Citroen C ZERO 2015 1.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2015, Model line: C ZERO, Model: Citroen C ZERO 2015 1.GPages: 176, PDF Size: 5.21 MB

Page 101 of 176

99

C-zero_en_Chap08_info-pratiques_ed01-2014

Repair procedure

1. Sealing

F Switch off the ignition.

F In dicate on the speed restriction sticker

provided, the wheel to be repaired, then fix

it to the steering wheel as a reminder that a

wheel is in temporary use.

F

Sh

ake the sealant cartridge, remove the

cap and screw on the injection pipe. F

Re

move the valve cap for the tyre to be

repaired.

F Re move the valve core using the tool

provided, and store in in a clean place.

F

Co

nnect the injection pipe to the valve of

the tyre to be repaired. F

Ta

p the sealant cartridge (top down)

several times with your hand, so as to

inject all of the product into the tyre.

F

Re

move the injection pipe.

F

Re

fit the valve core and tighten it using the

tool provided.

Take care, this product is harmful (e.g. ethylene-glycol, colophony...) if swallowed and

causes irritation to the eyes.

Keep it out of reach of children.

The use-by date of the sealant is marked on the cartridge.

After use, do not discard the empty cartridge but take it to a CITROËN dealer (France) or an

authorised waste disposal site.

Don't forget to obtain a replacement cartridge; they are available from a CITROËN dealer or

a qualified workshop.

Avoid removing any foreign bodies

which have penetrated into the tyre.

8

Practical information

Page 102 of 176

100

C-zero_en_Chap08_info-pratiques_ed01-2014

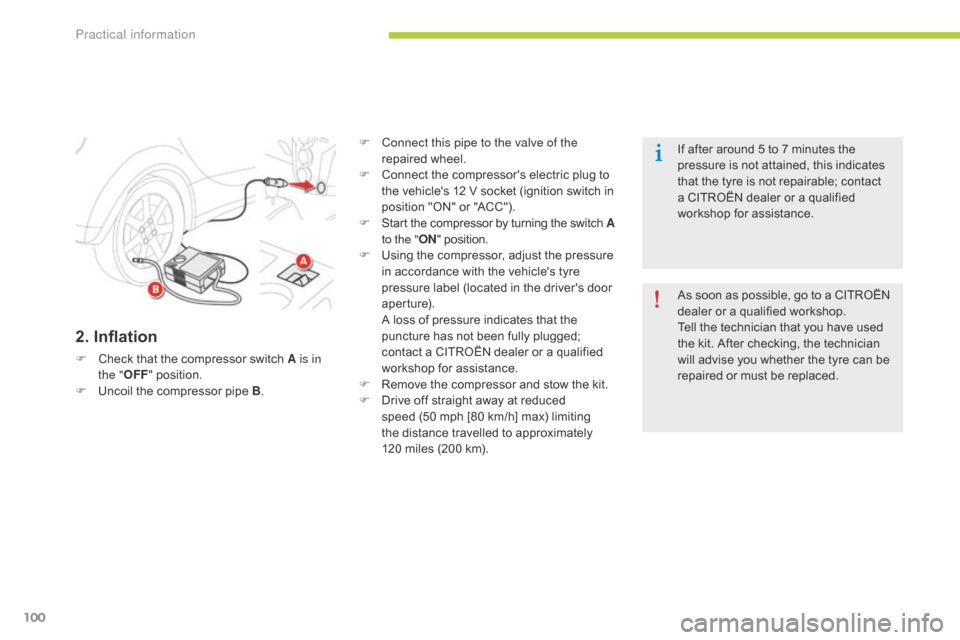

2. Inflation

F Check that the compressor switch A is in

the "OFF " position.

F

Un

coil the compressor pipe B .F

Co

nnect this pipe to the valve of the

repaired wheel.

F

Co

nnect the compressor's electric plug to

the vehicle's 12

V s

ocket (ignition switch in

position "ON" or "ACC").

F

St

art the compressor by turning the switch A

to the " ON" position.

F

Us

ing the compressor, adjust the pressure

in accordance with the vehicle's tyre

pressure label (located in the driver's door

aperture).

A lo

ss of pressure indicates that the

puncture has not been fully plugged;

contact a CITROËN dealer or a qualified

workshop for assistance.

F

Re

move the compressor and stow the kit.

F

Dr

ive off straight away at reduced

speed (50

m

ph [80

k

m/h] max) limiting

the distance travelled to approximately

120

m

iles (200

k

m).As soon as possible, go to a CITROËN

dealer or a qualified workshop.

Tell the technician that you have used

the kit. After checking, the technician

will advise you whether the tyre can be

repaired or must be replaced. If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a CITROËN dealer or a qualified

workshop for assistance.

Practical information

Page 103 of 176

101

C-zero_en_Chap08_info-pratiques_ed01-2014

Changing a wheel

Tools required

- A jack: for lifting the vehicle.

- A wh eelbrace: for removing and refitting

the wheel bolts.

-

A ha

ndle: for operating the jack.

These tools are not supplied with your vehicle.Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and not slippery.

Apply the parking brake, switch off the

ignition and put the drive selector in

position P to lock the wheels.

If necessary, place a chock under the

wheel diagonally opposite the wheel to

be changed.

You must ensure that the occupants get

out of the vehicle and wait where they

are safe.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first

remove the wheel trim using the

wheelbrace, by pulling at the valve hole.

When fitting the wheel , refit the wheel

trim starting by aligning the valve hole

with the valve, and then press on the

edge of the trim with the palm of your

hand.

8

Practical information

Page 104 of 176

102

C-zero_en_Chap08_info-pratiques_ed01-2014

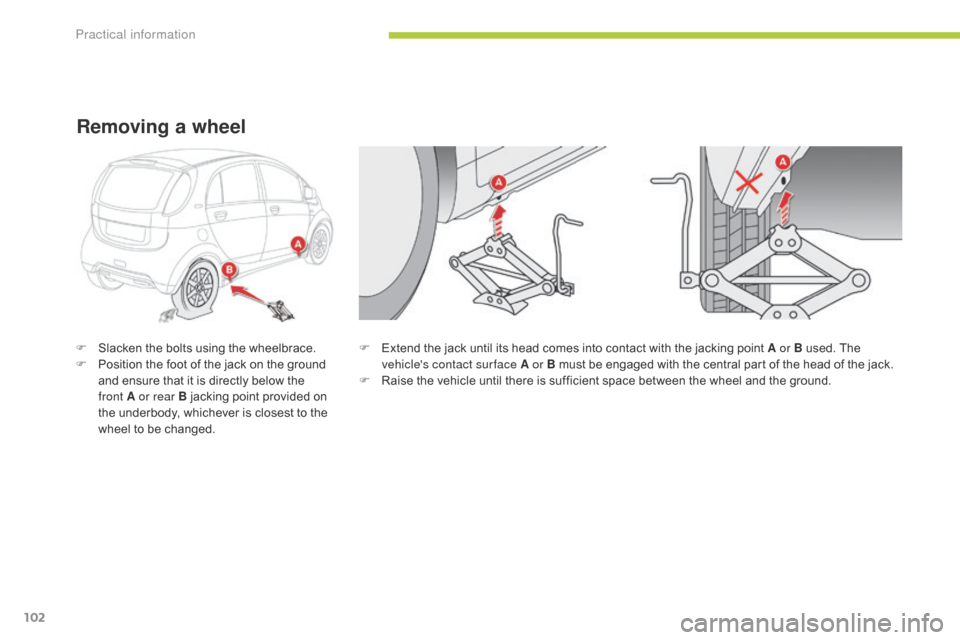

F Extend the jack until its head comes into contact with the jacking point A or B used. The

vehicle's contact sur face A or B must be engaged with the central part of the head of the jack.

F

Ra

ise the vehicle until there is sufficient space between the wheel and the ground.

F Sl

acken the bolts using the wheelbrace.

F Po

sition the foot of the jack on the ground

and ensure that it is directly below the

front

A

or rear B jacking point provided on

the underbody, whichever is closest to the

wheel to be changed.

Removing a wheel

Practical information

Page 105 of 176

103

C-zero_en_Chap08_info-pratiques_ed01-2014

F Remove the bolts and store them in a clean

place.

F

Re

move the wheel. Ensure that the jack is stable. If the

ground is slippery or loose, the jack

might slip or drop - Risk of injury!

Take care to position the jack only at

one of the vehicle’s jacking points A

or B under the vehicle, ensuring that the

contact sur face of the vehicle’s jacking

point is centred on the head of the jack.

Other wise there is a risk of damage to

the vehicle and/or that the jack might

drop - Risk of injury!

8

Practical information

Page 106 of 176

104

C-zero_en_Chap08_info-pratiques_ed01-2014

Fitting a wheel

F Put the wheel in place on the hub.

F Sc rew in the bolts by hand.

F

Pr

e-tighten the bolts using the wheelbrace. F Lo

wer the vehicle fully.

F Fo ld the jack and detach it.F Ti

ghten the bolts using the wheelbrace.

After changing a wheel

Have the tightness of the bolts and the

tyre pressure of the new wheel checked

by a CITROËN dealer or a qualified

workshop without delay.

Practical information

Page 107 of 176

105

C-zero_en_Chap08_info-pratiques_ed01-2014

Snow chains

The snow chains must be fitted only to the rear wheels (vehicle with rear wheel drive).It is strongly recommended that before

you leave, you practise fitting the snow

chains on a level and dry sur face. Take account of the legislation in force

in your country on the use of snow

chains and the maximum running speed

authorised. For more information on snow chains,

contact a CITROËN dealer or a

qualified workshop.Avoid driving with snow chains on roads

that have been cleared of snow, to

avoid damaging your vehicle's tyres and

the road sur face. If your vehicle is fitted

with alloy wheels, check that no part of

the chain or its fixings is in contact with

the wheel rim.Advice on installation

F If you have to fit the chains during a

j

ourney, stop the vehicle on a flat sur face

on the side of the road.

F

Ap

ply the parking brake and position any

wheel chocks to prevent movement of your

vehicle.

F

Fi

t the chains following the instructions

provided by the manufacturer.

F

Mov

e off gently and drive for a few

moments, without exceeding 30 mph

(50 km/h).

F

St

op your vehicle and check that the snow

chains are correctly tightened.

Use only the chains designed to be fitted to the

type of wheel fitted to your vehicle:

Original

tyre size Maximum link

size.

175/55 R15 9 mm

145/65 R15

cannot be fitted with chains

8

Practical information

Page 108 of 176

106

C-zero_en_Chap08_info-pratiques_ed01-2014

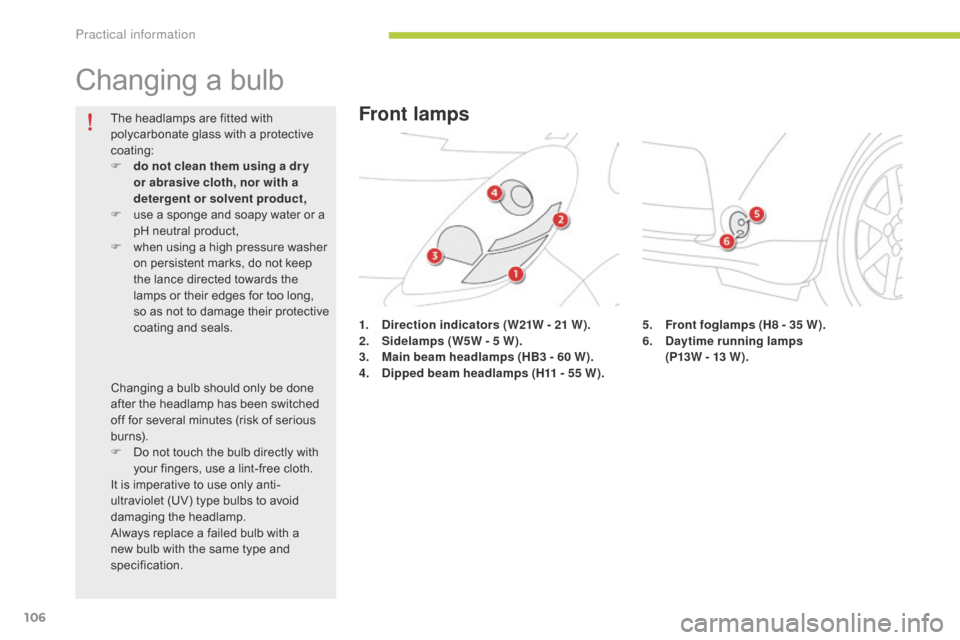

Changing a bulb

1. Direction indicators (W21W - 21 W).

2. Si delamps (W5W - 5 W).

3.

Ma

in beam headlamps (HB3 - 60 W).

4.

Di

pped beam headlamps (H11 - 55 W).

The headlamps are fitted with

polycarbonate glass with a protective

coating:

F

do n

ot clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

us

e a sponge and soapy water or a

pH neutral product,

F

wh

en using a high pressure washer

on persistent marks, do not keep

the lance directed towards the

lamps or their edges for too long,

so as not to damage their protective

coating and seals.

Changing a bulb should only be done

after the headlamp has been switched

off for several minutes (risk of serious

burns).

F

Do n

ot touch the bulb directly with

your fingers, use a lint-free cloth.

It is imperative to use only anti-

ultraviolet (UV) type bulbs to avoid

damaging the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

Front lamps

5. Front foglamps (H8 - 35 W).

6. Da ytime running lamps

(P13W - 13 W).

Practical information

Page 109 of 176

107

C-zero_en_Chap08_info-pratiques_ed01-2014

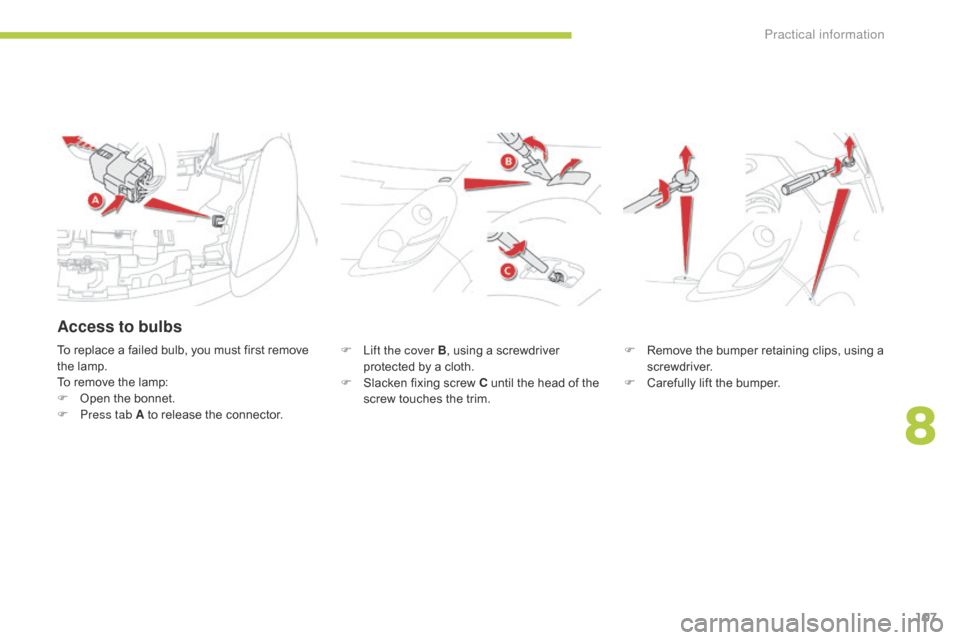

F Lift the cover B, u sing a screwdriver

protected by a cloth.

F

Sl

acken fixing screw C until the head of the

screw touches the trim. F Re

move the bumper retaining clips, using a

screwdriver.

F

Ca

refully lift the bumper.

To replace a failed bulb, you must first remove

the lamp.

To remove the lamp:

F

Op

en the bonnet.

F

Pr

ess tab A to release the connector.

Access to bulbs

8

Practical information

Page 110 of 176

108

C-zero_en_Chap08_info-pratiques_ed01-2014

F Slacken fixing screw D, w hile holding the

bumper away.

F

Sl

acken fixing screw E . F Pu

ll the lamp towards you, and disengage

the tab F to remove it completely.

Practical information