RFK Citroen C4 2005 2.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 232 of 462

![Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 226

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

[3 Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 226

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

[3](/img/9/4138/w960_4138-231.png)

Downloaded from www.Manualslib.com manuals search engine 226

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

[3] Timing belt retaining pin: (-) 0189.K

[4]Adaptor for angular tightening: 4069-T

[5]Hub immobilising tool: (-).0189.S

[5a] : (-).0189.S1

[5b] : (-).0189.S2

Pliers for removing plastic pins: 7504-T

IMPERATIVE: Respect the safety and cleanliness requirements.

Checking and setting the timing.

Removing.

Disconnect the negative terminal of the battery

(see corresponding operation).

Raise and support the vehicle, front wheels hanging.

Remove the auxiliaries drive belt

(see corresponding operation).

Unclip and move aside the fuel supply hose from the timing cover.

Remove the screw (1).

Move aside the power steering pipes.

Turn the engine by means of the screw (4)of the crankshaft pinion (3)to bring it to the pegging position.

B3EP15YC

B1BP36YC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 226

Page 233 of 462

![Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 227

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

Peg the crankshaft using tool [2].

Su Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 227

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

Peg the crankshaft using tool [2].

Su](/img/9/4138/w960_4138-232.png)

Downloaded from www.Manualslib.com manuals search engine 227

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

Peg the crankshaft using tool [2].

Suspend the engine, using a workshop hoist.

Remove:

- The upper RH engine support.

- The upper timing cover (2).

B1BP36YC

B1BP2V5D

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 227

Page 234 of 462

Downloaded from www.Manualslib.com manuals search engine 228

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

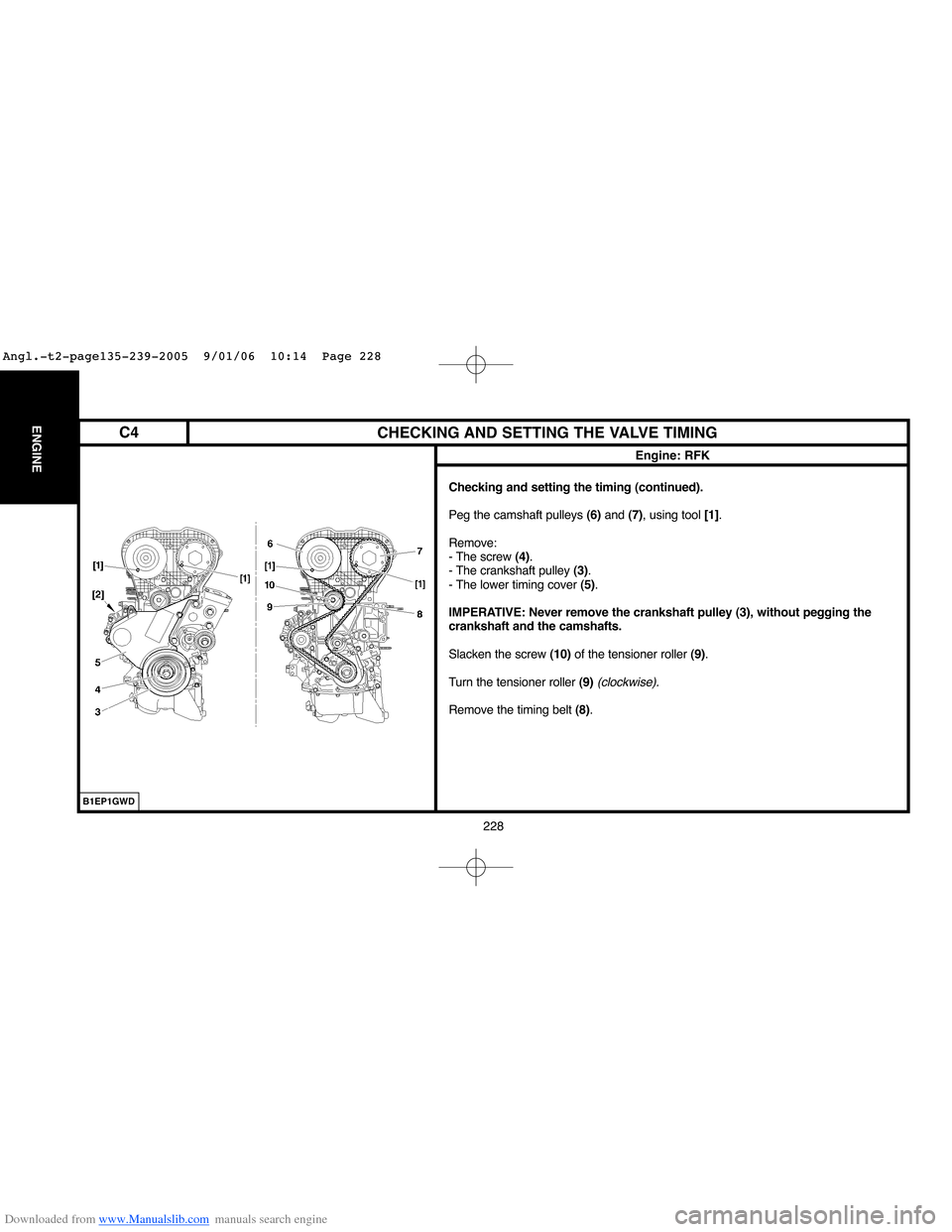

Checking and setting the timing (continued).

Peg the camshaft pulleys (6)and (7), using tool [1].

Remove:

- The screw (4).

- The crankshaft pulley (3).

- The lower timing cover (5).

IMPERATIVE: Never remove the crankshaft pulley (3), without pegging the

crankshaft and the camshafts.

Slacken the screw (10)of the tensioner roller (9).

Turn the tensioner roller (9)

(clockwise).

Remove the timing belt (8).

B1EP1GWD

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 228

Page 235 of 462

Downloaded from www.Manualslib.com manuals search engine 229

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

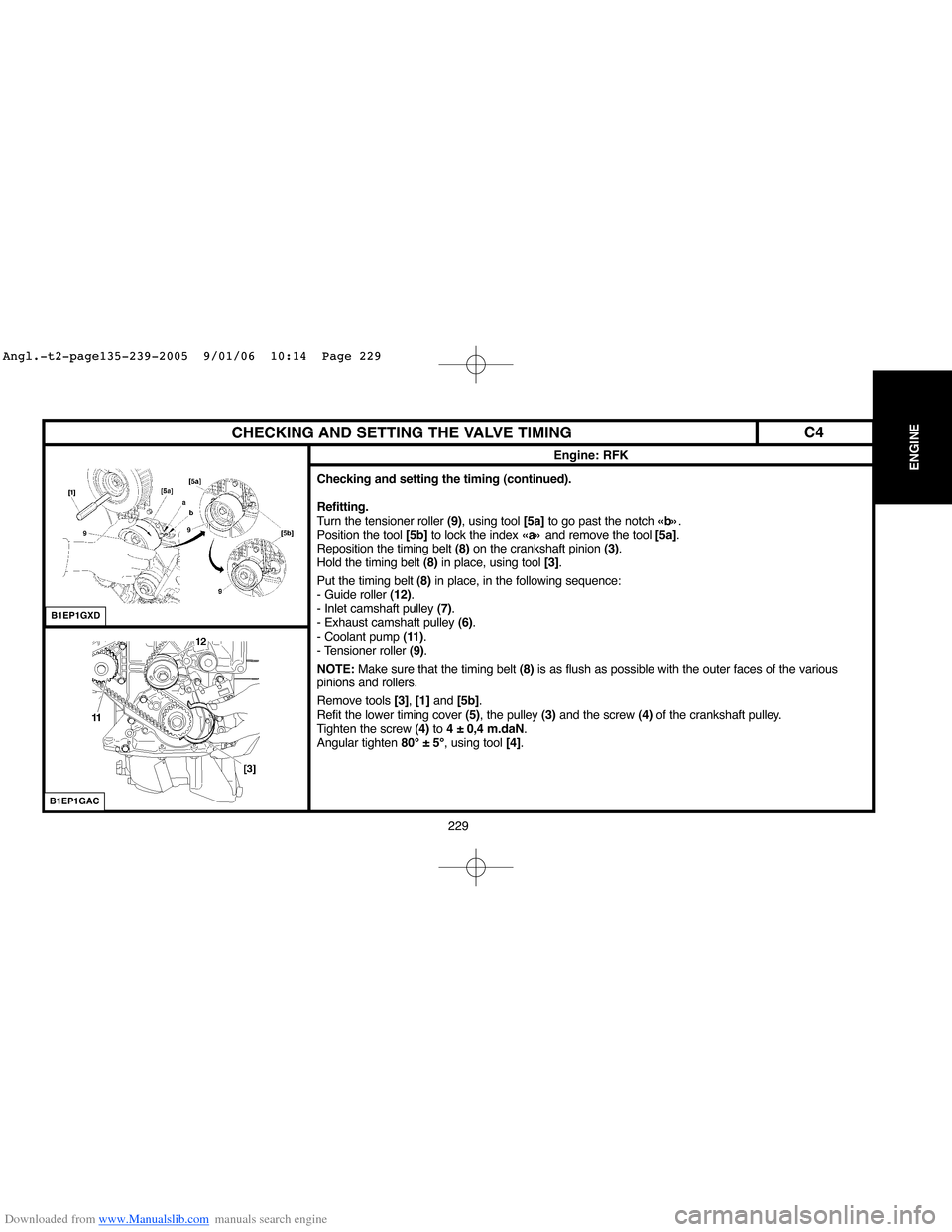

Refitting.

Turn the tensioner roller (9), using tool [5a]to go past the notch «b».

Position the tool [5b]to lock the index «a»and remove the tool [5a].

Reposition the timing belt (8)on the crankshaft pinion (3).

Hold the timing belt (8)in place, using tool [3].

Put the timing belt (8)in place, in the following sequence:

- Guide roller (12).

- Inlet camshaft pulley (7).

- Exhaust camshaft pulley (6).

- Coolant pump (11).

- Tensioner roller (9).

NOTE:Make sure that the timing belt (8)is as flush as possible with the outer faces of the various

pinions and rollers.

Remove tools [3], [1]and [5b].

Refit the lower timing cover (5), the pulley (3)and the screw (4)of the crankshaft pulley.

Tighten the screw (4)to 4 ± 0,4 m.daN.

Angular tighten 80° ± 5°, using tool [4].

B1EP1GXD

B1EP1GAC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 229

Page 236 of 462

Downloaded from www.Manualslib.com manuals search engine 230

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

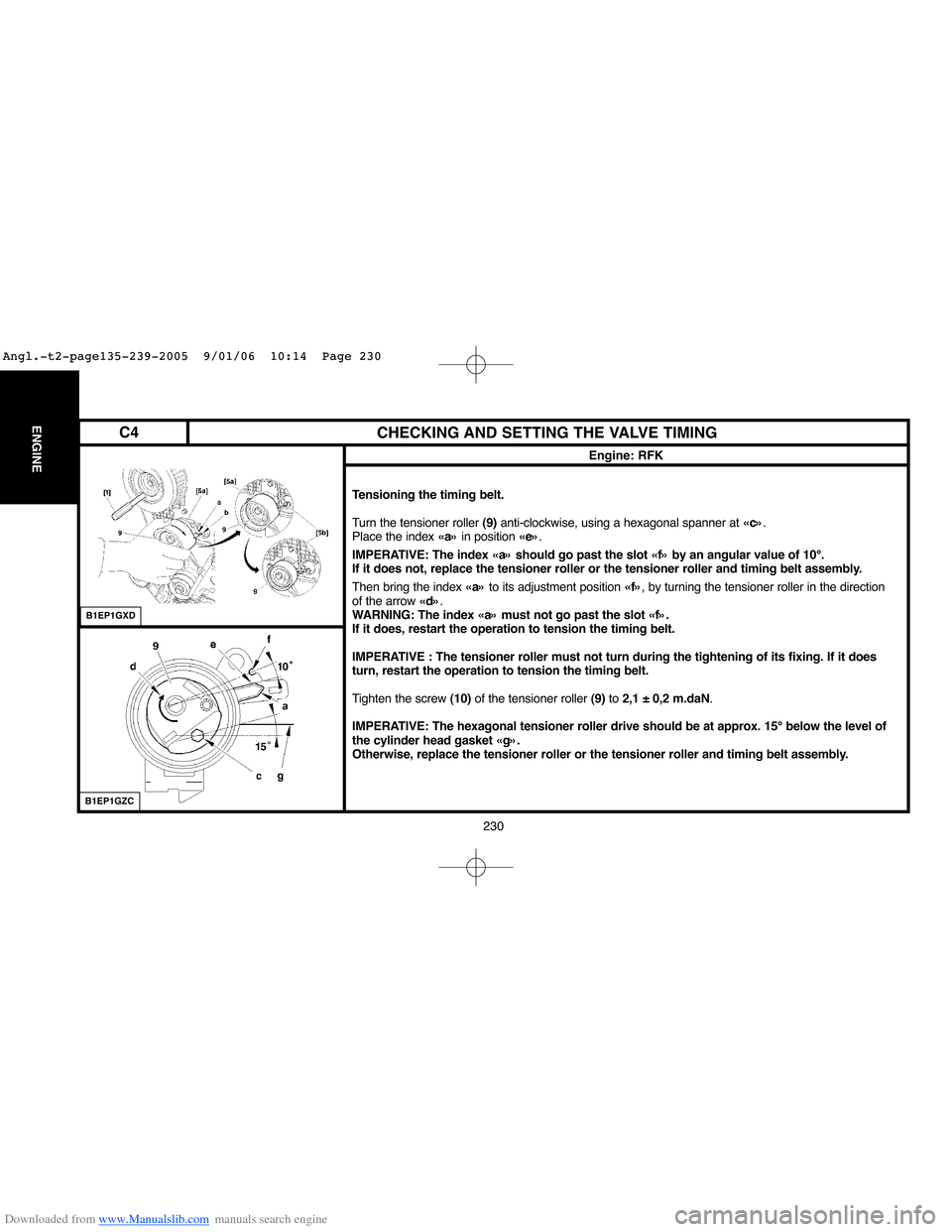

Tensioning the timing belt.

Turn the tensioner roller (9)anti-clockwise, using a hexagonal spanner at «c».

Place the index «a»in position «e».

IMPERATIVE: The index «a» should go past the slot «f» by an angular value of 10°.

If it does not, replace the tensioner roller or the tensioner roller and timing belt assembly.

Then bring the index «a»to its adjustment position «f», by turning the tensioner roller in the direction

of the arrow «d».

WARNING: The index «a» must not go past the slot «f».

If it does, restart the operation to tension the timing belt.

IMPERATIVE : The tensioner roller must not turn during the tightening of its fixing. If it does

turn, restart the operation to tension the timing belt.

Tighten the screw (10)of the tensioner roller (9)to 2,1 ± 0,2 m.daN.

IMPERATIVE: The hexagonal tensioner roller drive should be at approx. 15° below the level of

the cylinder head gasket «g».

Otherwise, replace the tensioner roller or the tensioner roller and timing belt assembly.

B1EP1GXD

B1EP1GZC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 230

Page 237 of 462

Downloaded from www.Manualslib.com manuals search engine 231

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

Refitting (continued).

Remove the tools [1]and [2].

Refit the upper RH engine support.

Remove the workshop hoist.

Rotate the crankshaft ten times

(normal direction of rotation).

IMPERATIVE: No exterior pressure or action should be applied on the timing belt.

Suspend the engine using a workshop hoist.

Remove the upper RH engine support.

Peg the inlet camshaft pulley, using tool [1].

Checking.

Timing belt tension.

IMPERATIVE: Check the position of the index «a», it should be opposite the slot «f». If the position of the index «a» is not correct, repeat

the operations to tension the timig belt.

Complete the refitting.

IMPERATIVE: Carry out the operations that are necessary following a reconnection of the battery

(see corresponding operation).

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 231

Page 285 of 462

Downloaded from www.Manualslib.com manuals search engine ENGINE

279

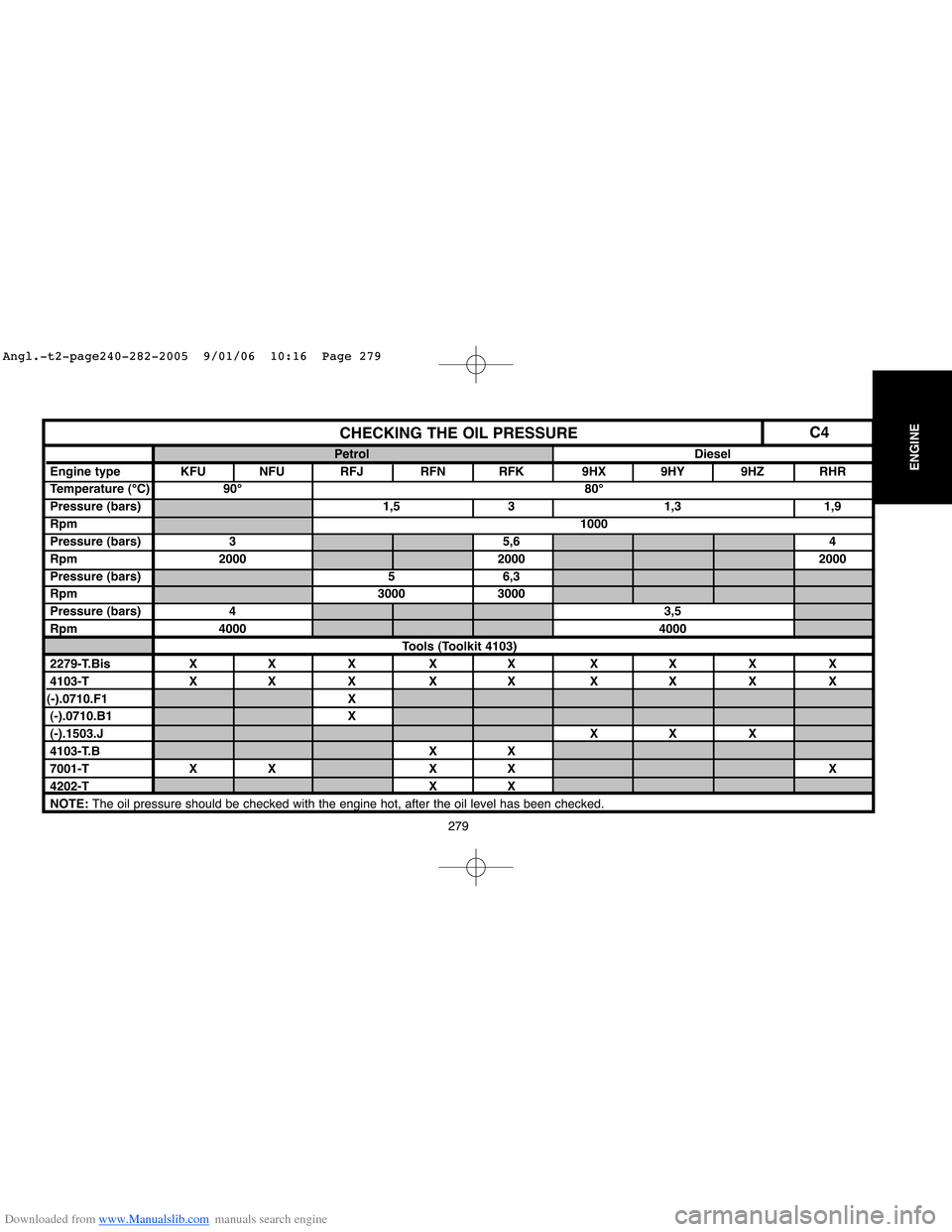

C4CHECKING THE OIL PRESSURE

Petrol Diesel

Engine type KFU NFU RFJ RFN RFK 9HX 9HY 9HZ RHR

Temperature (°C) 90° 80°

Pressure (bars) 1,5 3 1,3 1,9

Rpm1000

Pressure (bars) 3 5,6 4

Rpm 2000 2000 2000

Pressure (bars) 5 6,3

Rpm 3000 3000

Pressure (bars) 43,5

Rpm 40004000

Tools (Toolkit 4103)

2279-T.Bis X X X X X X X X X

4103-T X X X X X X X X X

(-).0710.F1 X

(-).0710.B1 X

(-).1503.JXX X

4103-T.B X X

7001-T X X X X X

4202-T X X

NOTE: The oil pressure should be checked with the engine hot, after the oil level has been checked.

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 279

Page 311 of 462

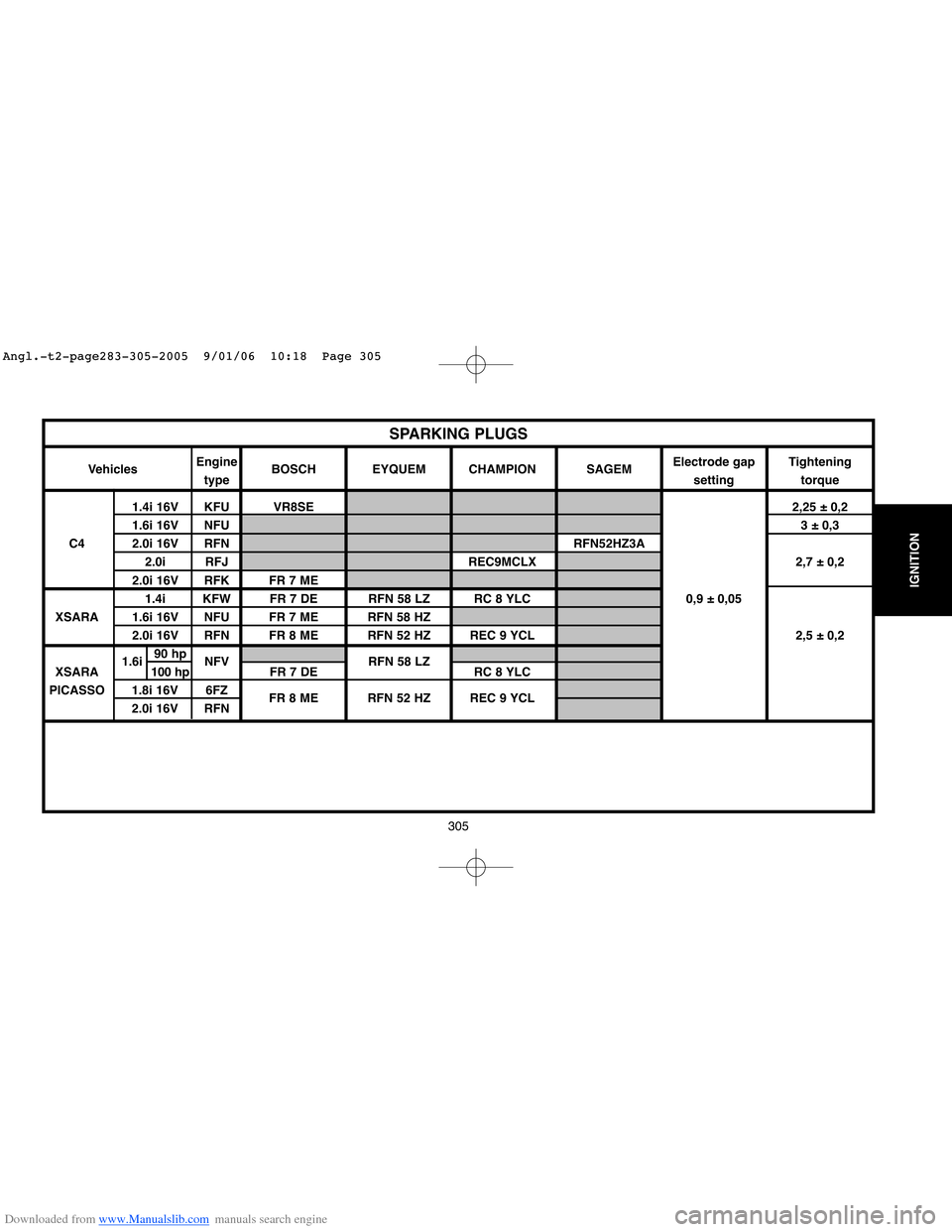

Downloaded from www.Manualslib.com manuals search engine 305

IGNITION

VehiclesEngine

BOSCH EYQUEM CHAMPION SAGEMElectrode gap Tightening

typesetting torque

1.4i 16V KFU VR8SE2,25 ± 0,2

1.6i 16V NFU3 ± 0,3

C4 2.0i 16V RFN RFN52HZ3A

2.0i RFJ REC9MCLX 2,7 ± 0,2

2.0i 16V RFK FR 7 ME

1.4i KFW FR 7 DE RFN 58 LZ RC 8 YLC 0,9 ± 0,05

XSARA 1.6i 16V NFU FR 7 ME RFN 58 HZ

2.0i 16V RFN FR 8 ME RFN 52 HZ REC 9 YCL 2,5 ± 0,2

1.6i90 hp

NFV RFN 58 LZ

XSARA100 hp FR 7 DE RC 8 YLC

PICASSO 1.8i 16V 6FZ

FR 8 ME RFN 52 HZ REC 9 YCL

2.0i 16V RFN

SPARKING PLUGS

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 305

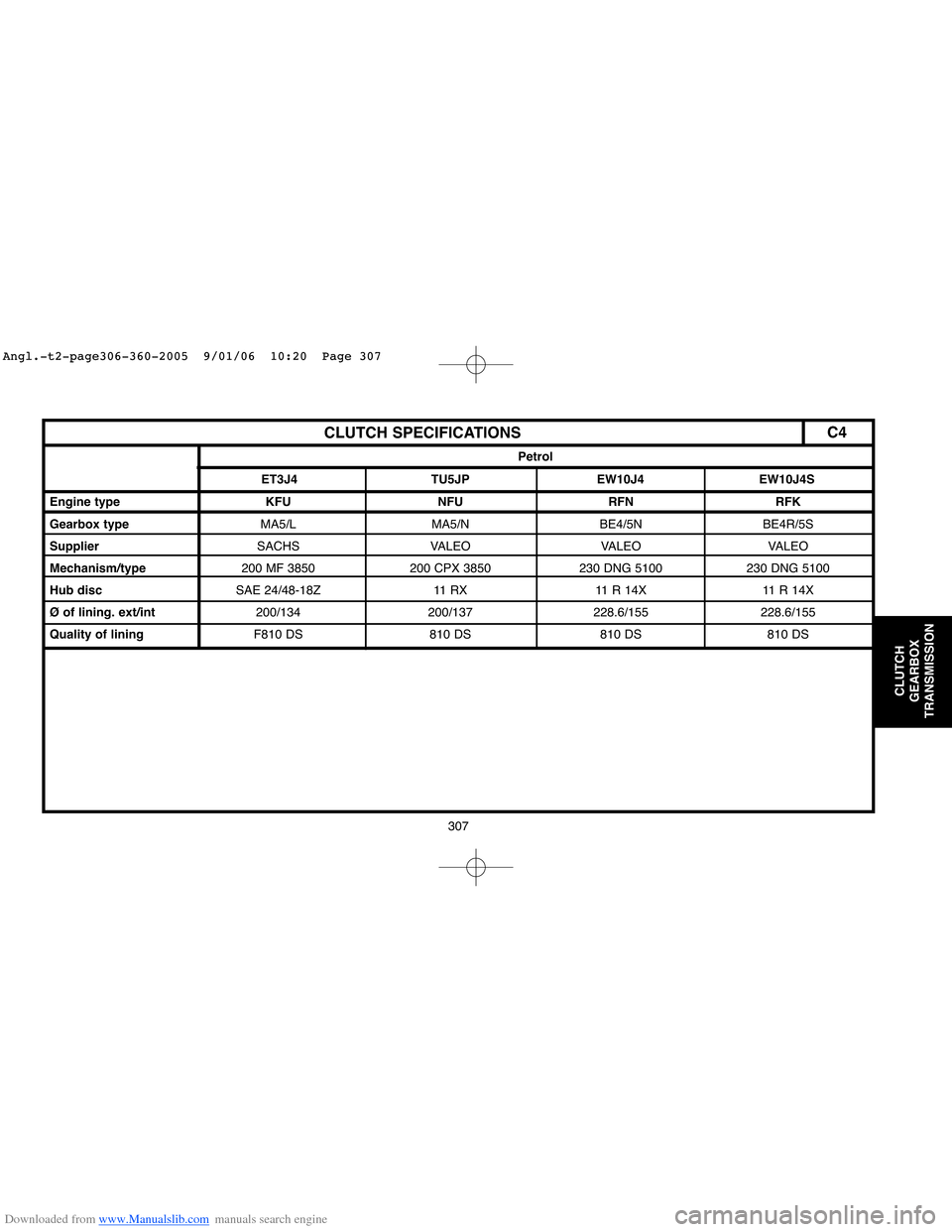

Page 313 of 462

Downloaded from www.Manualslib.com manuals search engine 307

CLUTCH

GEARBOX

TRANSMISSION

CLUTCH SPECIFICATIONS

Engine type KFU NFU RFN RFK

Gearbox type MA5/L MA5/N BE4/5N BE4R/5S

SupplierSACHS VALEO VALEO VALEO

Mechanism/type200 MF 3850 200 CPX 3850 230 DNG 5100 230 DNG 5100

Hub discSAE 24/48-18Z 11 RX 11 R 14X 11 R 14X

Ø of lining. ext/int200/134 200/137 228.6/155 228.6/155

Quality of liningF810 DS 810 DS 810 DS 810 DS

ET3J4 TU5JP EW10J4 EW10J4S

Petrol

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 307

Page 321 of 462

Downloaded from www.Manualslib.com manuals search engine 315

CLUTCH

GEARBOX

TRANSMISSION

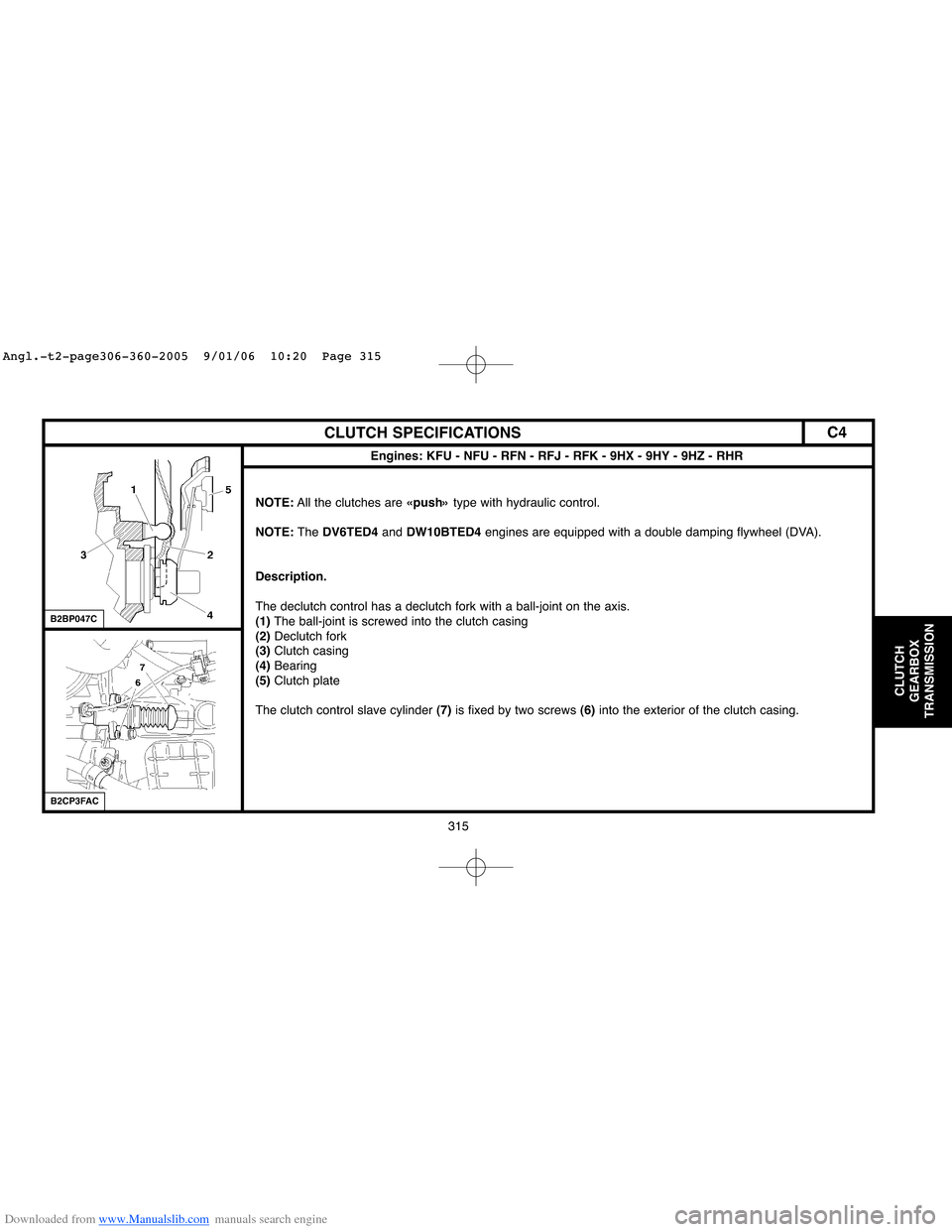

CLUTCH SPECIFICATIONS

Engines: KFU - NFU - RFN - RFJ - RFK - 9HX - 9HY - 9HZ - RHR

NOTE:All the clutches are «push»type with hydraulic control.

NOTE:The DV6TED4and DW10BTED4engines are equipped with a double damping flywheel (DVA).

Description.

The declutch control has a declutch fork with a ball-joint on the axis.

(1)The ball-joint is screwed into the clutch casing

(2) Declutch fork

(3)Clutch casing

(4)Bearing

(5) Clutch plate

The clutch control slave cylinder(7)is fixed by two screws (6) into the exterior of the clutch casing.

B2BP047C

B2CP3FAC

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 315