat back cover into position to clip

J-straps (Fig. 25) and (Fig. 26).

(4) Pull seat back cover tight, and attach the hook

and loop strip (Fig. 24).

Fig. 29 FRONT SEAT BACK COVER

1 - LOCKING STRIPS

Fig. 30 FRONT SEAT BACK FOAM

1 - KEEPERS

23 - 116 SEATSRS

FRONT SEAT BACK COVER (Continued)

Page 1912 of 2339

SEAT BACK COVER/FOAM -

SECOND ROW - FOLD-IN-

FLOOR

REMOVAL

(1) Remove both armrest. (Refer to 23 - BODY/

SEATS/ARMREST - REMOVAL).

(2) Remove headrest and headrest sleeves. (Refer

to 23 - BODY/SEATS/HEADREST SLEEVE -

REMOVAL).

(3) Remove seat back panel. (Refer to 23 - BODY/

SEATS/SEAT BACK PANEL - REMOVAL).

(4) Disengage seat back cover J-straps (Fig. 52).

(5) Remove two push pin fasteners attaching seat

back cover at the bottom of seat back.

(6) Remove seat back cover and foam from seat

back frame (Fig. 53).

(7) Separate seat back cover from the foam (Fig.

54).

INSTALLATION

(1) Place the seat back cover and foam together

(Fig. 54) and (Fig. 53).

(2) Place seat back cover/foam on the seat back

frame.

(3) Install two push pin fasteners attaching seat

back cover at the bottom of seat back.

(4) Engage seat back cover J-straps (Fig. 52).

(5) Remove seat back panel. (Refer to 23 - BODY/

SEATS/SEAT BACK PANEL - INSTALLATION)

(6)(7) Install headrest sleeves and headrest. (Refer to

23 - BODY/SEATS/HEADREST SLEEVE - INSTAL-

LATION).

(8) Install both armrest. (Refer to 23 - BODY/

SEATS/ARMREST - INSTALLATION).

Fig. 52 SECOND ROW SEAT BACK

1 - J-STRAPS

Fig. 53 SEAT BACK COVER 1

1 - LOCKING STRIPS

Fig. 54 SEAT BACK FOAM

1 - LOCKING CLIPS

RSSEATS23 - 133

Page 1926 of 2339

(7) Install bench seat back hinge covers. (Refer to

23 - BODY/SEATS/SEAT BACK HINGE COVERS -

50/50 SPLIT, BENCH - INSTALLATION)

(8) Verify seat back hinge operation and adjust

synchronizing cable, if equipped. (Refer to 23 -

BODY/SEATS/SYNCHRONIZING CABLE ADJUST-

MENT)

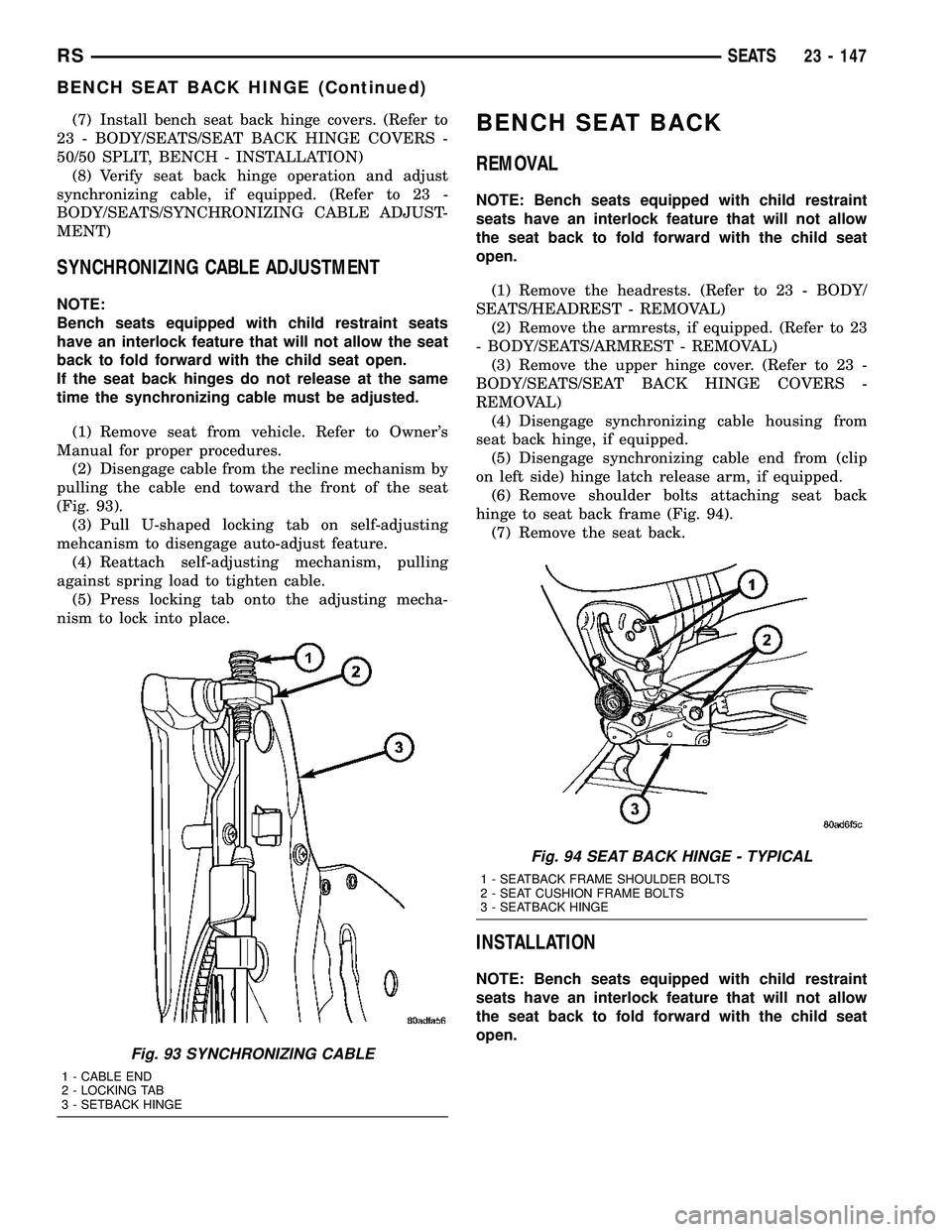

SYNCHRONIZING CABLE ADJUSTMENT

NOTE:

Bench seats equipped with child restraint seats

have an interlock feature that will not allow the seat

back to fold forward with the child seat open.

If the seat back hinges do not release at the same

time the synchronizing cable must be adjusted.

(1) Remove seat from vehicle. Refer to Owner's

Manual for proper procedures.

(2) Disengage cable from the recline mechanism by

pulling the cable end toward the front of the seat

(Fig. 93).

(3) Pull U-shaped locking tab on self-adjusting

mehcanism to disengage auto-adjust feature.

(4) Reattach self-adjusting mechanism, pulling

against spring load to tighten cable.

(5) Press locking tab onto the adjusting mecha-

nism to lock into place.

BENCH SEAT BACK

REMOVAL

NOTE: Bench seats equipped with child restraint

seats have an interlock feature that will not allow

the seat back to fold forward with the child seat

open.

(1) Remove the headrests. (Refer to 23 - BODY/

SEATS/HEADREST - REMOVAL)

(2) Remove the armrests, if equipped. (Refer to 23

- BODY/SEATS/ARMREST - REMOVAL)

(3) Remove the upper hinge cover. (Refer to 23 -

BODY/SEATS/SEAT BACK HINGE COVERS -

REMOVAL)

(4) Disengage synchronizing cable housing from

seat back hinge, if equipped.

(5) Disengage synchronizing cable end from (clip

on left side) hinge latch release arm, if equipped.

(6) Remove shoulder bolts attaching seat back

hinge to seat back frame (Fig. 94).

(7) Remove the seat back.

INSTALLATION

NOTE: Bench seats equipped with child restraint

seats have an interlock feature that will not allow

the seat back to fold forward with the child seat

open.

Fig. 93 SYNCHRONIZING CABLE

1 - CABLE END

2 - LOCKING TAB

3 - SETBACK HINGE

Fig. 94 SEAT BACK HINGE - TYPICAL

1 - SEATBACK FRAME SHOULDER BOLTS

2 - SEAT CUSHION FRAME BOLTS

3 - SEATBACK HINGE

RSSEATS23 - 147

BENCH SEAT BACK HINGE (Continued)

Page 1930 of 2339

SEAT RISER LATCH LOCKING

LINK

REMOVAL

(1) Remove seat as necessary to access latch lock-

ing link.

NOTE: If the seat is locked in the seated position

and cannot be tilted forward, it can be released by

reaching into the escutcheons with a hook tool or a

finger from the rear. Pulling the latch toward the

rear of the vehicle will unlock the seat latch allow-

ing the seat to tilt forward.

(2) Using a flat bladed tool pry plastic latch lock-

ing link free from both pins (Fig. 102).

(3) Remove link from seat.

INSTALLATION

(1) Place latch locking link into position (Fig. 102).

(2) Press latch locking link onto pins lock and seat

fully.

(3) Place seat into position and verify proper oper-

ation.

QUAD BUCKET SEAT SIDE

SHIELD/CUP HOLDER - FLAP

AND SPRING ASSEMBLY

REMOVAL

(1) Inspect the flap retaining tabs on cup holder

for damage (Fig. 103).(2) If cracked or broken, replace quad bucket seat

side shield with cup holder. (Refer to 23 - BODY/

SEATS/SEAT SIDE SHIELD - REMOVAL).

(3) If flap retaining tabs are not damaged replace

flap and spring assembly.

INSTALLATION

(1) Ensure the spring is position into mounting tab

(Fig. 104).

(2)

Hold flap and spring assembly in the horizontal

position and snap into cup holder flap retaining tabs.

(3) Verify cup holder flap operation several times

to ensure proper operation. Flap should fold down-

ward with little effort and spring back to a horizontal

position when released.

Fig. 102 SEAT RISER LATCH LOCKING LINK

1 - LATCH LOCKING LINK

2 - FLAT BLADED TOOL

3 - SEAT RISER

Fig. 103 CUP HOLDER FLAP RETAINING TABS

1 - FLAP RETAINING TABS

Fig. 104 FLAP AND SPRING ASSEMBLY

1 - CUP HOLDER FLAP

2 - SPRING IN MOUNTING TAB

RSSEATS23 - 151

Page 1946 of 2339

(6) Install fully the entire A-pillar glass run sec-

tion by indexing the molded corner detail into the

roll frame. Slide the glass run up the A-pillar until

the rubber molded joint just touches the roll frame.

(7) Verify that the tertiary seal is on the correct

side of the roll frame prior to seating the glass run

fully onto the frame. Verify the glass runs is fully

seated for the header, and A-pillar and B-pillar

(8) Install screw attaching glass run weatherstrip

to inner door panel.

(9) Install inner belt weatherstrip.

(10) Install watershed.

(11) Push weatherstrip groove onto lip along top of

door frame.

(12) Engage clip into slot in door frame.

(13) Push weatherstrip into channel at rear of door

frame, working from the top to bottom.

(14) Install door frame closeout moldings.

(15) Install door speaker, if equipped.

(16) Install door trim panel.FRONT DOOR OUTER BELT

MOLDING

REMOVAL

(1) Remove the side view mirror. (Refer to 23 -

BODY/EXTERIOR/SIDE VIEW MIRROR -

REMOVAL)

(2) Remove door trim panel.

(3) Roll door glass down.

(4) Using a hook tool, disengage interlocking lip at

the base of the inward edge of the belt molding (Fig.

1).

(5) Remove belt molding from door.

INSTALLATION

(1) Place belt molding in position on door (Fig. 1).

NOTE: Make sure end of applique is against outer

belt.

(2) Engage interlocking lip at the base of the

inward edge of the belt molding on door panel.

(3) Install door trim panel.

Fig. 1 FRONT DOOR WEATHERSTRIP

1 - DOOR GLASS RUN WEATHERSTRIP

2 - FRONT INNER DOOR

3 - DOOR BELT OUTER WEATHERSTRIP4 - DOOR MOUNTED WEATHERSTRIP

5 - DOOR OUTER BELT WEATHERSTRIP

RSWEATHERSTRIP/SEALS23 - 167

FRONT DOOR GLASS RUN WEATHERSTRIP (Continued)

Page 2319 of 2339

INTERMEDIATE - INSTALLATION, CABLE- PARKING BRAKE ..................... 5-69

INTERMEDIATE - REMOVAL, CABLE - PARKING BRAKE ...................... 5-69

INTERNATIONAL SYMBOLS - DESCRIPTION .........................0-1

INTRODUCTION - DIAGNOSIS AND TESTING, ENGINE DIAGNOSIS ........9-3,9-78

IOD FUSE - DESCRIPTION ...........8W-97-3

IOD FUSE - OPERATION .............8W-97-3

JOINT - DESCRIPTION, LOWER BALL ......2-10

JOINT - DIAGNOSIS AND TESTING, LOWER BALL ........................ 2-10

JOINT - OPERATION, LOWER BALL .......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-60

JOINT MOLDING - REMOVAL, ROOF ......23-60

JOUNCE BUMPER - DESCRIPTION ........2-35

JOUNCE BUMPER - OPERATION ..........2-35

JUMP STARTING - STANDARD PROCEDURE ......................... 0-25

JUNCTION BLOCK - DESCRIPTION, NON-ABS ............................ 5-33

JUNCTION BLOCK - INSTALLATION, NON-ABS ............................ 5-34

JUNCTION BLOCK - OPERATION, NON-ABS ............................ 5-33

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-34

KEY - DESCRIPTION, TRANSPONDER .....8Q-6

KEY - OPERATION, TRANSPONDER .......8Q-6

KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........23-90

KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ...........23-90

KEY REMOTE ENTRY MODULE - DESCRIPTION, SENTRY ................8Q-3

KEY REMOTE ENTRY MODULE - DIAGNOSIS AND TESTING, SENTRY .......8Q-5

KEY REMOTE ENTRY MODULE - INSTALLATION, SENTRY ................8Q-6

KEY REMOTE ENTRY MODULE - OPERATION, SENTRY .................. 8Q-4

KEY REMOTE ENTRY MODULE - REMOVAL, SENTRY ................... 8Q-6

KEY REMOTE ENTRY SYSTEM - DIAGNOSIS AND TESTING, SENTRY .......8Q-3

KEYLESS ENTRY TRANSMITTER, DIAGNOSIS AND TESTING .............8N-24

KEYLESS ENTRY TRANSMITTER PROGRAMMING - STANDARD

PROCEDURE, REMOTE ................8N-24

KEY/LOCK CYLINDER - DESCRIPTION ....19-20

KEY/LOCK CYLINDER - INSTALLATION ....19-20

KEY/LOCK CYLINDER - OPERATION ......19-20

KEY/LOCK CYLINDER - REMOVAL .......19-20

KNEE - INSTALLATION, BLOCKER- INFLATABLE ......................... 23-75

KNEE - REMOVAL, BLOCKER- INFLATABLE ......................... 23-75

KNEE BLOCKER AIRBAG - DESCRIPTION . . 8O-22

KNEE BLOCKER AIRBAG - INSTALLATION . 8O-23

KNEE BLOCKER AIRBAG - OPERATION . . . 8O-22

KNEE BLOCKER AIRBAG - REMOVAL .....8O-23

KNOB - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

KNOB - REMOVAL, SEAT BELT HEIGHT ADJUSTER ......................... 8O-38

KNOCK SENSOR - DESCRIPTION ..........8I-8

KNOCK SENSOR - OPERATION ...........8I-8

KNUCKLE - DESCRIPTION ................2-6

KNUCKLE - INSPECTION, STEERING ........2-9

KNUCKLE - INSTALLATION, STEERING ......2-9

KNUCKLE - OPERATION .................2-7

KNUCKLE - REMOVAL, STEERING .........2-7

LABEL, DESCRIPTION - VEHICLE EMISSION CONTROL INFORMATION .......25-1

LAMP - DESCRIPTION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - DIAGNOSIS AND TESTING, FRONT FOG .......................... 8L-7

LAMP - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP - INSTALLATION, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - INSTALLATION, COURTESY ......8L-21

LAMP - INSTALLATION, DOME/CARGO ....8L-22

LAMP - INSTALLATION, FRONT FOG .......8L-8

LAMP - INSTALLATION, LICENSE ........8L-17

LAMP - INSTALLATION, LIFTGATE .......8L-22 LAMP - INSTALLATION, PARK/TURN

SIGNAL ............................ 8L-18

LAMP - INSTALLATION, READING ........8L-23

LAMP - INSTALLATION, TAIL ...........8L-19

LAMP - INSTALLATION, VANITY .........8L-24

LAMP - OPERATION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - REMOVAL, CENTER CONSOLE ....8L-21

LAMP - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - REMOVAL, COURTESY ..........8L-21

LAMP - REMOVAL, DOME/CARGO .......8L-22

LAMP - REMOVAL, FRONT FOG ..........8L-8

LAMP - REMOVAL, LICENSE ............8L-17

LAMP - REMOVAL, LIFTGATE ...........8L-22

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-18

LAMP - REMOVAL, READING ...........8L-22

LAMP - REMOVAL, TAIL ...............8L-18

LAMP - REMOVAL, VANITY .............8L-24

LAMP SWITCH - DESCRIPTION, BRAKE ....8L-4

LAMP SWITCH - DIAGNOSIS AND TESTING, BRAKE ...................... 8L-4

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - INSTALLATION, GLOVE BOX ............................... 8L-22

LAMP SWITCH - OPERATION, BRAKE ......8L-4

LAMP SWITCH - REMOVAL, BRAKE .......8L-5

LAMP SWITCH - REMOVAL, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - REMOVAL, GLOVE BOX . . 8L-22

LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED STOP .................8L-6

LAMP UNIT - INSTALLATION, TAIL .......8L-19

LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP UNIT - REMOVAL, TAIL ...........8L-19

LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG .....8L-9

LAMP UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT FOG ...............8L-9

LAMPS - INSTALLATION, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS - REMOVAL, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS, SPECIFICATIONS - EXTERIOR .....8L-3

LAMPS, SPECIFICATIONS - INTERIOR ....8L-20

LAMPS/LIGHTING - EXTERIOR - DESCRIPTION ........................ 8L-2

LAMPS/LIGHTING - EXTERIOR - OPERATION .......................... 8L-2

LAMPS/LIGHTING - EXTERIOR - WARNING ........................... 8L-3

LAP BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER .....23-157

LAP BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER .................. 23-157

LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND TESTING, HYDRAULIC ....9-34

LASH ADJUSTERS - INSTALLATION, HYDRAULIC .......................... 9-35

LASH ADJUSTERS - REMOVAL, HYDRAULIC .......................... 9-35

LATCH - DESCRIPTION ...........8N-12,8N-49

LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE LID ....23-90

LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE LID .................23-90

LATCH - INSTALLATION .....23-18,23-41,23-63

LATCH - INSTALLATION ..........8N-13,8N-50

LATCH - INSTALLATION, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH - INSTALLATION, GLOVE BOX .....23-66

LATCH - INSTALLATION, HOLD OPEN .....23-25

LATCH / LOCK ASSEMBLY - INSTALLATION ....................... 23-27

LATCH / LOCK ASSEMBLY - REMOVAL ....23-26

LATCH - OPERATION ............8N-12,8N-49

LATCH - REMOVAL .........23-18,23-41,23-63

LATCH - REMOVAL ..............8N-12,8N-49

LATCH - REMOVAL, FUEL FILL DOOR BLOCKER ........................... 23-53

LATCH - REMOVAL, GLOVE BOX .........23-66

LATCH - REMOVAL, HOLD OPEN ........23-25

LATCH ACTUATOR - DESCRIPTION ......8N-13

LATCH ACTUATOR - INSTALLATION ......8N-14

LATCH ACTUATOR - OPERATION ........8N-13 LATCH ACTUATOR - REMOVAL

..........8N-13

LATCH CABLE - INSTALLATION, HOLD OPEN .............................. 23-38

LATCH CABLE - REMOVAL, HOLD OPEN . . . 23-38

LATCH HANDLE - INSTALLATION, INSIDE . . 23-34

LATCH HANDLE - REMOVAL, INSIDE .....23-34

LATCH LOCKING LINK - INSTALLATION, SEAT RISER ........................ 23-151

LATCH LOCKING LINK - REMOVAL, SEAT RISER ............................ 23-151

LATCH RELEASE CABLE - INSTALLATION . . 23-64

LATCH RELEASE CABLE - REMOVAL .....23-63

LATCH STRIKER - INSTALLATION . . 23-19,23-42, 23-64

LATCH STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER .................23-53

LATCH STRIKER - INSTALLATION, GLOVE BOX ............................... 23-66

LATCH STRIKER - INSTALLATION, HOLD OPEN .............................. 23-26

LATCH STRIKER - INSTALLATION, REAR . . 23-29

LATCH STRIKER - REMOVAL . 23-19,23-41,23-64

LATCH STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH STRIKER - REMOVAL, GLOVE BOX ............................... 23-66

LATCH STRIKER - REMOVAL, HOLD OPEN .............................. 23-26

LATCH STRIKER - REMOVAL, REAR ......23-29

LEAD - DIAGNOSIS AND TESTING, TIRE/VEHICLE ......................... 22-14

LEAF SPRING FRONT - INSTALLATION, BUSHING ............................ 2-30

LEAF SPRING FRONT - REMOVAL, BUSHING ............................ 2-29

LEAK DETECTION ASSY - INSTALLATION, NATURAL VAC ....................... 25-14

LEAK DETECTION ASSY - REMOVAL, NATURAL VAC ....................... 25-14

LEAK DETECTION PUMP - INSTALLATION . 25-15

LEAK DETECTION PUMP - REMOVAL .....25-15

LEAK INSPECTION - DIAGNOSIS AND TESTING, ENGINE OIL ...............9-8,9-84

LEAK REPAIRING - STANDARD PROCEDURE, TIRE ................... 22-17

LEAK TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM .....................7-2

LEAKAGE - DIAGNOSIS AND TESTING, TORQUE CONVERTER HOUSING FLUID . . 21-154, 21-9

LEAKAGE TEST - DIAGNOSIS AND TESTING, CYLINDER COMBUSTION

PRESSURE ....................... 9-85,9-9

LEAKS - DIAGNOSIS AND TESTING, INTAKE MANIFOLD ...............9-147,9-60

LEAKS, DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM ...............24-67

LEAKS, DIAGNOSIS AND TESTING - WATER ............................. 23-1

LEARN CYCLE, STANDARD PROCEDURE - POWER LIFTGATE ................... 8N-8

LEARN CYCLE, STANDARD PROCEDURE - POWER SLIDING DOOR ..............8N-48

LEARN PROCEDURE - STANDARD PROCEDURE, QUICK .................. 8E-15

LENS - INSTALLATION, CLUSTER ........8J-11

LENS - REMOVAL, CLUSTER ............8J-11

LEVEL AND CONDITION CHECK, STANDARD PROCEDURE - FLUID . . 21-230,21-82

LEVEL CHECK - STANDARD PROCEDURE, COOLANT .................7-4

LEVEL CHECK - STANDARD PROCEDURE, ENGINE OIL ..............9-140

LEVEL CHECK, STANDARD PROCEDURE - ENGINE OIL ........................ 9-54

LEVEL CHECKING - STANDARD PROCEDURE, BRAKE FLUID .............5-33

LEVEL CHECKING - STANDARD PROCEDURE, POWER STEERING FLUID . . . 19-44

LEVEL SENDING UNIT / SENSOR - DESCRIPTION, FUEL ................... 14-5

LEVEL SENDING UNIT / SENSOR - INSTALLATION, FUEL .................. 14-6

LEVEL SENDING UNIT / SENSOR - OPERATION, FUEL ..................... 14-5

LEVEL SENDING UNIT / SENSOR - REMOVAL, FUEL ...................... 14-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page