low oil pressure CHRYSLER VOYAGER 2023 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2023, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2023Pages: 256, PDF Size: 13.97 MB

Page 10 of 256

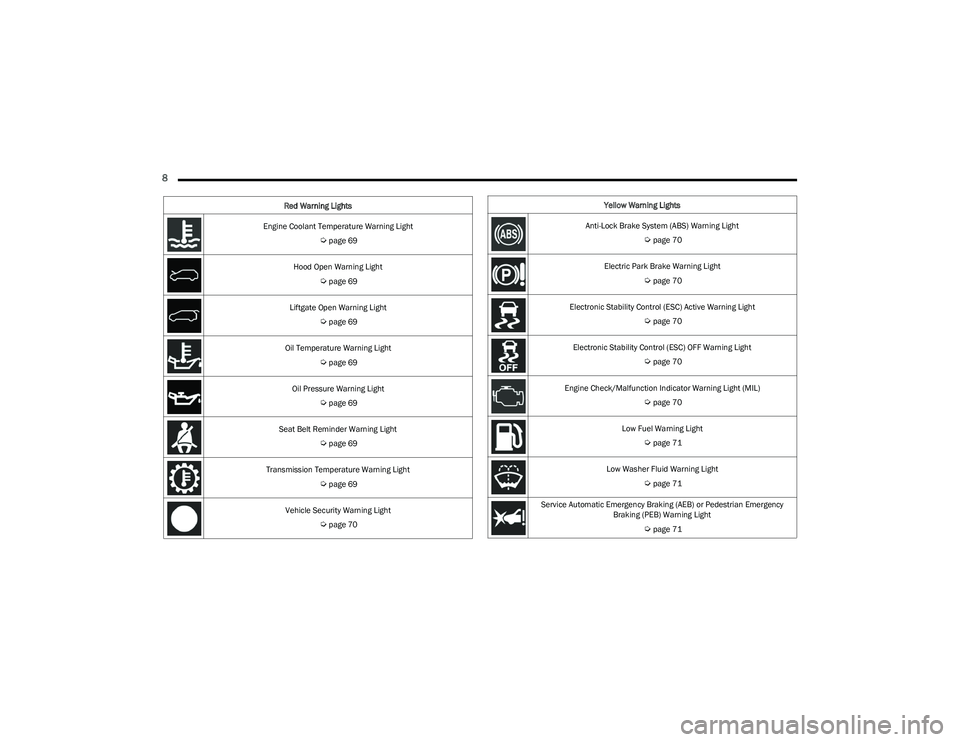

8

Engine Coolant Temperature Warning Light

Úpage 69

Hood Open Warning Light

Úpage 69

Liftgate Open Warning Light

Úpage 69

Oil Temperature Warning Light

Úpage 69

Oil Pressure Warning Light

Úpage 69

Seat Belt Reminder Warning Light

Úpage 69

Transmission Temperature Warning Light

Úpage 69

Vehicle Security Warning Light

Úpage 70

Red Warning Lights

Yellow Warning Lights

Anti-Lock Brake System (ABS) Warning Light

Úpage 70

Electric Park Brake Warning Light

Úpage 70

Electronic Stability Control (ESC) Active Warning Light

Úpage 70

Electronic Stability Control (ESC) OFF Warning Light

Úpage 70

Engine Check/Malfunction Indicator Warning Light (MIL)

Úpage 70

Low Fuel Warning Light

Úpage 71

Low Washer Fluid Warning Light

Úpage 71

Service Automatic Emergency Braking (AEB) or Pedestrian Emergency Braking (PEB) Warning Light

Úpage 71

23_RUV_OM_EN_US_t.book Page 8

Page 66 of 256

64GETTING TO KNOW YOUR INSTRUMENT PANEL

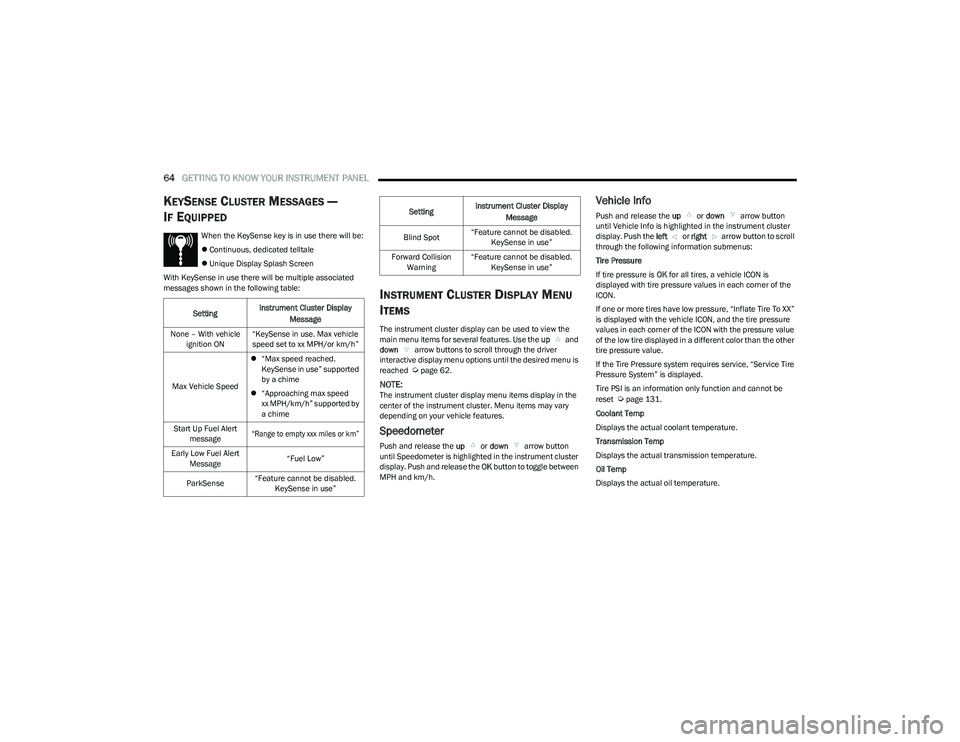

KEYSENSE CLUSTER MESSAGES —

I

F EQUIPPED

When the KeySense key is in use there will be:

Continuous, dedicated telltale

Unique Display Splash Screen

With KeySense in use there will be multiple associated

messages shown in the following table:

INSTRUMENT CLUSTER DISPLAY MENU

I

TEMS

The instrument cluster display can be used to view the

main menu items for several features. Use the up and

down arrow buttons to scroll through the driver

interactive display menu options until the desired menu is

reached

Úpage 62.

NOTE:The instrument cluster display menu items display in the

center of the instrument cluster. Menu items may vary

depending on your vehicle features.

Speedometer

Push and release the up or down arrow button

until Speedometer is highlighted in the instrument cluster

display. Push and release the OK button to toggle between

MPH and km/h.

Vehicle Info

Push and release the up or down arrow button

until Vehicle Info is highlighted in the instrument cluster

display. Push the left or right arrow button to scroll

through the following information submenus:

Tire Pressure

If tire pressure is OK for all tires, a vehicle ICON is

displayed with tire pressure values in each corner of the

ICON.

If one or more tires have low pressure, “Inflate Tire To XX”

is displayed with the vehicle ICON, and the tire pressure

values in each corner of the ICON with the pressure value

of the low tire displayed in a different color than the other

tire pressure value.

If the Tire Pressure system requires service, “Service Tire

Pressure System” is displayed.

Tire PSI is an information only function and cannot be

reset

Úpage 131.

Coolant Temp

Displays the actual coolant temperature.

Transmission Temp

Displays the actual transmission temperature.

Oil Temp

Displays the actual oil temperature.

Setting

Instrument Cluster Display

Message

None – With vehicle ignition ON “KeySense in use. Max vehicle

speed set to xx MPH/or km/h”

Max Vehicle Speed

“Max speed reached.

KeySense in use” supported

by a chime

“Approaching max speed

xx MPH/km/h” supported by

a chime

Start Up Fuel Alert message

“Range to empty xxx miles or km”

Early Low Fuel Alert Message “Fuel Low”

ParkSense “Feature cannot be disabled.

KeySense in use”

Blind Spot “Feature cannot be disabled.

KeySense in use”

Forward Collision Warning “Feature cannot be disabled.

KeySense in use”

Setting

Instrument Cluster Display

Message

23_RUV_OM_EN_US_t.book Page 64

Page 67 of 256

GETTING TO KNOW YOUR INSTRUMENT PANEL65

Oil Pressure

Displays the actual oil pressure.

Oil Life

Displays the remaining engine oil life as a percentage.

To reset the Oil Life, you must hold the OK button.

The “Hold OK to Reset” instruction will be displayed at all

times, but the following conditions will need to be met in

order to reset Oil Life:

The ignition must be in the ON/RUN position

If the conditions are met, holding the OK button will reset

the gauge and the numeric display will return to 100%.

If the conditions are not met, a pop-up message will

display for five seconds, describing the required

conditions, and then the Oil Life screen will reappear.

Battery Voltage

Displays the actual battery voltage.

Engine Hours — If Equipped

Displays the number of hours of engine operation.

Driver Assist — If Equipped

Push and release the up or down arrow button

until the Driver Assist display icon is highlighted in the

instrument cluster display

Úpage 86.

Fuel Economy

Push and release the up or down arrow button

until the Fuel Economy Menu item is highlighted in the

instrument cluster display. The Fuel Economy Menu will

display the following:

Two submenu pages that can be toggled between

using the left and right arrow buttons; one

with Current Value displayed and one without the

Current Value displayed:

Average Fuel Economy (MPG, L/100 km, or km/L)

Range To Empty (miles or km)

Current Fuel Economy (MPG, L/100 km, or km/L)

The Max and Min values will correspond to the

particular engine requirements

Hold OK to reset average fuel eco nomy information.

Trip Info

Push and release the up or down arrow button

until the Trip Menu item is highlighted in the instrument

cluster display. Push the left or right arrow button

to scroll through the Trip A and Trip B submenus. The Trip

information will display the following:

Distance

Average Fuel Economy

Elapsed Time

Hold the OK button to reset feature information.

Stop / Start – If Equipped

Push and release the up or down arrow button

until the Stop/Start menu title is displayed in the

instrument cluster display.

Audio

Push and release the up or down arrow button

until the Audio Menu displays in the instrument cluster

display.

Messages

Push and release the up or down arrow button

until Messages is highlighted in the instrument cluster

display. This feature shows the number of stored warning

messages. Pushing the right arrow button will allow

you to see what the stored messages are.

NOTE:The pop-up messages indicate the status of the system

and/or the conditions that need to be met. Messages

remain in the stored stack until condition is cleared.

Screen Setup

Push and release the up or down arrow button

until the Screen Setup Menu displays in the instrument

cluster display. Push and release the OK button to enter

the submenus. The Screen Setup feature allows you to

change what information is displayed in the instrument

cluster as well as the location that information is

displayed.

NOTE:Based on your vehicles trim level, some of the following

options may not be available.

3

23_RUV_OM_EN_US_t.book Page 65

Page 71 of 256

GETTING TO KNOW YOUR INSTRUMENT PANEL69

NOTE:This light may turn on if the accelerator and brake pedals

are pressed at the same time.

If the light continues to flash when the vehicle is running,

immediate service is required and you may experience

reduced performance, an elevated/rough idle, or engine

stall and your vehicle may require towing. The light will

come on when the ignition is placed in the ON/RUN or

ACC/ON/RUN position and remain on briefly as a bulb

check. If the light does not come on during starting, have

the system checked by an authorized dealer.

Engine Coolant Temperature Warning Light

This warning light warns of an overheated

engine condition. If the engine coolant

temperature is too high, this indicator will

illuminate and a single chime will sound. If the

temperature reaches the upper limit, a continuous chime

will sound for four minutes or until the engine is able to

cool; whichever comes first.

If the light turns on while driving, safely pull over and stop

the vehicle. If the Air Conditioning (A/C) system is on, turn

it off. Also, shift the transmission into NEUTRAL (N) and

idle the vehicle. If the temperature reading does not return

to normal, turn the engine off immediately and call for

service

Úpage 187.

Hood Open Warning Light

This warning light will illuminate when the hood

is left open and not fully closed.

NOTE:If the vehicle is moving, there will also be a single chime.

Liftgate Open Warning Light

This warning light will illuminate when the

liftgate is open.

NOTE:If the vehicle is moving, there will also be a single chime.

Oil Temperature Warning Light

This warning light will illuminate to indicate the

engine oil temperature is high. If the light turns

on while driving, stop the vehicle and shut off

the engine as soon as possible. Wait for oil

temperature to return to normal levels.

Oil Pressure Warning Light

This warning light will illuminate to indicate low

engine oil pressure. If the light turns on while

driving, stop the vehicle, shut off the engine as

soon as possible, and contact an authorized

dealer. A chime will sound when this light turns on.

Do not operate the vehicle until the cause is corrected.

This light does not indicate how much oil is in the engine.

The engine oil level must be checked under the hood.

Seat Belt Reminder Warning Light

This warning light indicates when the driver or

passenger seat belt is unbuckled. When the

ignition is first placed in the ON/RUN or

ACC/ON/RUN position and if the driver’s seat

belt is unbuckled, a chime will sound and the light will turn on. When driving, if the driver or front passenger seat belt

remains unbuckled, the Seat Belt Reminder Light will flash

or remain on continuously and a chime will sound

Úpage 134.

Transmission Temperature Warning Light

This warning light will illuminate to warn of a

high transmission fluid temperature. This may

occur with strenuous usage such as trailer

towing. If this light turns on, stop the vehicle

and run the engine at idle or slightly faster, with the

transmission in PARK (P) or NEUTRAL (N), until the light

turns off. Once the light turns off, you may continue to

drive normally.

WARNING!

If you continue operating the vehicle when the Transmission

Temperature Warning Light is illuminated you could cause

the fluid to boil over, come in contact with hot engine or

exhaust components and cause a fire.

CAUTION!

Continuous driving with the Transmission Temperature

Warning Light illuminated will eventually cause severe

transmission damage or transmission failure.

3

23_RUV_OM_EN_US_t.book Page 69

Page 181 of 256

IN CASE OF EMERGENCY179

PORTABLE AIR COMPRESSOR —

I

F EQUIPPED

Your vehicle may be equipped with a Portable Air

Compressor. Use the Portable Air Compressor located in

the side compartment of the cargo area to inflate the

inflatable tire to 60 psi (4.2 Bar).

Portable Air Compressor

Portable Air Compressor Usage With Inflatable Spare Tire

1. Remove the Portable Air Compressor from the

storage location.

2. Raise the vehicle as described in the Jacking

Instructions within this section.

3. Install the Inflatable Spare tire as described

in the Jack Instructions section in this manual.

Make sure that the valve stem is located near

the ground, and then screw the air hose of the

Portable Air Compressor to the valve stem.

4. Uncoil the power plug and connect it the

vehicles 12 Volt power Outlet.

5. Always start the engine before turning ON

the Portable Air Compressor.

6. Switch the power button ON.

7. Inflate the tire to 60 psi (4.2 Bar)

recommended as per the label on the wheel or

if the vehicle equipped with the inflatable spare

tire pressure indicated on the Tire and Loading

information label located on the driver-side door opening.NOTE:If the tire is overinflated, use the deflation button to

reduce the tire air pressure.

8. After the tire reaches the recommended

pressure, lower the vehicle with the jack as

described in the Jack Instructions section in

this manual.

9. Remove the speed limit label sticker from

the Portable Air Compressor and place it on the

center of the steering wheel.

10. Return the Portable Air Compressor to the foam tray and secure it with the strap. Store the foam tray in the

cargo area.

1 — Power Plug

2 — Deflation Button

3 — Pressure Gauge

4 — Power Button

5 — Air Hose

WARNING!

Do not lift or carry the Portable Air Compressor by

the hose.

Always stow the Portable Air Compressor only in the

provided place.

The metal end fitting from Power Plug may get hot

after use, so it should be handled carefully.

Keep the Portable Air Compressor away from open

flames or heat source.

7

23_RUV_OM_EN_US_t.book Page 179

Page 185 of 256

IN CASE OF EMERGENCY183

If the sealant (white fluid) does flow through the

Sealant Hose:

1. Continue to operate the pump until sealant

is no longer flowing through hose (typically

takes 30 - 70 seconds). As the sealant flows

through the Sealant Hose, the Pressure

Gauge can read as high as 70 psi (4.8 Bar). The Pressure

Gauge will decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the Sealant

Bottle is empty.

2. The pump will start to inject air into the tire

immediately after the Sealant Bottle is empty.

Continue to operate the pump and inflate the

tire to the cold tire inflation pressure found

on the tire and loading information label located in the

driver-side door opening. Check the tire pressure by

looking at the Pressure Gauge.

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

1. Push the Power Button to turn the Tire

Service Kit off.

2. Remove the speed limit label from the Tire

Service Kit and place sticker on the steering

wheel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the fitting at the end

of the hose, and place the Tire Service Kit in the

vehicle storage location.

Drive Vehicle: Immediately after injecting sealant and

inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution

of the Tire Service Kit Sealant within the tire.

Do not exceed 50 mph (80 km/h).

After Driving:

Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hose to reach the

valve stem and keep the Tire Service Kit flat on the ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

Place the transmission in PARK (P) and cycle the igni -

tion in the OFF position.

Apply the parking brake.

If tire has improper inflation, see the following the steps.

1. Uncoil the Sealant Hose, and then remove the cap from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on the ground

next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the Sealant Hose onto the

valve stem.

4. Uncoil the Power Plug and insert the plug

into the vehicle's 12 Volt power outlet.

5. Uncoil the Hose and screw the fitting at the

end of the hose onto the valve stem.

6. Turn the Mode Select Knob and turn to the

Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

WARNING!

The Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using the Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced. Failure

to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you. Have the tire checked as soon as possible

at an authorized dealer.

7

23_RUV_OM_EN_US_t.book Page 183

Page 198 of 256

196SERVICING AND MAINTENANCE

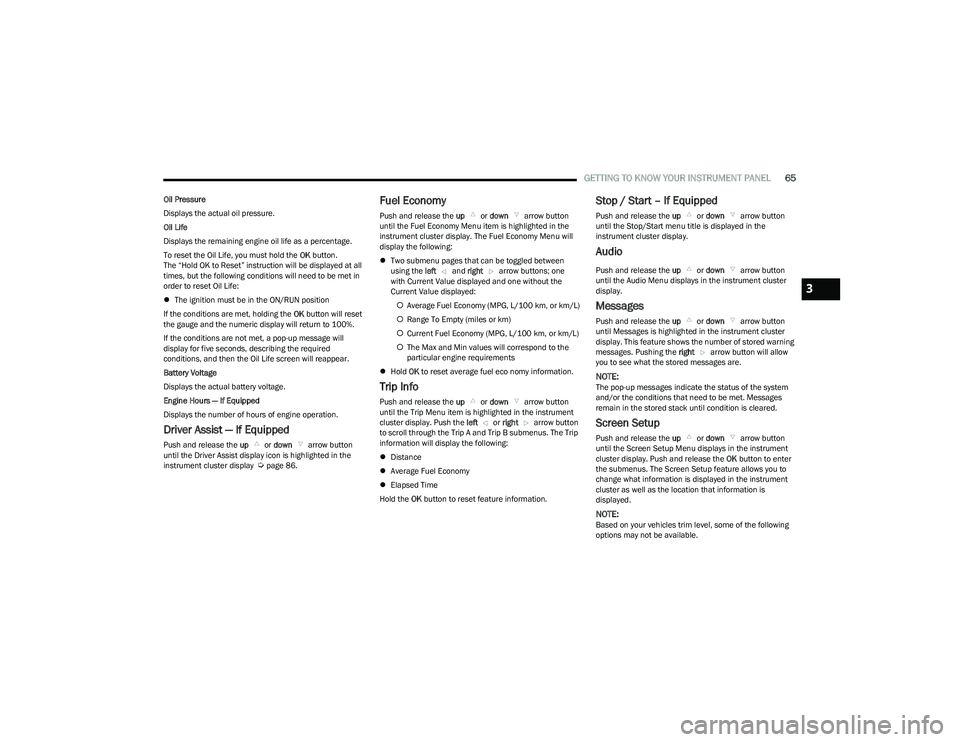

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop. The best time to

check the engine oil level is about five minutes after a fully

warmed up engine is shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low end of

the range and MAX at the high end of the range.

Crosshatched zone marked with dimples at the MIN

and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 qt (1 L) of oil when the reading is at the low end

of the dipstick range will raise the oil level to the high end

of the range marking.

ADDING WASHER FLUID

The fluid reservoir is located in the front of the engine

compartment. Be sure to check the fluid level in the

reservoir at regular intervals. Fill the reservoir with

windshield washer solvent (not radiator antifreeze) and

operate the system for a few seconds to flush out the

residual washer fluid.

When refilling the washer fluid reservoir, take some

washer fluid, apply it to a cloth or towel, and wipe clean the

wiper blades; this will help blade performance.

To prevent freeze-up of your windshield washer system in

cold weather, select a solution or mixture that meets or

exceeds the temperature range of your climate. This rating

information can be found on most washer fluid containers.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free battery.

You will never have to add water, and periodic

maintenance is not required.CAUTION!

Overfilling or underfilling the crankcase will cause

aeration or loss of oil pressure. This could damage your

engine.

WARNING!

Commercially available windshield washer solvents are

flammable. They could ignite and burn you. Care must

be exercised when filling or working around the washer

solution.

WARNING!

Battery fluid is a corrosive acid solution and can burn

or even blind you. Do not allow battery fluid to

contact your eyes, skin, or clothing. Do not lean over

a battery when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately with large

amounts of water

Úpage 185.

Battery gas is flammable and explosive. Keep flame

or sparks away from the battery. Do not use a

booster battery or any other booster source with an

output greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands after

handling.

CAUTION!

It is essential when replacing the cables on the

battery that the positive cable is attached to the posi -

tive post and the negative cable is attached to the

negative post. Battery posts are marked positive (+)

and negative (-) and are identified on the battery

case. Cable clamps should be tight on the terminal

posts and free of corrosion.

If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables

before connecting the charger to the battery. Do not

use a “fast charger” to provide starting voltage.

23_RUV_OM_EN_US_t.book Page 196

Page 199 of 256

SERVICING AND MAINTENANCE197

PRESSURE WASHING

Cleaning the engine compartment with a high pressure

washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service

operations in an expert manner. Service Manuals are

available which include detailed service information for

your vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control systems may

void your warranty and could result in civil penalties being

assessed against you.

ENGINE OIL

Engine Oil Selection

Use only the manufacturer's recommended fluid Úpage 238.

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified by the API.

The manufacturer only recommends API trademark oils.

The API Starburst trademark certifies 0W-20,

0W-30 and 5W-30 engine oils.

The API Donut trademark certifies 0W-40 and

5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils, only

use synthetic API approved engine oils.

Synthetic engine oils which do not have both the correct

API trademark and the correct SAE viscosity grade

numbers should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product

and its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and oil

filters from your vehicle. Used oil and oil filters, indiscriminately

discarded, can present a problem to the environment. Contact

an authorized dealer, service station or governmental agency

for advice on how and where used oil and oil filters can be

safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used for

replacement. The quality of replacement filters varies

considerably. Only high quality Mopar® certified filters

should be used. If a Mopar® Engine Oil Filters are

unavailable only use filters that meet or exceed

SAE/USCAR-36 Filter Performance Requirements.

CAUTION!

Precautions have been taken to safeguard all parts and

connections however, the pressures generated by these

machines is such that complete protection against

water ingress cannot be guaranteed.

WARNING!

You can be badly injured working on or around a motor

vehicle. Only do service work for which you have the

knowledge and the proper equipment. If you have any

doubt about your ability to perform a service job, take

your vehicle to a competent mechanic.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is

not covered by the New Vehicle Limited Warranty.

8

23_RUV_OM_EN_US_t.book Page 197

Page 201 of 256

SERVICING AND MAINTENANCE199

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.

Refrigerant Recovery And Recycling —

R–1234yf

R–1234yf Air Conditioning Refrigerant is a Hydrofluo -

roolefin (HFO) that is endorsed by the Environmental

Protection Agency and is an ozone-friendly substance with

a low global-warming potential. It is recommended that air

conditioning service be performed by an authorized dealer

using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil, and refrigerants.

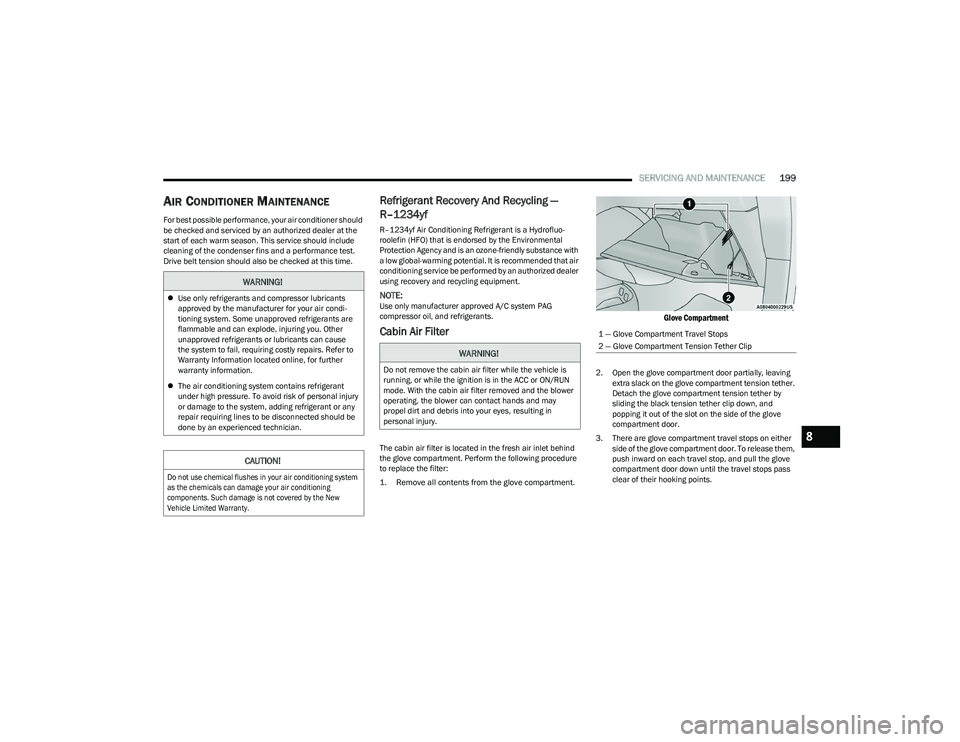

Cabin Air Filter

The cabin air filter is located in the fresh air inlet behind

the glove compartment. Perform the following procedure

to replace the filter:

1. Remove all contents from the glove compartment.

Glove Compartment

2. Open the glove compartment door partially, leaving extra slack on the glove compartment tension tether.

Detach the glove compartment tension tether by

sliding the black tension tether clip down, and

popping it out of the slot on the side of the glove

compartment door.

3. There are glove compartment travel stops on either side of the glove compartment door. To release them,

push inward on each travel stop, and pull the glove

compartment door down until the travel stops pass

clear of their hooking points.

WARNING!

Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi -

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause

the system to fail, requiring costly repairs. Refer to

Warranty Information located online, for further

warranty information.

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced technician.

CAUTION!

Do not use chemical flushes in your air conditioning system

as the chemicals can damage your air conditioning

components. Such damage is not covered by the New

Vehicle Limited Warranty.

WARNING!

Do not remove the cabin air filter while the vehicle is

running, or while the ignition is in the ACC or ON/RUN

mode. With the cabin air filter removed and the blower

operating, the blower can contact hands and may

propel dirt and debris into your eyes, resulting in

personal injury.

1 — Glove Compartment Travel Stops

2 — Glove Compartment Tension Tether Clip

8

23_RUV_OM_EN_US_t.book Page 199

Page 208 of 256

206SERVICING AND MAINTENANCE

(Continued)

As long as the engine operating temperature is satisfactory, the

coolant bottle need only be checked once a month.

When additional coolant is needed to maintain the proper

level, it should be added to the coolant bottle. Do not

overfill.

See an authorized dealer for service.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilometers

of operation, you may observe vapor coming from the front

of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumulating

on the radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to enter

the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant needs

to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

If frequent engine coolant additions are required, the

cooling system should be pressure tested for leaks.

Maintain engine coolant concentration at a minimum

of 50% OAT coolant (conforming to MS.90032) and

distilled water for proper corrosion protection of your

engine which contains aluminum components.

Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine cooling performance,

poor gas mileage, and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all brake

system components should be inspected periodically.

For the proper maintenance intervals

Úpage 193.

Brake Master Cylinder

The fluid in the master cylinder should be checked when

performing under hood services or immediately if the

Brake Warning Light is illuminated.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the fluid

level up to the requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be expected to

fall as the brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low fluid level

may be caused by a leak and a checkup may be needed.

Use only manufacturer recommended brake fluid

Úpage 239.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on

the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

Use only manufacturer recommended brake fluid Úpage 239. Using the wrong type of brake fluid can

severely damage your brake system and/or impair its

performance. The proper type of brake fluid for your

vehicle is also identified on the original factory

installed hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or moisture,

use only new brake fluid or fluid that has been in a tightly

closed container. Keep the master cylinder reservoir cap

secured at all times. Brake fluid in an open container

absorbs moisture from the air resulting in a lower boiling

point. This may cause it to boil unexpectedly during hard

or prolonged braking, resulting in sudden brake failure.

This could result in a collision.

23_RUV_OM_EN_US_t.book Page 206