Rear control CHRYSLER VOYAGER 2005 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 519 of 2339

(38) Remove the two passenger airbag to instru-

ment panel cover/pad retaining screws.

(39) Remove the three passenger airbag to instru-

ment panel reinforcement retaining bolts.

(40) Pull rearward slightly on the instrument

panel cover/pad to maneuver passenger airbag out

from reinforcement and instrument panel.

INSTALLATION

DEPLOYED AIRBAG

Transfer all reusable components to the new

instrument panel.

(1) Install new Passenger Airbag into instrument

panel.

(2) Install airbag attaching bolts to the instrument

panel.

(a) Torque the two bolts at instrument panel

retainer bosses to 2.7 .5 N´m (24 5 in. lbs.).

(b) Torque the three bolts that attach the pas-

senger airbag to cross-car beam to 10 2 N´m (90

15 in. lbs.).

(3) Connect yellow wire connector to passenger air-

bag and affix connector to instrument panel rein-

forcement with push pins.

(4) Install Instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

UNDEPLOYED AIRBAG

(1) Pull rearward slightly on the instrument panel

cover/pad to maneuver passenger airbag up onto

reinforcement and instrument panel.

(2) Install the three passenger airbag to instru-

ment panel reinforcement retaining bolts but leave

loose. This will help align the passenger airbag for

the cover/pad fit.

(3) Install the two passenger airbag to instrument

panel cover/pad retaining screws. Torque screws to

2.7 .5 N´m (24 5 in. lbs.).

NOTE: Insure that the instrument panel cover/pad

locator pins are indexed properly at center stack

area prior to reassembly.

(4) Tighten the three passenger airbag to instru-

ment panel reinforcement retaining bolts. Torque

bolts to 10 2 N´m (90 15 in. lbs.).(5) Connect the passenger airbag electrical connec-

tor. Install the connector onto the instrument panel

reinforcement with the push-pin fasteners.

(6) Roll the instrument panel forward lifting

slightly so as to seat the instrument panel air distri-

bution duct on top of the HVAC unit properly to

avoid any leaks or damage to the seal.

(7) Install six upper fence line instrument panel

retaining bolts.

(8) Install three right side instrument panel A-pil-

lar retaining bolts and tighten the right instrument

panel roll down bolt. Install the smaller 10 mm bolt

first to align the instrument panel properly.

(9) Install three left side instrument panel A-pillar

retaining bolts and tighten the left instrument panel

roll down bolt. Install the smaller 10 mm bolt first to

align the instrument panel properly.

(10) Install seven lower instrument panel cover/

pad retaining screws.

(11) Install four screws along top front edge of

instrument panel cover/pad.

(12) Install one far left instrument panel speaker

retaining screw.

(13) Install wiring connectors to radio. Install

radio and four retaining screws.

(14) Connect glove box lamp wiring connector and

place right lower instrument panel trim (glove box

surround) into position.

(15) Install nineteen right lower instrument panel

trim (glove box surround) and install panel screws.

(16) Slide cup holder assembly into instrument

panel.

(17) Install center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats).

(18) Install instrument panel center bezel by align-

ing slots and firmly snapping into place.

(19) Install two screws to instrument panel center

bezel.

(20) Align filler bezel above cup holder over retain-

ing slots and firmly snap into place.

(21) Place instrument panel top cover into position

and firmly snap down rear edge of top cover.

(22) Install glove box. Align hinges, snap into

place, roll glove box upwards and push in sides to

fully install.

(23) Align right side upper A-pillar trim over

retaining slots and firmly snap into place.

(24) Align right A-pillar lower extension trim over

retaining slots and firmly snap into place.

(25) Align right instrument panel end cap over

retaining slots and firmly snap into place.

(26) Align right cowl panel over retaining slots and

firmly snap into place.

(27) Align right front door sill plate over retaining

slots and firmly snap into place.

8O - 32 RESTRAINTSRS

PASSENGER AIRBAG (Continued)

Page 546 of 2339

WIPERS/WASHERS

TABLE OF CONTENTS

page page

WIPERS/WASHERS

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT WIPER

SYSTEM.............................2

DIAGNOSIS AND TESTING - FRONT

WIPER/WASHER SWITCH................2

DIAGNOSIS AND TESTING - FAILED PARK

SWITCH.............................2

DIAGNOSIS AND TESTING - REAR WIPER

SYSTEM.............................4

DIAGNOSIS AND TESTING - WASHER

SYSTEM.............................5

FRONT WIPER ARMS

STANDARD PROCEDURE - FRONT WIPER

ARM ALIGNMENT......................9

REMOVAL.............................9

INSTALLATION..........................9

FRONT WIPER MOTOR

REMOVAL.............................9

INSTALLATION.........................10

REAR WIPER ARM

REMOVAL.............................10

INSTALLATION.........................10

REAR WIPER MOTOR

REMOVAL.............................10INSTALLATION.........................10

REAR WIPER/WASHER SWITCH

DESCRIPTION.........................10

OPERATION...........................11

WASHER FLUID LEVEL SWITCH

REMOVAL.............................11

INSTALLATION.........................11

WASHER HOSES

REMOVAL.............................11

INSTALLATION.........................12

WASHER PUMP MOTOR

REMOVAL.............................12

INSTALLATION.........................12

WASHER RESERVOIR

REMOVAL.............................12

INSTALLATION.........................13

WIPER BLADES

REMOVAL.............................13

CLEANING............................13

INSTALLATION.........................13

WIPER LINKAGE

REMOVAL.............................13

INSTALLATION.........................14

WIPER MODULE

REMOVAL.............................14

INSTALLATION.........................14

WIPERS/WASHERS

DESCRIPTION

FRONT WIPER/WASHER SYSTEM

The windshield wipers can be operated with the

windshield wiper switch when the ignition switch is

in the RUN or ACCESSORY positions. The wind-

shield wiper system is protected by a 30 amp fuse (9)

located in the Power Distribution Center (PDC) part

of the Integrated Power Module (IPM) in the engine

compartment. The wiper/washer switch is integral to

the multi-function switch. It is a resistive MUX

switch that sends inputs to the BCM to operate the

wiper/washer system.

REAR WIPER/WASHER SYSTEM

The rear windshield wiper and washers can be

operated when the ignition switch is in the RUN

position.

If equipped with Manual Temperature Controls

(MTC), the rear wiper/washer switch is integral to

the HVAC control unit. It replaces what was formerly

the ON/OFF switch. If equipped with Automatic Tem-

perature Controls (ATC), the rear wiper/washer

switch is located on the accessory switch panel in the

center stack of the instrument panel.

RSWIPERS/WASHERS8R-1

Page 547 of 2339

OPERATION

FRONT WIPER/WASHER SYSTEM

The windshield washer circuit is protected by a 15

amp Cartridge Fuse located in the IPM. The wiper

motor has permanent magnetic fields. The speeds are

determined by current flow to the appropriate set of

brushes inside the motor. The current flow is con-

trolled by the multi-function switch. The high speed/

low speed relays are located in the IPM. The speed

sensitive intermittent wiper is controlled by the Body

Control Module (BCM). The intermittent mode, with

the vehicle traveling greater than 10.4 mph, has a

range of 0.5 to 18 seconds. With the vehicle traveling

less than 10.4 mph, the time delay doubles to a

range of 1 to 36 seconds. The wiper arms will park at

the base of the windshield just above the cowl cover

after the wiper switch is turned OFF.

The windshield wiper motor and linkage is located

in an integral wiper unit at the rear of the engine

compartment. The wiper unit must be removed to

gain access to the wiper motor.

The front and rear washer systems share the same

washer pump motor.

REAR WIPER/WASHER SYSTEM

When rear wiper operation is required, the BCM

will provide ignition ON voltage to the rear wiper

motor (Export and ATC equipped vehicles only).

When the wiper switch is turned OFF, the BCM pro-

vides circuit ground to operate the motor until the

wipe cycle is complete and the wiper arm returns to

the base of the rear window.

Switch only offers an intermittent rear wiper

mode. The wiper motor will cycle every 7 seconds.

The intermittent delay time is also adjusted based

upon vehicle speed. With the vehicle traveling

greater than 50 mph, the cycle changes to every 5

seconds.

When rear washer is requested by depressing and

holding down the switch, the BCM then provides a

ground for the washer motor. Until the switch is

released, the motor will be in a continuous wipe

mode, then return to an intermittent wipe mode.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT WIPER

SYSTEM

The windshield wiper system operates in several

modes:

²Low and high speed normal wipe

²Speed sensitive intermittent wipe

²Wipe after wash

²Park (switch OFF)The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. DTC's can

be retrieved using a DRB IIItscan tool. Refer to the

proper Body Diagnostic Procedures manual for DTC

descriptions and retrieval information.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the Wiper System Diagnosis

table.

DIAGNOSIS AND TESTING - FRONT

WIPER/WASHER SWITCH

(1) Remove the multi-function switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - REMOVAL).

(2) Using an ohmmeter check resistance readings

between switch pins. Refer to the WIPER/WASHER

SWITCH RESISTANCE table.

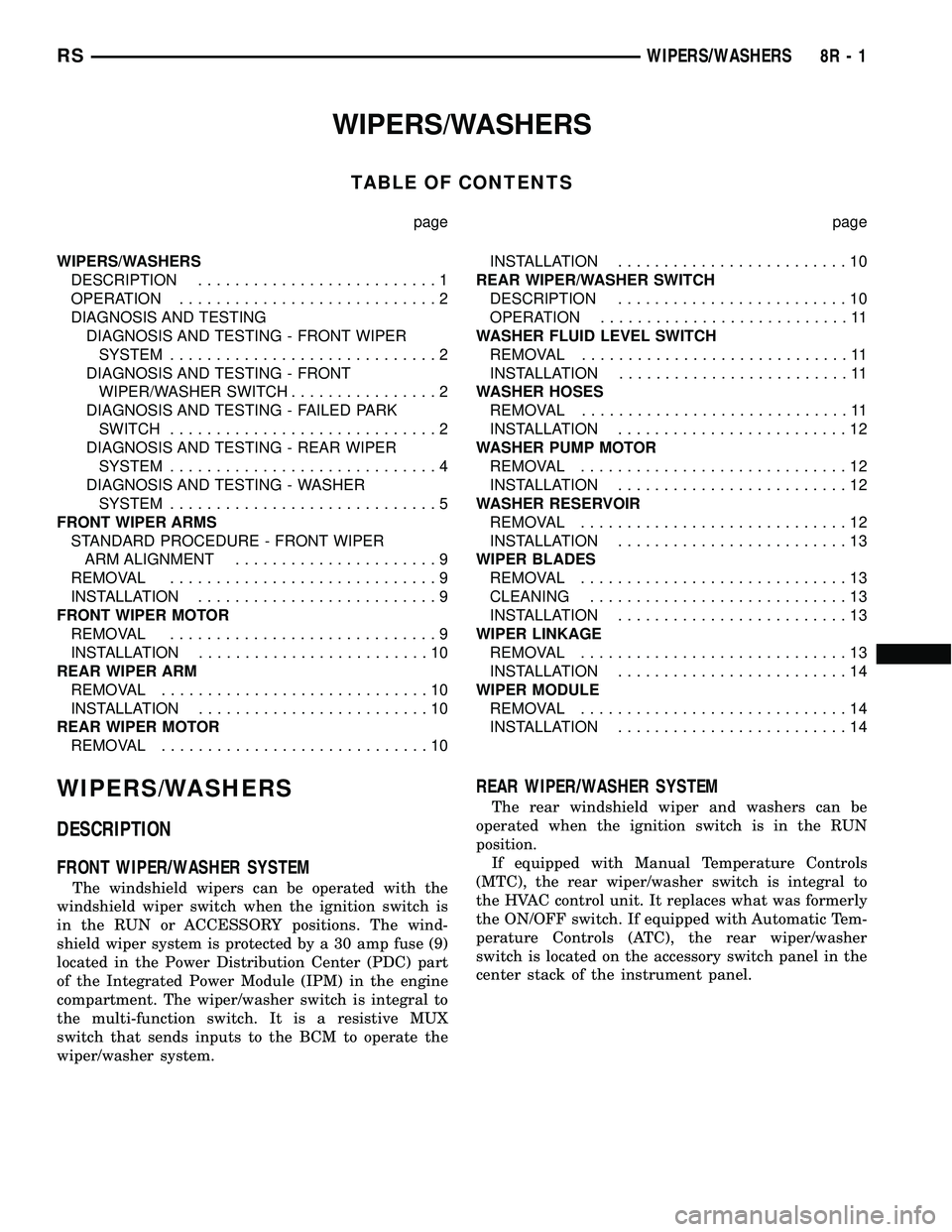

WIPER/WASHER SWITCH RESISTANCE

SWITCH POSITION RESISTANCE BETWEEN

OFF 1 AND 2 = 23.9KV 5%

DELAY POSITION

1ST 1 AND 2 = 7.9KV 5%

2ND 1 AND 2 = 4.6KV 5%

3RD 1 AND 2 = 2.9KV 5%

4TH 1 AND 2 = 1.9KV 5%

5TH 1 AND 2 = 1.3KV 5%

LOW 1 AND 2 = 670V 5%

HIGH 1 AND2=240V 5%

WASH 1 AND 4 = 5.9KV 5%

DIAGNOSIS AND TESTING - FAILED PARK

SWITCH

If the wiper park switch has failed, the windshield

wipers will operate as follows:

²SWITCH OFF- Wipers stop in current location

regardless of the park signal.

²INTERMITTENT MODE- Wipers operate con-

tinuously or at low speed for one or more extra

wipes.

²LOW SPEED- Wipers operate at low speed.

²HIGH SPEED- Wipers operate at high speed.

8R - 2 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

Page 549 of 2339

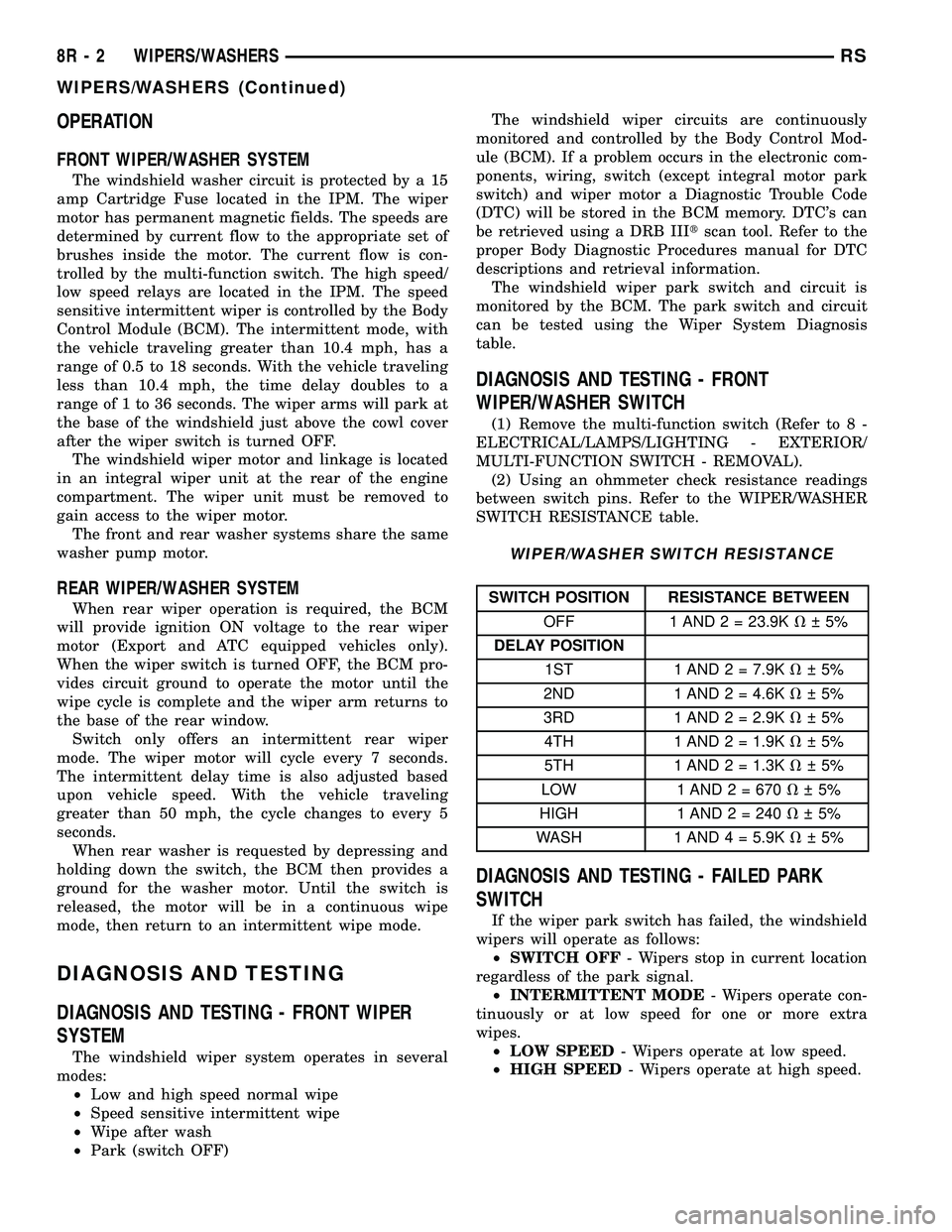

CONDITION POSSIBLE CAUSES CORRECTION

WIPER KNOCK AT

REVERSAL1. LINKAGE BUSHINGS WORN. 1. REPLACE WORN LINK. REFER TO

WIPER LINKAGE REMOVAL AND

INSTALLATION.

2. ARMATURE ENDPLAY IN

MOTOR.2. REPLACE WIPER MOTOR. REFER TO

WIPER MOTOR REMOVAL AND

INSTALLATION.

WIPER MOTOR WILL NOT

RUN1. BLOWN FUSE. 1. REPLACE FUSE, AND RUN SYSTEM.

2. NEW FUSE BLOWS. 2. CHECK FOR SHORT IN WIRING OR

SWITCH.

3. NEW FUSE BLOWS. 3. REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON, FUSE

DOES NOT BLOW, REPLACE MOTOR.

4. NO VOLTAGE AT MOTOR. 4. CHECK SWITCH AND WIRING

HARNESS. REFER TO WIRING

DIAGRAMS.

5. POOR GROUND. 5. REPAIR GROUND WIRE CONNECTION

AS NECESSARY.

DIAGNOSIS AND TESTING - REAR WIPER

SYSTEM

The rear window wiper system operates in several

modes:

²Continuous wipe (Export and ATC equipped

vehicles only)

²Intermittent wipe

²Wash²Wipe after wash

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. The

DTC(s) can be retrieved using a DRB IIItscan tool.

8R - 4 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

Page 552 of 2339

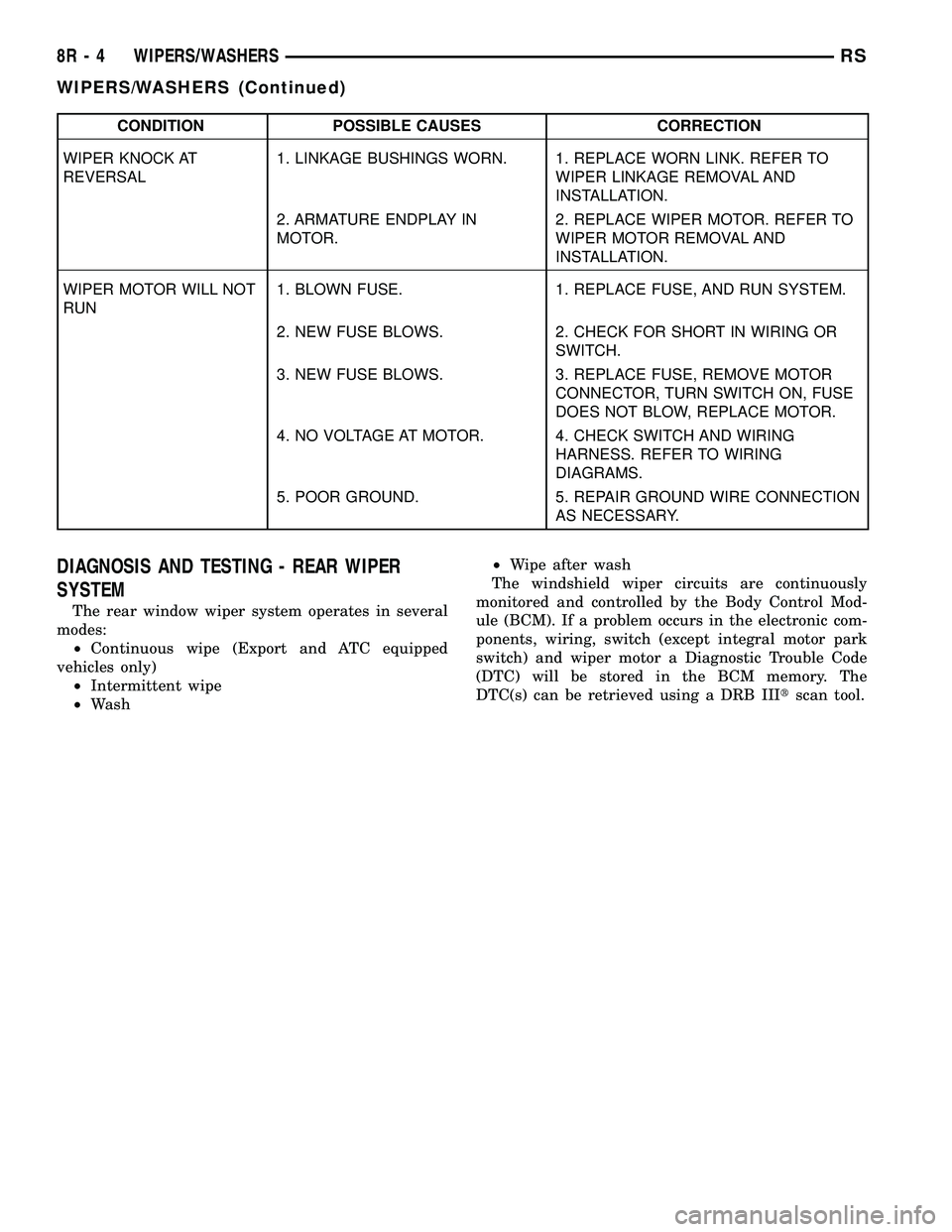

CONDITION POSSIBLE CAUSES CORRECTION

12. NO BUS MESSAGE FROM

MTC CONTROL (MANUAL

TEMP. CONTROL ONLY).12. CHECK FOR CORRECT PCI BUS

MESSAGE WITH DRBIIIT.

COWL GRILLE NOZZLE

WILL NOT FLOW.1. FROZEN NOZZLE. 1. MOVE VEHICLE INTO HEATED AREA TO

ALLOW TIME TO THAW NOZZLE. ASSURE

WASHER FLUID IS PROPERLY BLENDED

FOR AMBIENT OUTSIDE TEMPERATURES.

2. NOZZLE HOSE NOT

FLOWING.2. ASSURE NOZZLE HOSE IS NOT

PINCHED, LOOSE, BROKEN, OR

DISCONNECTED. IF NOT OK, PROPERLY

ROUTE OR REPAIR NOZZLE HOSE.

3. NOZZLE HOSE PLUGGED

BY CONTAMINATION.3. CLEAN NOZZLE HOSE OF

CONTAMINATION. DETERMINE SOURCE

OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

4. NOZZLE PLUGGED BY

CONTAMINATION.4. CLEAN NOZZLE OF CONTAMINATION

OR REPLACE NOZZLE. DETERMINE

SOURCE OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

5. DEFECTIVE WASHER HOSE

CHECK VALVE.5. REPLACE COWL GRILLE PANEL

WASHER HOSE/CHECK VALVE ASSEMBLY.

WASHER FLUID OUTPUT IS

LOW.1. PARTIALLY PINCHED HOSE. 1. ASSURE WASHER HOSE IS NOT

PARTIALLY PINCHED. IF NOT OK,

PROPERLY ROUTE HOSE.

2. FRONT REAR VALVE

DEFECTIVE.2. REPLACE WASHER PUMP.

3. WORN OUT WASHER PUMP. 3. REPLACE WASHER PUMP.

COWL GRILLE NOZZLE

STREAM OVERSHOOTS

WINDSHIELD.1. NOZZLE NOT SEATED IN

COWL GRILLE.1. ASSURE NOZZLE IS SNAPPED IN

PLACE.

WIPER WILL NOT CYCLE

WHEN WASHER SELECT

SWITCH IS DEPRESSED.1. DEFECTIVE IPM. 1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. DEFECTIVE IPM/BODY

CONTROLLER.2. REFER TO IPM/BODY CONTROLLER

DIAGNOSTIC PROCEDURES IN WIRING

DIAGRAMS.

3. REAR WIPER OUTPUT

SHORT FAULT.3. A GROUND SHORT DETECTED

BETWEEN BCM AND REAR WIPER

MOTOR. CLEAR FAULT. IF IT WON'T

CLEAR, REPAIR SHORT

4. REAR WIPER OUTPUT

OPEN FAULT.4. AN OPEN CIRCUIT DETECTED

BETWEEN BCM AND REAR WIPER

MOTOR. CLEAR FAULT. IF IT WON'T

CLEAR, REPAIR OPEN CIRCUIT.

RSWIPERS/WASHERS8R-7

WIPERS/WASHERS (Continued)

Page 555 of 2339

(5) Remove wiper linkage from motor crank. DO

NOT remove crank from motor.

(6) Remove bolts holding wiper motor and remove

motor.

INSTALLATION

(1) Place wiper module on a suitable work surface.

(2) Install wiper linkage into wiper unit.

(3) Connect wire connectors to wiper motor.

(4) Place the wiper module into engine compart-

ment and connect wiper module wire connector to

engine wire harness (Fig. 7).

(5) Install the four backwall bolts and four brace

nuts to wiper module.

(6) Operate wiper motor and verify that the wiper

motor parks when wiper switch is turned OFF.

REAR WIPER ARM

REMOVAL

(1) Remove arm nut cap.

(2) Remove wiper arm nut.

(3) Pull wiper from pivot by rocking back and

forth.

INSTALLATION

(1) Verify that wipers are in parked position.

(2) Position arm on pivot.

(3) Install wiper arm nut and torque to 20 N´m

(175 in. lbs.).

REAR WIPER MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear wiper arm. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/REAR WIPER ARM -

REMOVAL) in this section.

(3) Open liftgate.

(4) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(5) Disconnect wire connector from rear wiper

motor.

(6) Remove screws holding rear wiper motor to lift-

gate.

(7) Remove wiper motor from liftgate.

INSTALLATION

(1) Position the wiper motor in the liftgate.

(2) Install the retaining screws.

(3) Connect the wire harness connector.(4) Install the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

(5) Connect wire connector to rear wiper motor.

(6) Install the screws holding rear wiper motor to

liftgate.

(7) Install the wiper motor to the liftgate.

(8) Close the liftgate.

(9) Install the wiper arm. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/REAR WIPER ARM -

INSTALLATION) in this section.

(10) Connect the battery negative cable.

REAR WIPER/WASHER

SWITCH

DESCRIPTION

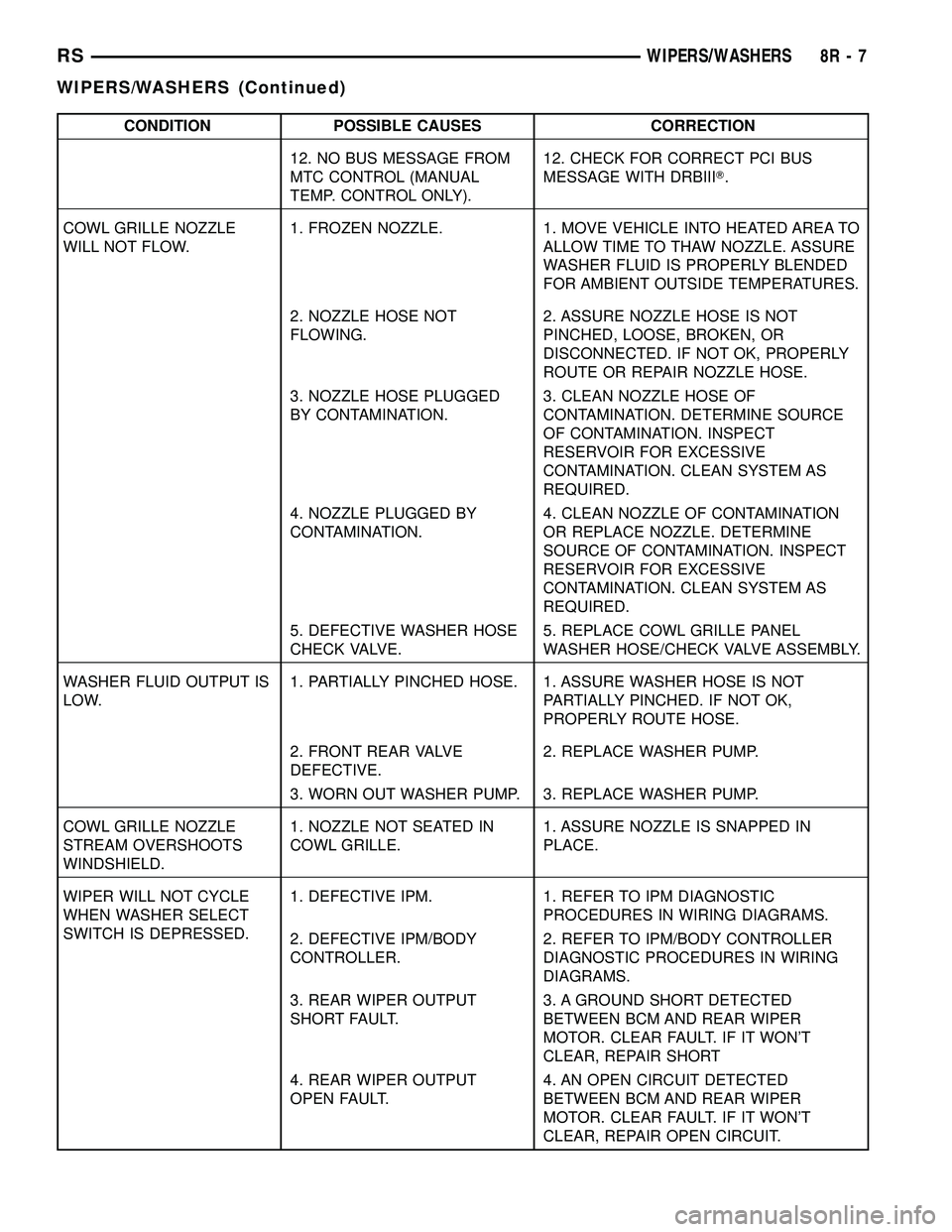

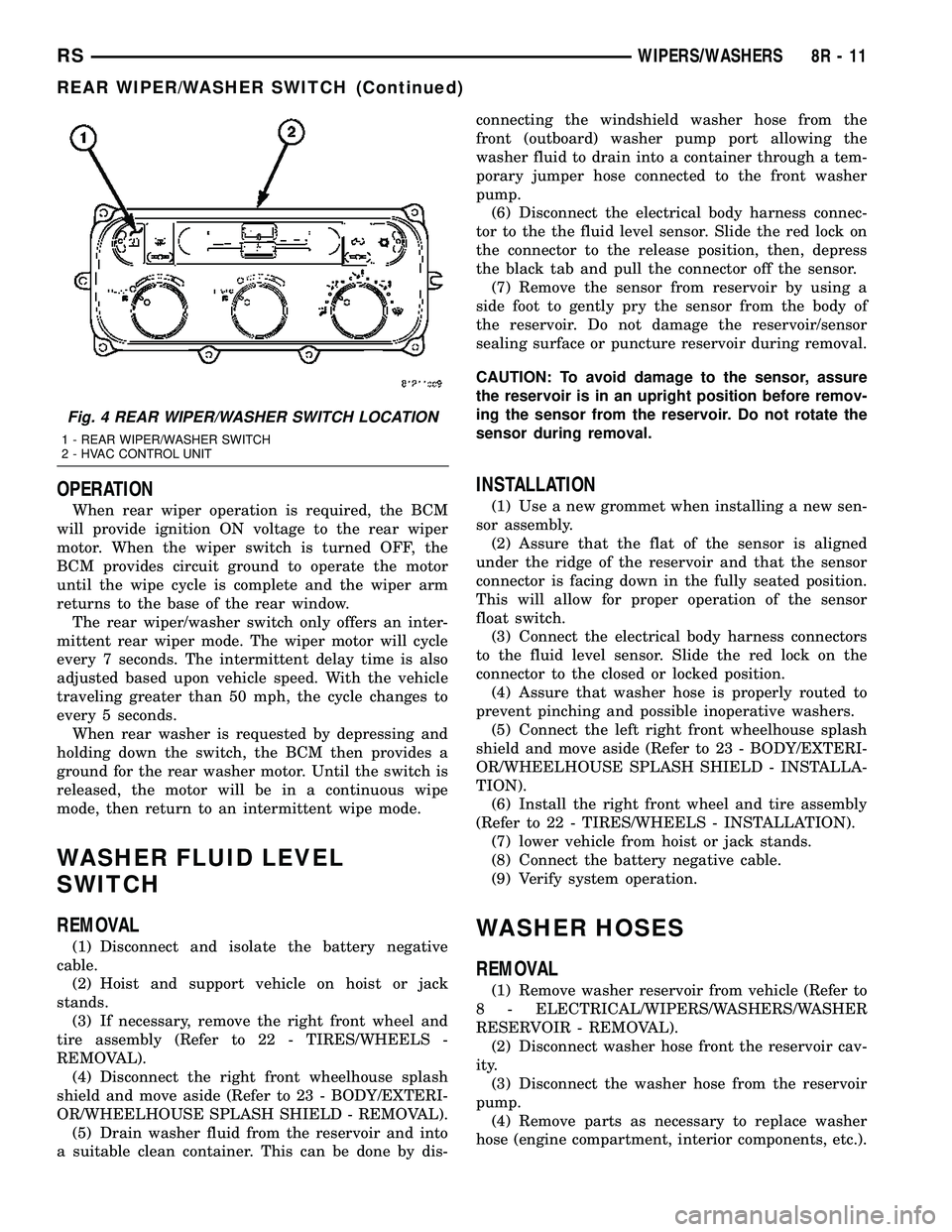

On Automatic Temperature Control (ATC) vehicles

only, the rear window wiper/washer switches are

located on the center bezel with the hazard and

heated seat switches (Fig. 3). They are not service-

able separately from the hazard and heated seat

switches. If defective, the entire switch assembly

must be replaced.

On Manual Temperature Control (MTC) vehicles

only, the rear window wiper/washer switch is located

on the HVAC control head (Fig. 4) attached to the

center bezel. They are not serviceable separately

from the control head. If found faulty, the entire

MTC head must be replaced.

Fig. 3 INSTRUMENT PANEL CENTER BEZEL

1 - TRIM BEZEL

2 - IN CAR TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8R - 10 WIPERS/WASHERSRS

FRONT WIPER MOTOR (Continued)

Page 556 of 2339

OPERATION

When rear wiper operation is required, the BCM

will provide ignition ON voltage to the rear wiper

motor. When the wiper switch is turned OFF, the

BCM provides circuit ground to operate the motor

until the wipe cycle is complete and the wiper arm

returns to the base of the rear window.

The rear wiper/washer switch only offers an inter-

mittent rear wiper mode. The wiper motor will cycle

every 7 seconds. The intermittent delay time is also

adjusted based upon vehicle speed. With the vehicle

traveling greater than 50 mph, the cycle changes to

every 5 seconds.

When rear washer is requested by depressing and

holding down the switch, the BCM then provides a

ground for the rear washer motor. Until the switch is

released, the motor will be in a continuous wipe

mode, then return to an intermittent wipe mode.

WASHER FLUID LEVEL

SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist and support vehicle on hoist or jack

stands.

(3) If necessary, remove the right front wheel and

tire assembly (Refer to 22 - TIRES/WHEELS -

REMOVAL).

(4) Disconnect the right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - REMOVAL).

(5) Drain washer fluid from the reservoir and into

a suitable clean container. This can be done by dis-connecting the windshield washer hose from the

front (outboard) washer pump port allowing the

washer fluid to drain into a container through a tem-

porary jumper hose connected to the front washer

pump.

(6) Disconnect the electrical body harness connec-

tor to the the fluid level sensor. Slide the red lock on

the connector to the release position, then, depress

the black tab and pull the connector off the sensor.

(7) Remove the sensor from reservoir by using a

side foot to gently pry the sensor from the body of

the reservoir. Do not damage the reservoir/sensor

sealing surface or puncture reservoir during removal.

CAUTION: To avoid damage to the sensor, assure

the reservoir is in an upright position before remov-

ing the sensor from the reservoir. Do not rotate the

sensor during removal.

INSTALLATION

(1) Use a new grommet when installing a new sen-

sor assembly.

(2) Assure that the flat of the sensor is aligned

under the ridge of the reservoir and that the sensor

connector is facing down in the fully seated position.

This will allow for proper operation of the sensor

float switch.

(3) Connect the electrical body harness connectors

to the fluid level sensor. Slide the red lock on the

connector to the closed or locked position.

(4) Assure that washer hose is properly routed to

prevent pinching and possible inoperative washers.

(5) Connect the left right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(6) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(7) lower vehicle from hoist or jack stands.

(8) Connect the battery negative cable.

(9) Verify system operation.

WASHER HOSES

REMOVAL

(1) Remove washer reservoir from vehicle (Refer to

8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - REMOVAL).

(2) Disconnect washer hose front the reservoir cav-

ity.

(3) Disconnect the washer hose from the reservoir

pump.

(4) Remove parts as necessary to replace washer

hose (engine compartment, interior components, etc.).

Fig. 4 REAR WIPER/WASHER SWITCH LOCATION

1 - REAR WIPER/WASHER SWITCH

2 - HVAC CONTROL UNIT

RSWIPERS/WASHERS8R-11

REAR WIPER/WASHER SWITCH (Continued)

Page 560 of 2339

NAVIGATION/TELECOMMUNICATION

TABLE OF CONTENTS

page page

NAVIGATION/TELECOMMUNICATION

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

TELECOMMUNICATION.................1HANDS FREE MODULE

REMOVAL.............................3

INSTALLATION..........................3

NAVIGATION/

TELECOMMUNICATION

DESCRIPTION

TELECOMMUNICATIONS

A hands-free cellular system is an available option

on this vehicle. It uses BluetoothŸ technology to pro-

vide wireless communication between the operator's

compatible cellular telephone and the vehicle's

on-board receiver.

The system uses voice recognition technology to

control operation. The incoming voice is broadcast

through the vehicle's radio speakers, automatically

overriding any other audio signals on the speakers

when the hands-free system is in use. A microphone

in the rearview mirror picks up vehicle occupant's

voices. If a call is in progress when the ignition is

switched off, the hands-free system will continue to

operate for up to 45 seconds as part of the Accessory

Relay Delay function. Thereafter, the call can con-

tinue on the hand-held telephone.

The center console front storage compartment

includes a cellular telephone holder, but the system

will communicate with a telephone that is anywhere

within the vehicle. However, covering the hand held

phone or the hands-free phone module with a metal

object may block the signal. The system will recog-

nize up to seven telephones, each of which is given a

spoken identification by the user during the setup

process. The system includes Spanish voice recogni-

tion in addition to English.

Two buttons on the rearview mirror, identified with

ISO icons, control the system: A9phone9button turns

the system on and off; a9voice recognition9(or voice

command) button prompts the hands-free system to

listen for a voice command.

OPERATION

TELECOMMUNICATION

Two buttons on the rearview mirror, identified with

ISO icons, control the system: A9phone9button turns

the system on and off; a9voice recognition9(or voice

command) button prompts the hands-free system to

listen for a voice command. The system includes the

following features:

²Phonebook - Stores telephone numbers for later

recall by name or other verbal identification, called a

voice tag, and memory location.

²Four memory locations - Home, Work, Mobile

and Pager. A maximum of 32 unique names or voice

tags may be stored at the same time, with a different

number in each of the four memory locations.

²Voice tag dialing - Dials the number associated

with a voice tag and memory location.

²Digit dialing - Dials the telephone number by

recognizing the names of the digits as they are spo-

ken.

²Receiving calls - A voice prompt notifies the user

of an incoming call. Pressing the ªphoneº button

answers the call.

²Privacy Mode - Switches the call to the hand-

held telephone and the hands-free system and back

again using the ªvoice recognitionº (or ªvoice com-

mandº) button and a voice command, if desired.

DIAGNOSIS AND TESTING

TELECOMMUNICATION

Any diagnosis of the Telecommunication sys-

tem should begin with the use of the DRB IIIt

diagnostic tool. For information on the use of

the DRB IIIt, refer to the appropriate Diagnos-

tic Service Information.

For complete circuit diagrams, refer to the appro-

priate wiring information.

RSNAVIGATION/TELECOMMUNICATION8T-1

Page 564 of 2339

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

OCCUPANT RESTRAINT SYSTEM........ 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1

MESSAGE CENTER................... 8W-46-1

AUDIO SYSTEM..................... 8W-47-1REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATIONS.... 8W-55-1

CONVENIENCE SYSTEMS.............. 8W-56-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION SYSTEM........ 8W-97-1 RSWIRING

8W-1

Page 583 of 2339

Component Page

Ignition Coil......................... 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Inlet Air Temperature Sensor............ 8W-30

Instrument Cluster.................... 8W-40

Instrument Panel Switch

Bank.................. 8W-43, 44, 52, 53, 63

Integrated Power Module............... 8W-10

Knock Sensor........................ 8W-30

Lamp Assemblies...................... 8W-51

License Lamp..................... 8W-51, 61

Lift Pump Motor...................... 8W-30

Lift Pump Relay...................... 8W-30

Liftgate Ajar Switch................ 8W-39, 61

Liftgate Cinch/Release Motor............ 8W-61

Liftgate Flood Lamps.................. 8W-44

Liftgate Pinch Sensors................. 8W-61

Low Beam Lamps..................... 8W-50

Manifold Absolute Pressure Sensor........ 8W-30

Mass Air Flow Sensor.................. 8W-30

Memory Seat/Mirror/Adjustable Pedals

Module...................... 8W-56, 62, 63

Memory Set Switch.................... 8W-63

Message Center.................... 8W-40, 46

Mode Door Actuator................... 8W-42

Multi-Function Switch............ 8W-50, 52, 53

Natural Vacuum Leak Detection Assembly . . 8W-30

Occupant Classification Module.......... 8W-43

Occupant Restraint Controller........... 8W-43

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Park Assist Display.................... 8W-56

Park Assist Module.................... 8W-56

Park Assist Sensors.................... 8W-56

Park Lamp Relay..................... 8W-10

Park Lamps.......................... 8W-50

Park/Turn Signal Lamps................ 8W-50

Parking Brake Switch.................. 8W-40

Power Folding Mirror Switch............ 8W-62

Power Liftgate Module................. 8W-61

Power Liftgate Motor.................. 8W-61

Power Mirror Switch................... 8W-62

Power Mirrors........................ 8W-62

Power Outlets........................ 8W-41

Power Seat Circuit Breaker.............. 8W-10

Power Seat Motors.................... 8W-63

Power Seat Position Sensors............. 8W-63

Power Seat Switches................... 8W-63

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module........... 8W-30, 31

PTCs............................... 8W-10

Radiator Fan Relaies................... 8W-42Component Page

Radiator Fans........................ 8W-42

Radio............................... 8W-47

Reading Lamps....................... 8W-44

Rear A/C-Heater Unit.................. 8W-42

Rear Auto Temp Control Switch.......... 8W-42

Rear Blower Control Switches............ 8W-42

Rear Blower Motor Power Module......... 8W-42

Rear Dome Lamp..................... 8W-44

Rear Intrusion Sensor.................. 8W-39

Rear Mode Motor..................... 8W-42

Rear Temperature Motor................ 8W-42

Rear View Mirror................ 8W-49, 55, 62

Rear Window Defogger Grid............. 8W-48

Rear Wiper Motor..................... 8W-53

Recirculation Door Actuator............. 8W-42

Remote Radio Switches................. 8W-47

Repeater Lamps...................... 8W-52

Seat Belt Switches.................... 8W-43

Seat Belt Tensioners................... 8W-43

Seat Weight Sensor.................... 8W-43

Sentry Key Remote Entry Module......... 8W-39

Siren............................... 8W-39

Sliding Door Control Modules............ 8W-61

Sliding Door Latch Sensing Switches...... 8W-61

Sliding Door Lock Motors............... 8W-61

Sliding Door Motors................... 8W-61

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Speed Sensors........................ 8W-31

Splices.............................. 8W-70

Starter Motor........................ 8W-21

Starter Motor Relay................... 8W-21

Sunroof Module....................... 8W-64

Sunroof Switch....................... 8W-64

Thatcham Alarm Indicator.............. 8W-39

Thatcham Alarm Module................ 8W-39

Throttle Position Sensor................ 8W-30

Traction Control Switch................. 8W-35

Trailer Tow Connector.................. 8W-54

Transmission Control Module............ 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid/Pressure Switch

Assembly.......................... 8W-31

Turn Signal Lamps.................... 8W-52

Vehicle Speed Sensor................... 8W-30

Vent Motors.......................... 8W-60

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor................... 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper Module........................ 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXRS