M.dan Citroen C4 2005 2.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 156 of 462

Downloaded from www.Manualslib.com manuals search engine 150

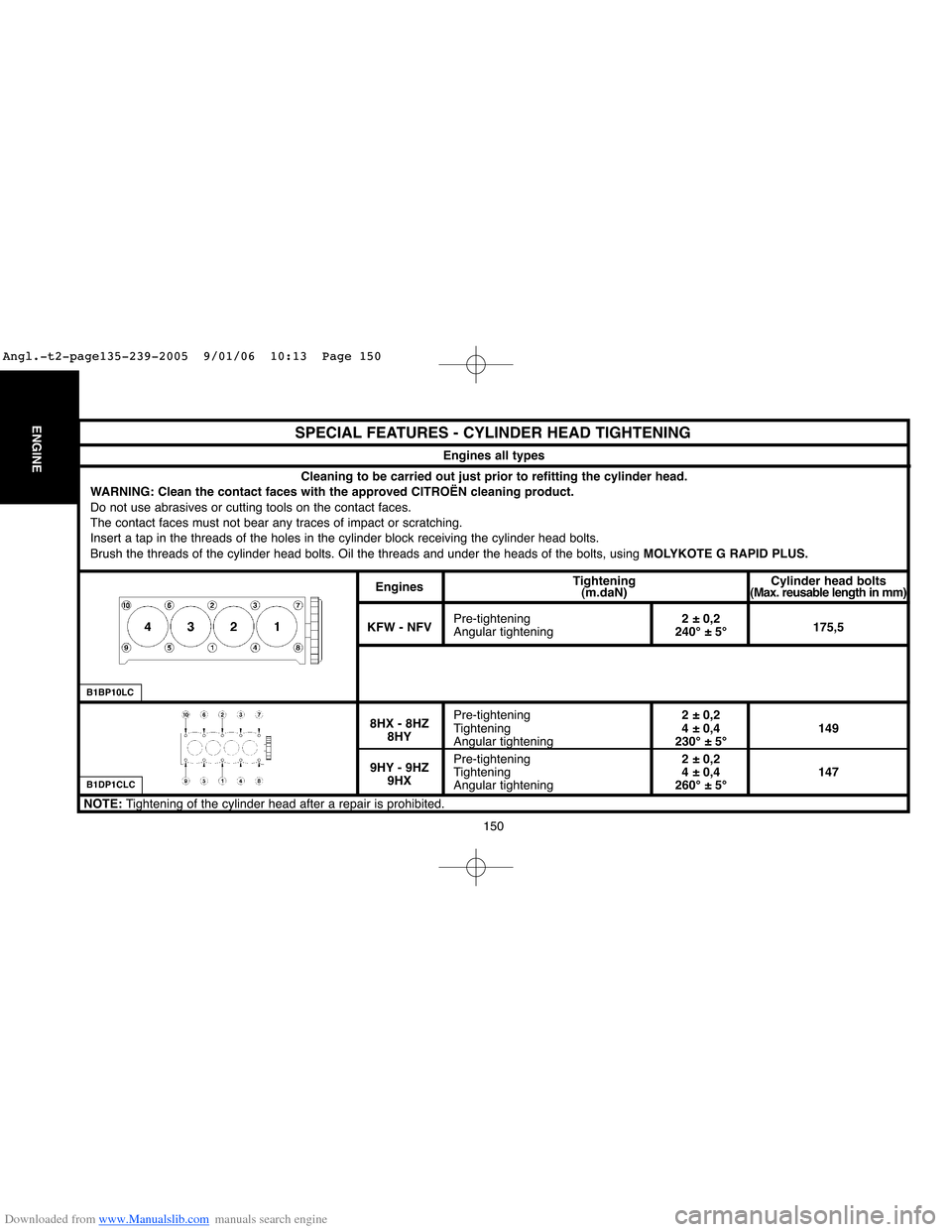

ENGINESPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

B1DP1CLC

Cleaning to be carried out just prior to refitting the cylinder head.

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts. Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

EnginesTightening Cylinder head bolts

(m.daN)(Max. reusable length in mm)

Pre-tightening2 ± 0,2

KFW - NFV

Angular tightening240° ± 5°175,5

Pre-tightening2 ± 0,2

8HX - 8HZ

Tightening4 ± 0,4 149

8HY

Angular tightening230° ± 5°

Pre-tightening2 ± 0,2

9HY - 9HZ

Tightening4 ± 0,4 147

9HX

Angular tightening260° ± 5°

NOTE: Tightening of the cylinder head after a repair is prohibited.

B1BP10LC

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 150

Page 167 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 161

ENGINE

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1]«Junior» T extension: (-).1608.E

Removing.

Engage tool [1]in Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 161

ENGINE

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1]«Junior» T extension: (-).1608.E

Removing.

Engage tool [1]in](/img/9/4138/w960_4138-166.png)

Downloaded from www.Manualslib.com manuals search engine 161

ENGINE

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1]«Junior» T extension: (-).1608.E

Removing.

Engage tool [1]in the notch «a».

Exert on the roller (1)an effort upwards to hold it at maximum.

Remove the auxiliaries drive belt.

Carefully release the tensioner roller (1)to reach its minimum.

Remove tool[1].

IMPERATIVE: Check that the roller (1) turns freely

(without play and without tight spots).

Refitting.

If removing the auxiliaries drive belt tensioner roller, tighten the screws 2 ± 0,2 m.daN.

Engage tool [1]in the notch at «a».

Exert on the roller (1)an effort upwards to hold it at maximum.

Position the

(new)auxiliaries drive belt, in the following sequence:

- Auxiliaries drive pulley (4), aircon compressor pulley (3), tensioner roller (1)and alternator pulley (2).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Release the tensioner roller (1).

Remove tool [1].

Checking the tension of the auxiliaries drive belt.

Check the tension of the auxiliaries drive belt:

- Mark «b»at the level of mark «c», new belt.

- Mark «b»at the level of mark «d», belt to be changed.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 161

Page 169 of 462

Downloaded from www.Manualslib.com manuals search engine 163

ENGINE

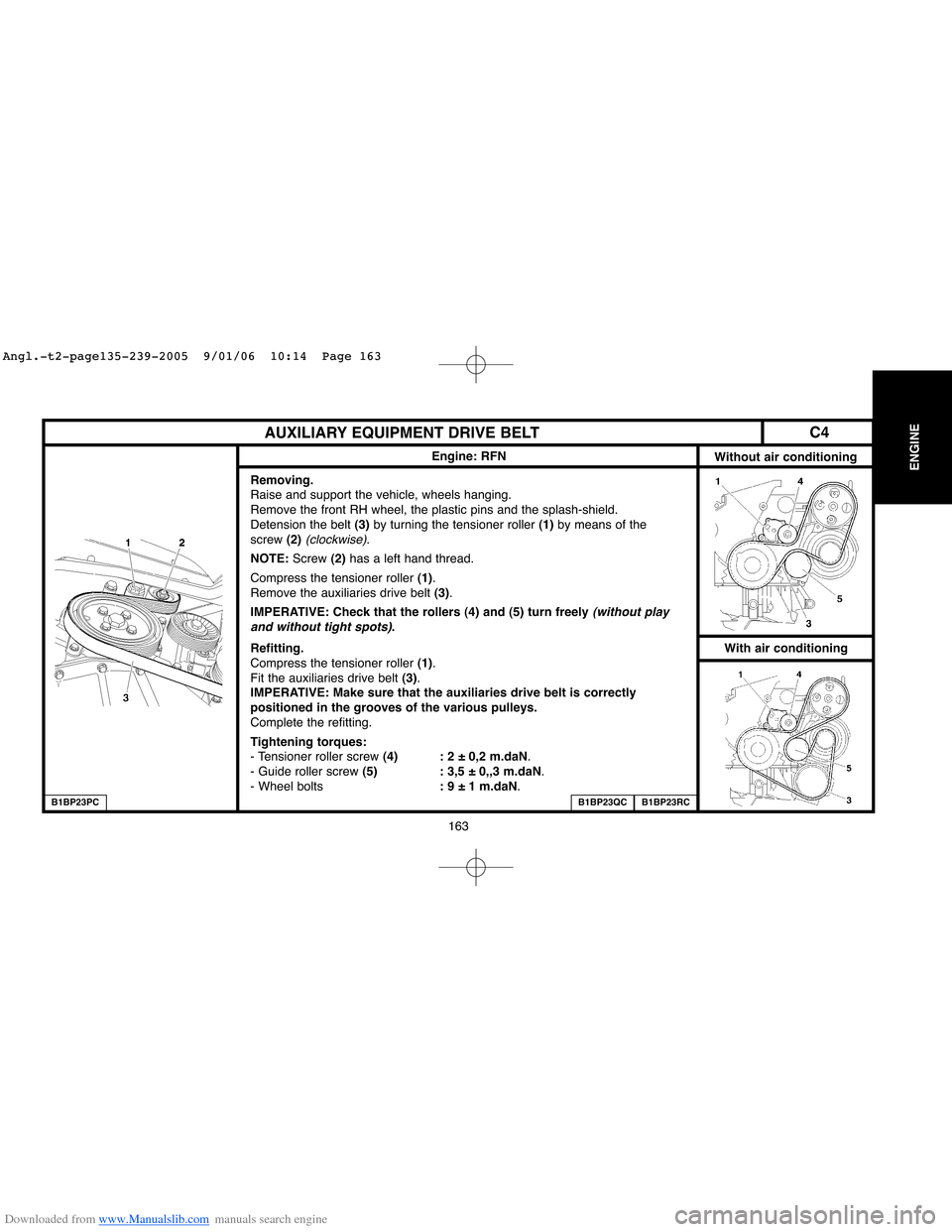

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFN

Without air conditioning

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Detension the belt (3)by turning the tensioner roller (1)by means of the

screw (2)

(clockwise).

NOTE:Screw (2)has a left hand thread.

Compress the tensioner roller (1).

Remove the auxiliaries drive belt (3).

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play

and without tight spots).

Refitting.

Compress the tensioner roller (1).

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly

positioned in the grooves of the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4) : 2 ± 0,2 m.daN.

- Guide roller screw (5) : 3,5 ± 0,,3 m.daN.

- Wheel bolts: 9 ± 1 m.daN.

B1BP23PCB1BP23QCB1BP23RC

With air conditioning

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 163

Page 170 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle](/img/9/4138/w960_4138-169.png)

Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner roller:

Dynamic spanner extension: FACOM SJ.214

Adaptor for socket 9x12 : FACOM J.274

Polygon socket 9x12 : 016

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Turn the tensioner roller(1)by the screw (2)

(anti-clockwise), using tool [1]to detension the belt (3).

NOTE: Screw (2)has a left hand thread.

Remove the auxiliaries drive belt (3).

Refitting.

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play and without tight spots).

Refitting.

Compress the tensioner roller (1), using tool [1].

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4)tighten to: 2 ± 0,2 m.daN.

- Guide roller screw (5)tighten to: 3,5 ± 0,3 m.daN.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 164

Page 176 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 170

ENGINEAUXILIARY EQUIPMENT DRIVE BELT

Without power-assisted steering

Tool.

[1]Belt tension measuring instrument: 4122-T

Removal.

Loosen the Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 170

ENGINEAUXILIARY EQUIPMENT DRIVE BELT

Without power-assisted steering

Tool.

[1]Belt tension measuring instrument: 4122-T

Removal.

Loosen the](/img/9/4138/w960_4138-175.png)

Downloaded from www.Manualslib.com manuals search engine 170

ENGINEAUXILIARY EQUIPMENT DRIVE BELT

Without power-assisted steering

Tool.

[1]Belt tension measuring instrument: 4122-T

Removal.

Loosen the screws (2).

Tighten the screw (1)until it is against its stop.

Remove the belt.

Refitting.

Refit the belt.

Fit the tool [1] on the belt at "d".

Tighten the screw (1)to obtain: 106 ± 10 SEEMunits.

Tighten the screws (2)to 2 m.daN.

Remove the tool [1].

B1BP1SECB1BP1SDC

Engine: WJY

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 170

Page 177 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 171

ENGINE

XSARAAUXILIARY EQUIPMENT DRIVE BELT

Without power-assisted steering, with air conditioning

Tool.

[1] Belt tension measuring instrume Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 171

ENGINE

XSARAAUXILIARY EQUIPMENT DRIVE BELT

Without power-assisted steering, with air conditioning

Tool.

[1] Belt tension measuring instrume](/img/9/4138/w960_4138-176.png)

Downloaded from www.Manualslib.com manuals search engine 171

ENGINE

XSARAAUXILIARY EQUIPMENT DRIVE BELT

Without power-assisted steering, with air conditioning

Tool.

[1] Belt tension measuring instrument: 4122-T

Removal.

Loosen the screws (1).

Tighten the screw (2)until it is against its stop.

Remove the belt.

Refitting.

Refit the belt.

Fit the tool [1] at "e".

Tighten the screw (2)to obtain: 106 ± 10 SEEMunits.

Tighten the screws (1)to 2 m.daN.

Remove the tool [1].

B1BP1SGCB1BP1SFC

Engine: WJY

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 171

Page 179 of 462

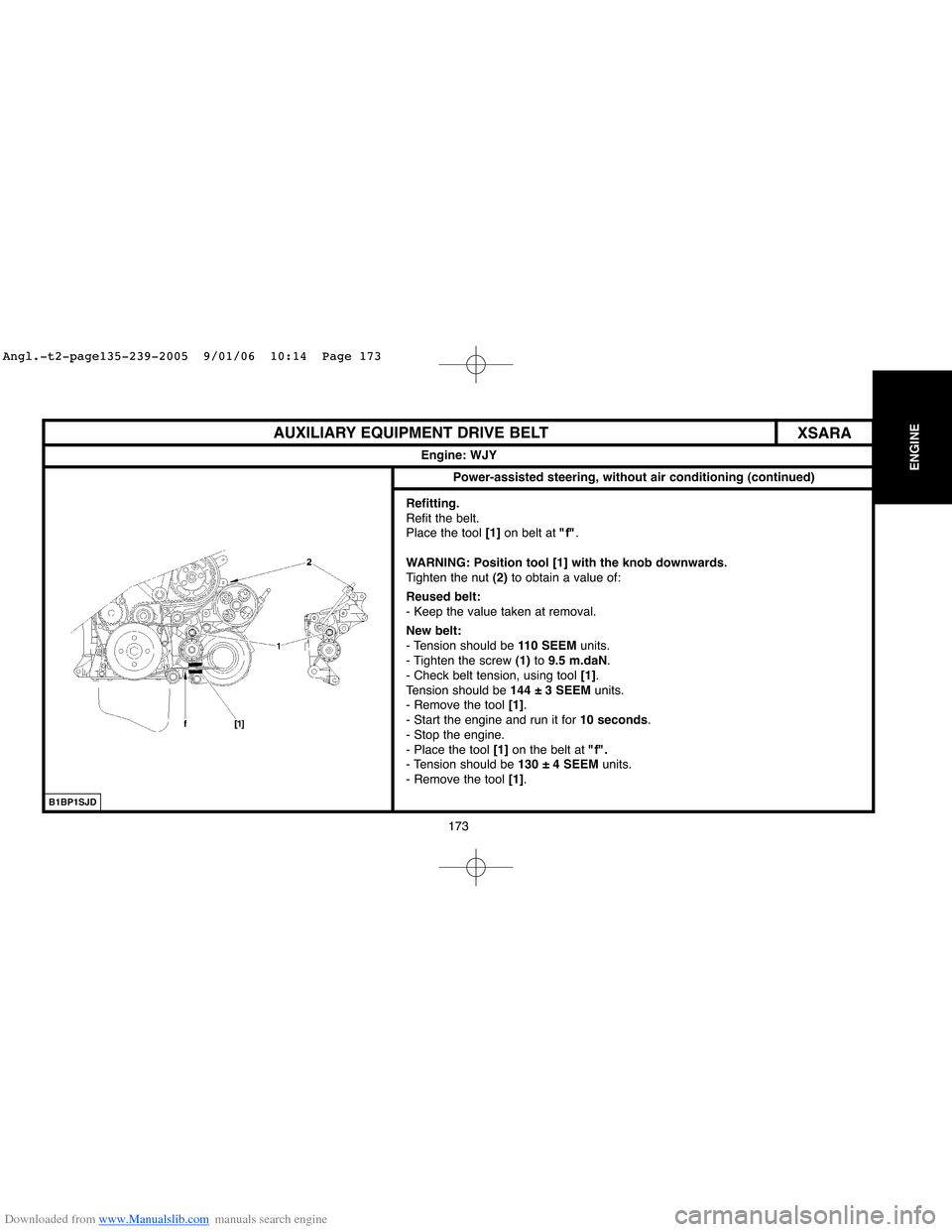

Downloaded from www.Manualslib.com manuals search engine 173

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engine: WJY

Power-assisted steering, without air conditioning (continued)

XSARA

Refitting.

Refit the belt.

Place the tool [1]on belt at "f".

WARNING: Position tool [1] with the knob downwards.

Tighten the nut (2)to obtain a value of:

Reused belt:

- Keep the value taken at removal.

New belt:

- Tension should be 110 SEEMunits.

- Tighten the screw (1)to 9.5 m.daN.

- Check belt tension, using tool [1].

Tension should be 144 ± 3 SEEMunits.

- Remove the tool [1].

- Start the engine and run it for 10 seconds.

- Stop the engine.

- Place the tool [1]on the belt at "f".

- Tension should be 130 ± 4 SEEMunits.

- Remove the tool [1].

B1BP1SJD

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 173

Page 183 of 462

Downloaded from www.Manualslib.com manuals search engine 177

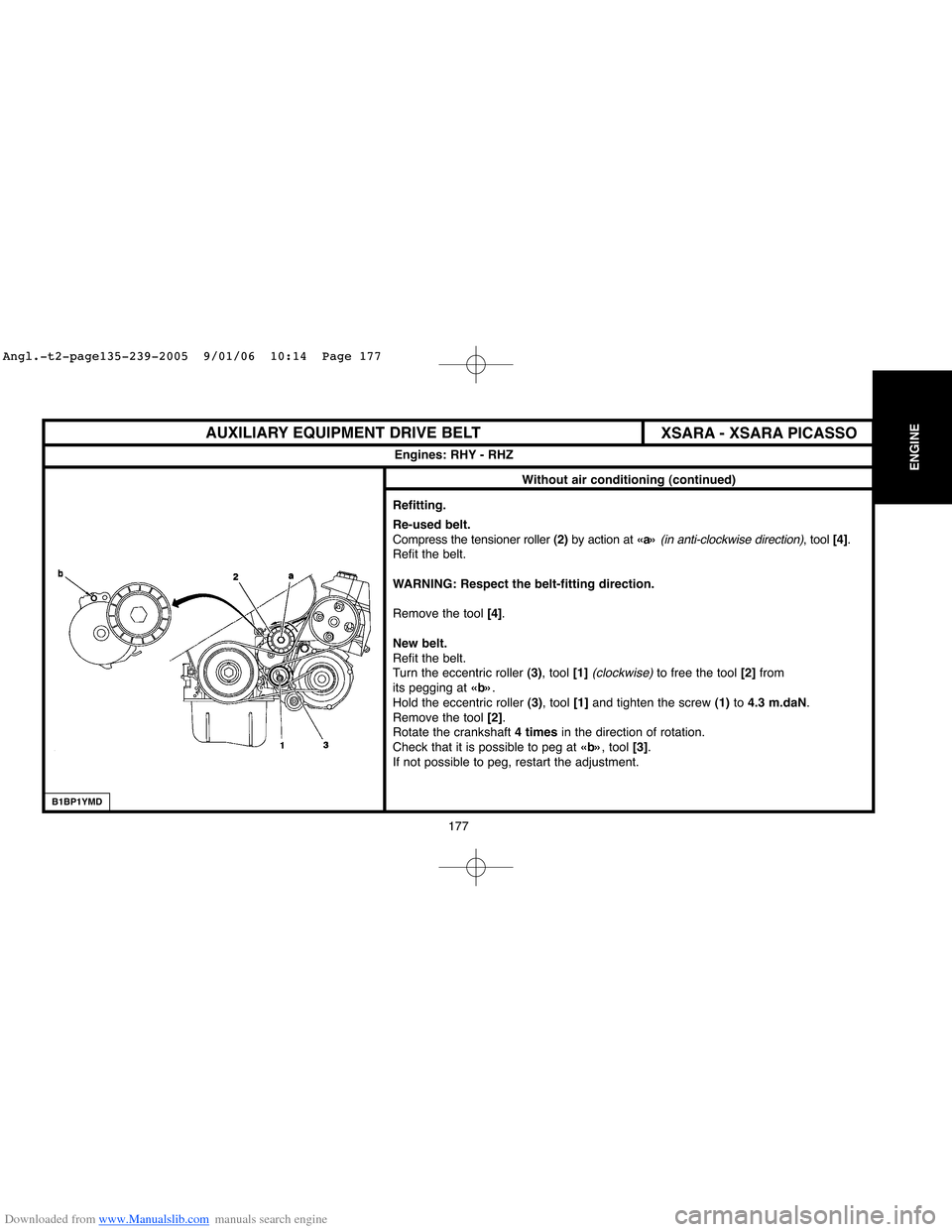

ENGINE

XSARA - XSARA PICASSO AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

Without air conditioning (continued)

Refitting.

Re-used belt.

Compress the tensioner roller (2)by action at «a»

(in anti-clockwise direction), tool [4].

Refit the belt.

WARNING: Respect the belt-fitting direction.

Remove the tool [4].

New belt.

Refit the belt.

Turn the eccentric roller (3), tool [1]

(clockwise)to free the tool [2]from

its pegging at «b».

Hold the eccentric roller (3), tool [1]and tighten the screw (1)to 4.3 m.daN.

Remove the tool [2].

Rotate the crankshaft 4 timesin the direction of rotation.

Check that it is possible to peg at «b», tool [3].

If not possible to peg, restart the adjustment.

B1BP1YMD

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 177

Page 185 of 462

Downloaded from www.Manualslib.com manuals search engine 179

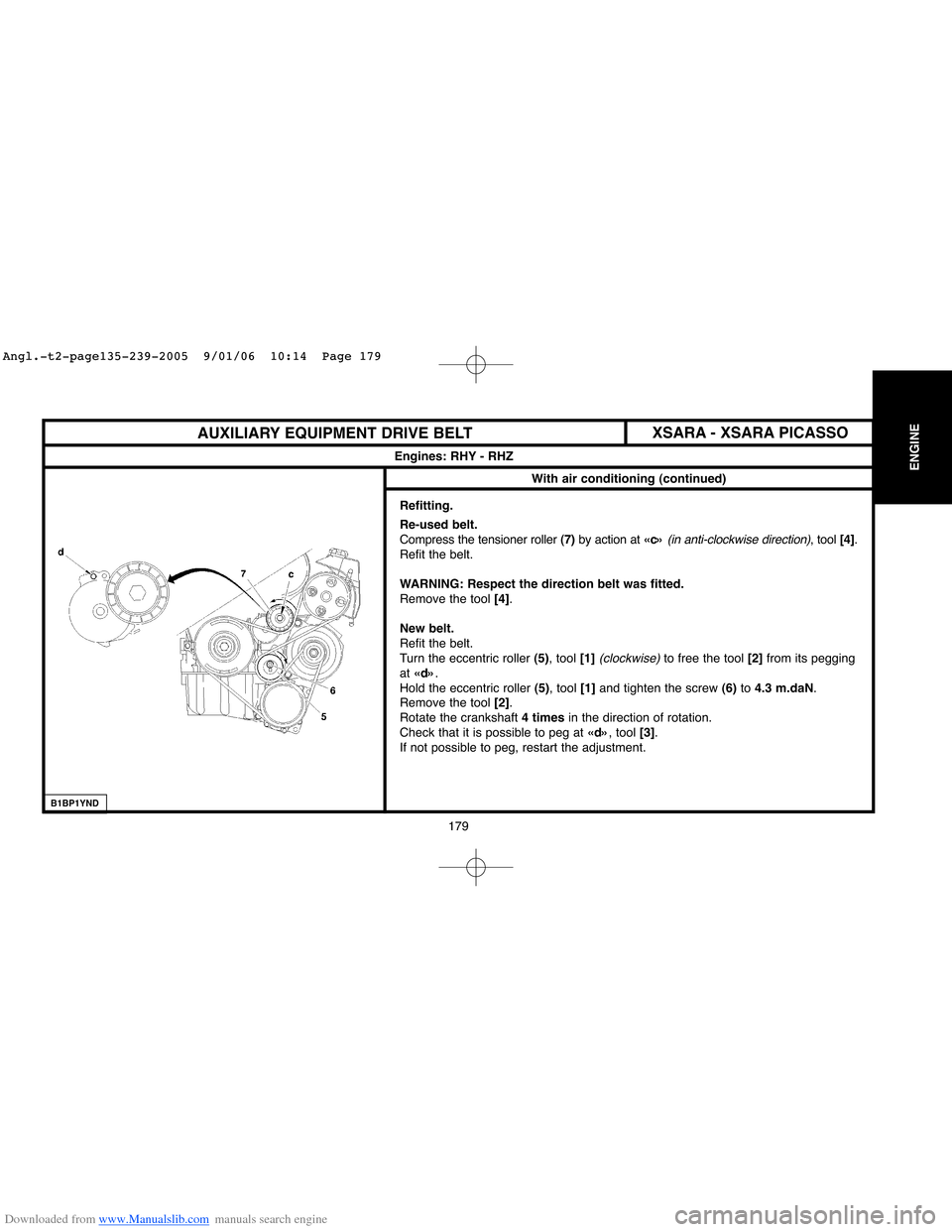

ENGINE

XSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning (continued)

Refitting.

Re-used belt.

Compress the tensioner roller (7)by action at «c»

(in anti-clockwise direction), tool [4].

Refit the belt.

WARNING: Respect the direction belt was fitted.

Remove the tool [4].

New belt.

Refit the belt.

Turn the eccentric roller (5), tool[1]

(clockwise)to free the tool [2]from its pegging

at «d».

Hold the eccentric roller (5), tool [1]and tighten the screw (6)to 4.3 m.daN.

Remove the tool [2].

Rotate the crankshaft 4 timesin the direction of rotation.

Check that it is possible to peg at «d», tool [3].

If not possible to peg, restart the adjustment.

B1BP1YND

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 179

Page 192 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 186

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

Refitting the timing belt.

NOTE :Check that the pegs [1]and [2]are in place. Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 186

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

Refitting the timing belt.

NOTE :Check that the pegs [1]and [2]are in place.](/img/9/4138/w960_4138-191.png)

Downloaded from www.Manualslib.com manuals search engine 186

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

Refitting the timing belt.

NOTE :Check that the pegs [1]and [2]are in place.

WARNING: Respect the direction of fitting of the belt: The arrows "a" indicate the direction of rotation of

the crankshaft.

Position:

-The timing belt, belt "b"well-tensioned in the following order: Crankshaft pinion, camshaft pulley, coolant pump

pulley, tensioner roller.

- Tool [5]

(respect the direction of fitting relative to the valve timing).

- Put the tensioner roller in contact with the belt.

- Tighten the nut (2).

Pre-tensioning the belt.

Place tool [4] on the tensioned part "b"of the belt.

Slacken the screw (2).

Turn the roller (3)in the anti-clockwise direction using the drive square, to obtain a value of: 44 SEEMunits.

Tighten the nut (2) to 2 m.daN.

Remove tools [1], [2] and [4].

Rotate the crankshaft 4 turnsin the normal direction of rotation.

IMPERATIVE: Never turn the crankshaft backwards.

B1EP06AC

B1EP069C

XSARA - XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 186