RFK Citroen C4 2005 2.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 97 of 462

Downloaded from www.Manualslib.com manuals search engine 91

ENGINE

91

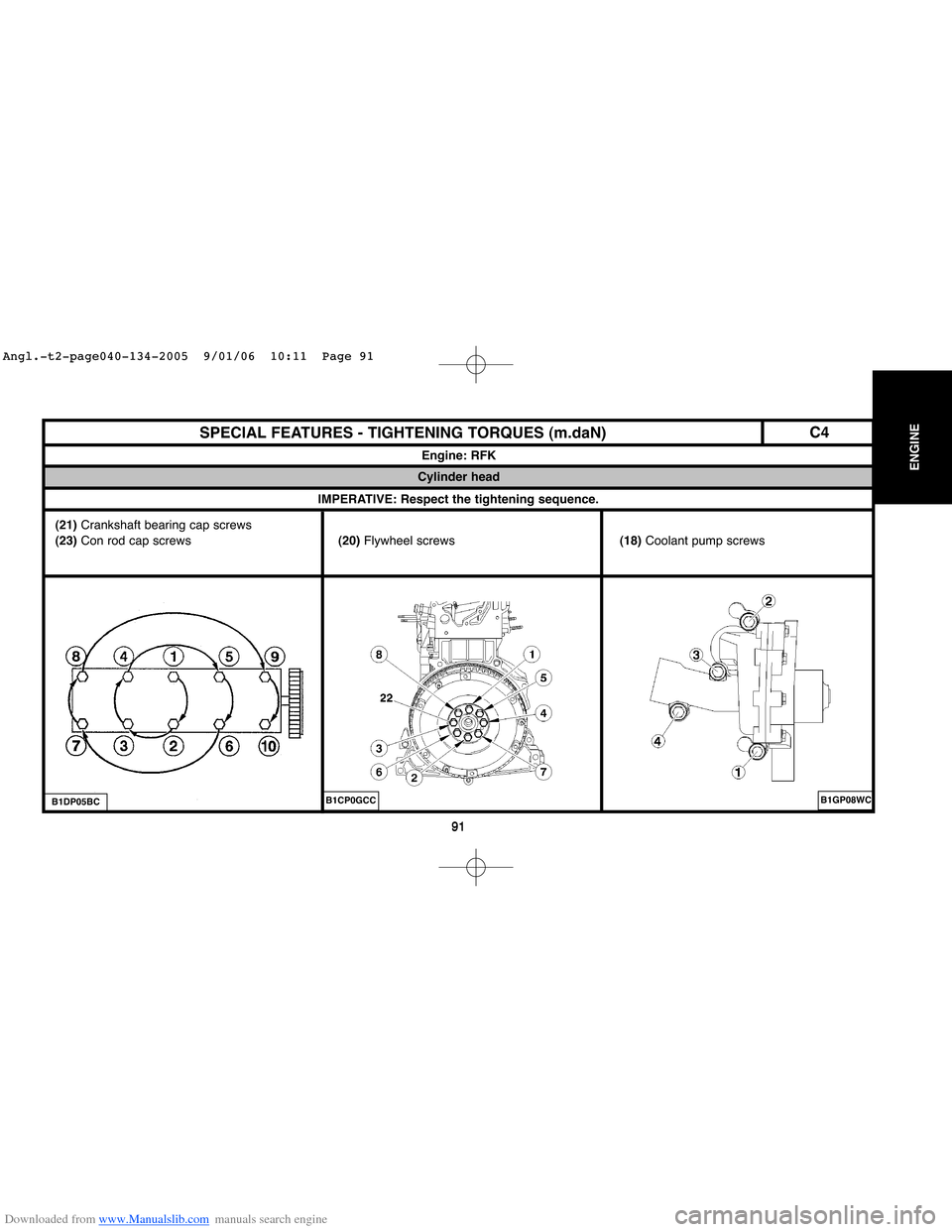

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Engine: RFK

B1GP08WCB1DP05BC

IMPERATIVE: Respect the tightening sequence.

Cylinder head

(21) Crankshaft bearing cap screws

(23) Con rod cap screws(20) Flywheel screws(18) Coolant pump screws

B1CP0GCC

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 91

Page 98 of 462

Downloaded from www.Manualslib.com manuals search engine 92

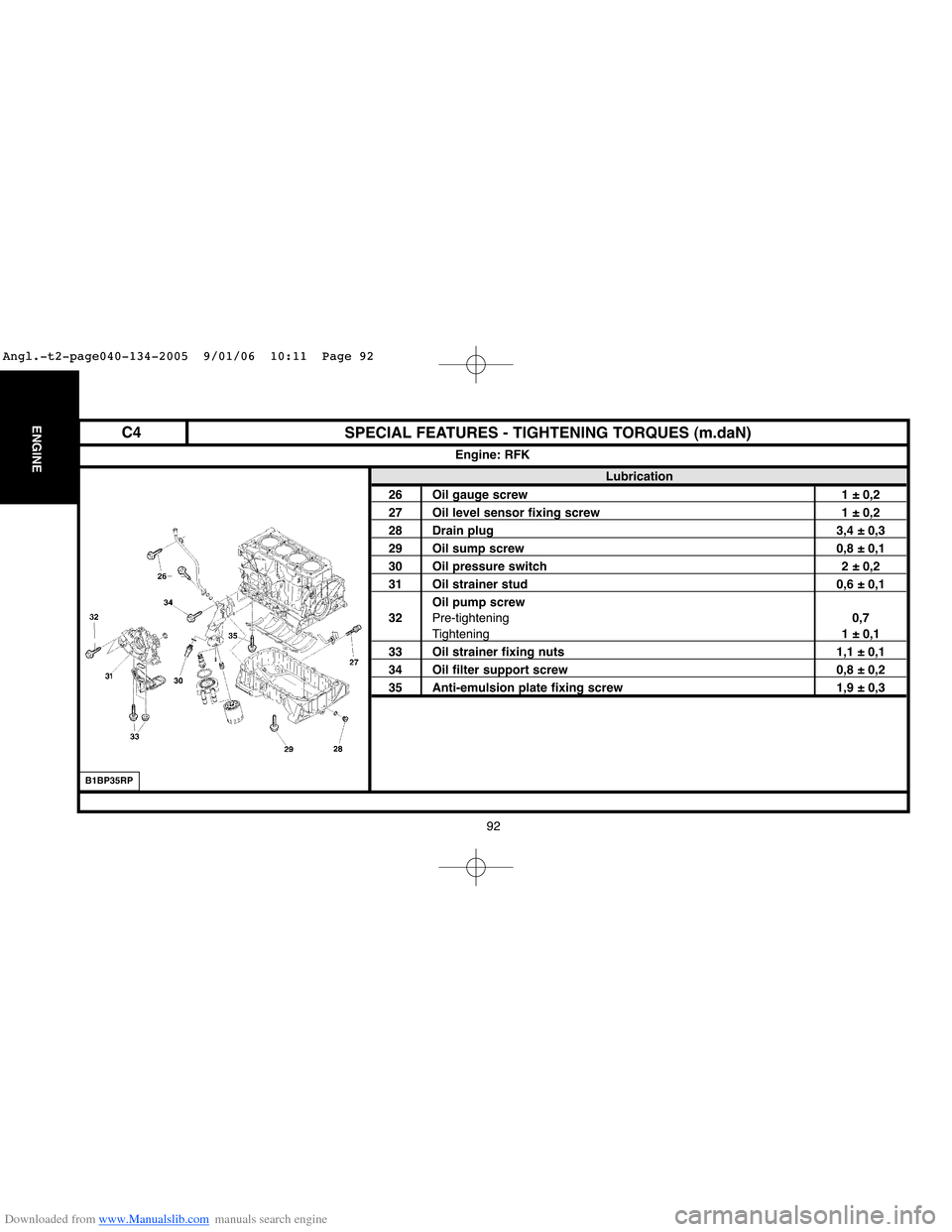

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Lubrication

26 Oil gauge screw 1 ± 0,2

27 Oil level sensor fixing screw 1 ± 0,2

28 Drain plug 3,4 ± 0,3

29 Oil sump screw 0,8 ± 0,1

30 Oil pressure switch 2 ± 0,2

31 Oil strainer stud 0,6 ± 0,1

Oil pump screw

32Pre-tightening0,7

Tightening1 ± 0,1

33 Oil strainer fixing nuts 1,1 ± 0,1

34 Oil filter support screw 0,8 ± 0,2

35 Anti-emulsion plate fixing screw 1,9 ± 0,3

Engine: RFK

B1BP35RP

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 92

Page 99 of 462

Downloaded from www.Manualslib.com manuals search engine 93

ENGINE

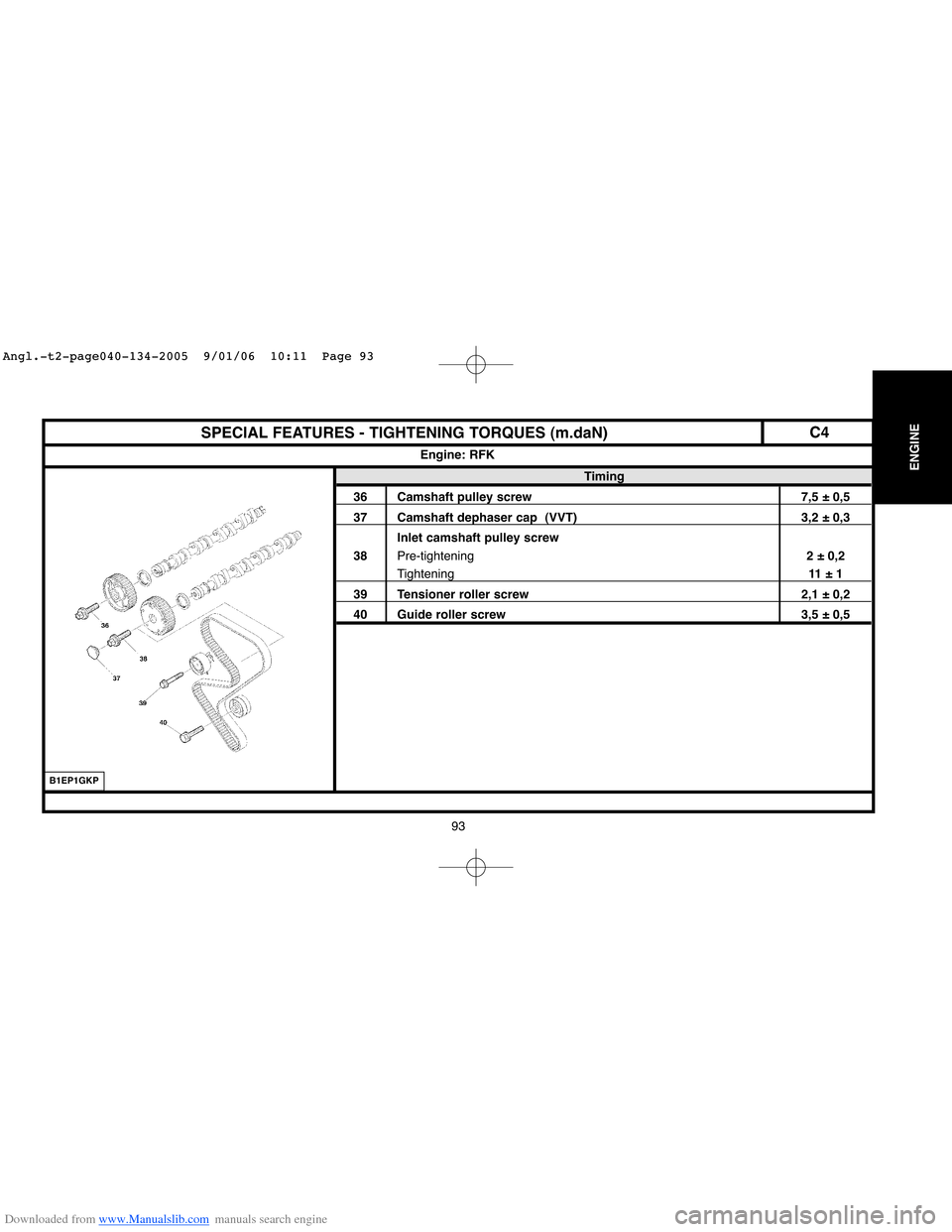

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Timing

36 Camshaft pulley screw 7,5 ± 0,5

37 Camshaft dephaser cap (VVT) 3,2 ± 0,3

Inlet camshaft pulley screw

38Pre-tightening2 ± 0,2

Tightening11 ± 1

39 Tensioner roller screw 2,1 ± 0,2

40 Guide roller screw 3,5 ± 0,5

Engine: RFK

B1EP1GKP

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 93

Page 100 of 462

Downloaded from www.Manualslib.com manuals search engine 94

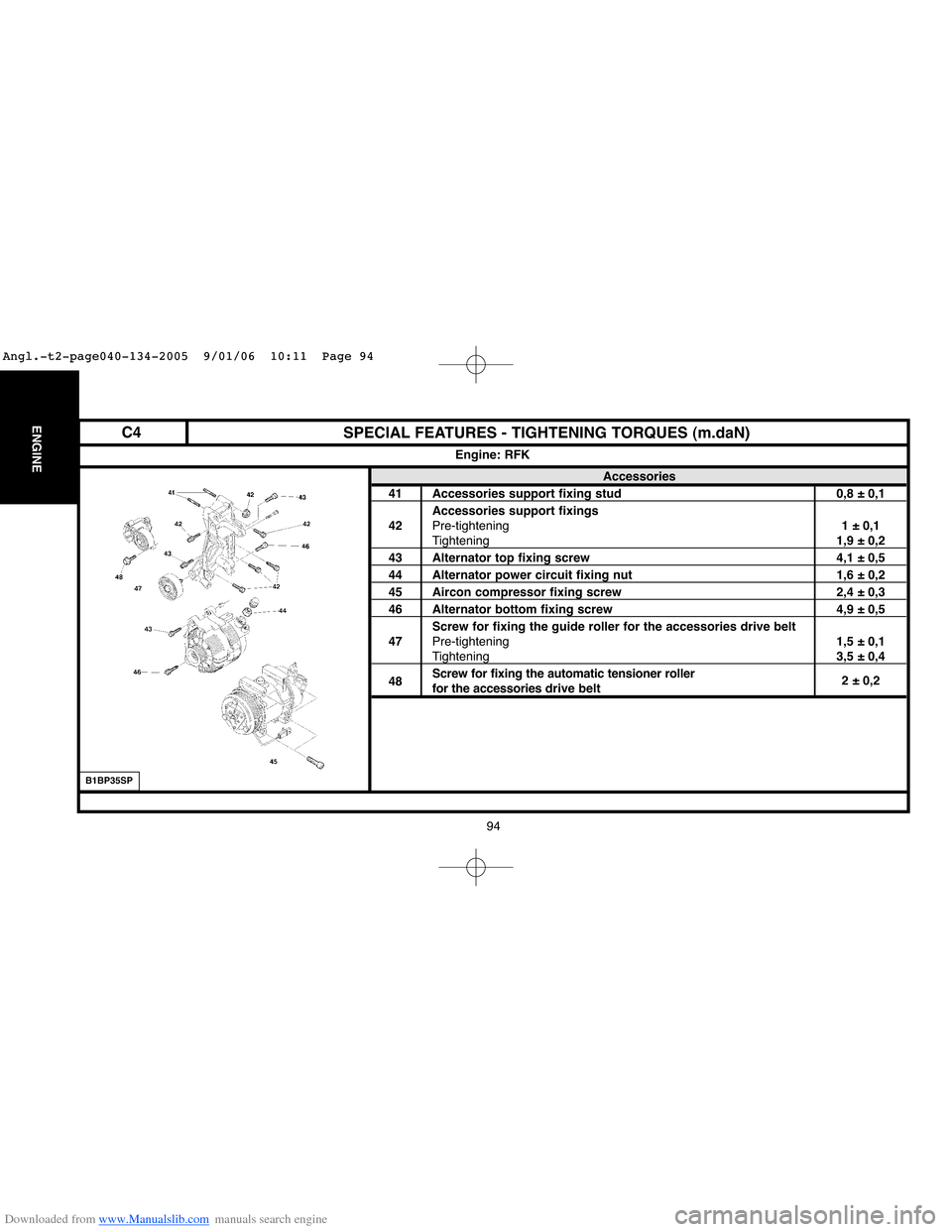

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Accessories

41 Accessories support fixing stud 0,8 ± 0,1

Accessories support fixings

42Pre-tightening1 ± 0,1

Tightening1,9 ± 0,2

43 Alternator top fixing screw 4,1 ± 0,5

44 Alternator power circuit fixing nut 1,6 ± 0,2

45 Aircon compressor fixing screw 2,4 ± 0,3

46 Alternator bottom fixing screw 4,9 ± 0,5

Screw for fixing the guide roller for the accessories drive belt

47Pre-tightening1,5 ± 0,1

Tightening3,5 ± 0,4

48Screw for fixing the automatic tensioner roller

for the accessories drive belt2 ± 0,2

Engine: RFK

B1BP35SP

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 94

Page 154 of 462

Downloaded from www.Manualslib.com manuals search engine 148

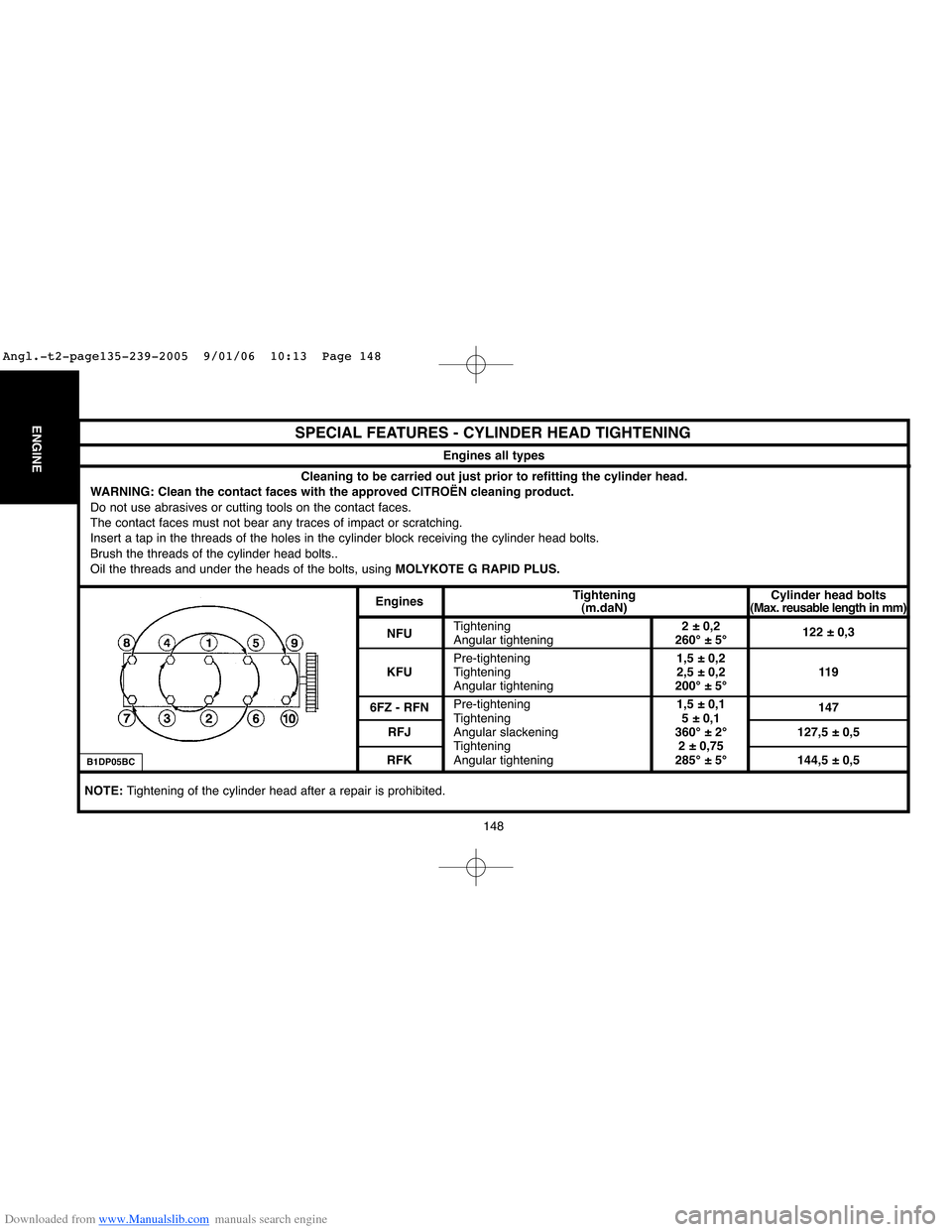

ENGINESPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

B1DP05BC

Cleaning to be carried out just prior to refitting the cylinder head.

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts..

Oil the threads and under the heads of the bolts, usingMOLYKOTE G RAPID PLUS.

EnginesTightening Cylinder head bolts

(m.daN)(Max. reusable length in mm)

NFUTightening2 ± 0,2

Angular tightening260° ± 5°122 ± 0,3

Pre-tightening1,5 ± 0,2

KFUTightening2,5 ± 0,2 119

Angular tightening200° ± 5°

6FZ - RFNPre-tightening1,5 ± 0,1

147

Tightening5 ± 0,1

RFJAngular slackening360° ± 2° 127,5 ± 0,5

Tightening2 ± 0,75

RFKAngular tightening285° ± 5° 144,5 ± 0,5

NOTE: Tightening of the cylinder head after a repair is prohibited.

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 148

Page 158 of 462

Downloaded from www.Manualslib.com manuals search engine 152

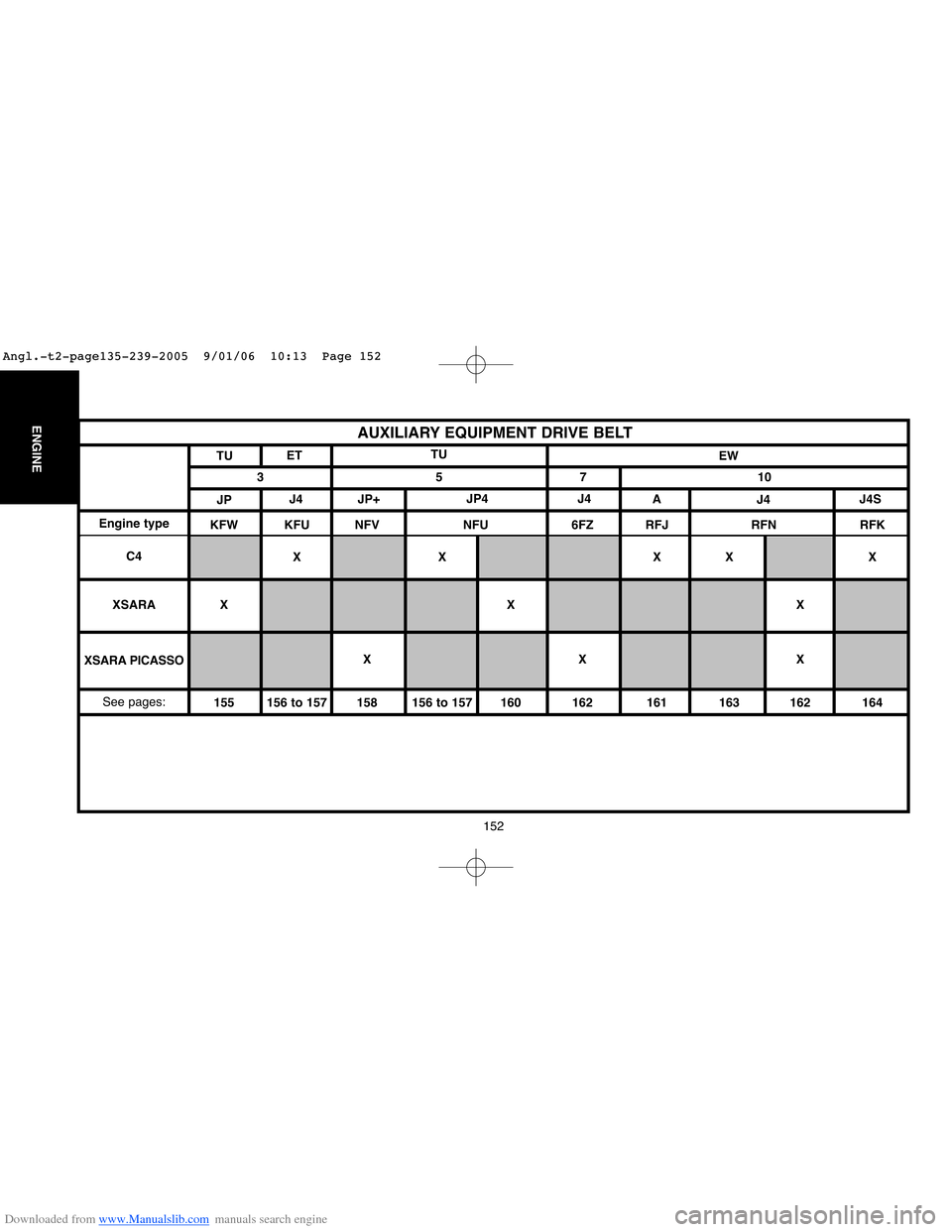

ENGINEAUXILIARY EQUIPMENT DRIVE BELT

TU

JP

3

J410

A J4S

Engine type

C4

XSARA

XSARA PICASSO

See pages:

KFW KFU NFV NFU 6FZ RFJ RFN RFK

XX XXX

XX X

XX X

155 156 to 157 158 156 to 157 160 162 161 163 162 164EW

5

J4 7 ETTUJP4 J4JP+

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 152

Page 170 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle](/img/9/4138/w960_4138-169.png)

Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner roller:

Dynamic spanner extension: FACOM SJ.214

Adaptor for socket 9x12 : FACOM J.274

Polygon socket 9x12 : 016

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Turn the tensioner roller(1)by the screw (2)

(anti-clockwise), using tool [1]to detension the belt (3).

NOTE: Screw (2)has a left hand thread.

Remove the auxiliaries drive belt (3).

Refitting.

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play and without tight spots).

Refitting.

Compress the tensioner roller (1), using tool [1].

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4)tighten to: 2 ± 0,2 m.daN.

- Guide roller screw (5)tighten to: 3,5 ± 0,3 m.daN.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 164

Page 187 of 462

Downloaded from www.Manualslib.com manuals search engine 181

ENGINE

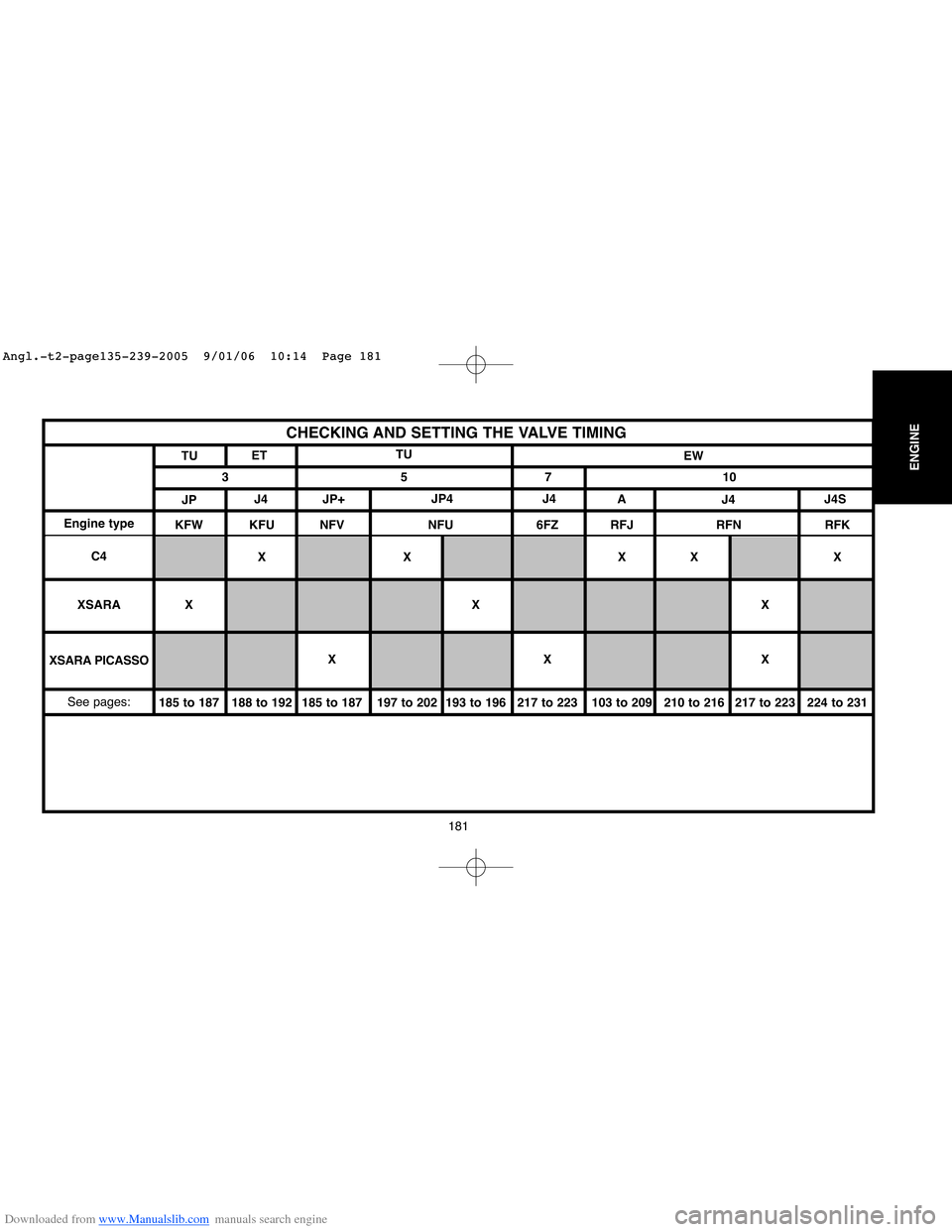

CHECKING AND SETTING THE VALVE TIMING

TU

JP

3

J410

A J4S

Engine type

C4

XSARA

XSARA PICASSO

See pages:

KFW KFU NFV NFU 6FZ RFJ RFN RFK

XX XXX

XX X

XX X

185 to 187 188 to 192 185 to 187 197 to 202 193 to 196 217 to 223 103 to 209 210 to 216 217 to 223 224 to 231EW

5

J4 7 ETTUJP4 J4JP+

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 181

Page 230 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 224

ENGINECHECKING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0194.B

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Re Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 224

ENGINECHECKING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0194.B

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Re](/img/9/4138/w960_4138-229.png)

Downloaded from www.Manualslib.com manuals search engine 224

ENGINECHECKING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0194.B

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Respect the safety and cleanliness requirements.

Checking the timing.

Removing.

Disconnect the battery negative terminal.

Raise and support the vehicle, front wheels hanging.

Remove the front RH wheel and the splash-shield.

A:Pegging on the manualgearbox.

Turn the engine by means of the crankshaft pinion screw, to bring it to the pegging position.

Peg the crankshaft, using tool [2].

Unclip:

- The fuel supply hose from the upper timing cover.

- The fuel vapour re-induction circuit.

B1BP2V5D

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 224

Page 231 of 462

Downloaded from www.Manualslib.com manuals search engine 225

ENGINE

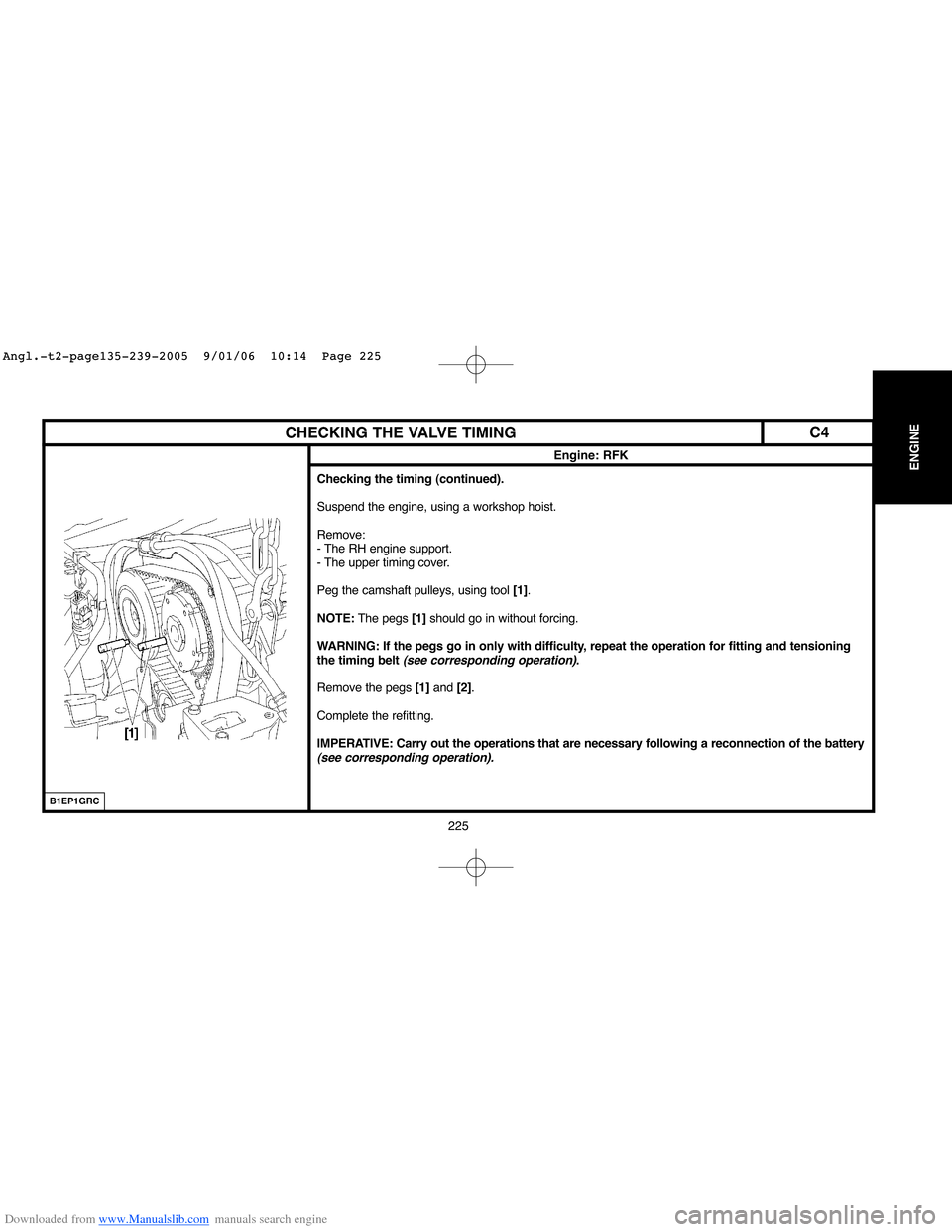

CHECKING THE VALVE TIMING

Engine: RFK

Checking the timing (continued).

Suspend the engine, using a workshop hoist.

Remove:

- The RH engine support.

- The upper timing cover.

Peg the camshaft pulleys, using tool [1].

NOTE:The pegs [1] should go in without forcing.

WARNING: If the pegs go in only with difficulty, repeat the operation for fitting and tensioning

the timing belt

(see corresponding operation).

Remove the pegs [1]and [2].

Complete the refitting.

IMPERATIVE: Carry out the operations that are necessary following a reconnection of the battery

(see corresponding operation).

B1EP1GRC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 225