battery fuse CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1039 of 2339

EVAP/PURGE SOLENOID (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K52 18DB/WT EVAP PURGE CONTROL

2 K70 18DB/BR EVAP PURGE RETURN

EVAPORATOR TEMPERATURE SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 C21 20DB/LG EVAPORATOR TEMPERATURE SENSOR SIGNAL

2 C121 20DB/DG SENSOR GROUND

FLOOR CONSOLE LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 M27 18OR (FRONT POSITION) READING LAMPS DRIVER

1 F307 18OR (REAR POSITION/ACCES-

SORY RELAY POSITION)FUSED ACCESSORY RELAY OUTPUT

1 F307 18OR (REAR POSITION/BATTERY

POSITION)FUSED B(+)

2 Z746 16BK (FRONT POSITION) GROUND

2 Z747 16BK (REAR POSITION) GROUND

FLOOR CONSOLE POWER OUTLET (EXPORT) - RED 3 WAY

CAV CIRCUIT FUNCTION

1 A105 16RD (FRONT POSITION) FUSED B(+)

1 F307 16RD (REAR POSITION/ACCES-

SORY RELAY POSITION)FUSED ACCESSORY RELAY OUTPUT

1 F307 16RD (REAR POSITION/BATTERY

POSITION)FUSED B(+)

2- -

3 Z746 16BK (FRONT POSITION) GROUND

3 Z747 16BK (REAR POSITION) GROUND

8W - 80 - 70 8W-80 CONNECTOR PIN-OUTSRS

Page 1053 of 2339

INTEGRATED POWER MODULE C5 - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 A1 4RD B(+)

2- -

3- -

4- -

INTEGRATED POWER MODULE C6 - NATURAL 10 WAY

CAV CIRCUIT FUNCTION

1 A101 12VT/RD FUSED B(+)

2 Z117 16BK/WT GROUND

3 Z118 16BK/WT (LWB/EXPORT) GROUND

3 Z118 16BK/YL (SWB/EXCEPT EXPORT) GROUND

4 A110 12OR/RD (POWER SEAT) FUSED B(+)

5- -

6- -

7 C7 12DB FUSED FRONT BLOWER MOTOR RELAY OUTPUT

8 F307 18LB/PK (ACCESSORY RELAY

POSITION)FUSED ACCESSORY RELAY OUTPUT

8 F307 18LB/PK (BATTERY POSITION) FUSED B(+)

9 A113 12WT/RD (POWER SLIDING

DOOR)FUSED B(+)

10 - -

INTEGRATED POWER MODULE C7 - 20 WAY

CAV CIRCUIT FUNCTION

1 C16 20DB/GY FUSED DEFOGGER RELAY OUTPUT

2 T141 20YL/OR (DIESEL) FUSED IGNITION SWITCH OUTPUT (START)

2 T751 20YL (GAS) FUSED IGNITION SWITCH OUTPUT (START)

3 D25 20WT/VT PCI BUS

4 L13 20WT/YL (EXPORT) HEADLAMP ADJUST SIGNAL

5 K32 18DB/YL BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID

CONTROL

6- -

7 W7 20BR/GY WIPER PARK SWITCH SENSE

8 B20 20DG/OR BRAKE FLUID LEVEL SWITCH SENSE

9 F201 20PK/OR ORC RUN-START DRIVER

10 - -

11 A106 20LB/RD FUSED B(+)

12 P201 20LG/DB (EXCEPT EXPORT/EX-

CEPT MEMORY)ADJUSTABLE PEDALS RELAY CONTROL

13 F2 18PK/YL FCM OUTPUT (UNLOCK-RUN-START)

14 - -

15 A114 16GY/RD FUSED B(+) (I.O.D.)

16 D123 20WT/BR FLASH PROGRAM ENABLE

17 L50 18WT/TN (DIESEL) PRIMARY BRAKE SWITCH SIGNAL

17 L50 18WT/TN (GAS) BRAKE LAMP SWITCH OUTPUT

18 - -

19 X3 20DG/VT HORN SWITCH SENSE

20 F100 18PK/VT ORC RUN ONLY DRIVER

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTSRS

Page 1087 of 2339

POWERTRAIN CONTROL MODULE C3 - NATURAL 38 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3 K51 18BR/WT ASD RELAY CONTROL

4- -

5 V35 18VT/OR S/C VENT CONTROL

6 K173 18BR/VT RAD FAN RELAY CONTROL

7 V32 18VT/YL SPEED CONTROL SUPPLY

8 K106 20VT/LB (EXCEPT EXPORT) NVLD SOL CONTROL

9 K299 18BR/WT O2 1/2 HEATER CONTROL

10 - -

11 C13 18LB/OR A/C CLUTCH RELAY CONTROL

12 V36 18VT/YL S/C VACUUM CONTROL

13 - -

14 - -

15 - -

16 - -

17 - -

18 - -

19 K342 16BR/WT ASD RELAY OUTPUT

20 K52 18DB/WT EVAP PURGE CONTROL

21 T141 18YL (MTX EXPORT) FUSED IGNITION SWITCH OUTPUT (START)

22 - -

23 B29 18DG/WT BRAKE SWITCH SIGNAL

24 - -

25 - -

26 - -

27 - -

28 K342 16BR/WT ASD RELAY OUTPUT

29 K70 18DB/BR EVAP PURGE SIGNAL

30 - -

31 C18 18LB/BR A/C PRESSURE SIGNAL

32 K91 18DB/YL BATTERY TEMP SIGNAL

33 - -

34 V37 18VT S/C SWITCH NO. 1 SIGNAL

35 K107 20VT/WT (EXCEPT EXPORT) NVLD SWITCH SIGNAL

36 - -

37 K31 18BR FUEL PUMP RELAY CONTROL

38 T752 18DG/OR STARTER RELAY CONTROL

8W - 80 - 118 8W-80 CONNECTOR PIN-OUTSRS

Page 1095 of 2339

REAR DOME LAMP (EXCEPT LUXURY) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 M22 20YL/OR COURTESY LAMPS DRIVER

2 Z327 20BK/OR GROUND

3- -

REAR INTRUSION SENSOR (UNITED KINGDOM)-3WAY

CAV CIRCUIT FUNCTION

1 A645 20RD/VT REAR INTRUSION SENSOR SIGNAL

2- -

3 G945 20VT/DG SENSOR GROUND

REAR MODE MOTOR (3 ZONE ATC) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 C154 18LB/GY REAR MODE DOOR DRIVER (B)

2 C53 18LB REAR MODE DOOR DRIVER (A)

REAR POWER OUTLET - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 F307 18LB/PK (ACCESSORY RELAY

POSITION)FUSED ACCESSORY RELAY OUTPUT

1 F307 18LB/PK (BATTERY POSITION) FUSED B(+)

2- -

3 Z737 18BK/LB GROUND

8W - 80 - 126 8W-80 CONNECTOR PIN-OUTSRS

Page 1174 of 2339

8W-97 POWER DISTRIBUTION SYSTEM

TABLE OF CONTENTS

page page

POWER DISTRIBUTION SYSTEM

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........1

INTEGRATED POWER MODULE

DESCRIPTION..........................1

OPERATION............................2

REMOVAL.............................2

INSTALLATION..........................2IOD FUSE

DESCRIPTION..........................3

OPERATION............................3

POWER OUTLET

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET . . 3

REMOVAL.............................4

INSTALLATION..........................4

POWER DISTRIBUTION

SYSTEM

DESCRIPTION

The power distribution system for this vehicle con-

sists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Outlets

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses

²Circuit splice blocks

²Flashers

²Fusible links

²Relays

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide theelectrical current needed to operate many accessories

that the vehicle owner may choose to have installed.

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

INTEGRATED POWER MODULE

DESCRIPTION

The Integrated Power Module (IPM) is a combina-

tion of the Power Distribution Center (PDC) and the

Front Control Module (FCM). The IPM is located in

the engine compartment, next to the battery. (Fig. 1).

The PDC mates directly with the FCM to form the

IPM. The PDC is a printed circuit board based mod-

ule that contains fuses and relays, while the FCM

contains the electronics controlling the IPM and

other functions. This IPM connects directly to the

battery positive through a four pin connector. The

ground connection is through two other connectors.

Terminal Pick Kit 6680

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-1

Page 1176 of 2339

(5) Connect the negative and positive battery

cables.

(6) Using a scan tool, check for any stored diagnos-

tic trouble codes. Ensure that all vehicle options are

operational.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IOD fuse is a 20 ampere blade-type mini fuse

and, when removed, it is stored in a fuse cavity adja-

cent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position.

The IOD fuse feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicle

as well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock. The only reason the

IOD fuse is removed is to reduce the normal IOD of

the vehicle electrical system during new vehicle

transportation and pre-delivery storage to reduce

battery depletion, while still allowing vehicle opera-

tion so that the vehicle can be loaded, unloaded and

moved as needed by both vehicle transportation com-

pany and dealer personnel.

The IOD fuse is removed from the Integrated

Power Module (IPM) fuse cavity when the vehicle is

shipped from the assembly plant. Dealer personnel

must install the IOD fuse when the vehicle is being

prepared for delivery in order to restore full electrical

system operation. Once the vehicle is prepared for

delivery, the IOD function of this fuse becomes trans-

parent and the fuse that has been assigned the IOD

designation becomes only another Fused B(+) circuit

fuse. The IOD fuse serves no useful purpose to the

dealer technician in the service or diagnosis of any

vehicle system or condition, other than the same pur-

pose as that of any other standard circuit protection

device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed approximately thirty days. However, it mustbe remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than thirty days,

the battery negative cable should be disconnected to

eliminate normal IOD; and, the battery should be

tested and recharged at regular intervals during the

vehicle storage period to prevent the battery from

becoming discharged or damaged.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the instrument

panel center lower bezel. Two additional power out-

lets are incorporated into the left rear C-pillar and

the center console (if equipped). The power outlets

bases are secured by a snap fit. A hinged plug flips

closed to conceal and protect the power outlet base

when not in use.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the ON position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1177 of 2339

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Note position of the retaining bosses (Fig. 4).

(3) Using external snap ring pliers with 90 degree

tips. Insert pliers with tips against bosses and

squeeze forcing bosses out of base.

(4) Pull out the base through mounting ring by

gently rocking pliers.

(5) Disconnect the base wires.

(6) Remove light ring and disconnect wire.

INSTALLATION

(1) Position the mounting ring on the instrument

panel and feed the wires through the ring. Index thecap and the mounting ring with the index tab at the

9 o'clock position to the key in the instrument panel.

Install the ring.

(2) Connect the wires to the base. Orientate the

base alignment rib at the 11 o'clock position to mate

the groove in the mounting ring to the base.

(3) Push the base into the bezel until it locks in

place.

(4) Check operation of outlet or element and

install the outlet cap.

Fig. 4 POWER OUTLET

1 - RETAINING BOSSES-ENGAGE PLIERS HERE

2 - PARTIALLY REMOVED

3 - EXTERNAL SNAP-RING PLIERS

4 - PULL BASE OUT-THROUGH MOUNTING RING

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER OUTLET (Continued)

Page 1397 of 2339

(5) Rotate injector and pull injector out of fuel rail.

The clip will stay on the injector.

(6) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. Replace the injector clip if it is dam-

aged.

(7) Repeat for remaining injectors.

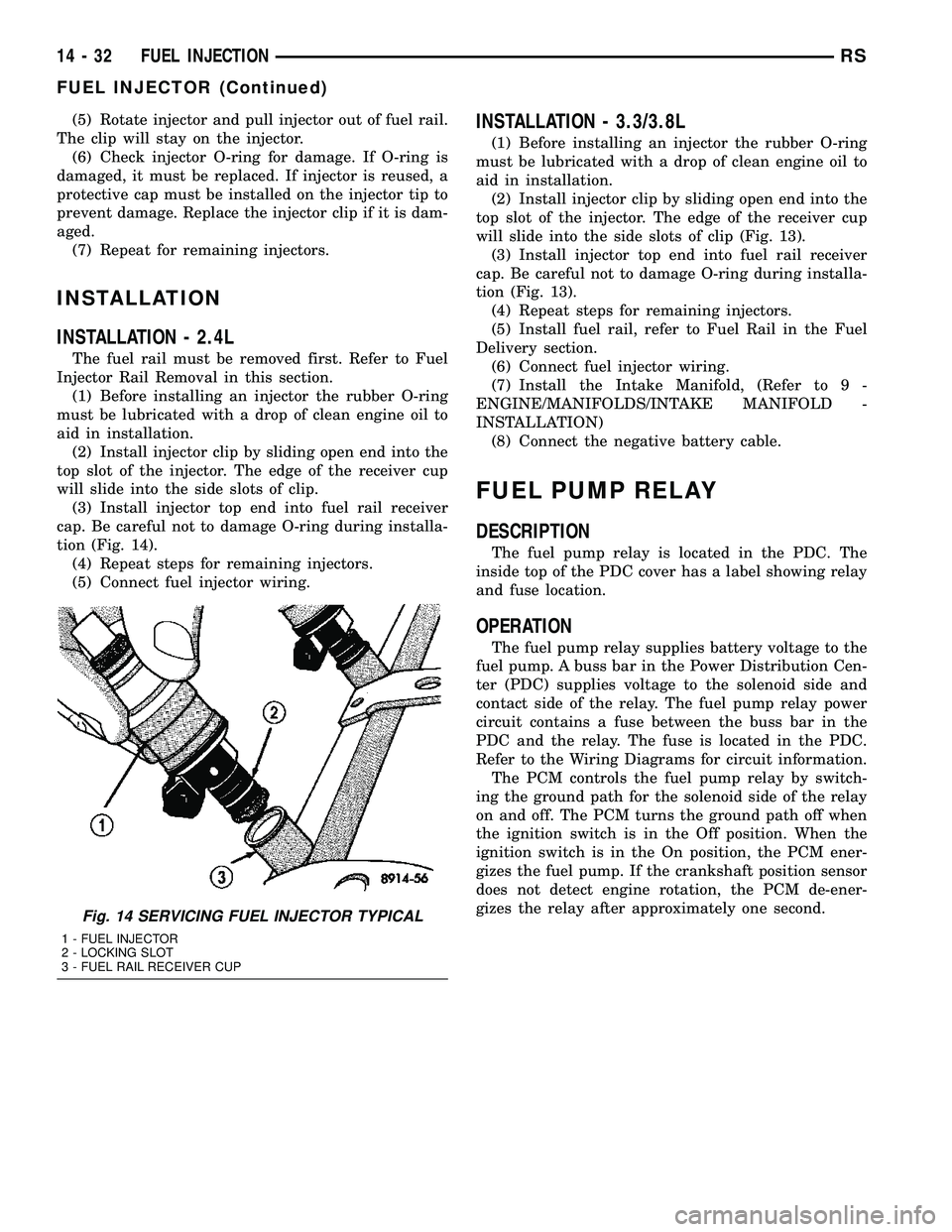

INSTALLATION

INSTALLATION - 2.4L

The fuel rail must be removed first. Refer to Fuel

Injector Rail Removal in this section.

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation.

(2) Install injector clip by sliding open end into the

top slot of the injector. The edge of the receiver cup

will slide into the side slots of clip.

(3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during installa-

tion (Fig. 14).

(4) Repeat steps for remaining injectors.

(5) Connect fuel injector wiring.

INSTALLATION - 3.3/3.8L

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation.

(2) Install injector clip by sliding open end into the

top slot of the injector. The edge of the receiver cup

will slide into the side slots of clip (Fig. 13).

(3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during installa-

tion (Fig. 13).

(4) Repeat steps for remaining injectors.

(5) Install fuel rail, refer to Fuel Rail in the Fuel

Delivery section.

(6) Connect fuel injector wiring.

(7) Install the Intake Manifold, (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

(8) Connect the negative battery cable.

FUEL PUMP RELAY

DESCRIPTION

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

OPERATION

The fuel pump relay supplies battery voltage to the

fuel pump. A buss bar in the Power Distribution Cen-

ter (PDC) supplies voltage to the solenoid side and

contact side of the relay. The fuel pump relay power

circuit contains a fuse between the buss bar in the

PDC and the relay. The fuse is located in the PDC.

Refer to the Wiring Diagrams for circuit information.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

Fig. 14 SERVICING FUEL INJECTOR TYPICAL

1 - FUEL INJECTOR

2 - LOCKING SLOT

3 - FUEL RAIL RECEIVER CUP

14 - 32 FUEL INJECTIONRS

FUEL INJECTOR (Continued)

Page 1591 of 2339

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The transmission control relay (Fig. 306) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized by

the PCM/TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal operating

mode. When the relay is ªoffº, no power is supplied to

the solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset (ignition key turned to the

ªrunº position or after cranking engine), the PCM/TCM

energizes the relay. Prior to this, the PCM/TCM verifies

that the contacts are open by checking for no voltage at

the switched battery terminals. After this is verified,

the voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the PCM/TCM

monitors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle andcan only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 307).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 308).

Fig. 306 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 307 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 308 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 130 40TE AUTOMATIC TRANSAXLERS

Page 1742 of 2339

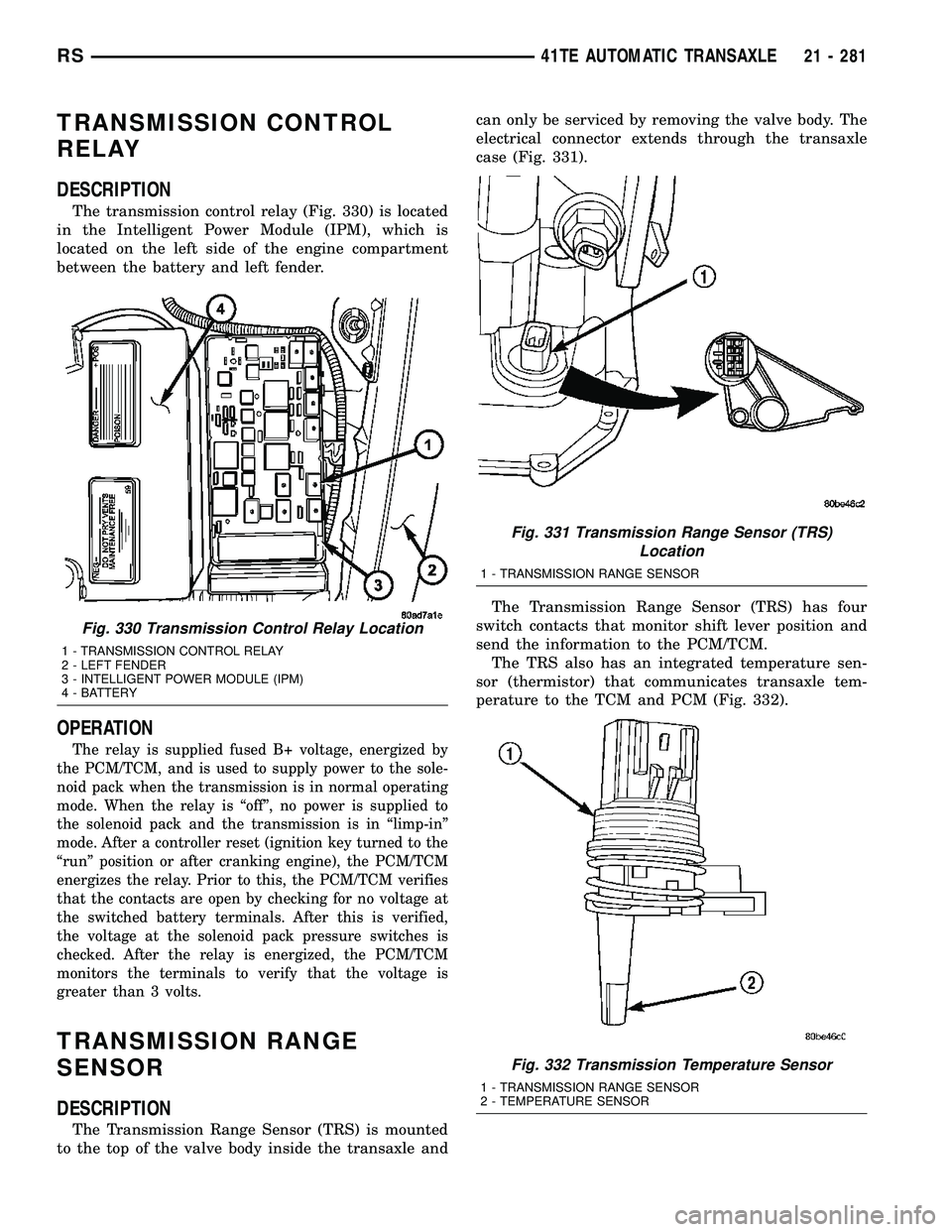

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The transmission control relay (Fig. 330) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized by

the PCM/TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal operating

mode. When the relay is ªoffº, no power is supplied to

the solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset (ignition key turned to the

ªrunº position or after cranking engine), the PCM/TCM

energizes the relay. Prior to this, the PCM/TCM verifies

that the contacts are open by checking for no voltage at

the switched battery terminals. After this is verified,

the voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the PCM/TCM

monitors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle andcan only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 331).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 332).

Fig. 330 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 331 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 332 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

RS41TE AUTOMATIC TRANSAXLE21 - 281