CITROEN C-CROSSER 2012 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2012, Model line: C-CROSSER, Model: CITROEN C-CROSSER 2012Pages: 244, PDF Size: 7.45 MB

Page 131 of 244

VIII

CHECKS

129

CHECKING LEVELS

Brake fluid level

To avoid any risk of scalding, unscrew

the cap by two turns to allow the pres-

sure to drop. When the pressure has

dropped, remove the cap and top up

the level.

Oil level

The reading will only be correct

if the vehicle is on level ground

and the engine has been off for

more than 30 minutes.

The check is carried out either when

the ignition is switched on using the oil

level indicator on the instrument panel,

or using the dipstick.

It is normal to top up the engine oil between

services. The manufacturer recommends

that the oil level be checked, and topped up

if necessary, every 3 000 miles (5 000 km).

The brake fl uid level should be

between the "MAX" and "MIN"

marks.

If it is not, check the brake pad

wear.

Changing the brake fl uid

Refer to the servicing booklet for details

of the interval for this operation.

Coolant level

The coolant level must be mea-

sured when the engine is cold

and should be between the

"LOW" and "FULL" marks.

When the engine is warm, the

temperature of the coolant is regulated

by the fan. This can operate with the ig-

nition off.

On vehicles which are fi tted with a

particle emission fi lter, the fan may

operate after the vehicle has been

switched off, even if the engine is

cold.

In addition, as the cooling system is

pressurised, wait at least one hour after

switching off the engine before carrying

out any work.

Screenwash and headlamp

wash * fluid

Check the fl uid level regularly,

using the gauge.

*

According to country.

Changing the engine oil

Refer to the servicing booklet for details

of the interval for this operation.

In order to maintain the reliability of the

engine and emission control system,

the use of additives in the engine oil is

prohibited.

Oil specifi cation

The oil must correspond to your engine

and conform to the manufacturer's recom-

mendations.

Fluid specifi cation

The brake fl uid must conform to the

manufacturer's recommendations and

fulfi l the DOT4 standards.

Changing the coolant fl uid

Refer to the servicing booklet for details

of the interval for this operation.

Fluid specifi cation

The coolant must conform to the manu-

facturer's recommendations.

Fluid specifi cation

This fl uid must conform to the manufac-

turer's recommendations for optimum

cleaning.

Power steering fluid level

Check the fl uid level with the engine at

idle.

Check that the power steering fl uid

level is always between the "MAX" and

"MIN" marks and top up if necessary.

Fluid specifi cation

This fl uid must conform to the manufac-

turer's recommendations.

Check all of these levels regularly and

top them up if necessary, unless other-

wise indicated.

If a level drops signifi cantly, have the

corresponding system checked by a

CITROËN dealer or a qualifi ed work-

shop.

When working under the bonnet, take

care as certain areas of the engine may

be extremely hot (risk of burns).

Page 132 of 244

VIII

!

CHECKS

130

Diesel additive level (Diesel

with particle emission filter) The minimum level of this additive is indicat-

ed by lighting of the service warning lamp,

accompanied by an audible signal and a

message on the multifunction screen.

Topping up

This additive must be topped up by a

CITROËN dealer or a qualifi ed work-

shop without delay.

Waste productsCHECK

S

Battery

Check the electrolyte level

regularly. If necessary, top up

the level with distilled water.

Check that the terminals are

clean and correctly tightened,

particularly in summer and winter.

When carrying out work on the battery,

refer to the "Practical information" sec-

tion for details of the precautions to be

taken before disconnecting the battery

and following its reconnection.

Air filter and passenger compartment filter

Refer to the servicing booklet

for details of the replacement

intervals for these compo-

nents.

Depending on the environ-

ment (dusty atmosphere...) and the use

of the vehicle (city driving...), replace

them twice as often if necessary (refer

to the "Engines" paragraph).

A clogged passenger compartment fi l-

ter may have an adverse effect on the

performance of the air conditioning sys-

tem and generate undesirable odours.

Oil filter

Replace the oil fi lter each time

the engine oil is changed.

Refer to the servicing booklet

for details of the replacement

interval for this component.

Particle emission filter (Diesel)

Maintenance of the particle emission fi l-

ter must be carried out by a CITROËN

dealer or a qualifi ed workshop.

Following prolonged operation of

the vehicle at very low speed or at

idle, you may, exceptionally, notice

the emission of water vapour at the

exhaust on acceleration. This does

not have any adverse effect on the

performance of the vehicle or on the

environment.

Avoid any prolonged contact of

used oil or fl uids with the skin.

Most of these fl uids are harmful to

health or indeed very corrosive.

Do not discard used oil or fl uids

into sewers or onto the ground.

Empty used oil into the contain-

ers provided for this purpose at

CITROËN dealers (France) or a

qualifi ed workshop, or take them to

an authorised waste disposal site.

Do not discard the oil fi lter through public

channels, deposit it in the containers dedi-

cated to this use in the CITROËN network

(France) or a qualifi ed workshop or take them to

an authorised waste disposal site.

Unless otherwise indicated, check

these components in accordance with

the servicing booklet and in relation to

your engine.

Otherwise, have them checked by a

CITROËN dealer or a qualifi ed workshop.

Page 133 of 244

VIII

!

CHECKS

131

Manual gearbox

Refer to the servicing booklet

for details of gearbox mainte-

nance.

Brake pads

Brake wear depends on the

style of driving, particularly in

the case of vehicles used in

town, over short distances. It

may be necessary to have the

condition of the brakes checked, even

between vehicle services.

Unless there is a leak on the circuit, a

drop in the brake fl uid level indicates

that the brake pads are worn.

Brake disc wear

For information on checking

brake disc wear, contact a

CITROËN dealer or a quali-

fi ed workshop.

Parking brake

If the parking brake travel is

too long or if you notice a loss

of effectiveness of this sys-

tem, the parking brake must

be adjusted, even between

two services.

This system must be checked by a

CITROËN dealer or a qualifi ed workshop.

Only use products recommended by

CITROËN or products of equivalent

quality and specifi cations.

In order to optimise the operation

of units as important as the braking

system, CITROËN selects and

offers very specifi c products.

To avoid damaging the electrical

units, the use of a high pressure

washer in the engine compartment is

strictly prohibited.

Transfer box and rear differential

Refer to the servicing booklet

for details of the service inter-

val for these components.

Page 134 of 244

IX

!

PRACTICAL INFORMATION

132

CHANGING A WHEEL

1.

Wheelbrace.

Used to remove the wheel trim and

the wheel fi xing bolts.

2.

Jack.

Used to raise the vehicle.

3.

Handle.

Used to extend the jack.

4.

Removable towing eye.

Refer to the "Towing" paragraph.

Other accessories

Wheel with trim

When removing the wheel

, remove

the trim fi rst using the handle 3

, pulling

at the notch.

When refi tting the wheel

, refi t the trim

starting by placing its notch F

(indicated

on the back of the trim) opposite the

valve G

and press on its outer edge

with the palm of your hand.

List of tools

When changing a wheel, ensure

that the four wheels are of identi-

cal specifi cation and brand. When storing, take care to secure

the tool bag D

fi rmly using the fi xing

band C

.

Access to the tools

The tools are stored in the storage

compartment in the boot right-hand trim.

To gain access to them:

�)

open the boot,

�)

turn button A

to the left,

�)

remove the cover B

,

�)

remove the fi xing band C

and take

out the tool bag D

containing the

tools,

�)

take the jack E

in your hand and re-

move it from its fi xing position.

Page 135 of 244

IX

PRACTICAL INFORMATION

133

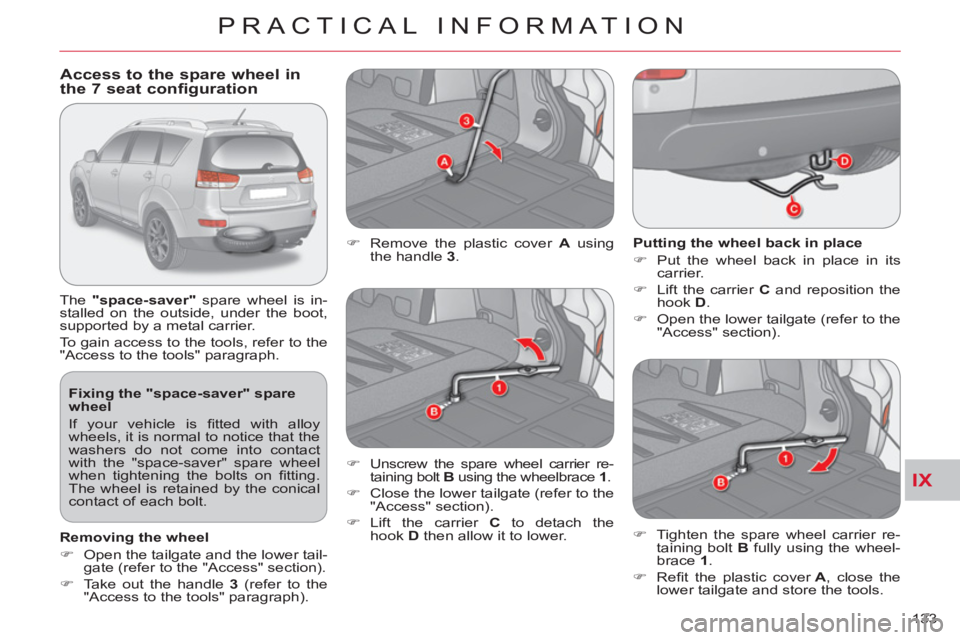

Fixing the "space-saver" spare

wheel

If your vehicle is fi tted with alloy

wheels, it is normal to notice that the

washers do not come into contact

with the "space-saver" spare wheel

when tightening the bolts on fi tting.

The wheel is retained by the conical

contact of each bolt.

Access to the spare wheel in

the 7 seat configuration

The "space-saver"

spare wheel is in-

stalled on the outside, under the boot,

supported by a metal carrier.

To gain access to the tools, refer to the

"Access to the tools" paragraph.

Putting the wheel back in place

�)

Put the wheel back in place in its

carrier.

�)

Lift the carrier C

and reposition the

hook D

.

�)

Open the lower tailgate (refer to the

"Access" section).

�)

Remove the plastic cover A

using

the handle 3

.

�)

Unscrew the spare wheel carrier re-

taining bolt B

using the wheelbrace 1

.

�)

Close the lower tailgate (refer to the

"Access" section).

�)

Lift the carrier C

to detach the

hook D

then allow it to lower.

�)

Tighten the spare wheel carrier re-

taining bolt B

fully using the wheel-

brace 1

.

�)

Refi t the plastic cover A

, close the

lower tailgate and store the tools.

Removing the wheel

�)

Open the tailgate and the lower tail-

gate (refer to the "Access" section).

�)

Take out the handle 3

(refer to the

"Access to the tools" paragraph).

Page 136 of 244

IX

PRACTICAL INFORMATION

134

Access to the spare wheel in

the 5 seat configuration

The pressed steel

spare wheel is installed

on the outside, under the boot, supported

by a winch and a plastic carrier.

To gain access to the tools, refer to the

"Access to the tools" paragraph.

Fixing the pressed steel spare

wheel

If your vehicle is fi tted with alloy

wheels, it is normal to notice that the

washers do not come into contact

with the pressed steel spare wheel

when tightening the bolts on fi tting.

The wheel is retained by the conical

contact of each bolt.

Removing the wheel

�)

Open the tailgate and the lower tail-

gate (refer to the "Access" section).

�)

Take out the handle 3

(refer to the

"Access to the tools" paragraph).

�)

Remove the plastic cover A

using

the handle 3

.

Putting the wheel back in place

�)

Put the wheel back in place in its

carrier.

�)

Pass the hook C

into the chain.

�)

Open the lower tailgate (refer to the

"Access" section).

�)

Unscrew the retaining bolt B fully

using the wheelbrace 1

, to unwind

the winch cable.

�)

Close the lower tailgate (refer to the

"Access" section).

�)

Detach the hook C

from the chain.

Unwind the winch cable fully to make

unhooking of the chain easier.

�)

Tighten the winch retaining bolt B

fully using the wheelbrace 1

.

�)

Refi t the plastic cover A

, close the

lower tailgate and store the tools.

Page 137 of 244

IX

PRACTICAL INFORMATION

135

Parking the vehicle

Immobilise the vehicle where it does

not block traffi c: if possible, park the

vehicle on level, stable and non-slip-

pery ground.

Apply the parking brake, switch off

the ignition and engage fi rst gear to

lock the wheels.

If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

Never go underneath a vehicle

raised using a jack; use a stand.

Removing a wheel

List of operations

�)

If your vehicle is equipped with secu-

rity wheel bolts (equipment available as an accessory) fi t the security socket 5

on the wheelbrace 1

to slacken the

security bolt.

�)

Slacken the other bolts using the

wheelbrace 1

only.

�)

Place the jack 2

in contact with one

of the two front A

or rear B

locations

provided on the underbody, which-

ever is closest to the wheel to be

changed.

�)

Extend the jack 2

until its base plate

is in contact with the ground. Ensure

that the centreline of the jack base

plate is directly below the location A

or B

used.

�)

Raise the vehicle until there is suffi -

cient space between the wheel and

the ground to admit the spare (not

punctured) wheel easily.

�)

Remove the bolts and store them in

a clean place.

�)

Remove the wheel.

Page 138 of 244

IX

PRACTICAL INFORMATION

136

After changing a wheel

When using the "space-saver" spare

wheel, do not exceed a speed of

50 mph (80 km/h).

Have the tightening of the bolts and

the pressure of the spare wheel

checked by a CITROËN dealer or a

qualifi ed workshop without delay.

Have the punctured wheel repaired

and replace it on the vehicle as soon

as possible.

Fitting a wheel

List of operations

�)

Lower the vehicle fully.

�)

Fold the jack 2

and detach it.

�)

Tighten the security bolt using the

wheelbrace 1

fi tted with the security

socket 5

(if your vehicle is equipped

with security wheel bolts).

�)

Tighten the other bolts using the

wheelbrace 1

only.

�)

Store the tools (refer to the para-

graph "Access to the tools").

Fitting snow tyres

If you equip your vehicle with snow

tyres fi tted on steel wheel rims,

special bolts available from your

CITROËN dealer or a qualifi ed work-

shop must

be used.

�)

Put the wheel in place on the hub.

�)

Screw in the bolts fully by hand.

�)

Pre-tighten the security bolt us-

ing the wheelbrace 1

fi tted with the

security socket 5 (if your vehicle is

equipped with security wheel bolts).

�)

Pre-tighten the other bolts using the

wheelbrace 1

only.

Page 139 of 244

IX

!

!

PRACTICAL INFORMATION

137

CHANGING A BULB

Handle the bulbs using a dry

cloth.

Do not clean the headlamps using

a dry or abrasive cloth, or using

detergent or solvent products,

use

a sponge and soapy water. In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the

glass of the headlamps and rear lamps

is normal; it disappears after the lamps

have been on for a few minutes.

Front lamps

1.

Direction indicators

(PY21W - 21 W).

2.

Dipped beam headlamps

(H11 - 55 W)

or xenon bulb (D2S - 35 W).

3.

Sidelamps (W5W - 5 W).

4.

Main beam headlamps

(H7 - 55 W).

5.

Front foglamps

(H11 - 55 W).

WARNING: RISK OF

ELECTROCUTION

Xenon bulbs must be replaced by a

CITROËN dealer or a qualifi ed work-

shop.

Page 140 of 244

IX

PRACTICAL INFORMATION

138

Changing direction indicator bulbs (1)

Coloured bulbs must be replaced

with bulbs of identical specifi cation

and colour.

�)

Turn the bulb holder A

to the left

and remove it.

�)

Pull the bulb and change it.

To r efi t, carry out these operations in

reverse order.

Access to the bulbs on the left-hand

side

When you change a bulb on the left-

hand side, remove the relay box fi xing

nut B

and move the relay box towards

the rear.

Access to the bulbs on the right-

hand side

When you change a bulb on the right-

hand side:

�)

Remove the screenwash reservoir

fi xing C

and move the reservoir to-

wards the rear.

�)

Remove the coolant reservoir fi xing

nut D

.

�)

Remove the clip E

and raise the res-

ervoir moving it towards the front.