engin oil Citroen C4 2005 2.G Manual PDF

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 350 of 462

Downloaded from www.Manualslib.com manuals search engine 344

CLUTCH

GEARBOX

TRANSMISSION

RECOMMENDATIONS/PRECAUTIONS : AL4 AUTOMATIC GEARBOX

Precautions to be taken

Repairs on mechanical components.

Never place the gearbox on the ground without protection.

In order to avoid breaking the input shaft ring, it is imperative

that the

converter retaining bracket should be in place when handling the

gearbox.

It is imperative

to use the centring peg and the converter retaining

bracket to couple the gearbox on the engine.

After coupling the gearbox on the engine, remove the centring peg. Modification of the oil usage counter value.

Exchanging the gearbox ECU:

- Note down the gearbox counter value.

- Transfer the value read into the the new gearbox ECU.

Exchanging the gearbox:

- Initialise the oil usage counter to 0.

Draining the gearbox:

- Initialise the oil usage counter

(follow the diagnostic tool procedure).

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 344

Page 351 of 462

Downloaded from www.Manualslib.com manuals search engine 345

CLUTCH

GEARBOX

TRANSMISSION

RECOMMENDATIONS/PRECAUTIONS : AL4 AUTOMATIC GEARBOX

Procedure to be followed prior to carrying out repairs on AL4 autoactive gearbox

If a gearbox malfunction occurs, there are two possible configurations

depending on the seriousness of the fault:

- Gearbox in back-up mode with a replacement programme of

(the fault

values are taken in substitution).

- Gearbox in back-up mode with an emergency programme (3rd hydraulic).

WARNING: In the emergency programme, an impact is felt when

changing P/R, N/R and N/D.

Réception client.

Discuss with the customer, to find out all the malfunction symptoms.

Oil quality - Oil level.

Oil quality.

If the gearbox has suffered a serious fault resulting in a malfunction or

the destruction of a clutch, the oil will overheat and become

contaminated with impurities: the oil is said to be «burnt».

This is characterised by a black colour and the presence of an

unpleasant smell.

ESSENTIAL: The gearbox must be replaced.Oil level

(see corresponding operation).

An excessive oil level can result in the following consequences:

- Excessive heating of the oil.

- Oil leaks.

An insufficent level causes the destruction of the gearbox.

Top up the level of oil in the gearbox

(if necessary).

Check using a diagnostic tool.

Read the fault codes

(engine and gearbox).

Absence of fault codes.

Carry out parameter measures, actuator tests and a road test.

Presence of fault codes.

Carry out the necessary repairs.

Delete the fault codes.

Carry out a road test to check the repair and, if need be, modify the

gearbox ECU parameters

(this is essential after an initialisation of the

ECU).

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 345

Page 352 of 462

Downloaded from www.Manualslib.com manuals search engine 346

CLUTCH

GEARBOX

TRANSMISSION

RECOMMENDATIONS/PRECAUTIONS : AL4 AUTOMATIC GEARBOX

Procedure for initialising the automatic gearbox ECU

Downloading.

Updating the gearbox ECU by downloading:

- Follow the procedure using the diagnostic tool.

The downloading operation enables the automatic gearbox to be

updated, or adapted to an evolution of the engine ECU.

Before commencing the downloading, take the value of the oil usage

counter present in the automatic gearbox ECU.

After the downloading operation, carry out the following:

- A clearing of faults.

- An initialisation of the auto-adaptives.

- A writing of the value of the oil usage counter previously read.

- A road test.

ESSENTIAL: Every update of the automatic gearbox ECU should

be accompanied by an update of the engine ECU.Updating the value of the oil usage counter.

Using PROXIA.

Access to reading and recording of the oil counter is via the menu:

- «Configuration

(integrated circuit button)/Oil counter».

Adjustment of the oil counter value is done in incremental steps of

2750 units.

Using LEXIA.

Access to reading and recording of the oil counter is via the menu:

- «Oil counter».

Adjustment of the oil counter value is done by entering directly

the 5 figuresof the oil counter.

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 346

Page 353 of 462

Downloaded from www.Manualslib.com manuals search engine 347

CLUTCH

GEARBOX

TRANSMISSION

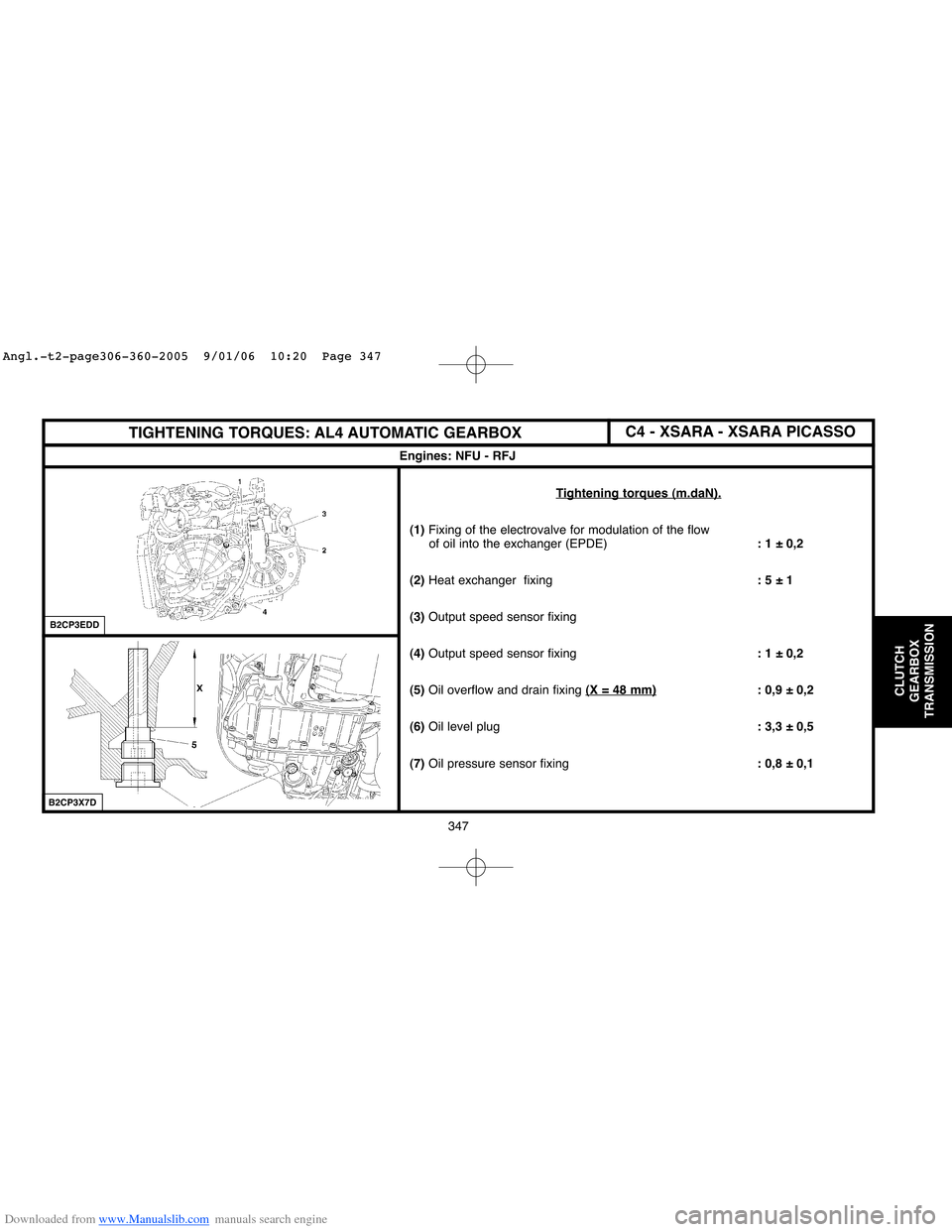

TIGHTENING TORQUES: AL4 AUTOMATIC GEARBOX

Engines: NFU - RFJ

B2CP3EDD

B2CP3X7D

Tightening torques (m.daN).

(1) Fixing of the electrovalve for modulation of the flow

of oil into the exchanger (EPDE): 1 ± 0,2

(2)Heat exchanger fixing: 5 ± 1

(3) Output speed sensor fixing

(4)Output speed sensor fixing: 1 ± 0,2

(5)Oil overflow and drain fixing(X = 48 mm)

: 0,9 ± 0,2

(6)Oil level plug: 3,3 ± 0,5

(7)Oil pressure sensor fixing: 0,8 ± 0,1

C4 - XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 347

Page 355 of 462

Downloaded from www.Manualslib.com manuals search engine 349

CLUTCH

GEARBOX

TRANSMISSION

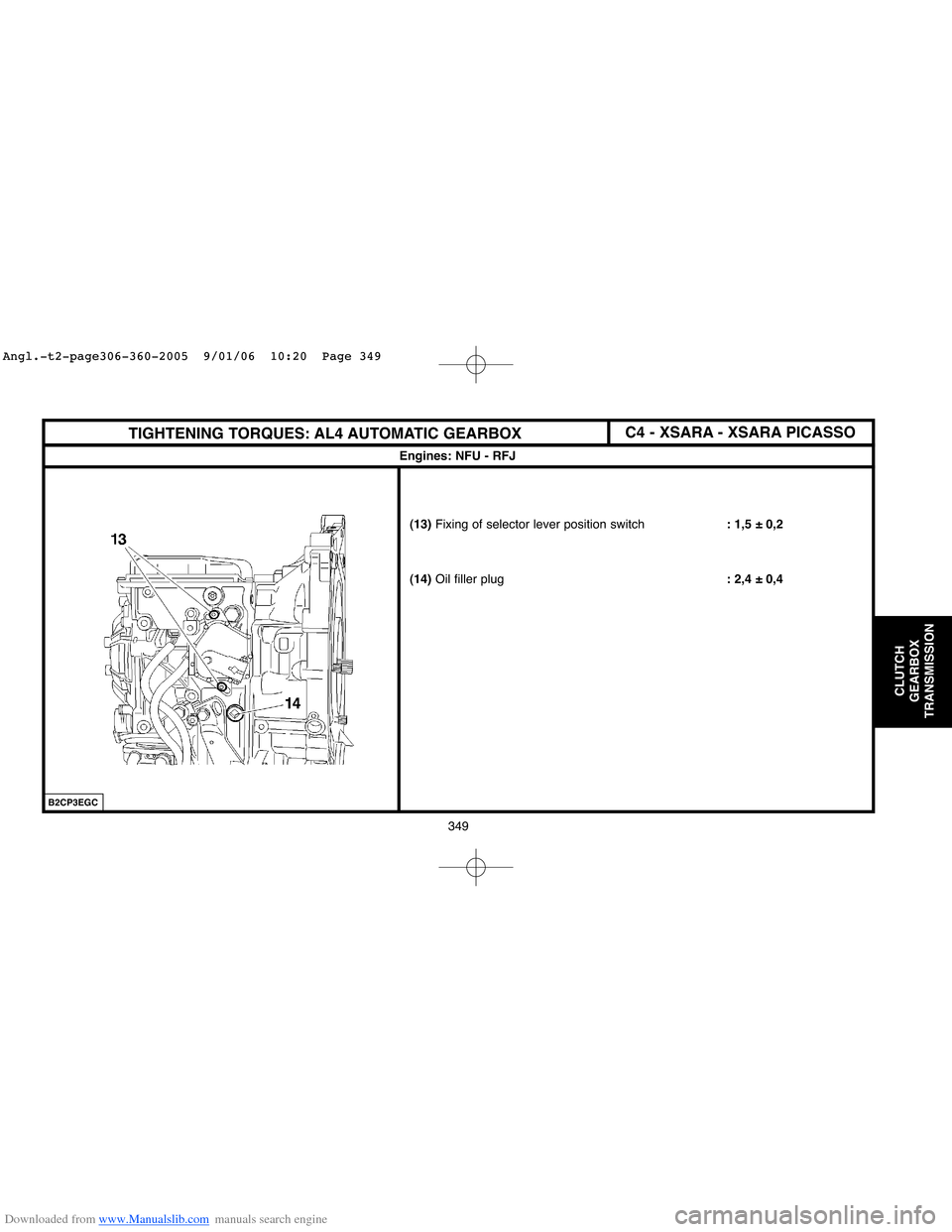

Engines: NFU - RFJ

B2CP3EGC

(13)Fixing of selector lever position switch: 1,5 ± 0,2

(14)Oil filler plug: 2,4 ± 0,4

TIGHTENING TORQUES: AL4 AUTOMATIC GEARBOXC4 - XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 349

Page 366 of 462

Downloaded from www.Manualslib.com manuals search engine 360

CLUTCH

GEARBOX

TRANSMISSION

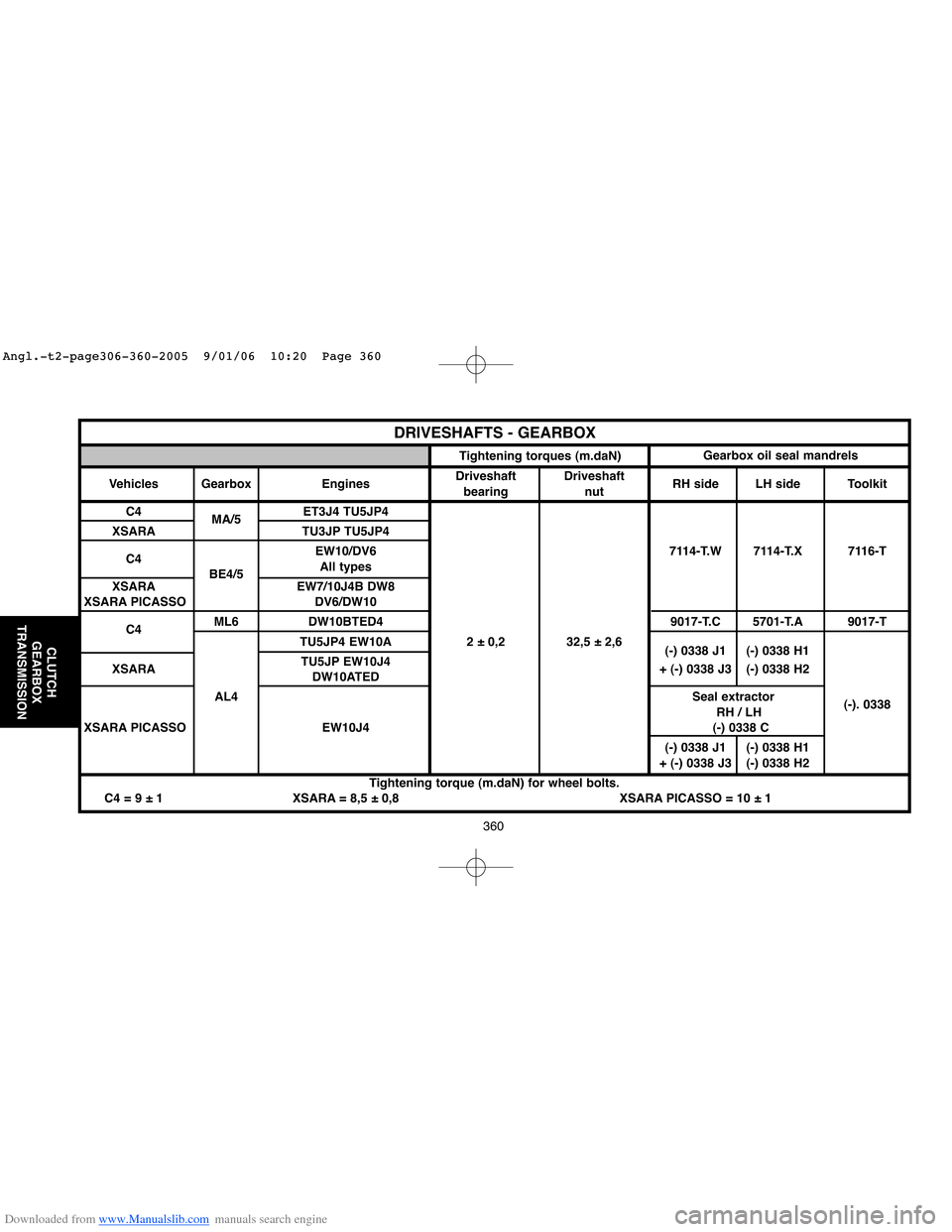

DRIVESHAFTS - GEARBOX

Tightening torques (m.daN)Gearbox oil seal mandrels

Vehicles GearboxDriveshaft Driveshaft

Engines

bearing nutRH side LH side Toolkit

C4

MA/5ET3J4 TU5JP4

XSARA TU3JP TU5JP4

C4EW10/DV6 7114-T.W 7114-T.X 7116-T

BE4/5All types

XSARA EW7/10J4B DW8

XSARA PICASSO DV6/DW10

C4ML6 DW10BTED4 9017-T.C 5701-T.A 9017-T

TU5JP4 EW10A 2 ± 0,2 32,5 ± 2,6

(-) 0338 J1 (-) 0338 H1

XSARATU5JP EW10J4

+ (-) 0338 J3 (-) 0338 H2

DW10ATED

AL4Seal extractor

RH / LH(-). 0338

XSARA PICASSO EW10J4 (-) 0338 C

(-) 0338 J1 (-) 0338 H1

+ (-) 0338 J3 (-) 0338 H2

Tightening torque (m.daN) for wheel bolts.

C4 = 9 ± 1 XSARA = 8,5 ± 0,8 XSARA PICASSO = 10 ± 1

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 360

Page 434 of 462

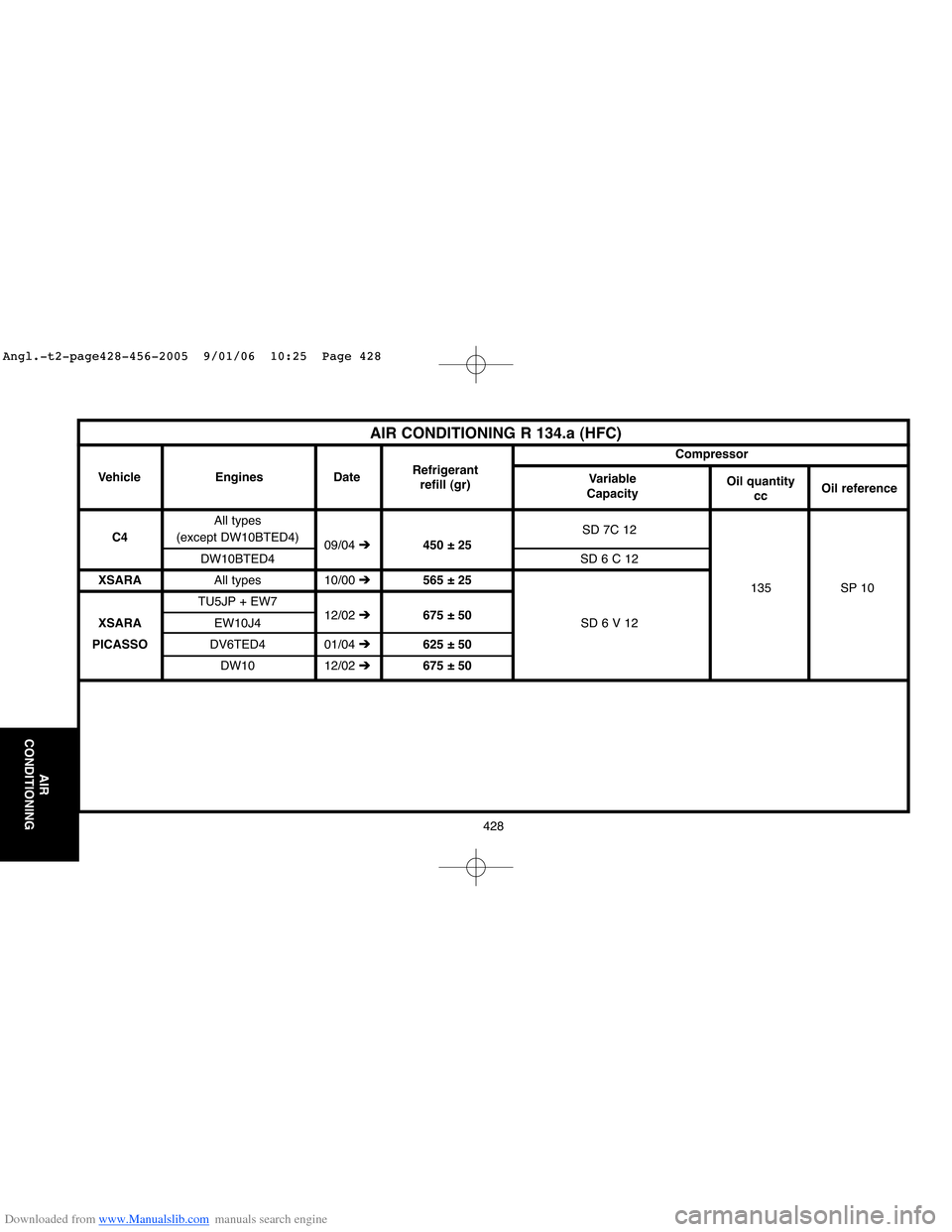

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING R 134.a (HFC)

Vehicle

All types

C4(except DW10BTED4)

09/04 ➔ ➔

450 ± 25SD 7C 12

DW10BTED4 SD 6 C 12

XSARAAll types 10/00 ➔ ➔

565 ± 25

135 SP 10

TU5JP + EW7

XSARAEW10J412/02 ➔ ➔

675 ± 50

SD 6 V 12

PICASSODV6TED4 01/04 ➔ ➔

625 ± 50

DW10 12/02 ➔ ➔

675 ± 50 Engines DateRefrigerant

refill (gr)Compressor

Variable

CapacityOil quantity

ccOil reference

428

AIR

CONDITIONING

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 428

Page 435 of 462

Downloaded from www.Manualslib.com manuals search engine 429

AIR

CONDITIONING

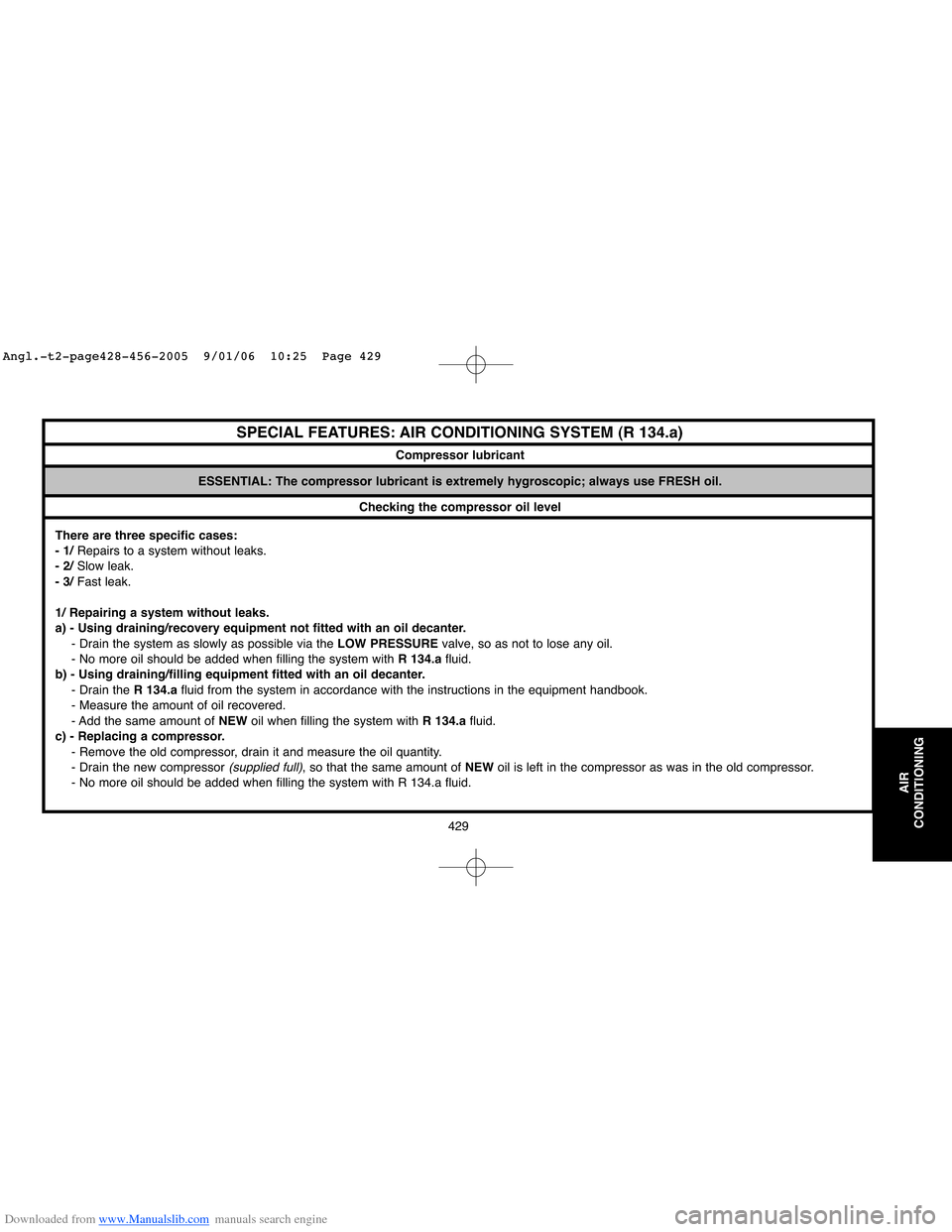

ESSENTIAL: The compressor lubricant is extremely hygroscopic; always use FRESH oil.

Checking the compressor oil level

There are three specific cases:

- 1/Repairs to a system without leaks.

- 2/Slow leak.

- 3/Fast leak.

1/ Repairing a system without leaks.

a) - Using draining/recovery equipment not fitted with an oil decanter.

- Drain the system as slowly as possible via the LOW PRESSUREvalve, so as not to lose any oil.

- No more oil should be added when filling the system with R 134.afluid.

b) - Using draining/filling equipment fitted with an oil decanter.

- Drain the R 134.afluid from the system in accordance with the instructions in the equipment handbook.

- Measure the amount of oil recovered.

- Add the same amount of NEWoil when filling the system with R 134.afluid.

c) - Replacing a compressor.

- Remove the old compressor, drain it and measure the oil quantity.

- Drain the new compressor

(supplied full), so that the same amount of NEWoil is left in the compressor as was in the old compressor.

- No more oil should be added when filling the system with R 134.a fluid.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Compressor lubricant

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 429

Page 436 of 462

Downloaded from www.Manualslib.com manuals search engine 430

AIR

CONDITIONING

Checking the compressor oil level (continued)

2/ Slow leak.

Slow leaks do not lead to oil loss, therefore the same procedure should be followed as if there was no leak at all.

3/ Fast leak.

This type of leak causes both oil loss as well as allowing air to enter the system.

It is therefore necessary to:

- Replace the dehydrator.

- Drain as much oil as possible

(when replacing the faulty component).

Either before or during filling of the system with R 134.afluid, introduce 80 ccof NEWoil into the circuit.

When changing one of the following components, add the quantity stated:

- A drying bottle : 15 ccof compressor oil.

- A condenser or an evaporator : 20 ccof compressor oil.

- High pressure or low pressure pipework : 5 ccof compressor oil.

- A drying cartridge : 15 ccof compressor oil.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 430

Page 442 of 462

Downloaded from www.Manualslib.com manuals search engine 436

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

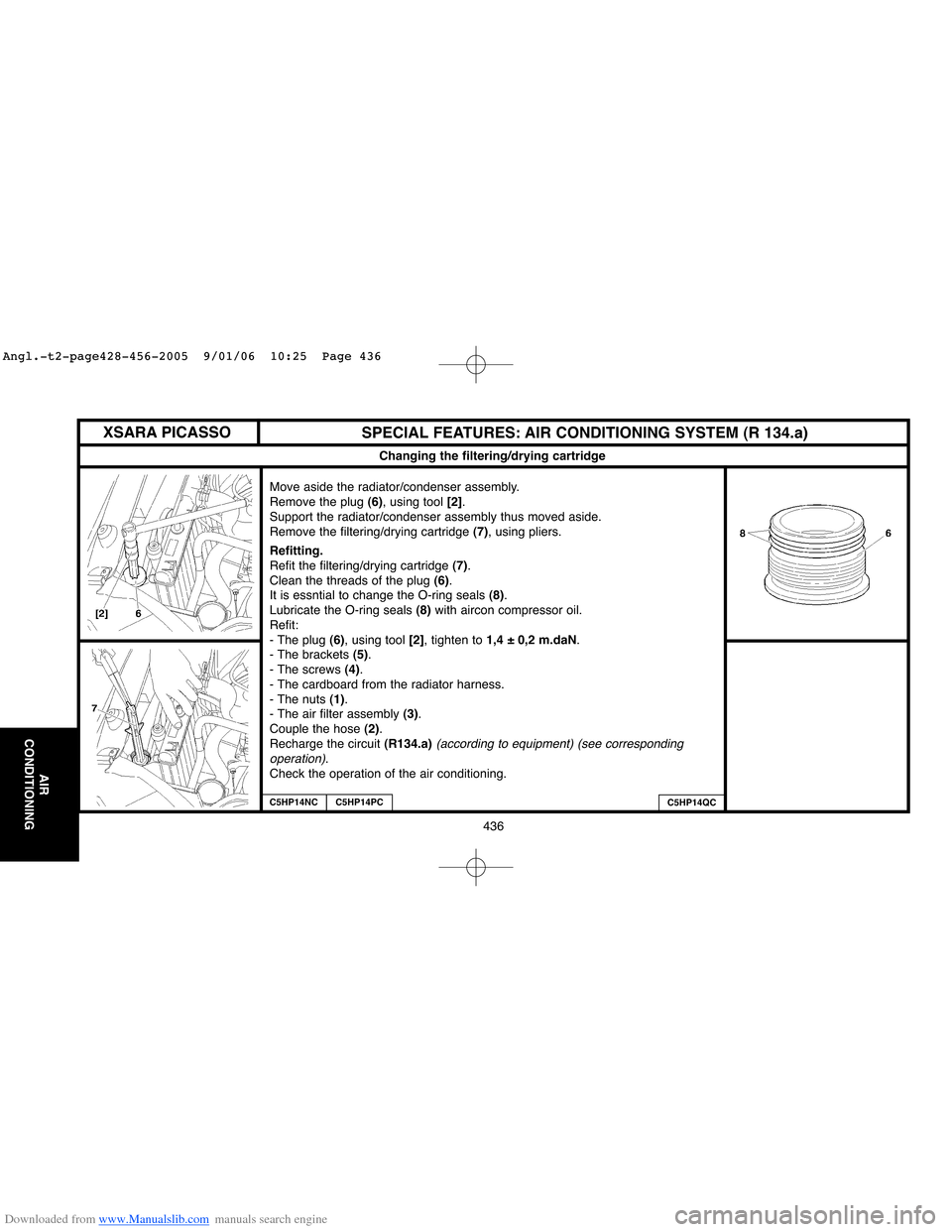

Changing the filtering/drying cartridge

Move aside the radiator/condenser assembly.

Remove the plug (6), using tool [2].

Support the radiator/condenser assembly thus moved aside.

Remove the filtering/drying cartridge (7), using pliers.

Refitting.

Refit the filtering/drying cartridge (7).

Clean the threads of the plug (6).

It is essntial to change the O-ring seals (8).

Lubricate the O-ring seals (8)with aircon compressor oil.

Refit:

- The plug (6), using tool [2], tighten to 1,4 ± 0,2 m.daN.

- The brackets (5).

- The screws (4).

- The cardboard from the radiator harness.

- The nuts (1).

- The air filter assembly (3).

Couple the hose (2).

Recharge the circuit (R134.a)

(according to equipment) (see corresponding

operation).

Check the operation of the air conditioning.

C5HP14NCC5HP14PCC5HP14QC

XSARA PICASSO

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 436