CHRYSLER VOYAGER 2022 Owners Manual

Manufacturer: CHRYSLER, Model Year: 2022, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2022Pages: 316, PDF Size: 17.41 MB

Page 261 of 316

SERVICING AND MAINTENANCE259

Do not use water alone or alcohol-based engine

coolant products. Do not use additional rust

inhibitors or anti-rust products, as they may not

be compatible with the radiator engine coolant

and may plug the radiator.

This vehicle has not been designed for use with

propylene glycol-based engine coolant. Use of

propylene glycol-based engine coolant is not

recommended.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized dealer.

Adding Coolant

Your vehicle has been built with an improved

engine coolant (OAT coolant conforming to

MS.90032) that allows extended maintenance

intervals. This engine coolant (antifreeze)

can be used up to ten years or 150,000 miles

(240,000 km) before replacement. To prevent

reducing this extended maintenance period, it is

important that you use the same engine coolant

(OAT coolant conforming to MS.90032) throughout

the life of your vehicle. Please review these recommendations for using

OAT engine coolant that meets the requirements of

the manufacturer Material Standard MS.90032.

When adding engine coolant:

We recommend using Mopar® Antifreeze/

Coolant 10 Year/150,000 Mile (240,000 km)

Formula OAT that meets the requirements of the

manufacturer Material Standard MS.90032.

Mix a minimum solution of 50% OAT engine

coolant that meets the requirements of the

manufacturer Material Standard MS.90032

and distilled water. Use higher concentrations

(not to exceed 70%) if temperatures below

−34°F (−37°C) are anticipated. Please contact

an authorized dealer for assistance.

Use only high purity water such as distilled or

deionized water when mixing the water/engine

coolant solution. The use of lower quality water

will reduce the amount of corrosion protection

in the engine cooling system.

NOTE:

It is the owner's responsibility to maintain the

proper level of protection against freezing

according to the temperatures occurring in the

area where the vehicle is operated.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system, please contact an authorized

dealer.

Mixing engine coolant types is not recom

-

mended and can result in cooling system

damage. If HOAT and OAT coolant are mixed in

an emergency, have an authorized dealer drain,

flush, and refill with OAT coolant (conforming to

MS.90032) as soon as possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

engine coolant (antifreeze), and to ensure that

engine coolant will return to the radiator from

the coolant expansion bottle/recovery tank

(if equipped).

The cap should be inspected and cleaned if there

is any accumulation of foreign material on the

sealing surfaces.

8

22_RUVG_OM_EN_USC_t.book Page 259

Page 262 of 316

260SERVICING AND MAINTENANCE

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is

a regulated substance requiring proper disposal.

Check with your local authorities to determine the

disposal rules for your community. To prevent

ingestion by animals or children, do not store

ethylene glycol-based coolant in open containers

or allow it to remain in puddles on the ground. If

ingested by a child or pet, seek emergency

assistance immediately. Clean up any ground spills

immediately.

Coolant Level

The coolant expansion bottle provides a quick

visual method for determining that the coolant

level is adequate. With the engine off and cold, the

level of the coolant (antifreeze) in the bottle should

be between the “MAX” and “MIN” lines marked on

the bottle.

As long as the engine operating temperature is

satisfactory, the coolant bottle need only be

checked once a month.

When additional coolant is needed to maintain the

proper level, it should be added to the coolant

bottle. Do not overfill.

See an authorized dealer for service.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilo -

meters of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to

enter the radiator.

If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

WARNING!

Do not open hot engine cooling system. Never

add engine coolant (antifreeze) when the

engine is overheated. Do not loosen or

remove the cap to cool an overheated engine.

Heat causes pressure to build-up in the

cooling system. To prevent scalding or injury,

do not remove the pressure cap while the

system is hot or under pressure.

Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or

engine damage may result.

22_RUVG_OM_EN_USC_t.book Page 260

Page 263 of 316

SERVICING AND MAINTENANCE261

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Úpage 244.

Brake Master Cylinder

The fluid in the master cylinder should be checked

when performing under hood services or

immediately if the “Brake Warning Light” is

illuminated. Be sure to clean the top of the master cylinder area

before removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low

fluid level may be caused by a leak and a checkup

may be needed.

Use only manufacturer recommended brake fluid

Úpage 300.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer recommended brake

fluid Úpage 300. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in a open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum-based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

8

22_RUVG_OM_EN_USC_t.book Page 261

Page 264 of 316

262SERVICING AND MAINTENANCE

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission.

Avoid using transmission sealers as they may

adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer specified

transmission fluid

Úpage 300. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid.

NOTE:No chemical flushes should be used in any trans -

mission; only the approved lubricant should be

used.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.

CAUTION!

Using a transmission fluid other than

manufacturer recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder

Úpage 300.

22_RUVG_OM_EN_USC_t.book Page 262

Page 265 of 316

SERVICING AND MAINTENANCE263

FUSES

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check the

fuse element inside the blade fuse for a break/

melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery discharge.

Blade Fuses

Underhood Fuses

The Power Distribution Center (PDC) is located in

the engine compartment near the battery. This

center contains cartridge fuses, mini-fuses,

micro-fuses, circuit breakers and relays. A label

that identifies each component is printed on the

inside of the cover.

Before any procedure is done on the PDC, make

sure engine is turned off.

Remove the cover by unlatching the two locks

located at each side of the PDC cover, avoid using

screwdrivers or any other tool to remove the cover,

since they may apply excessive force and result in

a broken/damaged part.

After service is done, secure the cover with its two

locks.

NOTE:The function and amperage of these fuses are

different, depending on vehicle trim level and

content.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

Never replace a blown fuse with metal wires or

any other material. Do not place a fuse inside

a circuit breaker cavity or vice versa. Failure to

use proper fuses may result in serious

personal injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, transmission

system) or steering system blows, contact an

authorized dealer.1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)8

22_RUVG_OM_EN_USC_t.book Page 263

Page 266 of 316

264SERVICING AND MAINTENANCE

Power Distribution Center

22_RUVG_OM_EN_USC_t.book Page 264

Page 267 of 316

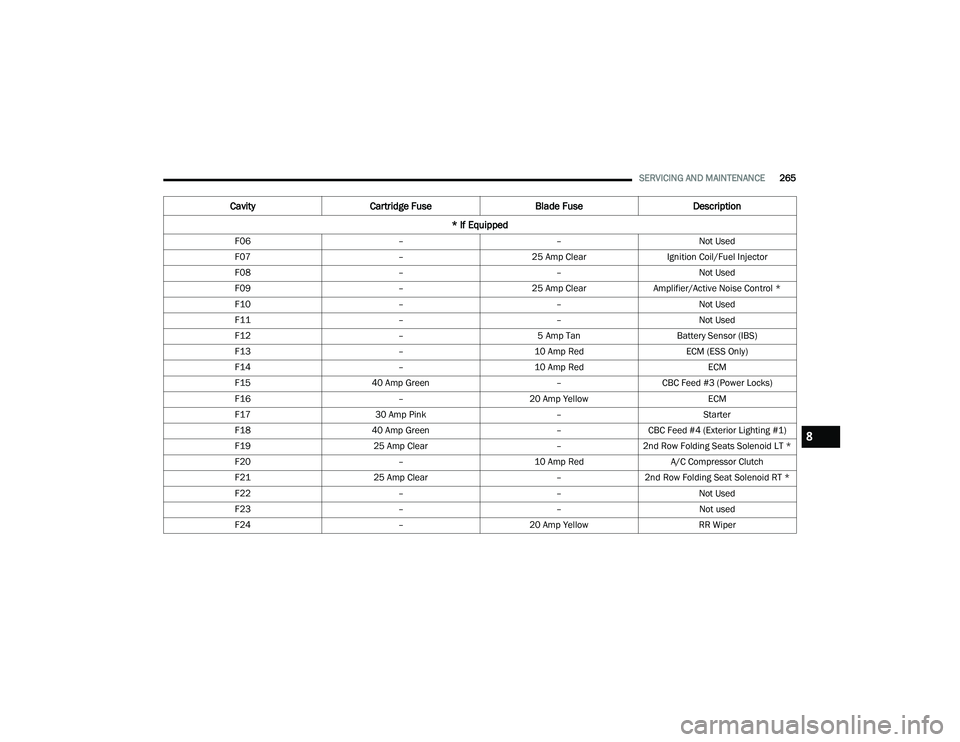

SERVICING AND MAINTENANCE265

CavityCartridge Fuse Blade FuseDescription

* If Equipped

F06 ––Not Used

F07 –25 Amp Clear Ignition Coil/Fuel Injector

F08 ––Not Used

F09 –25 Amp ClearAmplifier/Active Noise Control *

F10 ––Not Used

F11 ––Not Used

F12 –5 Amp TanBattery Sensor (IBS)

F13 –10 Amp Red ECM (ESS Only)

F14 –10 Amp Red ECM

F15 40 Amp Green –CBC Feed #3 (Power Locks)

F16 –20 Amp Yellow ECM

F17 30 Amp Pink –Starter

F18 40 Amp Green –CBC Feed #4 (Exterior Lighting #1)

F19 25 Amp Clear –2nd Row Folding Seats Solenoid LT *

F20 –10 Amp Red A/C Compressor Clutch

F21 25 Amp Clear –2nd Row Folding Seat Solenoid RT *

F22 ––Not Used

F23 ––Not used

F24 –20 Amp Yellow RR Wiper

8

22_RUVG_OM_EN_USC_t.book Page 265

Page 268 of 316

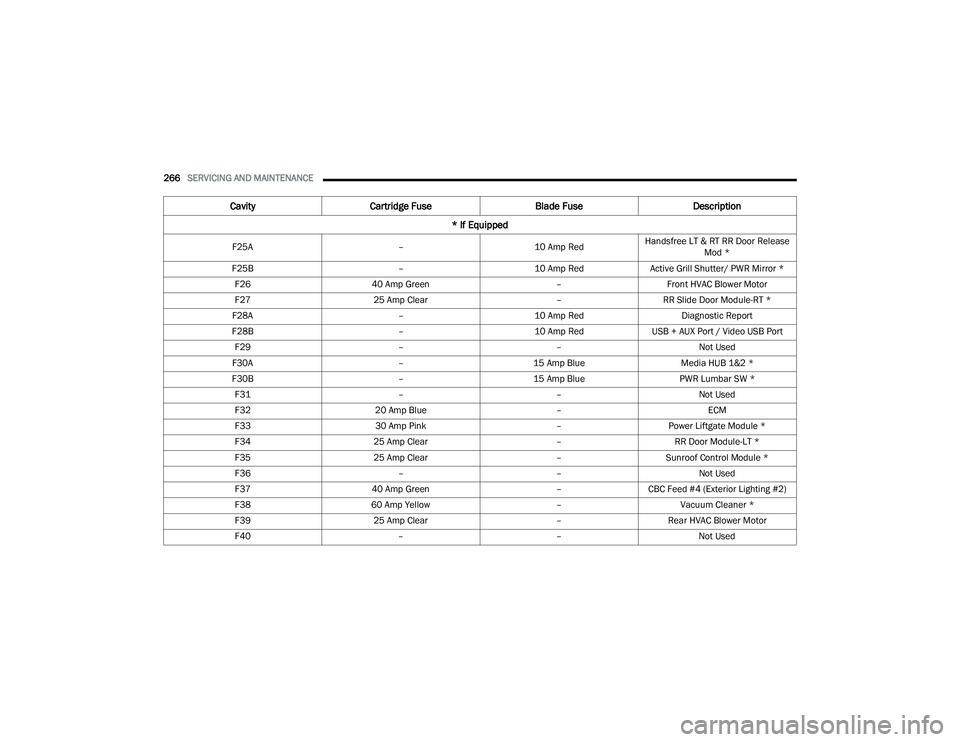

266SERVICING AND MAINTENANCE

F25A –10 Amp RedHandsfree LT & RT RR Door Release

Mod *

F25B –10 Amp RedActive Grill Shutter/ PWR Mirror *

F26 40 Amp Green –Front HVAC Blower Motor

F27 25 Amp Clear –RR Slide Door Module-RT *

F28A –10 Amp Red Diagnostic Report

F28B –10 Amp RedUSB + AUX Port / Video USB Port

F29 ––Not Used

F30A –15 Amp Blue Media HUB 1&2 *

F30B –15 Amp Blue PWR Lumbar SW *

F31 ––Not Used

F32 20 Amp Blue –ECM

F33 30 Amp Pink –Power Liftgate Module *

F34 25 Amp Clear –RR Door Module-LT *

F35 25 Amp Clear –Sunroof Control Module *

F36 ––Not Used

F37 40 Amp Green –CBC Feed #4 (Exterior Lighting #2)

F38 60 Amp Yellow –Vacuum Cleaner *

F39 25 Amp Clear –Rear HVAC Blower Motor

F40 ––Not Used

CavityCartridge Fuse Blade FuseDescription

* If Equipped

22_RUVG_OM_EN_USC_t.book Page 266

Page 269 of 316

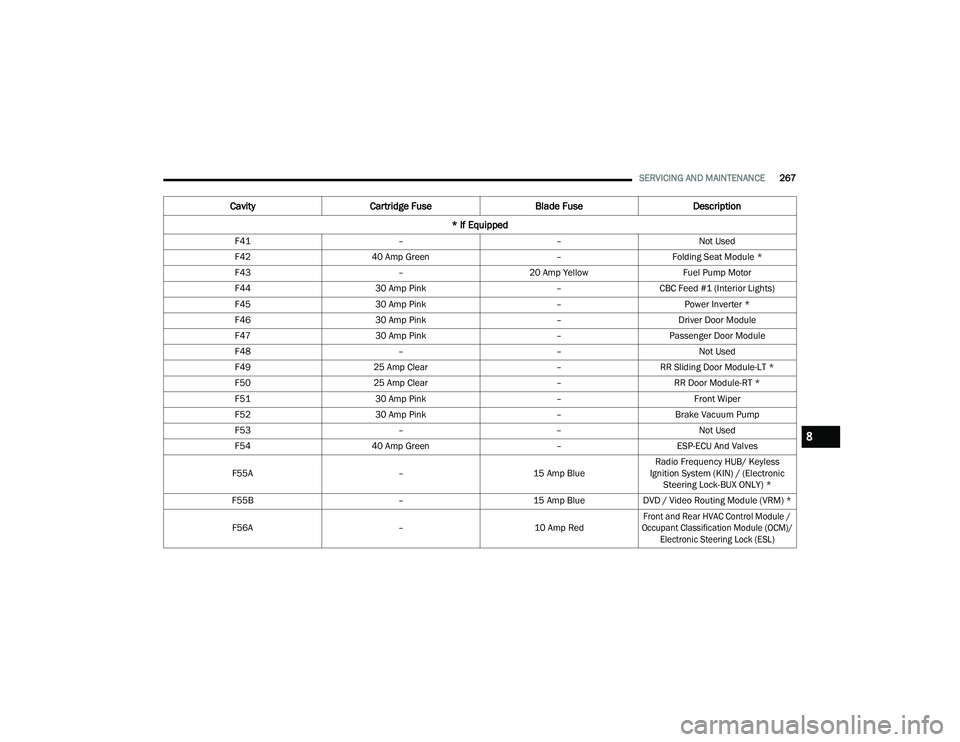

SERVICING AND MAINTENANCE267

F41 ––Not Used

F42 40 Amp Green –Folding Seat Module *

F43 –20 Amp Yellow Fuel Pump Motor

F44 30 Amp Pink –CBC Feed #1 (Interior Lights)

F45 30 Amp Pink –Power Inverter *

F46 30 Amp Pink –Driver Door Module

F47 30 Amp Pink –Passenger Door Module

F48 ––Not Used

F49 25 Amp Clear –RR Sliding Door Module-LT *

F50 25 Amp Clear –RR Door Module-RT *

F51 30 Amp Pink –Front Wiper

F52 30 Amp Pink –Brake Vacuum Pump

F53 ––Not Used

F54 40 Amp Green –ESP-ECU And Valves

F55A –15 Amp BlueRadio Frequency HUB/ Keyless

Ignition System (KIN) / (Electronic Steering Lock-BUX ONLY) *

F55B –15 Amp BlueDVD / Video Routing Module (VRM) *

F56A –10 Amp Red

Front and Rear HVAC Control Module /

Occupant Classification Module (OCM)/ Electronic Steering Lock (ESL)

Cavity Cartridge Fuse Blade FuseDescription

* If Equipped

8

22_RUVG_OM_EN_USC_t.book Page 267

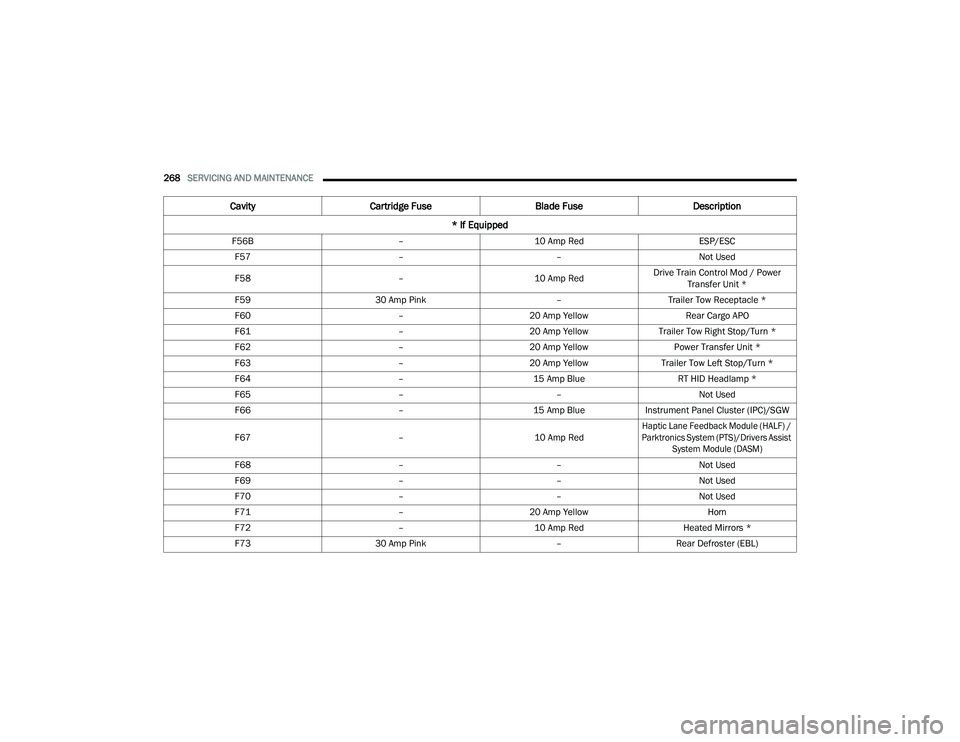

Page 270 of 316

268SERVICING AND MAINTENANCE

F56B –10 Amp Red ESP/ESC

F57 ––Not Used

F58 –10 Amp RedDrive Train Control Mod / Power

Transfer Unit *

F59 30 Amp Pink –Trailer Tow Receptacle *

F60 –20 Amp Yellow Rear Cargo APO

F61 –20 Amp YellowTrailer Tow Right Stop/Turn *

F62 –20 Amp Yellow Power Transfer Unit *

F63 –20 Amp Yellow Trailer Tow Left Stop/Turn *

F64 –15 Amp Blue RT HID Headlamp *

F65 ––Not Used

F66 –15 Amp BlueInstrument Panel Cluster (IPC)/SGW

F67 –10 Amp Red

Haptic Lane Feedback Module (HALF) /

Parktronics System (PTS)/Drivers Assist System Module (DASM)

F68 ––Not Used

F69 ––Not Used

F70 ––Not Used

F71 –20 Amp Yellow Horn

F72 –10 Amp Red Heated Mirrors *

F73 30 Amp Pink –Rear Defroster (EBL)

Cavity Cartridge Fuse Blade FuseDescription

* If Equipped

22_RUVG_OM_EN_USC_t.book Page 268