transmission CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 379 of 2339

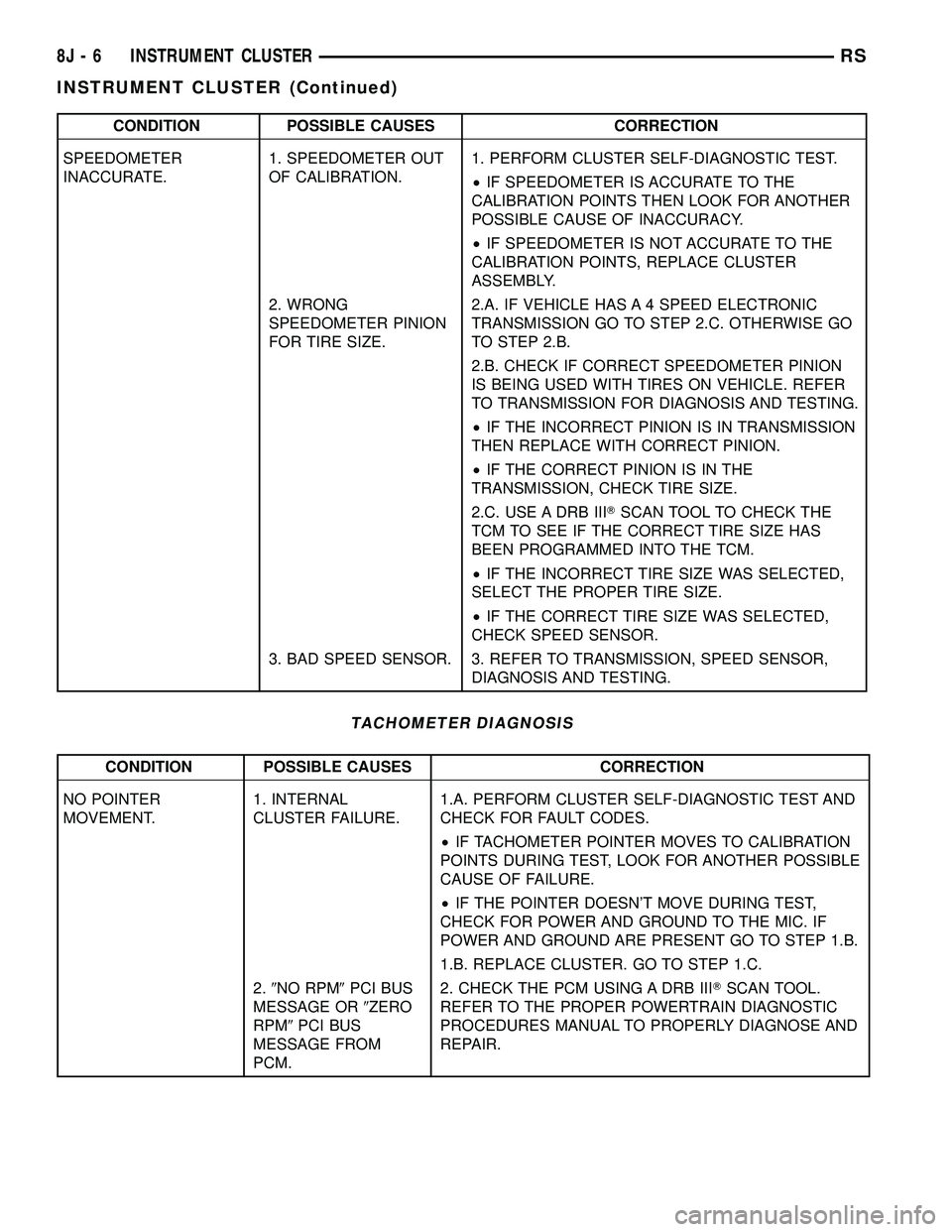

CONDITION POSSIBLE CAUSES CORRECTION

SPEEDOMETER

INACCURATE.1. SPEEDOMETER OUT

OF CALIBRATION.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF SPEEDOMETER IS ACCURATE TO THE

CALIBRATION POINTS THEN LOOK FOR ANOTHER

POSSIBLE CAUSE OF INACCURACY.

²IF SPEEDOMETER IS NOT ACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER

ASSEMBLY.

2. WRONG

SPEEDOMETER PINION

FOR TIRE SIZE.2.A. IF VEHICLE HAS A 4 SPEED ELECTRONIC

TRANSMISSION GO TO STEP 2.C. OTHERWISE GO

TO STEP 2.B.

2.B. CHECK IF CORRECT SPEEDOMETER PINION

IS BEING USED WITH TIRES ON VEHICLE. REFER

TO TRANSMISSION FOR DIAGNOSIS AND TESTING.

²IF THE INCORRECT PINION IS IN TRANSMISSION

THEN REPLACE WITH CORRECT PINION.

²IF THE CORRECT PINION IS IN THE

TRANSMISSION, CHECK TIRE SIZE.

2.C. USE A DRB IIITSCAN TOOL TO CHECK THE

TCM TO SEE IF THE CORRECT TIRE SIZE HAS

BEEN PROGRAMMED INTO THE TCM.

²IF THE INCORRECT TIRE SIZE WAS SELECTED,

SELECT THE PROPER TIRE SIZE.

²IF THE CORRECT TIRE SIZE WAS SELECTED,

CHECK SPEED SENSOR.

3. BAD SPEED SENSOR. 3. REFER TO TRANSMISSION, SPEED SENSOR,

DIAGNOSIS AND TESTING.

TACHOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT.1. INTERNAL

CLUSTER FAILURE.1.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST AND

CHECK FOR FAULT CODES.

²IF TACHOMETER POINTER MOVES TO CALIBRATION

POINTS DURING TEST, LOOK FOR ANOTHER POSSIBLE

CAUSE OF FAILURE.

²IF THE POINTER DOESN'T MOVE DURING TEST,

CHECK FOR POWER AND GROUND TO THE MIC. IF

POWER AND GROUND ARE PRESENT GO TO STEP 1.B.

1.B. REPLACE CLUSTER. GO TO STEP 1.C.

2.9NO RPM9PCI BUS

MESSAGE OR9ZERO

RPM9PCI BUS

MESSAGE FROM

PCM.2. CHECK THE PCM USING A DRB IIITSCAN TOOL.

REFER TO THE PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE AND

REPAIR.

8J - 6 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 383 of 2339

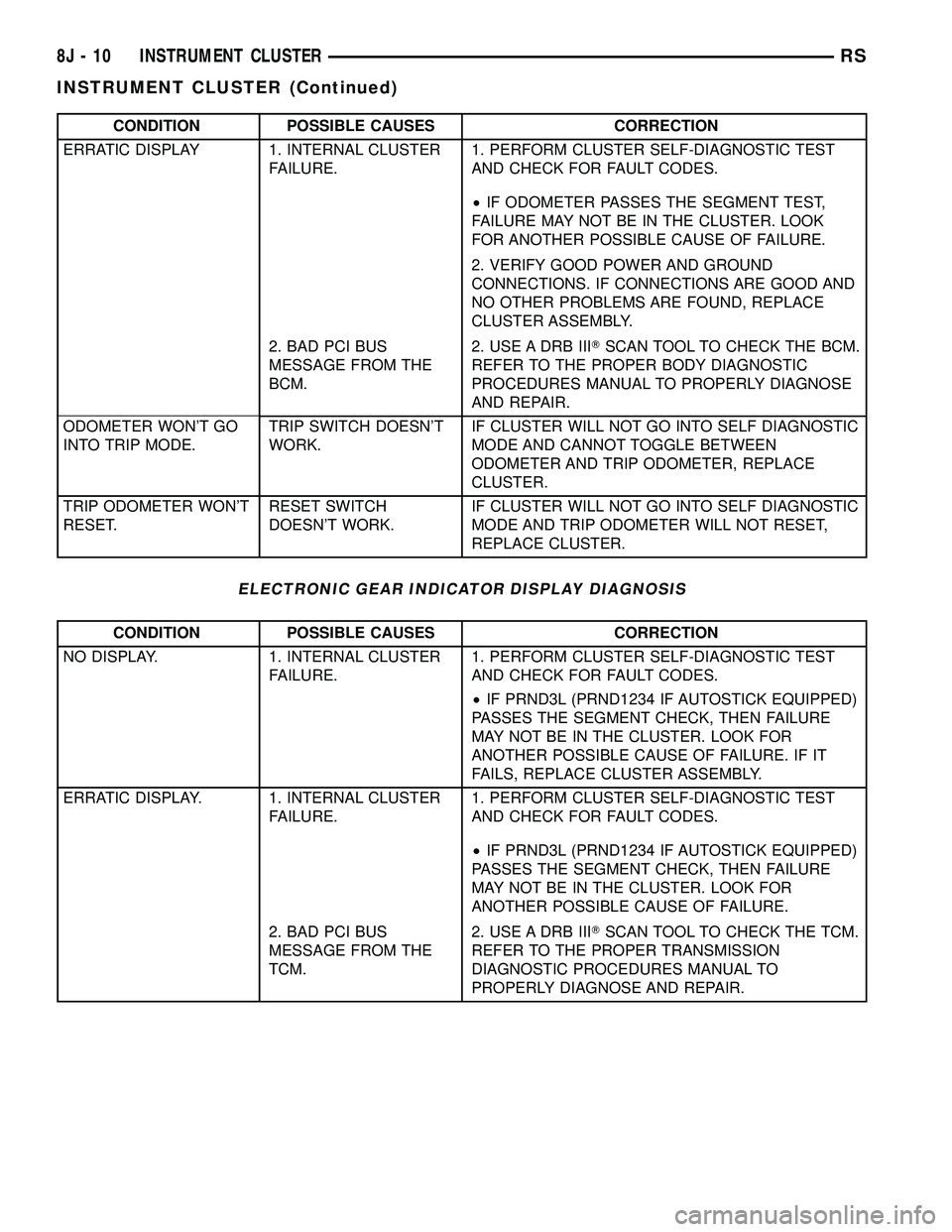

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC DISPLAY 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF ODOMETER PASSES THE SEGMENT TEST,

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE.

2. VERIFY GOOD POWER AND GROUND

CONNECTIONS. IF CONNECTIONS ARE GOOD AND

NO OTHER PROBLEMS ARE FOUND, REPLACE

CLUSTER ASSEMBLY.

2. BAD PCI BUS

MESSAGE FROM THE

BCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

REFER TO THE PROPER BODY DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

ODOMETER WON'T GO

INTO TRIP MODE.TRIP SWITCH DOESN'T

WORK.IF CLUSTER WILL NOT GO INTO SELF DIAGNOSTIC

MODE AND CANNOT TOGGLE BETWEEN

ODOMETER AND TRIP ODOMETER, REPLACE

CLUSTER.

TRIP ODOMETER WON'T

RESET.RESET SWITCH

DOESN'T WORK.IF CLUSTER WILL NOT GO INTO SELF DIAGNOSTIC

MODE AND TRIP ODOMETER WILL NOT RESET,

REPLACE CLUSTER.

ELECTRONIC GEAR INDICATOR DISPLAY DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO DISPLAY. 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES THE SEGMENT CHECK, THEN FAILURE

MAY NOT BE IN THE CLUSTER. LOOK FOR

ANOTHER POSSIBLE CAUSE OF FAILURE. IF IT

FAILS, REPLACE CLUSTER ASSEMBLY.

ERRATIC DISPLAY. 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES THE SEGMENT CHECK, THEN FAILURE

MAY NOT BE IN THE CLUSTER. LOOK FOR

ANOTHER POSSIBLE CAUSE OF FAILURE.

2. BAD PCI BUS

MESSAGE FROM THE

TCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE TCM.

REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

8J - 10 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 384 of 2339

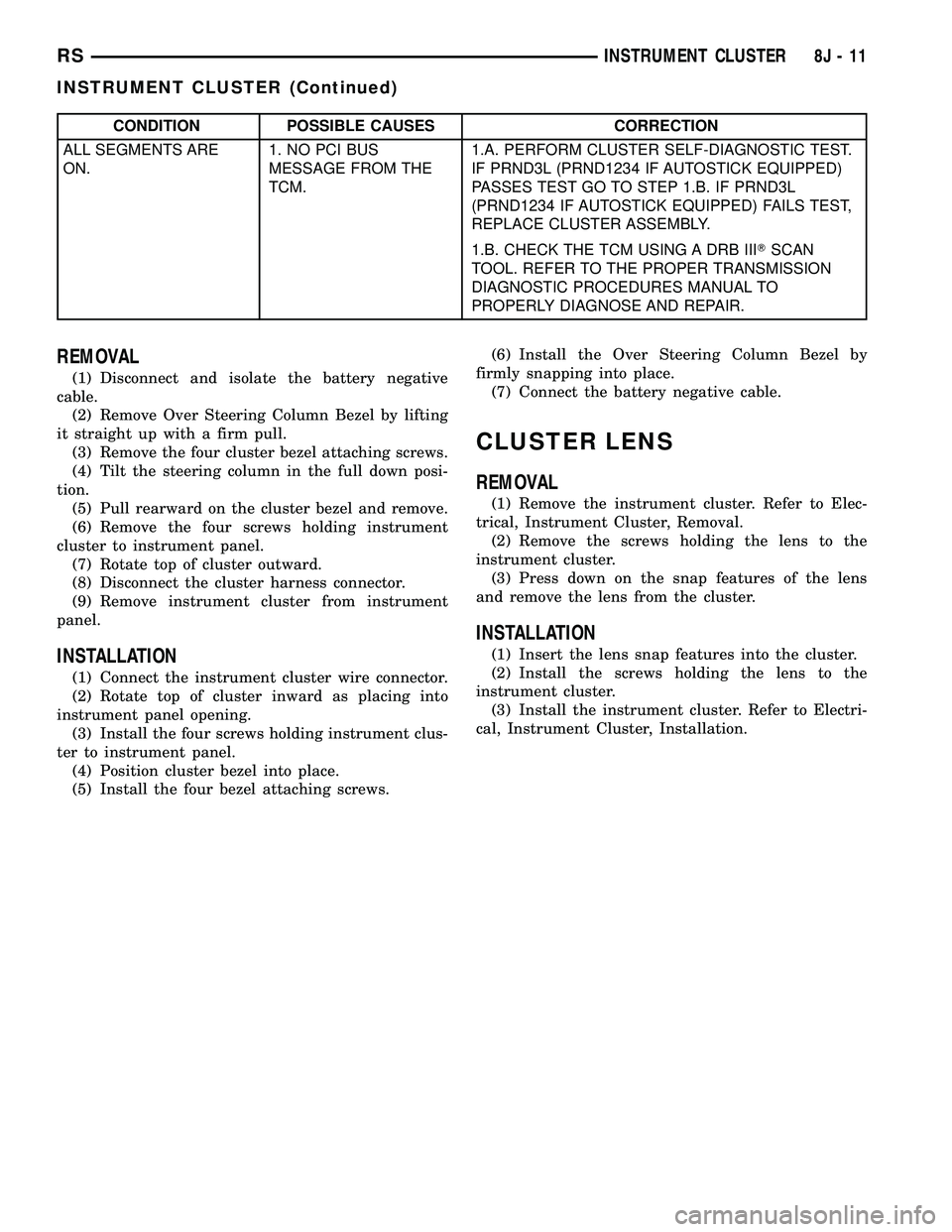

CONDITION POSSIBLE CAUSES CORRECTION

ALL SEGMENTS ARE

ON.1. NO PCI BUS

MESSAGE FROM THE

TCM.1.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES TEST GO TO STEP 1.B. IF PRND3L

(PRND1234 IF AUTOSTICK EQUIPPED) FAILS TEST,

REPLACE CLUSTER ASSEMBLY.

1.B. CHECK THE TCM USING A DRB IIITSCAN

TOOL. REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Over Steering Column Bezel by lifting

it straight up with a firm pull.

(3) Remove the four cluster bezel attaching screws.

(4) Tilt the steering column in the full down posi-

tion.

(5) Pull rearward on the cluster bezel and remove.

(6) Remove the four screws holding instrument

cluster to instrument panel.

(7) Rotate top of cluster outward.

(8) Disconnect the cluster harness connector.

(9) Remove instrument cluster from instrument

panel.

INSTALLATION

(1) Connect the instrument cluster wire connector.

(2) Rotate top of cluster inward as placing into

instrument panel opening.

(3) Install the four screws holding instrument clus-

ter to instrument panel.

(4) Position cluster bezel into place.

(5) Install the four bezel attaching screws.(6) Install the Over Steering Column Bezel by

firmly snapping into place.

(7) Connect the battery negative cable.

CLUSTER LENS

REMOVAL

(1) Remove the instrument cluster. Refer to Elec-

trical, Instrument Cluster, Removal.

(2) Remove the screws holding the lens to the

instrument cluster.

(3) Press down on the snap features of the lens

and remove the lens from the cluster.

INSTALLATION

(1) Insert the lens snap features into the cluster.

(2) Install the screws holding the lens to the

instrument cluster.

(3) Install the instrument cluster. Refer to Electri-

cal, Instrument Cluster, Installation.

RSINSTRUMENT CLUSTER8J-11

INSTRUMENT CLUSTER (Continued)

Page 389 of 2339

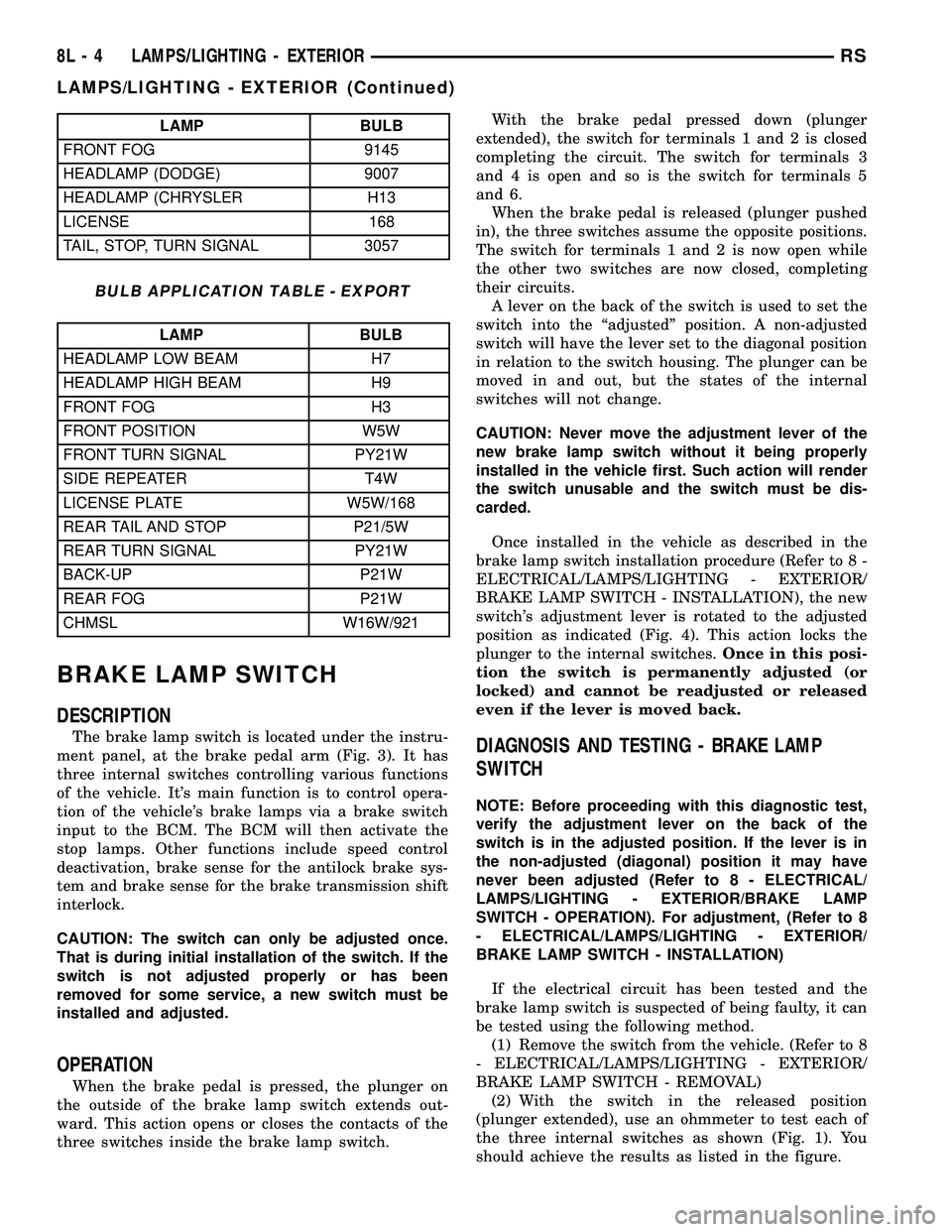

LAMP BULB

FRONT FOG 9145

HEADLAMP (DODGE) 9007

HEADLAMP (CHRYSLER H13

LICENSE 168

TAIL, STOP, TURN SIGNAL 3057

BULB APPLICATION TABLE - EXPORT

LAMP BULB

HEADLAMP LOW BEAM H7

HEADLAMP HIGH BEAM H9

FRONT FOG H3

FRONT POSITION W5W

FRONT TURN SIGNAL PY21W

SIDE REPEATER T4W

LICENSE PLATE W5W/168

REAR TAIL AND STOP P21/5W

REAR TURN SIGNAL PY21W

BACK-UP P21W

REAR FOG P21W

CHMSL W16W/921

BRAKE LAMP SWITCH

DESCRIPTION

The brake lamp switch is located under the instru-

ment panel, at the brake pedal arm (Fig. 3). It has

three internal switches controlling various functions

of the vehicle. It's main function is to control opera-

tion of the vehicle's brake lamps via a brake switch

input to the BCM. The BCM will then activate the

stop lamps. Other functions include speed control

deactivation, brake sense for the antilock brake sys-

tem and brake sense for the brake transmission shift

interlock.

CAUTION: The switch can only be adjusted once.

That is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

OPERATION

When the brake pedal is pressed, the plunger on

the outside of the brake lamp switch extends out-

ward. This action opens or closes the contacts of the

three switches inside the brake lamp switch.With the brake pedal pressed down (plunger

extended), the switch for terminals 1 and 2 is closed

completing the circuit. The switch for terminals 3

and 4 is open and so is the switch for terminals 5

and 6.

When the brake pedal is released (plunger pushed

in), the three switches assume the opposite positions.

The switch for terminals 1 and 2 is now open while

the other two switches are now closed, completing

their circuits.

A lever on the back of the switch is used to set the

switch into the ªadjustedº position. A non-adjusted

switch will have the lever set to the diagonal position

in relation to the switch housing. The plunger can be

moved in and out, but the states of the internal

switches will not change.

CAUTION: Never move the adjustment lever of the

new brake lamp switch without it being properly

installed in the vehicle first. Such action will render

the switch unusable and the switch must be dis-

carded.

Once installed in the vehicle as described in the

brake lamp switch installation procedure (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION), the new

switch's adjustment lever is rotated to the adjusted

position as indicated (Fig. 4). This action locks the

plunger to the internal switches.Once in this posi-

tion the switch is permanently adjusted (or

locked) and cannot be readjusted or released

even if the lever is moved back.

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH

NOTE: Before proceeding with this diagnostic test,

verify the adjustment lever on the back of the

switch is in the adjusted position. If the lever is in

the non-adjusted (diagonal) position it may have

never been adjusted (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - OPERATION). For adjustment, (Refer to 8

- ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION)

If the electrical circuit has been tested and the

brake lamp switch is suspected of being faulty, it can

be tested using the following method.

(1) Remove the switch from the vehicle. (Refer to 8

- ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL)

(2) With the switch in the released position

(plunger extended), use an ohmmeter to test each of

the three internal switches as shown (Fig. 1). You

should achieve the results as listed in the figure.

8L - 4 LAMPS/LIGHTING - EXTERIORRS

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 418 of 2339

²RETRAIN TIRE SENSORS?- This program-

mable feature only applies to vehicles equipped with

the optional Tire Pressure Monitoring System. The

options include Yes and No. The default is No. When

Yes is selected, and the menu button is depressed the

EVIC will enter the training mode, starting with the

left front tire.

²USE FACTORY SETTINGS?- The options

include Yes and No. The default is Yes. When yes is

selected all the programmable features will return to

there defaults and the rest of the programmable fea-

tures will not be displayed. If No is selected the rest

of the programmable features will be displayed at

there current chosen values. This feature will auto-

matically return to the Yes default under two condi-

tions. First, if no programmable features are changed

from there defaults. Second, if all the programmable

features equal there defaults.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors and the liftgate lock automatically when

vehicle speed reaches 25 kilometers-per-hour (15

miles-per-hour). If YES is selected, a second program-

mable feature appears,AUTO UNLOCK ON EXIT?

- The options again include Yes and No. The default

is No. When Yes is selected, following each Auto Door

Lock event all doors and the liftgate will automati-

cally unlock when the driver door is opened, if the

vehicle is stopped and the transmission gear selector

is in Park or Neutral. The Auto Door Unlock event

will only occur once following each Auto Door Lock

event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory / heated system. The

options include Yes and No. The default is No. When

Yes is selected, the memory system will recall the

Driver 1 or Driver 2 memory settings assigned to the

RKE transmitter being used to unlock the vehicle.

When No is selected, the memory system will only

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audibleconfirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps will

only turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²POWER ACCESSORY DELAY?- The options

include Yes and No. The default is Yes. When No is

selected, the accessory powered components will turn

off automatically when the ignition key is turned off.

When Yes is selected, the accessory powered compo-

nents will remain on for 45 seconds when the igni-

tion key is turned off.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove overhead console. (Refer to 8 - ELEC-

TRICAL/OVERHEAD CONSOLE - REMOVAL).

(3) Remove the ten screws holding the Electronic

Vehicle Information Center (EVIC) module in the

overhead console.

(4) Remove EVIC module from console assembly.

RSOVERHEAD CONSOLE8M-9

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 426 of 2339

travel is accomplished by hall effect sensors, drive

motor speed and pinch sensors (tape switches).

Anytime the liftgate is opened or closed using the

power liftgate system the power liftgate control mod-

ule learns from the cycle. If a replacement power lift-

gate component is installed or a liftgate adjustment

is made, the module will relearn the effort and/or

time required to open or close the liftgate. This learn

cycle can be performed with a DRB IIIt, or equiva-

lent scan tool, or with a complete cycle of the liftgate,

using any one of the command switches. (Refer to 8 -

ELECTRICAL/POWER DOORS - STANDARD PRO-

CEDURE) for detailed instructions.

The power liftgate system is designed with a num-

ber of system inhibitors. These inhibitors are neces-

sary for safety and / or feasibility of the power

liftgate system. The power liftgate system inhibitors

are:

²The Power Liftgate may not operate in extreme

temperatures. These extreme temperatures will be

approximately less than -12É F (-24.4É C) or greater

than 143É F (61.6É C). A chime/thermister assembly

in the rear light bar assembly monitors the outside

temperature.

²The vehicle transmission must be in Park or

Neutral for the power liftgate to start a cycle.

²If multiple obstacles are detected during the

same power open or close cycle, the liftgate goes into

manual operation.

²If severe problems occur, Diagnostic Trouble

Codes (DTC) are stored in the power liftgate control

module.

POWER LIFTGATE SYSTEM CAUTIONS AND

WARNINGS

WARNING: ALWAYS DISCONNECT THE BATTERY

NEGATIVE CABLE BEFORE ATTEMPTING ANY

POWER LIFTGATE SYSTEM SERVICE.

WARNING: THERE IS A SMALL AREA ON BOTH

SIDES OF THE LOWER POWER LIFTGATE WHICH

IS NOT PROTECTED BY PINCH SENSORS.

EXTREME CARE MUST BE TAKEN TO PREVENT

OBJECTS FROM ENTERING THIS AREA ONCE THELIFTGATE REACHES THE SECONDARY LATCH

CONTACT (APPROXIMATELY 1/2 INCH BEFORE

FULLY CLOSED).

WARNING: NEVER ATTEMPT TO ENTER OR EXIT

THE VEHICLE WITH THE LIFTGATE IN MOTION.

YOU COULD DAMAGE THE POWER LIFTGATE SYS-

TEM AND/OR COMPONENTS AND/OR CAUSE PER-

SONAL INJURY.

WARNING: NEVER STICK OBJECTS IN THE POWER

LIFTGATE WHEN CINCHING CLOSED. YOU COULD

DAMAGE THE VEHICLE, POWER LIFTGATE SYS-

TEM COMPONENTS AND/OR CAUSE PERSONAL

INJURY.

DIAGNOSIS AND TESTING

POWER LIFTGATE SYSTEM

The power liftgate system contains many compo-

nents and modules. In order to obtain conclusive

testing the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the power liftgate system must be checked.

The power liftgate system can be diagnosed with

an appropriate scan tool, such as the DRB IIItor

equivalent. The DRB IIItcan be used to observe var-

ious switch statuses throughout the power liftgate

system to help diagnose an inoperative switch or

component. The DRB IIItcan also be used to actuate

various components throughout the power liftgate

system to help diagnose an inoperative component.

Before any testing of the power liftgate system is

attempted, the battery should be fully charged, all

built-in power liftgate system inhibitors read and

understood, and all wire harness and ground connec-

tions inspected around the affected areas on the vehi-

cle.

The following are quick reference diagnostic tables

to help when diagnosing and testing the power lift-

gate system.

RSPOWER LIFTGATE SYSTEM8N-3

POWER LIFTGATE SYSTEM (Continued)

Page 451 of 2339

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

An automatic dimming inside day/night rear view

mirror and an automatic dimming driver side outside

rear view mirror are available factory-installed

options on this model. Following is a general descrip-

tion of this optional equipment.

The automatic day/night mirror is able to automat-

ically change its reflectance. A thin layer of electro-

chromic material between two pieces of conductive

glass make up the face of the mirror. Two photocell

sensors are used to monitor light levels and adjust

the reflectance of the mirror to reduce the glare of

headlamps approaching the vehicle from the rear.

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

OPERATION

The ambient photocell sensor faces forward, to

detect the outside light levels. A second sensor faces

rearward to detect the light level received through

the vehicles back window. When the difference

between the two light levels becomes too great (the

light level received at the rear of the mirror is much

higher than that at the front of the mirror), the mir-

ror begins to darken.

The mirror switch allows the driver a manual con-

trol of whether the automatic dimming feature is

operational. When AUTO is selected a small Light-

Emitting Diode (LED), to the right of the mirror

switch, is illuminated. The automatic dimming fea-

ture will only operate when the ignition switch is in

the On position. The mirror also senses the backup

lamp circuit, and will automatically disable its self-

dimming feature whenever the transmission gear

selector is in the Reverse position.

NOTE: The mirror always defaults to an ON state

upon ignition.

The driver side automatic dimming mirror is stan-

dard with the automatic dimming inside mirror. The

signal to control the dimming of that mirror is gen-

erated by the automatic day/night inside rear view

mirror circuitry. That signal is then delivered to the

driver side outside rear view mirror on a hard wired

circuit.

The automatic day/night mirror cannot be

repaired. If faulty or damaged, the entire inside rear

view mirror assembly must be replaced.

DIAGNOSIS AND TESTING

AUTOMATIC DAY / NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the intelligent power module.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the intelli-

gent power module. If OK, go to Step 3. If not OK,

repair the open circuit to the ignition switch as

required.

(3) Unplug the wire harness connector from the

automatic day/night mirror. Check for battery voltage

at the fused ignition switch output circuit cavity of

the automatic day/night mirror wire harness connec-

tor. If OK, go to Step 4. If not OK, repair the open

circuit to the junction block as required.

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Turn the ignition switch to the On position. Set

the parking brake. Place the transmission gear selec-

tor lever in the Reverse position. Check for battery

voltage at the backup lamp switch output circuit cav-

ity of the automatic day/night mirror wire harness

connector. If voltage is present, reinstall the auto-

matic day/night mirror wire harness connector and

go to Step 6. If not OK, repair the open circuit as

required.

(6) Place the transmission gear selector lever in

the Neutral position. Place the automatic day/night

mirror switch in the On (LED in the switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The automatic day/night mir-

ror should darken. The automatic day/night mirror

should darken within 2 minutes if testing for the

first time. For immediate response, turn the vehicle

8N - 28 POWER MIRRORSRS

Page 455 of 2339

(Refer to 8 - ELECTRICAL/HEATED SEATS -

DESCRIPTION) for more information on the heated

seat option. (Refer to 8 - ELECTRICAL/POWER

SEATS - DESCRIPTION - MEMORY SEAT SYS-

TEM) for more information on the memory seat sys-

tem.

The power seat system includes the following com-

ponents:

²Power seat recliners

²Power seat switches

²Power seat tracks

²Circuit breaker

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Heated Seat Module (HSM)

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

MEMORY SYSTEM

The memory system is able to store and recall the

driver side power seat positions (including the power

recliner position), power adjustable pedal positions

and the driver outside mirror position for two driv-

ers. On vehicles equipped with a factory radio, the

memory system is also able to store and recall radio

station presets for two drivers. The memory system

also will store and recall the last station listened to

for each driver, even if it is not one of the preset sta-

tions.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

Electronic Vehicle Information Center (EVIC) mod-

ule, which is located in the overhead console.

A Memory Seat Mirror Module (MSMM) is used to

control and integrate the many electronic functions

and features included in the memory seat and mirror

systems.

The memory system includes the following compo-

nents:

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Position potentiometers on the driver outside

side view mirror

²Position potentiometers on the power adjustable

pedal motor²Position potentiometers on the driver side power

seat track and power seat recliner motors

²Electronic Vehicle Information Center (EVIC)

²Radio receiver (if PCI data bus capable)

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) data bus network. Initial diagnosis of

these electronic modules or the PCI data bus network

requires the use of a DRBIIItor equivalent scan tool

and the proper Diagnostic Procedures information. If

this method does not prove conclusive, the proper

wiring schematics and the service manual diagnostic

information are required.

The other electronic modules that may affect mem-

ory system operation are:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for additional information.

²Powertrain Control Module (PCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) for additional information.

²Transmission Control Module (TCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

DESCRIPTION) for additional information.

(Refer to 8 - ELECTRICAL/HEATED SEATS -

DESCRIPTION) for additional information on the

heated seat system. (Refer to 8 - ELECTRICAL/

POWER LOCKS - DESCRIPTION) for additional

information on the RKE system.

OPERATION

POWER SEAT SYSTEM

The power seat system receives battery current

through fuse #22 in the Integrated Power Module

(IPM) and a circuit breaker under the front seats,

regardless of the ignition switch position.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction.

No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat adjuster motor each contain a

8N - 32 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

Page 464 of 2339

travel. This allows the power sliding door to stop and

reverse direction any time an obstruction is felt or

any of the command switches are operated (while

closing only). Battery voltage is supplied to the power

sliding door system through a 40 amp fuse, located in

the Integrated Power Module (IPM) assembly. The

child lockout switch prevents children from opening

or actuating the power sliding door system when

desired. In the unlikely event that the power sliding

door system develops a fault, the power sliding door

can still be operated manually from the interior or

exterior door handle, just like a standard manual

sliding door.

The power sliding door control module communi-

cates on the Programmable Communication Interface

(PCI) Data Bus Circuit. Therefore, the power sliding

door control module can generate and store its own

Diagnostic Trouble Codes (DTC). A diagnostic scan

tool, such as the DRB IIItis used to read and diag-

nose these trouble codes.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). Refer to the

appropriate wiring information for complete circuit

schematic or connector pin-out information.WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

THE POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the Programmable Communication Interface (PCI)

Data Bus circuit to the power sliding door module.

The power sliding door module then signals the

power sliding door latch to release the door to the

unlatched and movable position. The motor then

starts an open cycle.

During the door cycle, if the power sliding door

module detects sufficient resistance to door travel,

such as an obstruction in the door's path, the power

sliding door module will immediately stop door move-

ment and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors detecting the door

motor speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a complete cycle of the door, using any one of the

command switches or with the DRB IIIt, or equiva-

lent scan tool. (Refer to 8 - ELECTRICAL/POWER

DOORS - STANDARD PROCEDURE - LEARN

CYCLE) for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. The power sliding door system

inhibitors are:

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The transmission must be inpark or neutral

in order for the power sliding door system to start a

cycle.

²The child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

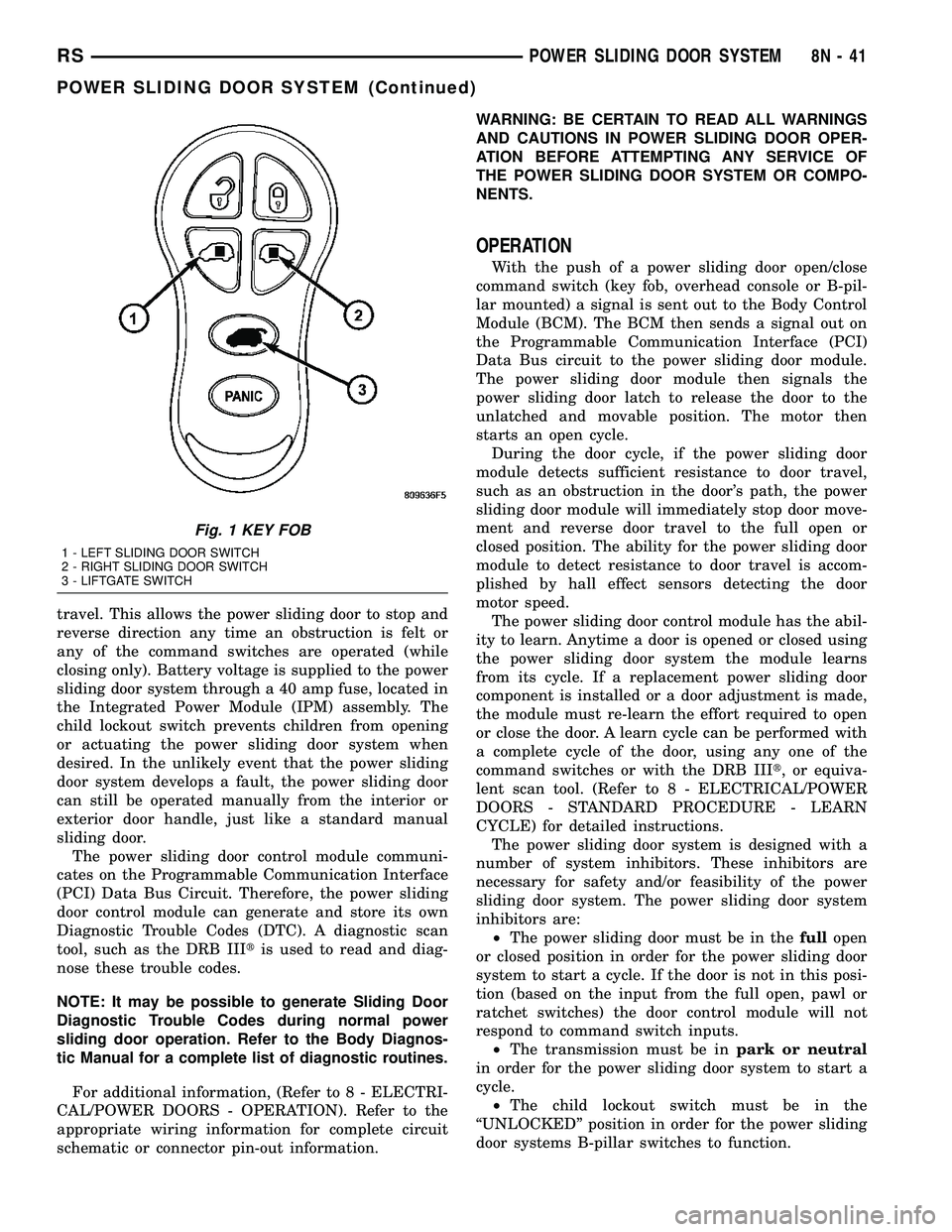

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR SWITCH

2 - RIGHT SLIDING DOOR SWITCH

3 - LIFTGATE SWITCH

RSPOWER SLIDING DOOR SYSTEM8N-41

POWER SLIDING DOOR SYSTEM (Continued)

Page 491 of 2339

²Occupant Classification Module- Vehicles

equipped with the Occupant Classification System

(OCS) include an Occupant Classification Module

(OCM) which is secured to a stamped steel mounting

bracket on the underside of the passenger side front

seat cushion frame.

²Occupant Restraint Controller- The Occu-

pant Restraint Controller (ORC) is also sometimes

referred to as the Airbag Control Module (ACM). The

ORC is located on a mount on the floor transmission

tunnel just underneath the instrument panel center

stack (Fig. 3).

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the instru-

ment panel top pad and above the glove box on the

passenger side of the vehicle (Fig. 3).

²Passenger Airbag Disabled (PAD) Indicator

- Vehicles equipped with the Occupant Classification

System (OCS) include a passenger airbag disabled

(PAD) indicator which is located in the instrument

panel center stack (Fig. 3).

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door (Fig. 3).

²Seat Belt Tensioner- A seat belt tensioner is

integral to both front seat belt buckles. The seat belt

buckles are secured to the inner seat frame sides,

beneath a cushion trim panel.

²Seat Weight Bladder and Pressure Sensor

Assembly- Vehicles equipped with the Occupant

Classification System (OCS) include a seat weight

bladder that is sandwiched between an insulator pad

on the top of the passenger side front seat pan and

the seat cushion foam padding. A short hose connects

the bladder to a pressure sensor which is secured to

the Occupant Classification Module (OCM) mounting

bracket on the underside of the passenger side front

seat cushion frame.

²Side Impact Sensors- Six side impact sensors

are used on vehicles equipped with the curtain air-

bags, three left side and three right side. The first

row side impact sensor is located in the B-pillar, just

above the front seat belt retractor. The second row

side impact sensor is located in the sliding side door

track opening, just in front of the C-pillar. The third

row side impact sensor is located behind the quarter

trim panel, above the rear tire wheel well, between

the C and D-pillars.

The ORC, the OCM, and the cluster each contain a

microprocessor and programming that allow them to

communicate with each other using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used by the

ORC for control of the airbag indicators.OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the seat belts and child restraint

anchors. Seat belts and child restraint anchors are

referred to as an active restraint because the vehicle

occupants are required to physically fasten and prop-

erly adjust these restraints in order to benefit from

them. See the owner's manual in the vehicle glove

box for more information on the features, use and

operation of all of the active restraints.

PASSIVE RESTRAINTS

The passive restraints are referred to as a supple-

mental restraint system because they were designed

and are intended to enhance the protection for the

occupants of the vehicleONLYwhen used in con-

junction with the seat belts. They are referred to as

passive restraints because the vehicle occupants are

not required to do anything to make them operate;

however, the vehicle occupants must be wearing their

seat belts in order to obtain the maximum safety

benefit from the supplemental restraint system.

The supplemental restraint system electrical cir-

cuits are continuously monitored and controlled by a

microprocessor and software contained within the

Occupant Restraint Controller (ORC). An airbag indi-

cator in the ElectroMechanical Instrument Cluster

(EMIC) illuminates for about seven seconds as a bulb

test each time the ignition switch is turned to the

ON or START positions. Following the bulb test, the

airbag indicator is turned ON or OFF by the ORC to

indicate the status of the supplemental restraint sys-

tem. If the airbag indicator comes ON at any time

other than during the bulb test, it indicates that

there is a problem in the supplemental restraint sys-

tem electrical circuits. Such a problem may cause air-

bags not to deploy when required, or to deploy when

not required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ORC signals the inflator of

the appropriate airbag units to deploy their airbag

cushions. The front seat belt tensioners are provided

with a deployment signal by the ORC in conjunction

with the front airbags. During a frontal vehicle

impact, the knee blockers work in concert with prop-

erly fastened and adjusted seat belts to restrain both

the driver and the front seat passenger in the proper

position for an airbag deployment. The knee blockers

also absorb and distribute the crash energy from the

8O - 4 RESTRAINTSRS

RESTRAINTS (Continued)