Rear control CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 432 of 2339

(2) Remove the rear light bar assembly from the

vehicle. (Refer to 8 - ELECTRICAL/POWER DOORS/

SWITCH - REMOVAL) for the procedure.

(3) Grasp the light bar at its sides next to ther-

mistor/chime assembly and gently pull the two sides

of the light bar apart until the thermistor/chime

assembly can be removed.

INSTALLATION

(1) Gently pull the two sides of the light bar apart

until the thermistor/chime assembly can be installed.

(2) Install the rear light bar assembly on the vehi-

cle. (Refer to 8 - ELECTRICAL/POWER DOORS/

SWITCH - INSTALLATION) for the procedure.

(3) Connect the battery negative cable.

ENGAGE ACTUATOR

DESCRIPTION

The 12 volt engage actuator (Fig. 3) provides the

engagement and disengagement of the liftgate gear

motor to the lift gear by way of an over center link,

activated by a lever.

The engage actuator is a serviceable component

and cannot be repaired, if found to be inoperative it

must be replaced.

OPERATION

The engage actuators normal position is disen-

gaged. When a power liftgate open or close command

is generated from any of the command switches, the

power liftgate control module signals the engage

actuator to move its lever to the engaged position.

This engages the gear motor to the lift gear, so when

the motor turns the lift gate moves upward or down-

wards depending on its current position.

During a manual liftgate open or close cycle the

engage actuator is disengaged, allowing unrestricted

liftgate movement.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the left rear D-pillar trim from the

vehicle, (Refer to 23 - BODY/INTERIOR/LEFT

D-PILLAR TRIM PANEL - REMOVAL).

(3) Manually engage the actuator link rod, this

must be done to access one of the engage actuator

retaining screws.

(4) Remove the two engage actuator retaining

screws (Fig. 4).

(5) Disconnect the engage actuator electrical con-

nector and remove the engage actuator from the

vehicle.

Fig. 3 LIFTGATE GEAR MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

Fig. 4 LIFTGATE GEAR MOTOR ASSEMBLY

1 - ENGAGE ACTUATOR RETAINING SCREWS

2 - LIFT GEAR RETAINING BOLTS

RSPOWER LIFTGATE SYSTEM8N-9

CHIME/THERMISTOR (Continued)

Page 433 of 2339

INSTALLATION

(1) Position the engage actuator in the vehicle and

connect the engage actuator electrical connector.

(2) Install the two engage actuator retaining

screws.

(3) Manually disengage the actuator.

(4) Install the left rear D-pillar trim on the vehi-

cle, (Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes.

(7) Verify power liftgate system and engage actua-

tor operation. Cycle the power liftgate through one

complete open and close cycle.

EXTERIOR HANDLE SWITCH

DESCRIPTION

The exterior handle switch is an electronic release

switch mounted to the rear license plate lamp hous-

ing assembly, located just above the license plate.

This switch controls the power liftgate release func-

tion and is also capable of reversing the power lift-

gate when it is in motion. A full power open cycle

cannot be performed using this switch, only one of

the power open command switches (key fob and over-

head console mounted) can be used to perform a full

power open cycle. The exterior handle switch is a ser-

viceable component.

OPERATION

When the exterior handle switch is depressed, with

the liftgate in the closed position, a message is sent

to the Body Control Module (BCM). The BCM then

sends a signal to the power liftgate control module

via the Programmable Communication Interface

(PCI) data bus circuit. The power liftgate control

module then sends a signal to the power latch

mounted actuator, which moves the liftgate from the

primary closed and latched position to the open and

movable position. If the liftgate is not pulled open

once the latch releases within a few seconds, the

latch will cinch closed again.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open the liftgate and remove the liftgate trim

panel, (Refer to 23 - BODY/DECKLID/HATCH/LIFT-

GATE/TAILGATE/TRIM PANEL - REMOVAL).

(3) Remove the rear lamp bar assembly from the

vehicle.(4) Locate the two wires going to the exterior han-

dle switch. Cut the tie strap and trace the wires to

the large electrical connector and back the wires out

of the large connector and through the grommet.

Take care to mark the location of the wire ter-

minals in relation to the large connector so

that they are positioned in the appropriate cav-

ities upon switch installation.

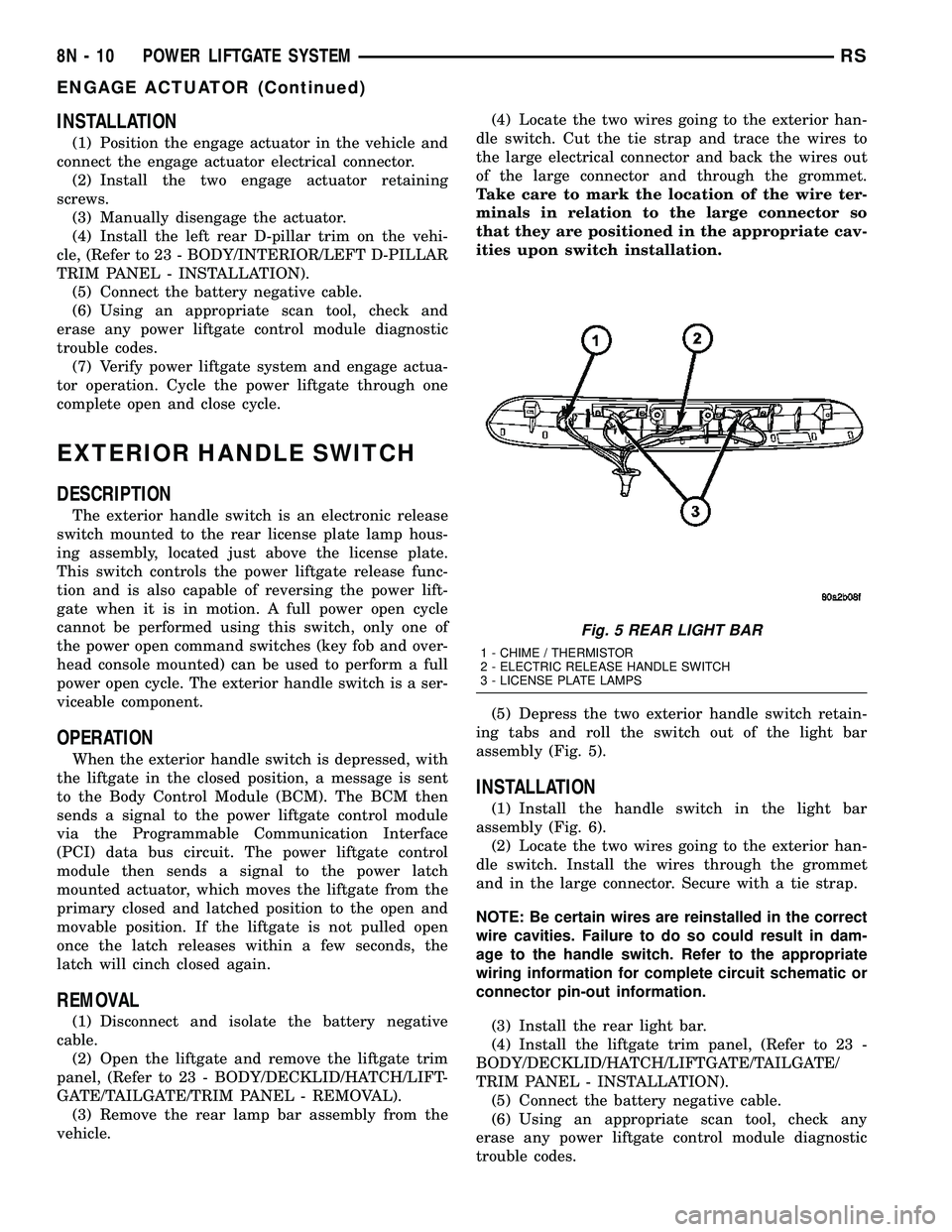

(5) Depress the two exterior handle switch retain-

ing tabs and roll the switch out of the light bar

assembly (Fig. 5).

INSTALLATION

(1) Install the handle switch in the light bar

assembly (Fig. 6).

(2) Locate the two wires going to the exterior han-

dle switch. Install the wires through the grommet

and in the large connector. Secure with a tie strap.

NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the handle switch. Refer to the appropriate

wiring information for complete circuit schematic or

connector pin-out information.

(3) Install the rear light bar.

(4) Install the liftgate trim panel, (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes.

Fig. 5 REAR LIGHT BAR

1 - CHIME / THERMISTOR

2 - ELECTRIC RELEASE HANDLE SWITCH

3 - LICENSE PLATE LAMPS

8N - 10 POWER LIFTGATE SYSTEMRS

ENGAGE ACTUATOR (Continued)

Page 434 of 2339

(7) Verify power liftgate system and handle switch

operation. Cycle the power liftgate through one com-

plete open and close cycle, this will allow the power

liftgate control module to relearn its cycle with the

new components.

FULL OPEN SWITCH

DESCRIPTION

The full open switch is located on the gear motor

housing (Fig. 7) and is used to signal the power lift-

gate control module when the power liftgate is in the

full open position. Two wires are used from the full

open switch contacts to the gear motor assemblies

main electrical connector. The full open switch is a

serviceable component.

OPERATION

When the power liftgate reaches the full open posi-

tion, the gear motor housing mounted full open

switch electrical contacts close. This sends a ground

signal to the power liftgate control module, telling

the module that the liftgate has reached the full open

position.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lift gear and link rod assembly

from the vehicle(Refer to 8 - ELECTRICAL/POWER

DOORS/CONTROL ROD - REMOVAL).(3) Cut the two wires leading to the full open

switch or back the wires out of the electrical connec-

tor.

(4) Remove the full open switch retaining screw

and remove the full open switch from the gear motor

housing assembly.

INSTALLATION

(1) Perform a wiring repair on the full open switch

wires following the approved procedure in the Wiring

section of the service manual. Or install new termi-

nals on the wire ends and reinstall in the main lift-

gate motor electrical connector.

(2) Position and install the full open switch retain-

ing screw.

(3) Install the power liftgate lift gear and link rod

assembly. (Refer to 8 - ELECTRICAL/POWER

DOORS/CONTROL ROD - INSTALLATION)

(4) Connect the battery negative cable.

(5) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes.

(6) Verify power liftgate system and full open

switch operation. Cycle the power liftgate through

one complete open and close cycle, this will allow the

power liftgate control module to relearn its cycle with

the new components.

Fig. 6 REAR LIGHT BAR

1 - CHIME / THERMISTOR

2 - ELECTRIC RELEASE HANDLE SWITCH

3 - LICENSE PLATE LAMPS

Fig. 7 FULL OPEN SWITCH LOCATION

1 - FULL OPEN SWITCH

2 - GEAR MOTOR ASSEMBLY RETAINING BOLT (1 OF 3)

RSPOWER LIFTGATE SYSTEM8N-11

EXTERIOR HANDLE SWITCH (Continued)

Page 438 of 2339

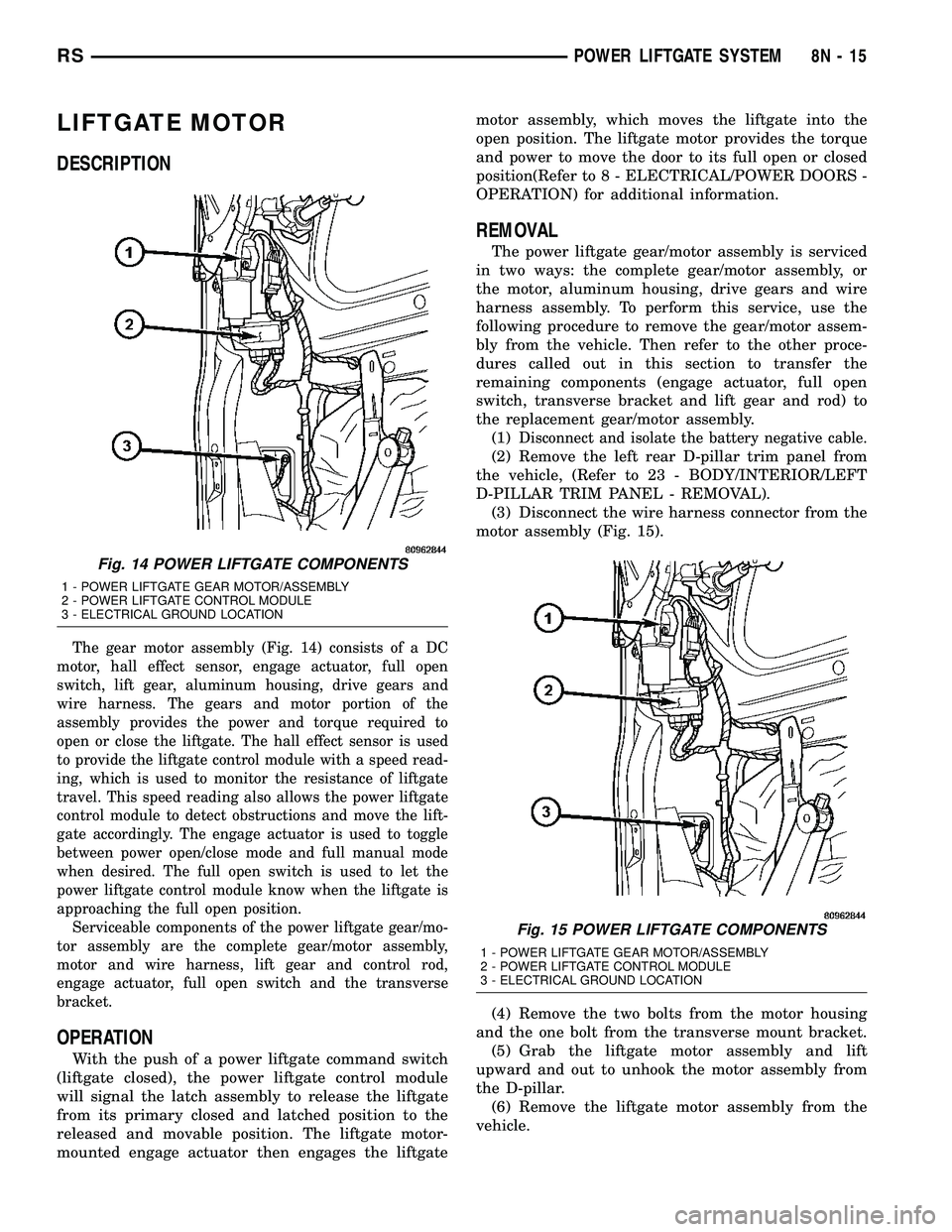

LIFTGATE MOTOR

DESCRIPTION

The gear motor assembly (Fig. 14) consists of a DC

motor, hall effect sensor, engage actuator, full open

switch, lift gear, aluminum housing, drive gears and

wire harness. The gears and motor portion of the

assembly provides the power and torque required to

open or close the liftgate. The hall effect sensor is used

to provide the liftgate control module with a speed read-

ing, which is used to monitor the resistance of liftgate

travel. This speed reading also allows the power liftgate

control module to detect obstructions and move the lift-

gate accordingly. The engage actuator is used to toggle

between power open/close mode and full manual mode

when desired. The full open switch is used to let the

power liftgate control module know when the liftgate is

approaching the full open position.

Serviceable components of the power liftgate gear/mo-

tor assembly are the complete gear/motor assembly,

motor and wire harness, lift gear and control rod,

engage actuator, full open switch and the transverse

bracket.

OPERATION

With the push of a power liftgate command switch

(liftgate closed), the power liftgate control module

will signal the latch assembly to release the liftgate

from its primary closed and latched position to the

released and movable position. The liftgate motor-

mounted engage actuator then engages the liftgatemotor assembly, which moves the liftgate into the

open position. The liftgate motor provides the torque

and power to move the door to its full open or closed

position(Refer to 8 - ELECTRICAL/POWER DOORS -

OPERATION) for additional information.

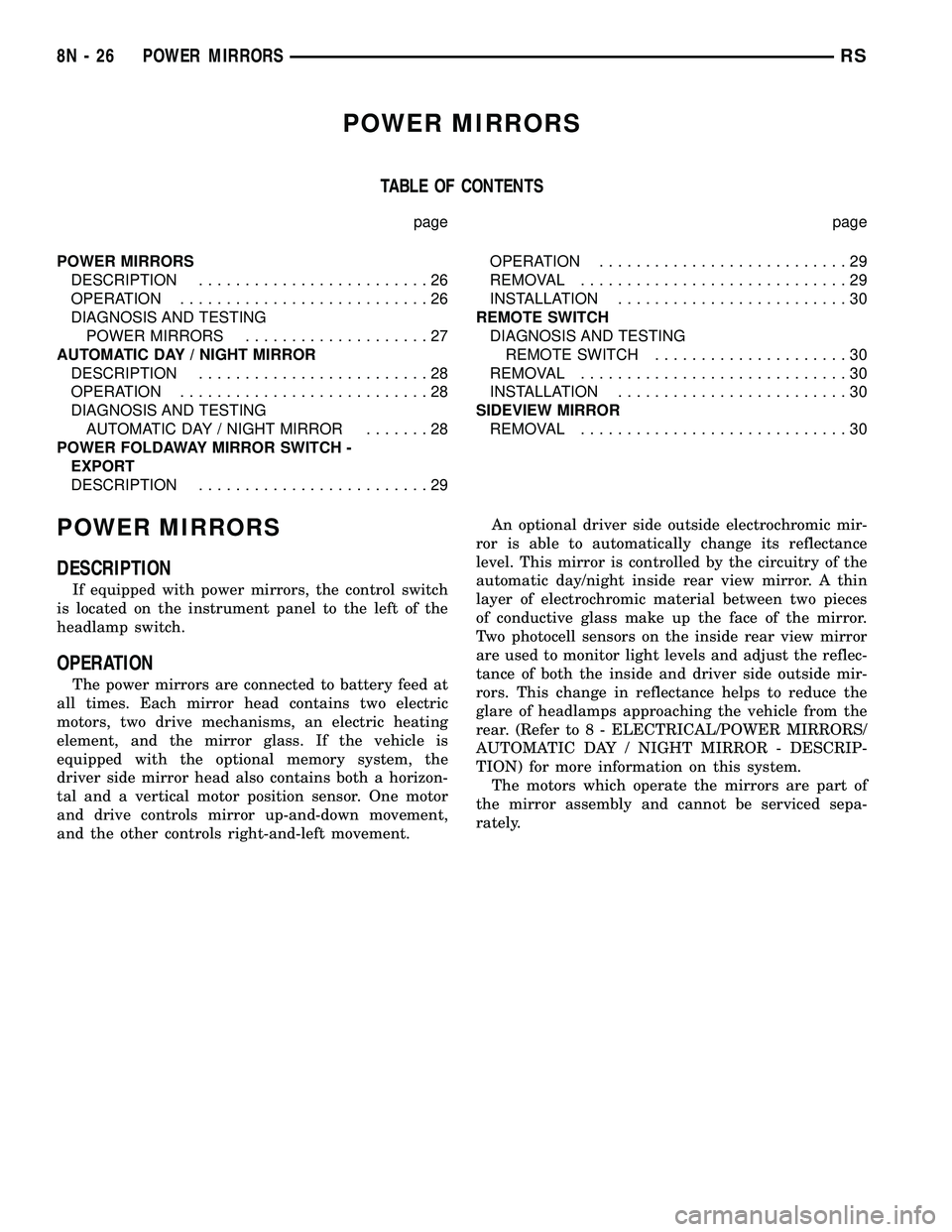

REMOVAL

The power liftgate gear/motor assembly is serviced

in two ways: the complete gear/motor assembly, or

the motor, aluminum housing, drive gears and wire

harness assembly. To perform this service, use the

following procedure to remove the gear/motor assem-

bly from the vehicle. Then refer to the other proce-

dures called out in this section to transfer the

remaining components (engage actuator, full open

switch, transverse bracket and lift gear and rod) to

the replacement gear/motor assembly.

(1)

Disconnect and isolate the battery negative cable.

(2) Remove the left rear D-pillar trim panel from

the vehicle, (Refer to 23 - BODY/INTERIOR/LEFT

D-PILLAR TRIM PANEL - REMOVAL).

(3) Disconnect the wire harness connector from the

motor assembly (Fig. 15).

(4) Remove the two bolts from the motor housing

and the one bolt from the transverse mount bracket.

(5) Grab the liftgate motor assembly and lift

upward and out to unhook the motor assembly from

the D-pillar.

(6) Remove the liftgate motor assembly from the

vehicle.

Fig. 14 POWER LIFTGATE COMPONENTS

1 - POWER LIFTGATE GEAR MOTOR/ASSEMBLY

2 - POWER LIFTGATE CONTROL MODULE

3 - ELECTRICAL GROUND LOCATION

Fig. 15 POWER LIFTGATE COMPONENTS

1 - POWER LIFTGATE GEAR MOTOR/ASSEMBLY

2 - POWER LIFTGATE CONTROL MODULE

3 - ELECTRICAL GROUND LOCATION

RSPOWER LIFTGATE SYSTEM8N-15

Page 439 of 2339

INSTALLATION

(1) Using the motor housing tab, hook the liftgate

motor assembly on the D-pillar.

(2) Install the three motor assembly retaining

bolts. Torque the two rear most bolts first to 9.5 N´m

(85 in. lbs.). Torque the remaining bolt next to the

window actuator to 9.5 N´m (85 in. lbs.).

(3) Connect the liftgate motor assembly electrical

connector.

(4) Install the D-pillar trim panel on the vehicle,

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes related to the door motor assembly.

(7) Verify power liftgate system operation. Cycle

the power liftgate through one complete open and

close cycle, this will allow the power liftgate control

module to relearn its cycle with the new components.

LIFT GEAR & LINK ROD

DESCRIPTION

The lift gear and rod assembly are located in the

left rear of the vehicle and are visible without remov-ing the D-pillar trim (Fig. 16). The lift gear provides

the leverage to move the liftgate from the closed to

the open position. The lift gear attaches to a bearing

on the gear motor assembly with four bolts. On the

outboard side of the lift gear are riveted on teeth,

which mesh with the gear motor assembly drive

gears during a open or close operation. The rod

assembly is a steel shaft, equipped with two spheri-

cal rod ends which attaches the lift gear to the lift-

gate. The lift gear and rod assembly are serviceable

components.

OPERATION

One end of the rod assembly is attached to the lift-

gate, the other attached to the lift gear. When the lift

gear is driven by the gear motor assembly the lift-

gate is moved to the open or closed position.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the left rear D-pillar trim panel from

the vehicle, (Refer to 23 - BODY/INTERIOR/LEFT

D-PILLAR TRIM PANEL - REMOVAL).

(3) Remove the lift gear retaining bolts (Fig. 17).

(4) Remove the lift gear and rod from the vehicle.

Fig. 16 LIFTGATE GEAR/MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

Fig. 17 LIFTGATE GEAR MOTOR ASSEMBLY

1 - ENGAGE ACTUATOR RETAINING SCREWS

2 - LIFT GEAR RETAINING BOLTS

8N - 16 POWER LIFTGATE SYSTEMRS

LIFTGATE MOTOR (Continued)

Page 442 of 2339

TRANSVERSE BRACKET

DESCRIPTION

The transverse bracket (Fig. 22) is used to support

and secure the power liftgate gear/motor assembly to

the left rear body D-pillar. The transverse bracket is

a serviceable power liftgate component.

OPERATION

The power liftgate transverse bracket supports the

gear motor assembly by supplying an additional

attachment point. Located on the leading edge of the

gear motor assembly, one end of the transverse

bracket attaches to the motor assembly the other to

the leading edge of the vehicles D-pillar.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the left D-pillar trim from the vehicle,

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - REMOVAL).

(3) Disconnect the gear motor assembly electrical

connector and disengage retaining pushpin.

(4) Loosen the gear motor assembly retaining bolts

to allow room for transverse bracket to be removed.

(5) Remove the transverse bracket retaining bolts

(Fig. 23).

(6)

Remove the transverse bracket from the vehicle.

INSTALLATION

(1) Position the transverse bracket in the vehicle.

Be certain the transverse bracket is properly posi-

tioned. The bracket should just touch the engage

actuator arm and be positioned between the actuator

arm and the motor housing.

(2) Torque the transverse bracket retaining bolts

to the gear motor assembly to 9.5 N´m (85 in. lbs.).

Do not tighten the transverse bracket retaining bolt,

located under the window actuator at this time.

(3) Torque the gear motor assembly retaining bolts

to 9.5 N´m (85 in. lbs.).

(4) Torque the final transverse bracket retaining

bolt to 9.5 N´m (85 in. lbs.).

(5) Connect the gear motor assembly electrical con-

nector and engage retaining pushpin.

(6) Install the left D-pillar trim, (Refer to 23 -

BODY/INTERIOR/LEFT D-PILLAR TRIM PANEL -

INSTALLATION).

(7) Connect the battery negative cable.

(8) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes related to the door motor assembly.

(9) Verify power liftgate system operation. Cycle

the power liftgate through one complete open and

close cycle, this will allow the power liftgate control

module to relearn its cycle with the new components.

Fig. 22 LIFTGATE GEAR/MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

Fig. 23 LIFTGATE GEAR MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

RSPOWER LIFTGATE SYSTEM8N-19

Page 449 of 2339

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................26

OPERATION...........................26

DIAGNOSIS AND TESTING

POWER MIRRORS....................27

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING

AUTOMATIC DAY / NIGHT MIRROR.......28

POWER FOLDAWAY MIRROR SWITCH -

EXPORT

DESCRIPTION.........................29OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................30

REMOTE SWITCH

DIAGNOSIS AND TESTING

REMOTE SWITCH.....................30

REMOVAL.............................30

INSTALLATION.........................30

SIDEVIEW MIRROR

REMOVAL.............................30

POWER MIRRORS

DESCRIPTION

If equipped with power mirrors, the control switch

is located on the instrument panel to the left of the

headlamp switch.

OPERATION

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric

motors, two drive mechanisms, an electric heating

element, and the mirror glass. If the vehicle is

equipped with the optional memory system, the

driver side mirror head also contains both a horizon-

tal and a vertical motor position sensor. One motor

and drive controls mirror up-and-down movement,

and the other controls right-and-left movement.An optional driver side outside electrochromic mir-

ror is able to automatically change its reflectance

level. This mirror is controlled by the circuitry of the

automatic day/night inside rear view mirror. A thin

layer of electrochromic material between two pieces

of conductive glass make up the face of the mirror.

Two photocell sensors on the inside rear view mirror

are used to monitor light levels and adjust the reflec-

tance of both the inside and driver side outside mir-

rors. This change in reflectance helps to reduce the

glare of headlamps approaching the vehicle from the

rear. (Refer to 8 - ELECTRICAL/POWER MIRRORS/

AUTOMATIC DAY / NIGHT MIRROR - DESCRIP-

TION) for more information on this system.

The motors which operate the mirrors are part of

the mirror assembly and cannot be serviced sepa-

rately.

8N - 26 POWER MIRRORSRS

Page 451 of 2339

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

An automatic dimming inside day/night rear view

mirror and an automatic dimming driver side outside

rear view mirror are available factory-installed

options on this model. Following is a general descrip-

tion of this optional equipment.

The automatic day/night mirror is able to automat-

ically change its reflectance. A thin layer of electro-

chromic material between two pieces of conductive

glass make up the face of the mirror. Two photocell

sensors are used to monitor light levels and adjust

the reflectance of the mirror to reduce the glare of

headlamps approaching the vehicle from the rear.

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

OPERATION

The ambient photocell sensor faces forward, to

detect the outside light levels. A second sensor faces

rearward to detect the light level received through

the vehicles back window. When the difference

between the two light levels becomes too great (the

light level received at the rear of the mirror is much

higher than that at the front of the mirror), the mir-

ror begins to darken.

The mirror switch allows the driver a manual con-

trol of whether the automatic dimming feature is

operational. When AUTO is selected a small Light-

Emitting Diode (LED), to the right of the mirror

switch, is illuminated. The automatic dimming fea-

ture will only operate when the ignition switch is in

the On position. The mirror also senses the backup

lamp circuit, and will automatically disable its self-

dimming feature whenever the transmission gear

selector is in the Reverse position.

NOTE: The mirror always defaults to an ON state

upon ignition.

The driver side automatic dimming mirror is stan-

dard with the automatic dimming inside mirror. The

signal to control the dimming of that mirror is gen-

erated by the automatic day/night inside rear view

mirror circuitry. That signal is then delivered to the

driver side outside rear view mirror on a hard wired

circuit.

The automatic day/night mirror cannot be

repaired. If faulty or damaged, the entire inside rear

view mirror assembly must be replaced.

DIAGNOSIS AND TESTING

AUTOMATIC DAY / NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the intelligent power module.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the intelli-

gent power module. If OK, go to Step 3. If not OK,

repair the open circuit to the ignition switch as

required.

(3) Unplug the wire harness connector from the

automatic day/night mirror. Check for battery voltage

at the fused ignition switch output circuit cavity of

the automatic day/night mirror wire harness connec-

tor. If OK, go to Step 4. If not OK, repair the open

circuit to the junction block as required.

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Turn the ignition switch to the On position. Set

the parking brake. Place the transmission gear selec-

tor lever in the Reverse position. Check for battery

voltage at the backup lamp switch output circuit cav-

ity of the automatic day/night mirror wire harness

connector. If voltage is present, reinstall the auto-

matic day/night mirror wire harness connector and

go to Step 6. If not OK, repair the open circuit as

required.

(6) Place the transmission gear selector lever in

the Neutral position. Place the automatic day/night

mirror switch in the On (LED in the switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The automatic day/night mir-

ror should darken. The automatic day/night mirror

should darken within 2 minutes if testing for the

first time. For immediate response, turn the vehicle

8N - 28 POWER MIRRORSRS

Page 452 of 2339

OFF and back ON with the forward-facing light sen-

sor still covered. This defeats the day-detect logic. If

OK, go to Step 8. If not OK, replace the faulty mirror

unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty mirror

unit.

Bench testing both mirrors can be done, of care is

exercised. For an inside mirror, the pin closest to he

mount is 12V (+), the next is 12V (-). The third is

reverse override. The fourth is outside mirror (+), and

the fifth is outside mirror (-).Do not apply 12 volts to

the fourth and fifth pins.With 12 volts on pins 1 and

2, the mirror can be tested by blocking the rear sensor

and shining a light into the forward sensor. For an out-

side mirror, there is a 2±pin connector. Applying 1.2

volts will cause the mirror to dim. If the mirror does not

dim, the entire glass assembly can be replaced just as it

is when the glass is broken.

WARNING: Do not apply 12 volts to the outside mir-

ror. Damage to the mirror will result.

POWER FOLDAWAY MIRROR

SWITCH - EXPORT

DESCRIPTION

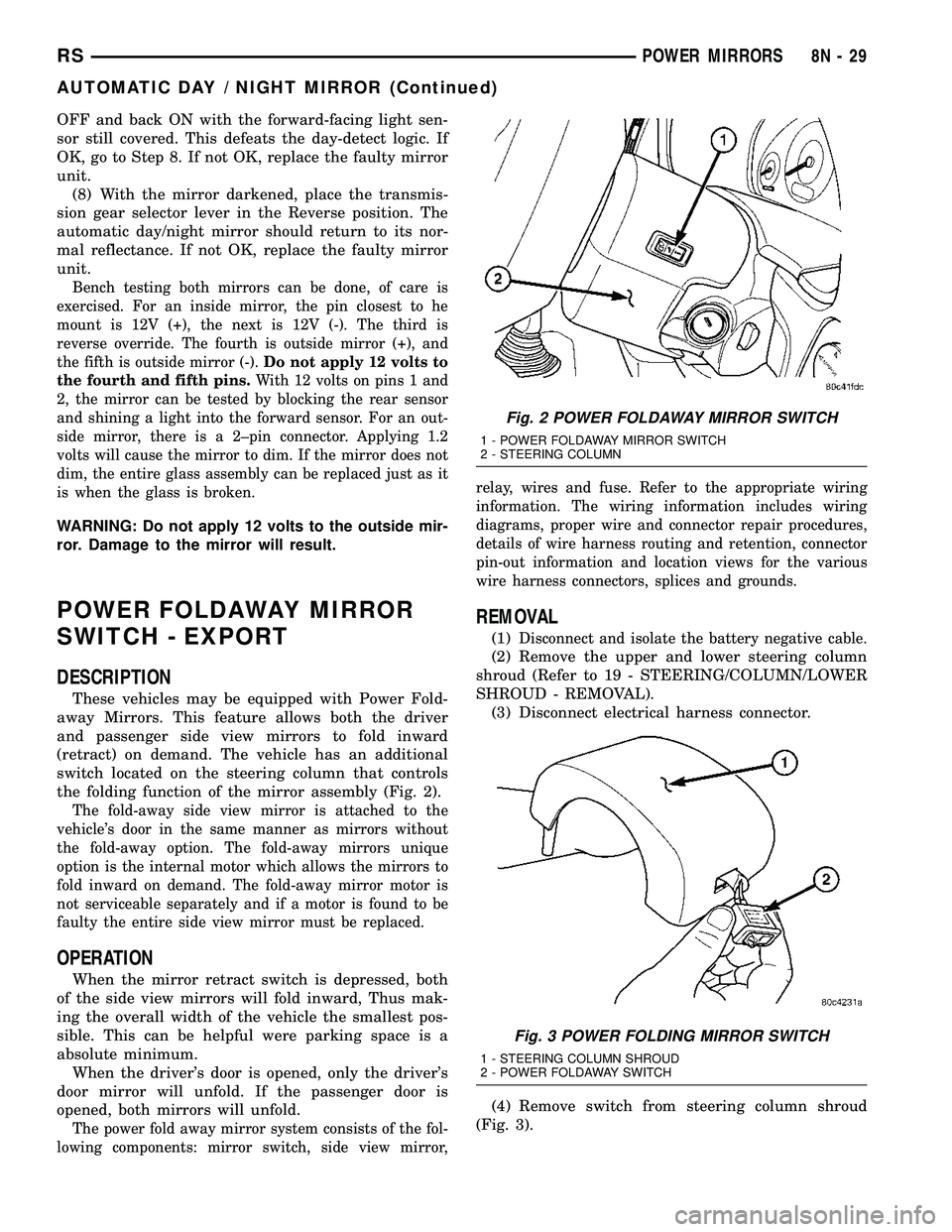

These vehicles may be equipped with Power Fold-

away Mirrors. This feature allows both the driver

and passenger side view mirrors to fold inward

(retract) on demand. The vehicle has an additional

switch located on the steering column that controls

the folding function of the mirror assembly (Fig. 2).

The fold-away side view mirror is attached to the

vehicle's door in the same manner as mirrors without

the fold-away option. The fold-away mirrors unique

option is the internal motor which allows the mirrors to

fold inward on demand. The fold-away mirror motor is

not serviceable separately and if a motor is found to be

faulty the entire side view mirror must be replaced.

OPERATION

When the mirror retract switch is depressed, both

of the side view mirrors will fold inward, Thus mak-

ing the overall width of the vehicle the smallest pos-

sible. This can be helpful were parking space is a

absolute minimum.

When the driver's door is opened, only the driver's

door mirror will unfold. If the passenger door is

opened, both mirrors will unfold.

The power fold away mirror system consists of the fol-

lowing components: mirror switch, side view mirror,relay, wires and fuse. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair procedures,

details of wire harness routing and retention, connector

pin-out information and location views for the various

wire harness connectors, splices and grounds.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove the upper and lower steering column

shroud (Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(3) Disconnect electrical harness connector.

(4) Remove switch from steering column shroud

(Fig. 3).

Fig. 2 POWER FOLDAWAY MIRROR SWITCH

1 - POWER FOLDAWAY MIRROR SWITCH

2 - STEERING COLUMN

Fig. 3 POWER FOLDING MIRROR SWITCH

1 - STEERING COLUMN SHROUD

2 - POWER FOLDAWAY SWITCH

RSPOWER MIRRORS8N-29

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 454 of 2339

POWER SEAT SYSTEM

TABLE OF CONTENTS

page page

POWER SEAT SYSTEM

DESCRIPTION

POWER SEAT SYSTEM................31

MEMORY SYSTEM....................32

OPERATION

POWER SEAT SYSTEM................32

MEMORY SYSTEM....................33

DIAGNOSIS AND TESTING

POWER SEAT SYSTEM................33

MEMORY SYSTEM....................33

SEAT SWITCH

DESCRIPTION.........................34

OPERATION...........................34

DIAGNOSIS AND TESTING

DRIVER SEAT SWITCH.................34

REMOVAL.............................36INSTALLATION.........................36

MEMORY SWITCH

DESCRIPTION.........................36

OPERATION...........................36

DIAGNOSIS AND TESTING

MEMORY SWITCH....................37

REMOVAL.............................37

INSTALLATION.........................37

POWER SEAT TRACK

DESCRIPTION.........................37

OPERATION...........................38

DIAGNOSIS AND TESTING

POWER SEAT TRACK..................38

REMOVAL.............................38

INSTALLATION.........................39

POWER SEAT SYSTEM

DESCRIPTION

POWER SEAT SYSTEM

The power seat system option allows the driver

and front seat passenger to electrically adjust their

seating positions for optimum control and comfort.

The driver side power front seat can be adjusted in

eight different directions: up, down, front up, front

down, rear up, rear down, forward, rearward and

recliner forward and rearward. The passenger side

power front seat can be adjusted in four different

directions: forward, rearward and recliner forward

and rearward.

The power seat system receives battery current

through a 40 amp fuse in the Integrated Power Mod-

ule (IPM) and a 30 amp circuit breaker under the

seat so that the power seats remain operational,

regardless of the ignition switch position.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The eight-way driver side power seat is also avail-

able with the heated seat and/or memory seat sys-

tem. The memory seat system automatically

positions the power seat for two different drivers.

Fig. 1 IDENTIFYING A SIDE AIRBAG EQUIPPED

SEAT

1 - AIRBAG LABEL

RSPOWER SEAT SYSTEM8N-31