wheel torque Citroen C4 2005 2.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 148 of 462

Downloaded from www.Manualslib.com manuals search engine 142

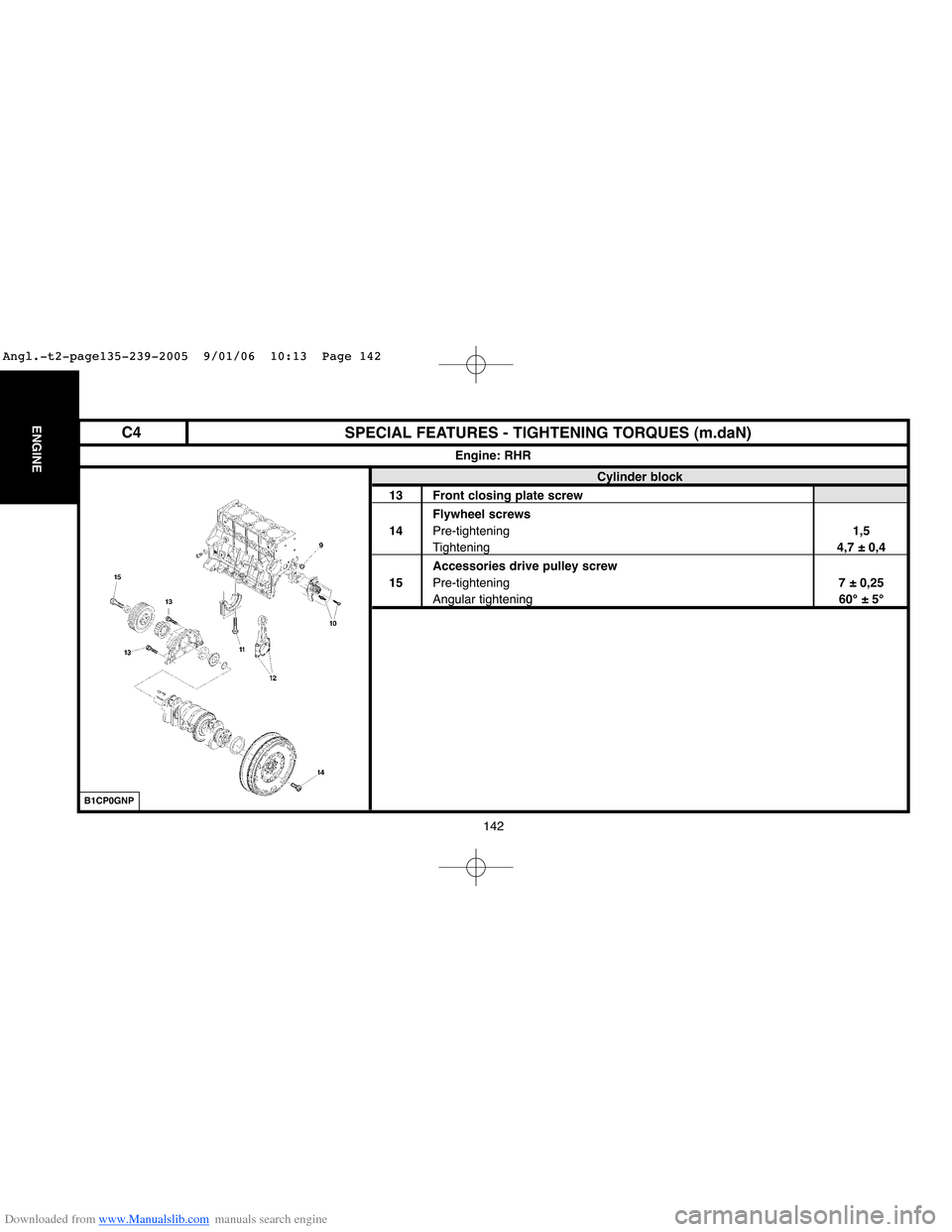

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder block

13 Front closing plate screw

Flywheel screws

14Pre-tightening1,5

Tightening4,7 ± 0,4

Accessories drive pulley screw

15Pre-tightening7 ± 0,25

Angular tightening60°±5°

Engine: RHR

B1CP0GNP

C4

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 142

Page 169 of 462

Downloaded from www.Manualslib.com manuals search engine 163

ENGINE

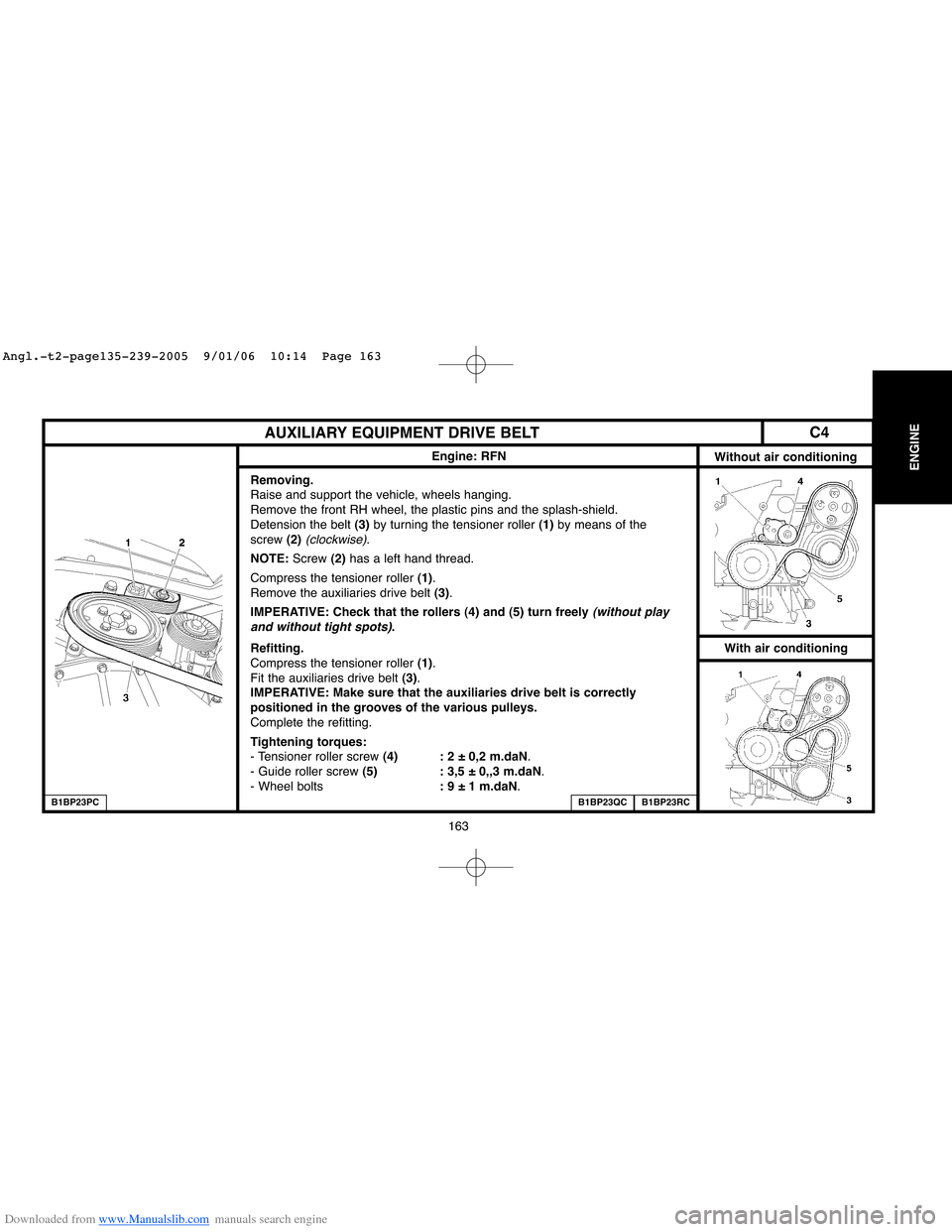

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFN

Without air conditioning

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Detension the belt (3)by turning the tensioner roller (1)by means of the

screw (2)

(clockwise).

NOTE:Screw (2)has a left hand thread.

Compress the tensioner roller (1).

Remove the auxiliaries drive belt (3).

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play

and without tight spots).

Refitting.

Compress the tensioner roller (1).

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly

positioned in the grooves of the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4) : 2 ± 0,2 m.daN.

- Guide roller screw (5) : 3,5 ± 0,,3 m.daN.

- Wheel bolts: 9 ± 1 m.daN.

B1BP23PCB1BP23QCB1BP23RC

With air conditioning

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 163

Page 170 of 462

![Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle](/img/9/4138/w960_4138-169.png)

Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner roller:

Dynamic spanner extension: FACOM SJ.214

Adaptor for socket 9x12 : FACOM J.274

Polygon socket 9x12 : 016

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Turn the tensioner roller(1)by the screw (2)

(anti-clockwise), using tool [1]to detension the belt (3).

NOTE: Screw (2)has a left hand thread.

Remove the auxiliaries drive belt (3).

Refitting.

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play and without tight spots).

Refitting.

Compress the tensioner roller (1), using tool [1].

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4)tighten to: 2 ± 0,2 m.daN.

- Guide roller screw (5)tighten to: 3,5 ± 0,3 m.daN.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 164

Page 258 of 462

![Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 252

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting.

Refit tool [1]at «b».

Remove the screw (10).

Refit:

- The uppe Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 252

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting.

Refit tool [1]at «b».

Remove the screw (10).

Refit:

- The uppe](/img/9/4138/w960_4138-257.png)

Downloaded from www.Manualslib.com manuals search engine 252

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting.

Refit tool [1]at «b».

Remove the screw (10).

Refit:

- The upper timing cover (12).

- The lower timing cover (11).

- The accessories drive pulley (9).

- The screw (10).

Tightening torque

Screw (10)Pre-tighten to : 3 ± 0,3 m.daN.

Angular tighten : 180° ± 5°.

Remove tool [1].

Refit:

- The engine support (8), tighten to 5,5 ± 0,4 m.daN.

- The engine support (4), tighten to 6,1 ± 0,6 m.daN.

- The engine support (5), tighten to 2,5 ± 0,2 m.daN.

- The electrical harness (7).

- The power steering fluid reservoir (6).

XSARA PICASSO

Couple:

- The tube (2).

- The exhaust line, tighten the clip to 2,5 ± 0,3 m.daN.

- The fuel unions (1).

- The air/air heat exchanger inlet and outlet pipes (3).

Connect the connector at «a».

Refit:

- The accessories drive belt

(see corresponding operation).

- The front RH splash-shield (see corresponding operation).

- The front RH wheel, tighten to 9 ± 1 m.daN.

- Reconnect the positive and negative terminals of the battery.

IMPERATIVE: Perform the operations that are necessary following

a reconnection of the battery

(see corresponding operation).

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 252

Page 264 of 462

![Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 258

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting (continued).

Refit tool [1]at «b».

Remove the screw (10).

Refit: Citroen C4 2005 2.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 258

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting (continued).

Refit tool [1]at «b».

Remove the screw (10).

Refit:](/img/9/4138/w960_4138-263.png)

Downloaded from www.Manualslib.com manuals search engine 258

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting (continued).

Refit tool [1]at «b».

Remove the screw (10).

Refit:

- The upper timing cover (12).

- The lower timing cover (11).

- The accessories drive pulley (9).

- The screw (10).

Tightening torque

- Screw (10)Pre-tighten to: 3 ± 0,3 m.daN.

Angular tighten: 180° ± 5°.

Remove tool [1].

Refit:

- The engine support (8), tighten to 5,5 ± 0,4 m.daN.

- The engine support (4), tighten to 6,1 ± 0,6 m.daN.

- The engine support (5), tighten to 2,5 ± 0,2 m.daN.

- The electrical harness (7).

- The power steering fluid reservoir (6).

XSARA PICASSO

Disengage the jack from under the engine.

Couple:

- The tube (2).

- The exhaust line, tighten the clip to 2,5 ± 0,3 m.daN.

- The fuel unions (1).

- The air/air heat exchanger inlet and outlet pipes (3).

Connect the connector at «a».

Refit:

- The accessories drive belt

(see corresponding operation).

- The front RH splash-shield (see corresponding operation).

- The front RH wheel, tighten to 9 ± 1 m.daN.

Reconnect the positive and negative terminals of the battery.

IMPERATIVE: Perform the operations that are necessary following

a reconnection of the battery

(see corresponding operation).

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 258

Page 272 of 462

Downloaded from www.Manualslib.com manuals search engine 266

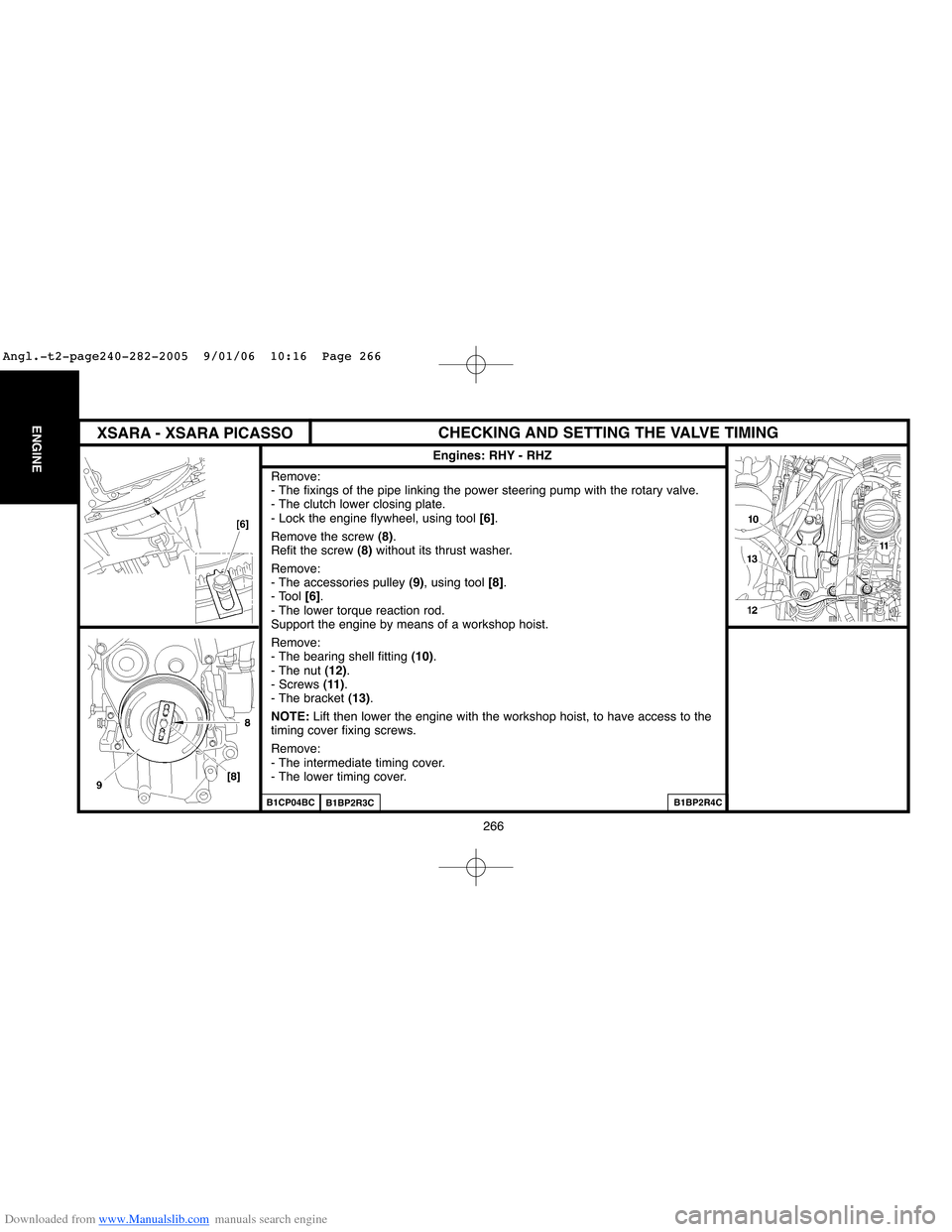

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: RHY - RHZ

Remove:

- The fixings of the pipe linking the power steering pump with the rotary valve.

- The clutch lower closing plate.

- Lock the engine flywheel, using tool [6].

Remove the screw (8).

Refit the screw (8)without its thrust washer.

Remove:

- The accessories pulley (9), using tool [8].

- Tool [6].

- The lower torque reaction rod.

Support the engine by means of a workshop hoist.

Remove:

- The bearing shell fitting (10).

- The nut (12).

- Screws (11).

- The bracket (13).

NOTE:Lift then lower the engine with the workshop hoist, to have access to the

timing cover fixing screws.

Remove:

- The intermediate timing cover.

- The lower timing cover.

B1CP04BCB1BP2R3CB1BP2R4C

XSARA - XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 266

Page 322 of 462

Downloaded from www.Manualslib.com manuals search engine 316

CLUTCH

GEARBOX

TRANSMISSION

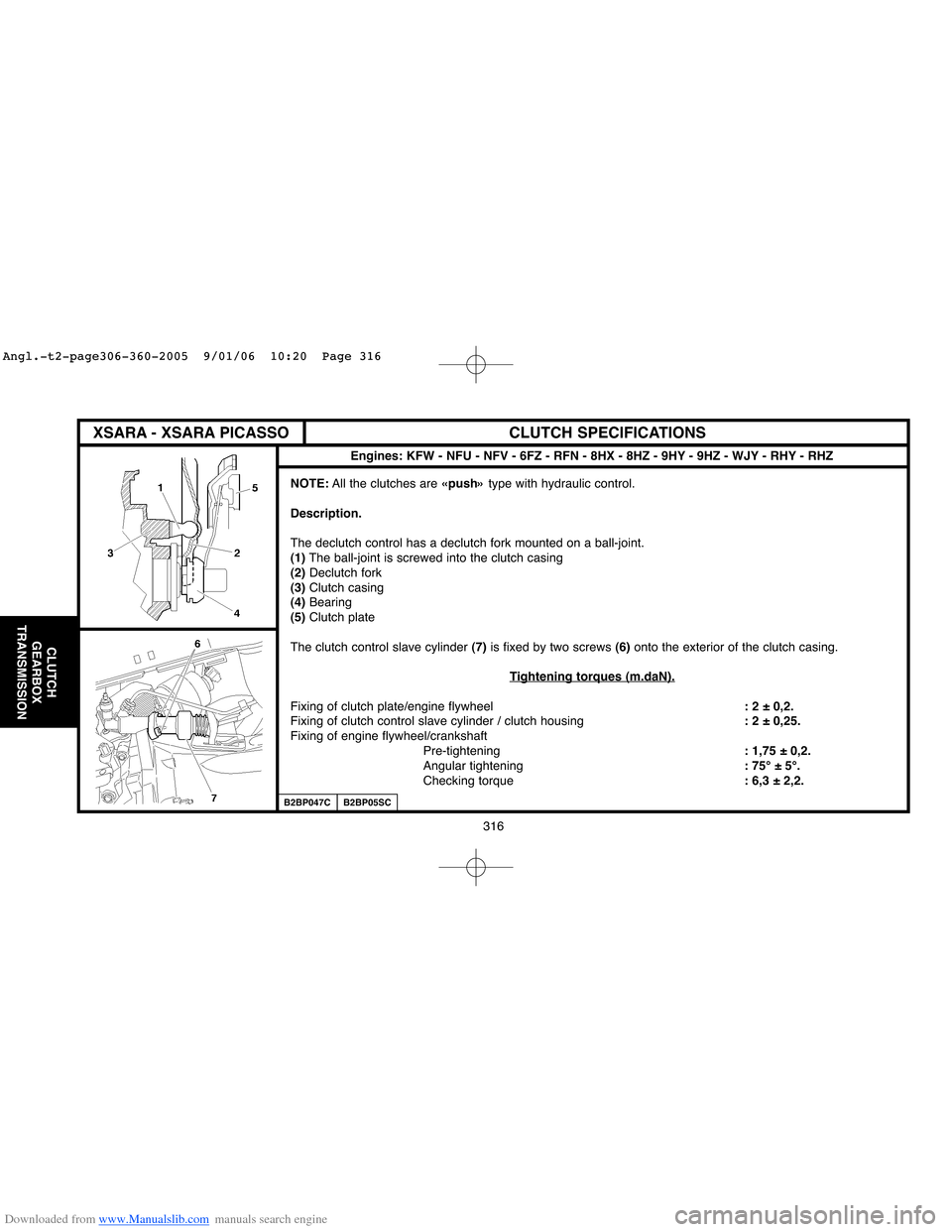

CLUTCH SPECIFICATIONS

Engines: KFW - NFU - NFV - 6FZ - RFN - 8HX - 8HZ - 9HY - 9HZ - WJY - RHY - RHZ

NOTE:All the clutches are «push»type with hydraulic control.

Description.

The declutch control has a declutch fork mounted on a ball-joint.

(1)The ball-joint is screwed into the clutch casing

(2)Declutch fork

(3)Clutch casing

(4)Bearing

(5)Clutch plate

The clutch control slave cylinder (7)is fixed by two screws (6)onto the exterior of the clutch casing.

T

ightening torques (m.daN).

Fixing of clutch plate/engine flywheel: 2 ± 0,2.

Fixing of clutch control slave cylinder / clutch housing: 2 ± 0,25.

Fixing of engine flywheel/crankshaft

Pre-tightening: 1,75 ± 0,2.

Angular tightening: 75° ± 5°.

Checking torque: 6,3 ± 2,2.

B2BP047CB2BP05SC

XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 316

Page 331 of 462

Downloaded from www.Manualslib.com manuals search engine 325

CLUTCH

GEARBOX

TRANSMISSION

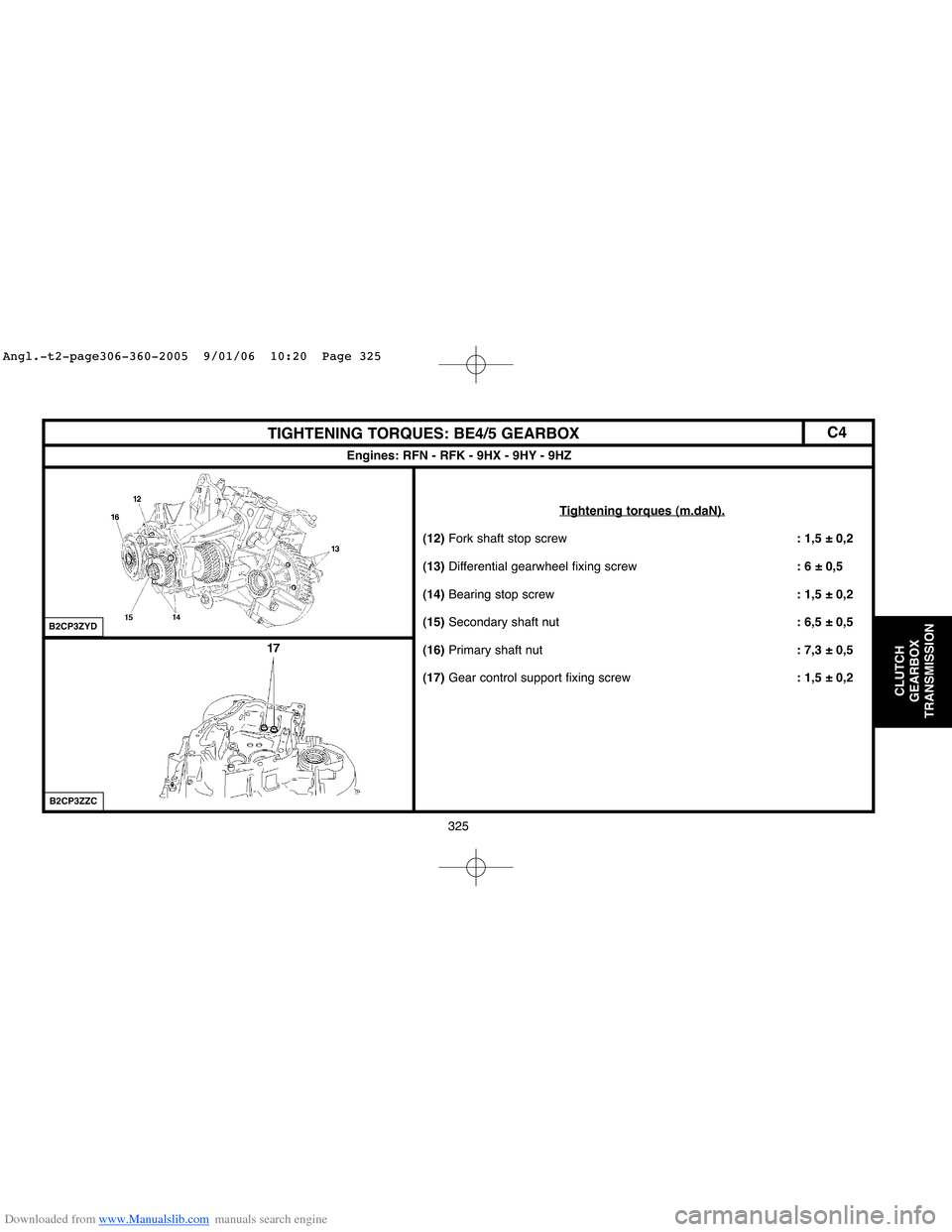

TIGHTENING TORQUES: BE4/5 GEARBOX

Engines: RFN - RFK - 9HX - 9HY - 9HZ

Tightening torques (m.daN).

(12)Fork shaft stop screw: 1,5 ± 0,2

(13)Differential gearwheel fixing screw: 6 ± 0,5

(14)Bearing stop screw: 1,5 ± 0,2

(15)Secondary shaft nut: 6,5 ± 0,5

(16)Primary shaft nut: 7,3 ± 0,5

(17)Gear control support fixing screw: 1,5 ± 0,2

B2CP3ZZC

B2CP3ZYD

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 325

Page 333 of 462

Downloaded from www.Manualslib.com manuals search engine 327

CLUTCH

GEARBOX

TRANSMISSION

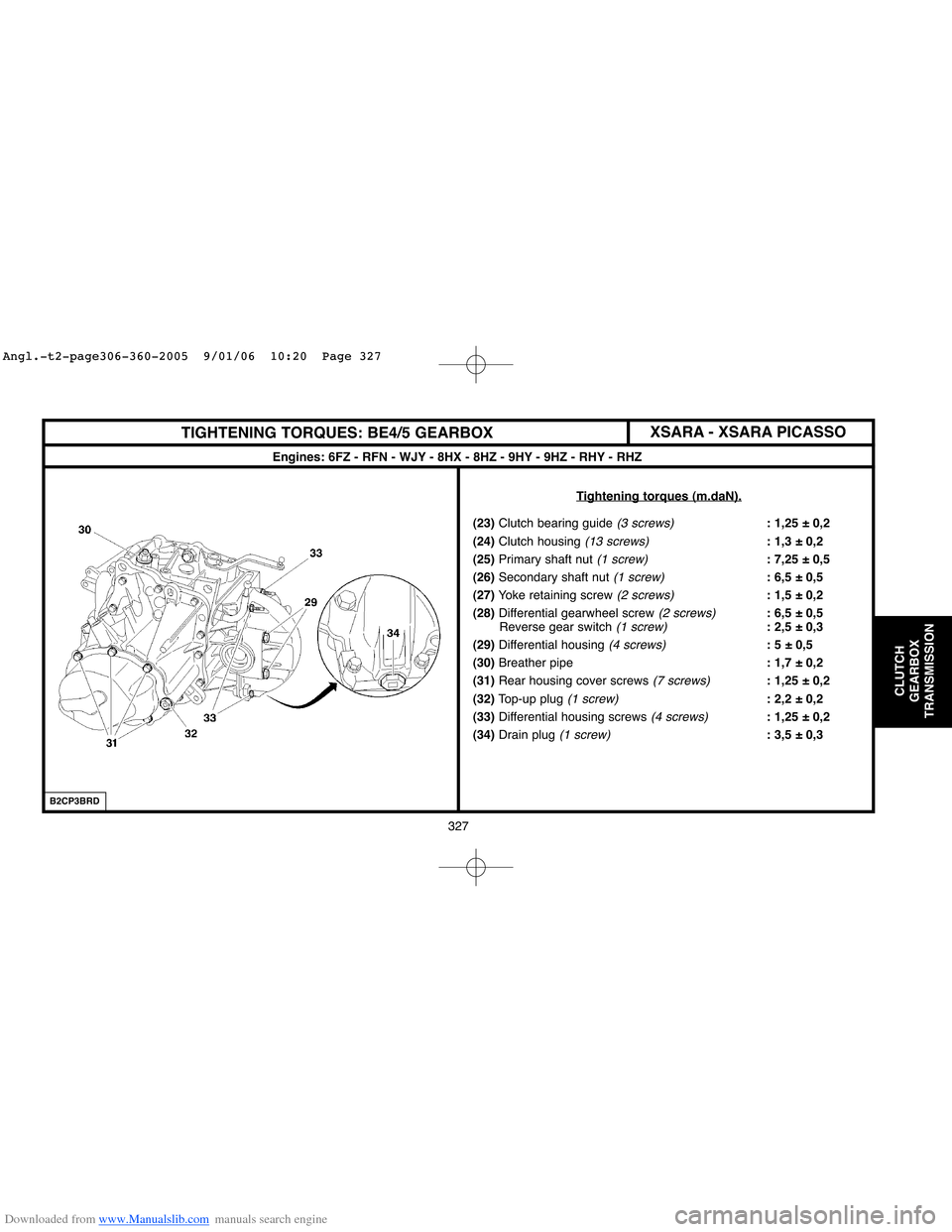

TIGHTENING TORQUES: BE4/5 GEARBOX

Engines: 6FZ - RFN - WJY - 8HX - 8HZ - 9HY - 9HZ - RHY - RHZ

T

ightening torques (m.daN).

(23)Clutch bearing guide (3 screws): 1,25 ± 0,2

(24)Clutch housing

(13 screws): 1,3 ± 0,2

(25)Primary shaft nut

(1 screw): 7,25 ± 0,5

(26)Secondary shaft nut

(1 screw): 6,5 ± 0,5

(27)Yoke retaining screw

(2 screws): 1,5 ± 0,2

(28)Differential gearwheel screw

(2 screws): 6,5 ± 0,5

Reverse gear switch (1 screw): 2,5 ± 0,3

(29)Differential housing

(4 screws): 5 ± 0,5

(30)Breather pipe: 1,7 ± 0,2

(31)Rear housing cover screws

(7 screws): 1,25 ± 0,2

(32)Top-up plug

(1 screw): 2,2 ± 0,2

(33) Differential housing screws

(4 screws): 1,25 ± 0,2

(34)Drain plug

(1 screw): 3,5 ± 0,3

B2CP3BRD

XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 327

Page 334 of 462

Downloaded from www.Manualslib.com manuals search engine 328

CLUTCH

GEARBOX

TRANSMISSION

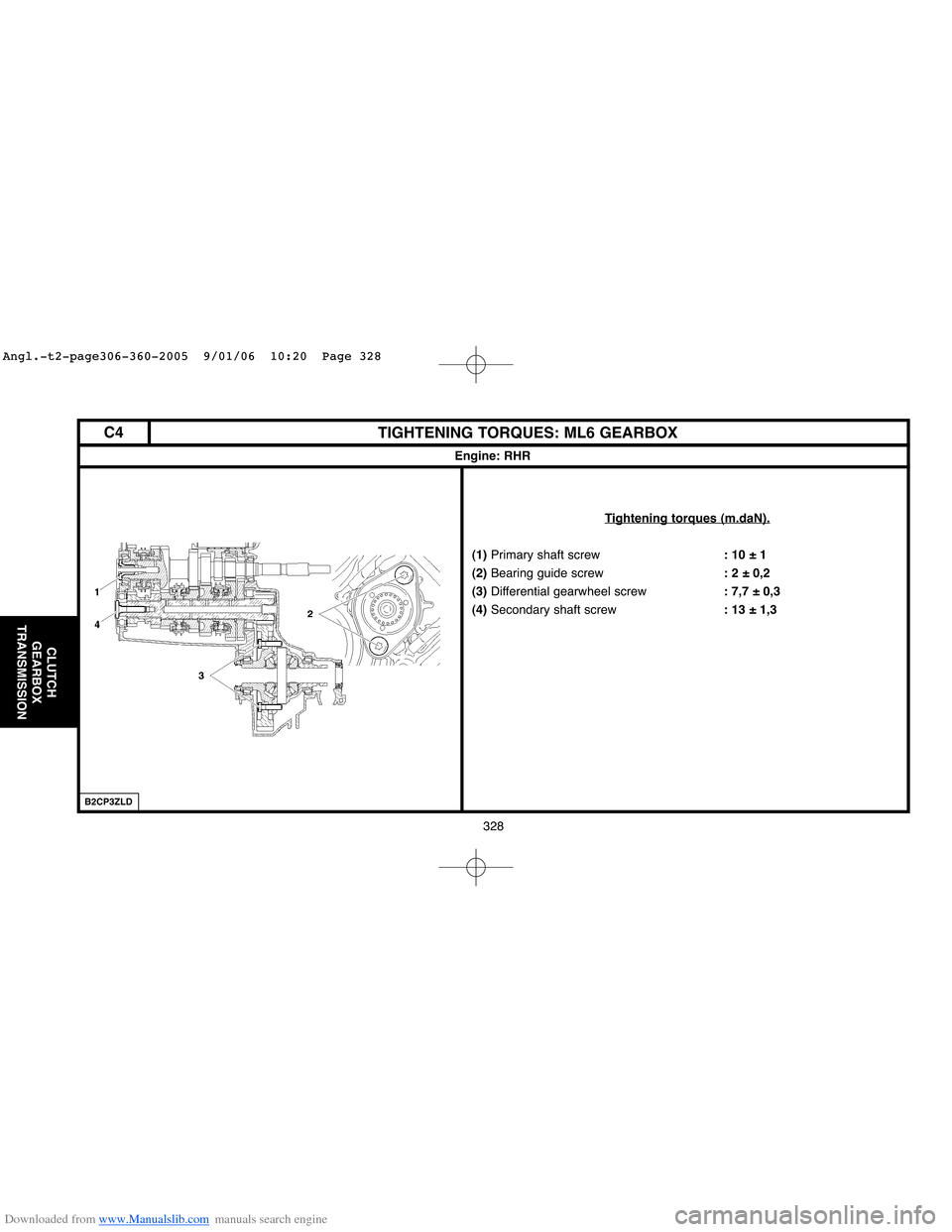

TIGHTENING TORQUES: ML6 GEARBOX

Engine: RHR

Tightening torques (m.daN).

(1)Primary shaft screw: 10 ± 1

(2)Bearing guide screw: 2 ± 0,2

(3) Differential gearwheel screw: 7,7 ± 0,3

(4)Secondary shaft screw: 13 ± 1,3

B2CP3ZLD

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 328