ipm CHRYSLER VOYAGER 2005 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1176 of 2339

(5) Connect the negative and positive battery

cables.

(6) Using a scan tool, check for any stored diagnos-

tic trouble codes. Ensure that all vehicle options are

operational.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IOD fuse is a 20 ampere blade-type mini fuse

and, when removed, it is stored in a fuse cavity adja-

cent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position.

The IOD fuse feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicle

as well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock. The only reason the

IOD fuse is removed is to reduce the normal IOD of

the vehicle electrical system during new vehicle

transportation and pre-delivery storage to reduce

battery depletion, while still allowing vehicle opera-

tion so that the vehicle can be loaded, unloaded and

moved as needed by both vehicle transportation com-

pany and dealer personnel.

The IOD fuse is removed from the Integrated

Power Module (IPM) fuse cavity when the vehicle is

shipped from the assembly plant. Dealer personnel

must install the IOD fuse when the vehicle is being

prepared for delivery in order to restore full electrical

system operation. Once the vehicle is prepared for

delivery, the IOD function of this fuse becomes trans-

parent and the fuse that has been assigned the IOD

designation becomes only another Fused B(+) circuit

fuse. The IOD fuse serves no useful purpose to the

dealer technician in the service or diagnosis of any

vehicle system or condition, other than the same pur-

pose as that of any other standard circuit protection

device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed approximately thirty days. However, it mustbe remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than thirty days,

the battery negative cable should be disconnected to

eliminate normal IOD; and, the battery should be

tested and recharged at regular intervals during the

vehicle storage period to prevent the battery from

becoming discharged or damaged.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the instrument

panel center lower bezel. Two additional power out-

lets are incorporated into the left rear C-pillar and

the center console (if equipped). The power outlets

bases are secured by a snap fit. A hinged plug flips

closed to conceal and protect the power outlet base

when not in use.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the ON position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1177 of 2339

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Note position of the retaining bosses (Fig. 4).

(3) Using external snap ring pliers with 90 degree

tips. Insert pliers with tips against bosses and

squeeze forcing bosses out of base.

(4) Pull out the base through mounting ring by

gently rocking pliers.

(5) Disconnect the base wires.

(6) Remove light ring and disconnect wire.

INSTALLATION

(1) Position the mounting ring on the instrument

panel and feed the wires through the ring. Index thecap and the mounting ring with the index tab at the

9 o'clock position to the key in the instrument panel.

Install the ring.

(2) Connect the wires to the base. Orientate the

base alignment rib at the 11 o'clock position to mate

the groove in the mounting ring to the base.

(3) Push the base into the bezel until it locks in

place.

(4) Check operation of outlet or element and

install the outlet cap.

Fig. 4 POWER OUTLET

1 - RETAINING BOSSES-ENGAGE PLIERS HERE

2 - PARTIALLY REMOVED

3 - EXTERNAL SNAP-RING PLIERS

4 - PULL BASE OUT-THROUGH MOUNTING RING

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER OUTLET (Continued)

Page 1345 of 2339

CAUTION: When servicing the exhaust system, care

must be exercised not to dent or bend the bellows

of the flex-joint. Should this occur, the flex-joint will

eventually fail, requiring replacement of the cata-

lytic converter.

(3) Disconnect the right side axle half shaft from

the rear differential module (AWD equipped only).

(4) Loosen the band clamp (Fig. 10) at the muffler

to converter pipe connection.

(5) Remove the exhaust hangers to body screws

(Fig. 10).

(6) Separate muffler pipe from converter pipe.

(7) Remove muffler/resonator assembly by moving

assembly forward and guiding the resonator through

the rear axle to body opening.

(8) Clean ends of pipes or muffler to assure mat-

ing of all parts. Discard broken or worn insulators,

rusted clamps, supports and attaching parts.When

replacement is required on any component of

the exhaust system, it is important that original

equipment parts (or equivalent) be used for the

following conditions:²Ensure proper alignment with other components

in the system.

²Provide acceptable exhaust noise levels.

²Provide proper exhaust system back pressure for

maintaining emission and performance levels.

INSTALLATION

(1) Install the muffler/resonator assembly by guid-

ing resonator between the rear axle and body.

(2) Connect the muffler pipe to the converter pipe

but do not tighten band clamp (Fig. 10).

(3) Position hangers to body and install screws

starting at the resonator working forward (Fig. 10).

Tighten hanger screws to 28 N´m (250 in. lbs.).

(4) Insert muffler pipe into catalytic converter pipe

until the hangers are positioned as shown in (Fig. 11)

CAUTION: Band clamps should never be tightened

such that the two sides of the clamps are bottomed

out against the center hourglass shaped center

block. Once this occurs, the clamp band has been

stretched and has lost its clamping force and must

be replaced.

To replace the band clamp; remove the nut and peel

back the ends of the clamp until spot weld breaks.

Clean remaining spot weld from the pipe using a

file or grinder until surface is smooth.

Fig. 10 Exhaust System - Typical (All Vehicles)

1 - SCREW - RESONATOR HANGER TO BODY 3 - MUFFLER & RESONATOR ASSEMBLY

2 - SCREW - MUFFLER HANGER TO BODY 4 - CATALYTIC CONVERTER PIPE

11 - 8 EXHAUST SYSTEMRS

MUFFLER (Continued)

Page 1353 of 2339

(3) Align and insert the center forward tab.

(4) Align the remaining tabs and press into the

slots, starting in the center and working outboard.

(5) Assure all tabs are fully engaged into the fas-

cia.

(6) If rear bumper fascia has been removed install.

(Refer to 13 - FRAME & BUMPERS/BUMPERS/

REAR FASCIA - INSTALLATION).

FRAME

SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS

Frame dimensions are listed in metric scale. All

dimensions are from center to center of PrincipalLocating Point (PLP), or from center to center of PLP

and fastener location.

VEHICLE PREPARATION

Position the vehicle on a frame alignment rack,

refer to instructions provided with equipment being

used. Adjust the vehicle PLP heights to the specified

dimension above the work surface (datum line). Ver-

tical dimensions can be taken from the datum line to

the locations indicated were applicable.

INDEX

DESCRIPTION FIGURE

CROSSMEMBER DIMENSIONS 8

ENGINE BOX - TOP VIEW 9

ENGINE COMPARTMENT AND FRAME RAIL - SIDE VIEW 10

FULL VEHICLE - BOTTOM VIEW 11

13 - 6 FRAME & BUMPERSRS

REAR FASCIA - SCUFF PAD (Continued)

Page 1361 of 2339

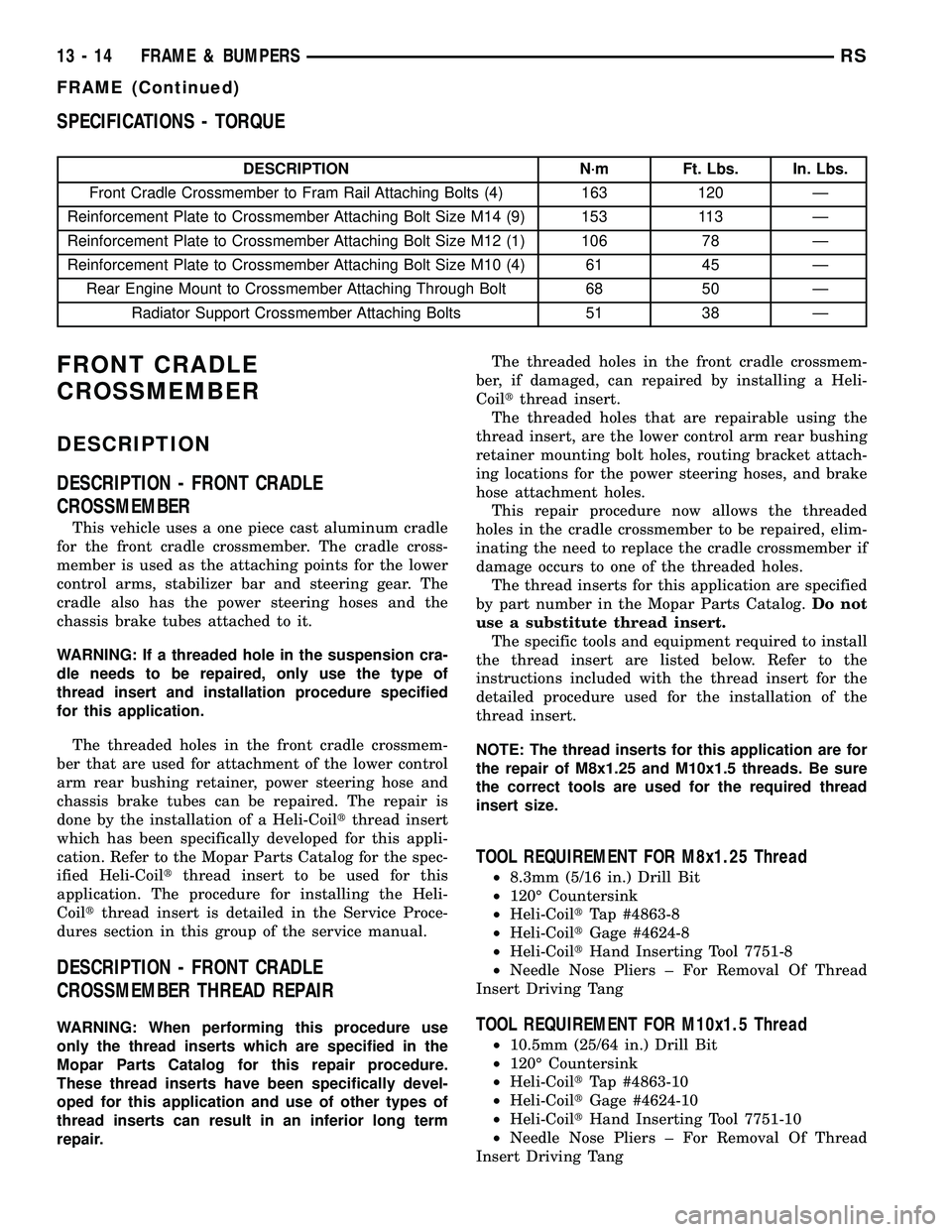

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front Cradle Crossmember to Fram Rail Attaching Bolts (4) 163 120 Ð

Reinforcement Plate to Crossmember Attaching Bolt Size M14 (9) 153 113 Ð

Reinforcement Plate to Crossmember Attaching Bolt Size M12 (1) 106 78 Ð

Reinforcement Plate to Crossmember Attaching Bolt Size M10 (4) 61 45 Ð

Rear Engine Mount to Crossmember Attaching Through Bolt 68 50 Ð

Radiator Support Crossmember Attaching Bolts 51 38 Ð

FRONT CRADLE

CROSSMEMBER

DESCRIPTION

DESCRIPTION - FRONT CRADLE

CROSSMEMBER

This vehicle uses a one piece cast aluminum cradle

for the front cradle crossmember. The cradle cross-

member is used as the attaching points for the lower

control arms, stabilizer bar and steering gear. The

cradle also has the power steering hoses and the

chassis brake tubes attached to it.

WARNING: If a threaded hole in the suspension cra-

dle needs to be repaired, only use the type of

thread insert and installation procedure specified

for this application.

The threaded holes in the front cradle crossmem-

ber that are used for attachment of the lower control

arm rear bushing retainer, power steering hose and

chassis brake tubes can be repaired. The repair is

done by the installation of a Heli-Coiltthread insert

which has been specifically developed for this appli-

cation. Refer to the Mopar Parts Catalog for the spec-

ified Heli-Coiltthread insert to be used for this

application. The procedure for installing the Heli-

Coiltthread insert is detailed in the Service Proce-

dures section in this group of the service manual.

DESCRIPTION - FRONT CRADLE

CROSSMEMBER THREAD REPAIR

WARNING: When performing this procedure use

only the thread inserts which are specified in the

Mopar Parts Catalog for this repair procedure.

These thread inserts have been specifically devel-

oped for this application and use of other types of

thread inserts can result in an inferior long term

repair.The threaded holes in the front cradle crossmem-

ber, if damaged, can repaired by installing a Heli-

Coiltthread insert.

The threaded holes that are repairable using the

thread insert, are the lower control arm rear bushing

retainer mounting bolt holes, routing bracket attach-

ing locations for the power steering hoses, and brake

hose attachment holes.

This repair procedure now allows the threaded

holes in the cradle crossmember to be repaired, elim-

inating the need to replace the cradle crossmember if

damage occurs to one of the threaded holes.

The thread inserts for this application are specified

by part number in the Mopar Parts Catalog.Do not

use a substitute thread insert.

The specific tools and equipment required to install

the thread insert are listed below. Refer to the

instructions included with the thread insert for the

detailed procedure used for the installation of the

thread insert.

NOTE: The thread inserts for this application are for

the repair of M8x1.25 and M10x1.5 threads. Be sure

the correct tools are used for the required thread

insert size.

TOOL REQUIREMENT FOR M8x1.25 Thread

²8.3mm (5/16 in.) Drill Bit

²120É Countersink

²Heli-CoiltTap #4863-8

²Heli-CoiltGage #4624-8

²Heli-CoiltHand Inserting Tool 7751-8

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

TOOL REQUIREMENT FOR M10x1.5 Thread

²10.5mm (25/64 in.) Drill Bit

²120É Countersink

²Heli-CoiltTap #4863-10

²Heli-CoiltGage #4624-10

²Heli-CoiltHand Inserting Tool 7751-10

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

13 - 14 FRAME & BUMPERSRS

FRAME (Continued)

Page 1372 of 2339

(4) Install level sensor wires in connector. Push

the wires up through the connector and then pull

them down until they lock in place. Ensure signal

and ground wires are installed in the correct posi-

tion.

(5) Install locking wedge on connector.

(6) Push connector up into bottom of fuel pump

module electrical connector.

(7) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL LINES

DESCRIPTION - FUEL LINES/HOSES AND

CLAMPS

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, use new original equipment

lines/tubes/hoses.

If equipped:The hose clamps used to secure rub-

ber hoses on vehicles are of a special rolled edge con-

struction. This construction is used to prevent the

edge of the clamp from cutting into the hose. Only

these rolled edge type clamps may be used in this

system. All other types of clamps may cut into the

hoses and cause leaks.

Use new original equipment type hose clamps.

STANDARD PROCEDURE - HOSES AND CLAMP

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that causeabrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (9 in. lbs.) torque.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes are

properly routed to prevent pinching and to avoid heat

sources.

FUEL PRESSURE REGULATOR

OPERATION

The fuel system uses a nonadjustable pressure reg-

ulator that maintains fuel system pressure at

approximately 400 34 kPa (58 5 psi). The fuel

pressure regulator contains a diaphragm, calibrated

spring and a fuel return valve. The spring pushes

down on the diaphragm and closes off the fuel return

port. System fuel pressure reflects the amount of fuel

pressure required to open the return port.

The pressure regulator is a mechanical device that

is NOT controlled by the PCM or engine vacuum.

REMOVAL

The fuel pressure regulator is part of the fuel

pump module (Fig. 9). Remove the fuel pump module

from the fuel tank to access the fuel pressure regula-

tor. Refer to the Fuel Pump Module removal in this

section.

(1) Squeeze tangs on pressure regulator retainer

and pull to remove retainer.

(2) Pry fuel pressure regulator out of housing.

(3) Ensure both upper and lower O-rings were

removed with regulator.

INSTALLATION

The fuel pressure regulator is part of the fuel

pump module. Remove the fuel pump module from

the fuel tank to access the fuel pressure regulator.

Refer to the Fuel Pump Module removal in this sec-

tion.

RSFUEL DELIVERY14-7

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1408 of 2339

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION - POWER STEERING SYSTEM . . 1

OPERATION - POWER STEERING SYSTEM . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM FLOW AND

PRESSURE TEST......................1

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS............3SPECIFICATIONS

POWER STEERING FASTENER TORQUE . . . 9

SPECIAL TOOLS

POWER STEERING....................9

COLUMN..............................10

GEAR.................................26

PUMP.................................36

STEERING

DESCRIPTION - POWER STEERING SYSTEM

This vehicle comes with power steering as stan-

dard equipment. The power steering system consists

of these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID

²POWER STEERING FLUID COOLER (If

Equipped)

²POWER STEERING FLUID RESERVOIR

²POWER STEERING FLUID SUPPLY HOSE

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on all other components can

be found in POWER STEERING PUMP.

OPERATION - POWER STEERING SYSTEM

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth within the

steering gear. The lateral travel pushes and pulls the

tie rods to change the direction of the vehicle's front

wheels.

Power assist steering is provided by a belt driven

rotary type pump. It directs fluid through power

steering fluid hoses to the power steering gear where

it is used to assist the driver's turning effort.

Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM FLOW AND PRESSURE TEST

ALL ENGINES

The following procedure is to be used to test the

operation of the power steering system on this vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed to determine if the

power steering pump or power steering gear is not

functioning properly. The following flow and pressure

test is performed using the Power Steering Analyzer

Kit, Special Tool 6815 (Fig. 1), hoses, Special Tools

6905 and 6959, and fittings from adapter kit, Special

Tool 6893.

Fig. 1 Power Steering Analyzer With Hoses Installed

1 - OUTLET

2 - SPECIAL TOOL 6815

3 - INLET

RSSTEERING19-1

Page 1412 of 2339

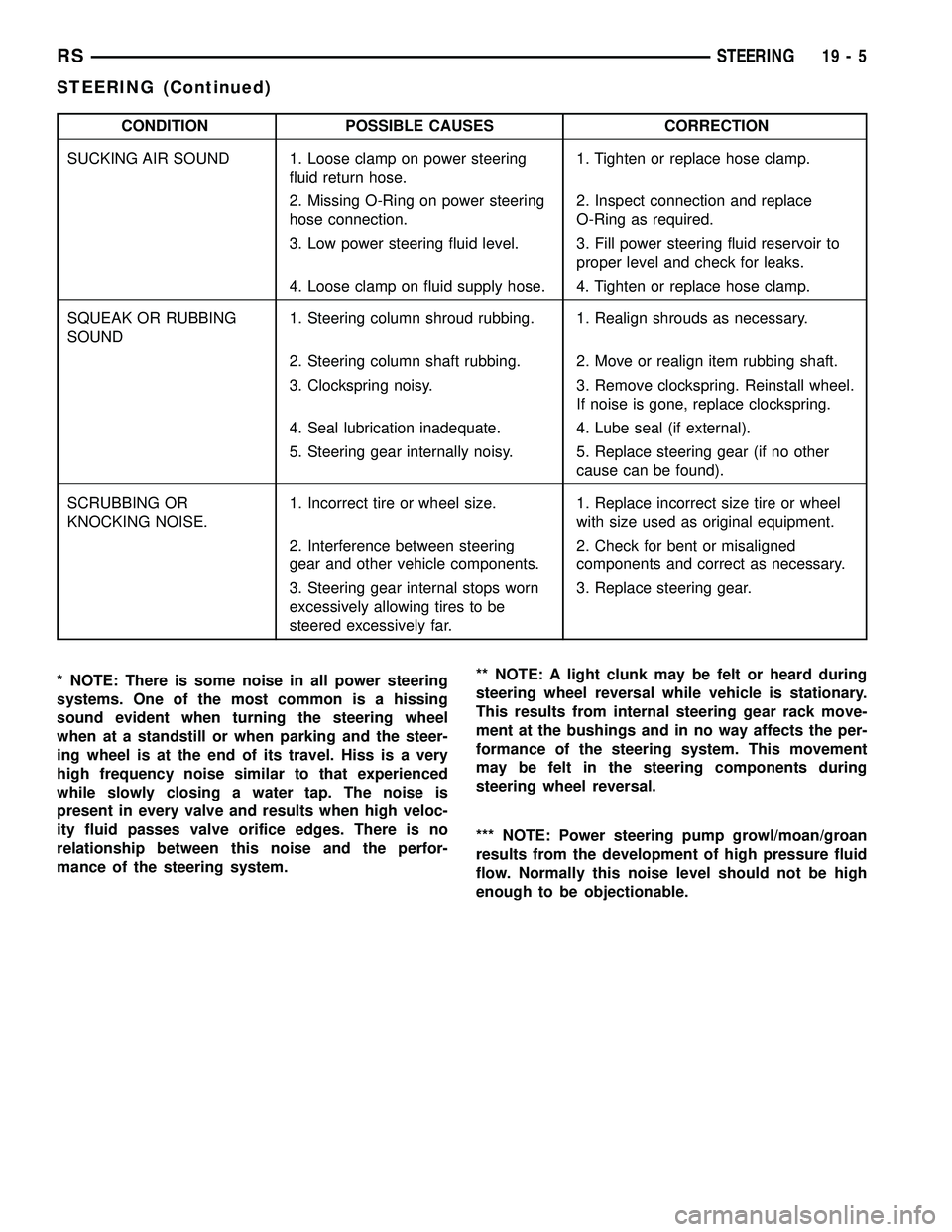

CONDITION POSSIBLE CAUSES CORRECTION

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Loose clamp on fluid supply hose. 4. Tighten or replace hose clamp.

SQUEAK OR RUBBING

SOUND1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing shaft.

3. Clockspring noisy. 3. Remove clockspring. Reinstall wheel.

If noise is gone, replace clockspring.

4. Seal lubrication inadequate. 4. Lube seal (if external).

5. Steering gear internally noisy. 5. Replace steering gear (if no other

cause can be found).

SCRUBBING OR

KNOCKING NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or wheel

with size used as original equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as necessary.

3. Steering gear internal stops worn

excessively allowing tires to be

steered excessively far.3. Replace steering gear.

* NOTE: There is some noise in all power steering

systems. One of the most common is a hissing

sound evident when turning the steering wheel

when at a standstill or when parking and the steer-

ing wheel is at the end of its travel. Hiss is a very

high frequency noise similar to that experienced

while slowly closing a water tap. The noise is

present in every valve and results when high veloc-

ity fluid passes valve orifice edges. There is no

relationship between this noise and the perfor-

mance of the steering system.** NOTE: A light clunk may be felt or heard during

steering wheel reversal while vehicle is stationary.

This results from internal steering gear rack move-

ment at the bushings and in no way affects the per-

formance of the steering system. This movement

may be felt in the steering components during

steering wheel reversal.

*** NOTE: Power steering pump growl/moan/groan

results from the development of high pressure fluid

flow. Normally this noise level should not be high

enough to be objectionable.

RSSTEERING19-5

STEERING (Continued)

Page 1575 of 2339

OPERATION

The Brake/Transmission Shift Interlock (BTSI)

Solenoid prevents the transmission shift lever from

being moved out of PARK (P) unless the brake pedal

is applied. The BTSI solenoid is hardwired to and

controlled by the Intelligent Power Module (IPM).

Battery voltage is applied to one side of the solenoid

with the ignition key is in either the OFF, ON/RUN,

or START positions (Fig. 269). The ground side of the

solenoid is controlled by a driver within the IPM. It

relies on voltage supplied from the stop lamp switch

to the stop lamp sense circuit within the IPM to tell

when the brake pedal is depressed. When the brake

pedal is depressed, the ground circuit opens, de-ener-

gizing the solenoid. When the brake pedal is

released, the ground circuit is closed, energizing the

solenoid.

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 270). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 271), allow-

ing the shift lever to be moved into any gear position.

Fig. 269 Ignition Key/Switch Positions

1 - ACC

2 - LOCK

3 - OFF

4 - ON/RUN

5-START

Fig. 270 Pawl Engaged to Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

Fig. 271 Pawl Disengaged From Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

21 - 114 40TE AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

Page 1591 of 2339

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The transmission control relay (Fig. 306) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized by

the PCM/TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal operating

mode. When the relay is ªoffº, no power is supplied to

the solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset (ignition key turned to the

ªrunº position or after cranking engine), the PCM/TCM

energizes the relay. Prior to this, the PCM/TCM verifies

that the contacts are open by checking for no voltage at

the switched battery terminals. After this is verified,

the voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the PCM/TCM

monitors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle andcan only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 307).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 308).

Fig. 306 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 307 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 308 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 130 40TE AUTOMATIC TRANSAXLERS