pipe Citroen C4 2005 2.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 112 of 462

Downloaded from www.Manualslib.com manuals search engine 106

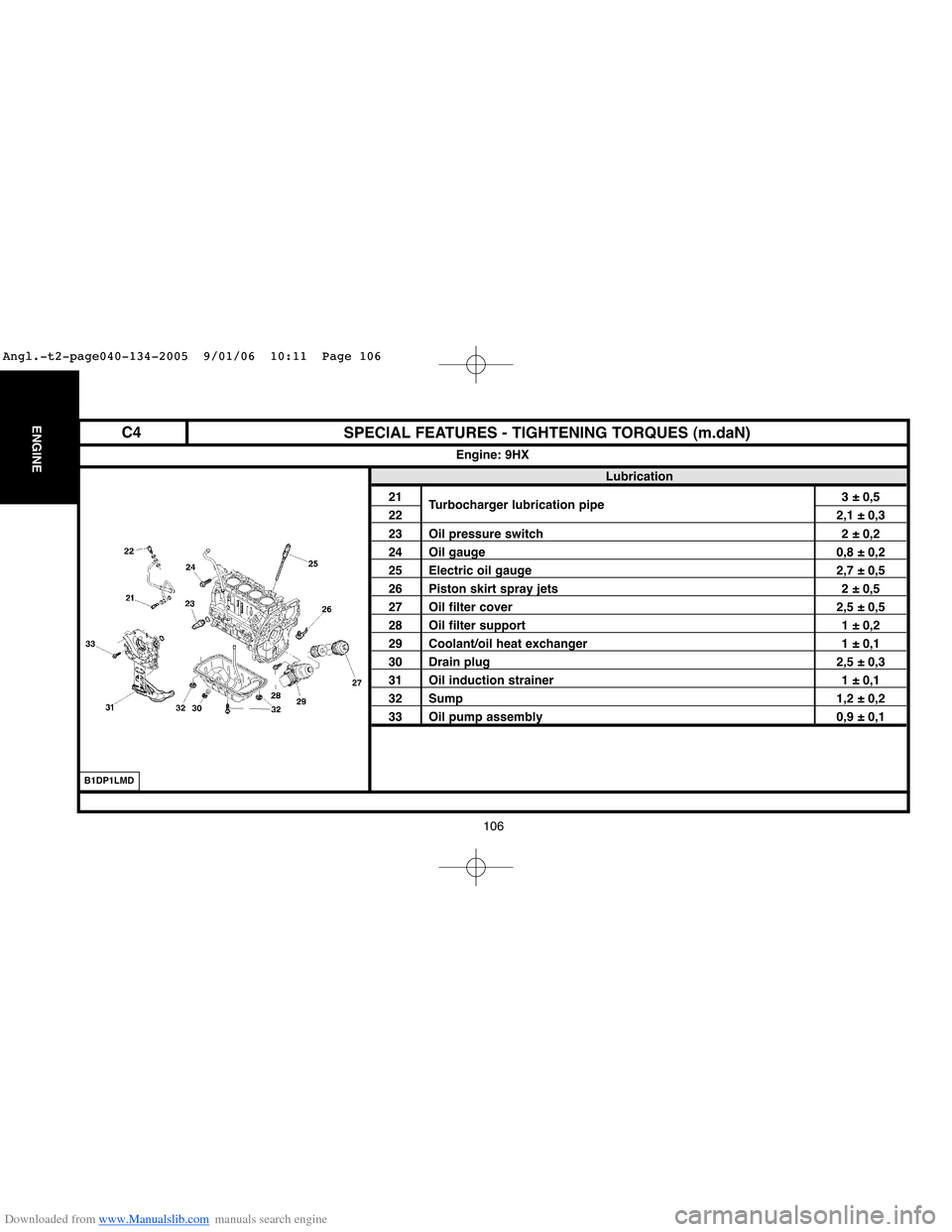

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Lubrication

21

Turbocharger lubrication pipe3 ± 0,5

222,1 ± 0,3

23 Oil pressure switch 2 ± 0,2

24 Oil gauge 0,8 ± 0,2

25 Electric oil gauge 2,7 ± 0,5

26 Piston skirt spray jets 2 ± 0,5

27 Oil filter cover 2,5 ± 0,5

28 Oil filter support 1 ± 0,2

29 Coolant/oil heat exchanger 1 ± 0,1

30 Drain plug 2,5 ± 0,3

31 Oil induction strainer 1 ± 0,1

32 Sump 1,2 ± 0,2

33 Oil pump assembly 0,9 ± 0,1

Engine: 9HX

B1DP1LMD

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 106

Page 124 of 462

Downloaded from www.Manualslib.com manuals search engine 118

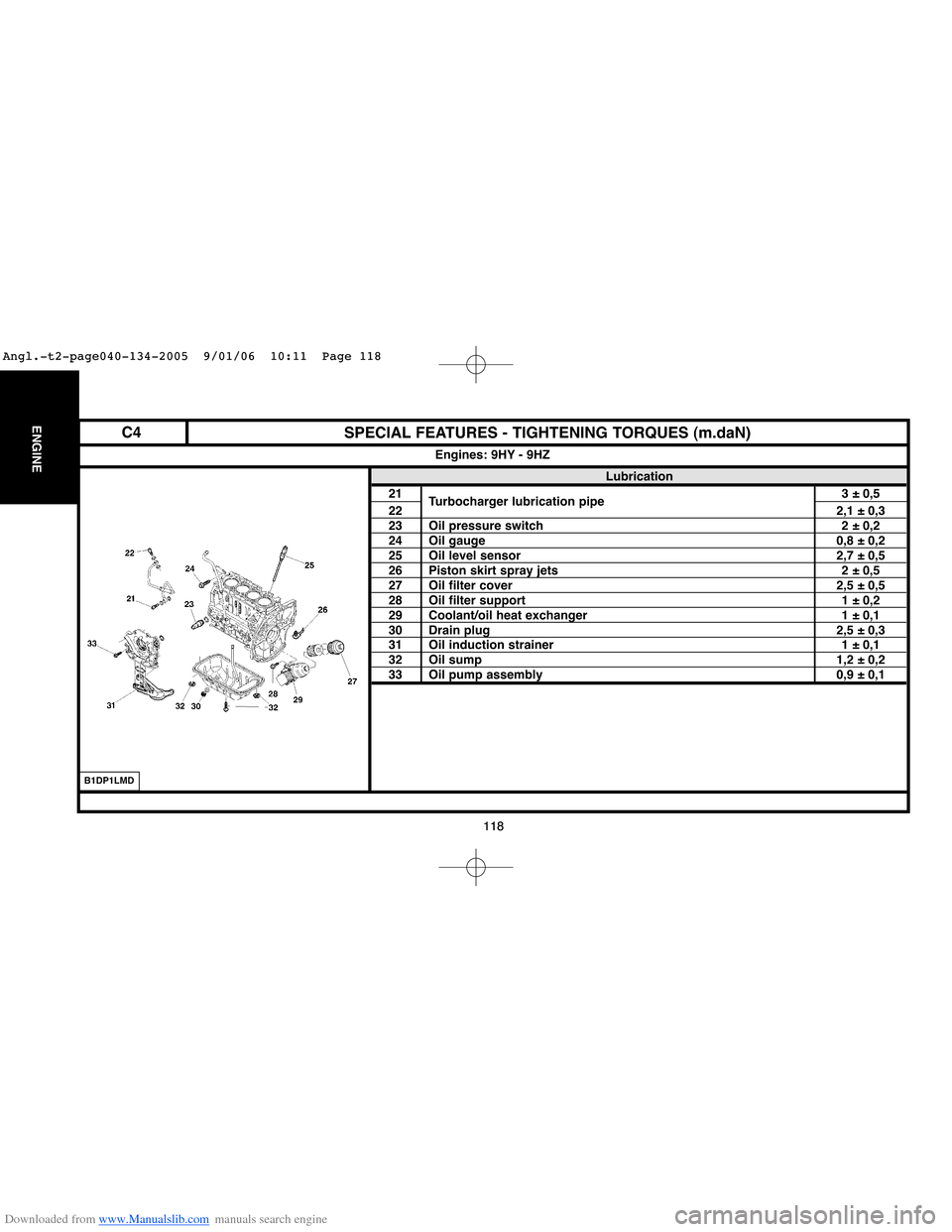

ENGINE

118

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Lubrication

21

Turbocharger lubrication pipe3 ± 0,5

222,1 ± 0,323 Oil pressure switch 2 ± 0,224 Oil gauge 0,8 ± 0,225 Oil level sensor 2,7 ± 0,526 Piston skirt spray jets 2 ± 0,527 Oil filter cover 2,5 ± 0,528 Oil filter support 1 ± 0,229 Coolant/oil heat exchanger 1 ± 0,130 Drain plug 2,5 ± 0,331 Oil induction strainer 1 ± 0,132 Oil sump 1,2 ± 0,233 Oil pump assembly 0,9 ± 0,1

Engines: 9HY - 9HZ

B1DP1LMD

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 118

Page 134 of 462

Downloaded from www.Manualslib.com manuals search engine 128

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Engines9HZ - 9HY

Lubrication circuit

Oil pump assembly

Pre-tightening0,5 ± 0,1

Tightening0,9 ± 0,1

Oil/coolant heat exchanger1 ± 0,2

Turbocharger lubrication pipe3 ± 0,5

Diesel injection circuit

Injector fixing flange nut

Pre-tightening4 ± 0,1

Angular tightening65°±5°

Fuel high pressure common injection rail on engine block 2,2 ± 0,2

Union on fuel high pressure common injection rail

Pre-tightening1,7 ± 0,2

Tightening2,2 ± 0,2

Diesel injection pump on support2,2 ± 0,2

Union on injector diesel

Pre-tightening2 ± 0,5

Tightening2,5 ± 0,3

XSARA PICASSO

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 128

Page 142 of 462

Downloaded from www.Manualslib.com manuals search engine 136

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Flywheel

Flywheel4,8 ± 0,4

Clutch mechanism2 ± 0,2

Lubrication circuit

Oil pump1,6 ± 0,2

Coolant oil heat exchanger7 ± 0,7

Turbocharger lubrication pipe

Engine end4,8 ± 0,4

Turbocharger end2,2 ± 0,2

Injection circuit

Injector fixing flange nut3 ± 0,3

Unions on fuel high pressure common injection rail2 ± 0,2

Injection pump on support2,3 ± 0,2

Union on diesel injector2 ± 0,2

Injection pump pulley5 ± 0,5

Union on fuel high pressure pump2 ± 0,2

Cooling circuit

Coolant pump1,5 ± 0,1

Coolant inlet housing1,8 ± 0,1 Engines: RHY - RHZ

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 136

Page 152 of 462

Downloaded from www.Manualslib.com manuals search engine 146

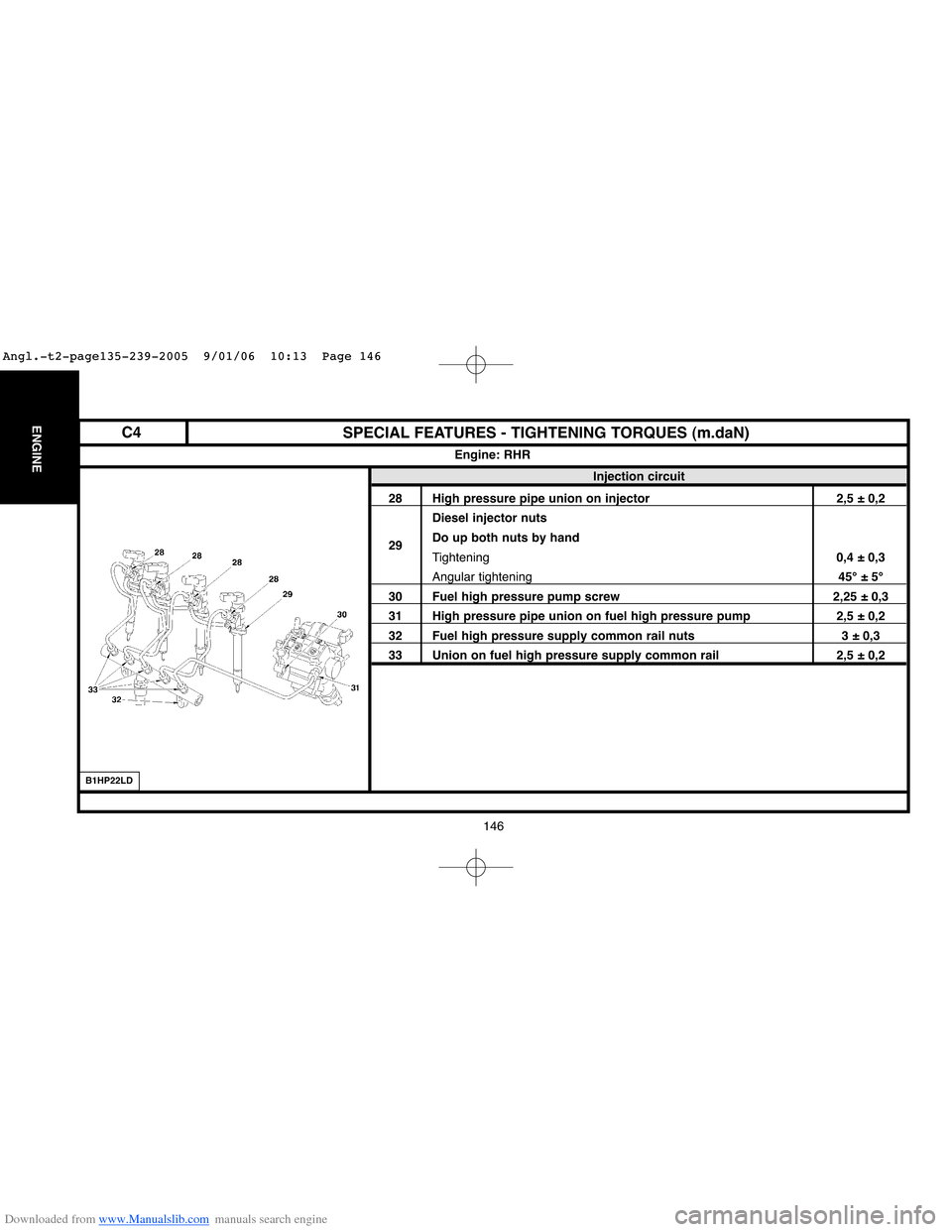

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Injection circuit

28 High pressure pipe union on injector 2,5 ± 0,2

Diesel injector nuts

29Do up both nuts by hand

Tightening0,4 ± 0,3

Angular tightening45°±5°

30 Fuel high pressure pump screw 2,25 ± 0,3

31 High pressure pipe union on fuel high pressure pump 2,5 ± 0,2

32 Fuel high pressure supply common rail nuts 3 ± 0,3

33 Union on fuel high pressure supply common rail 2,5 ± 0,2

Engine: RHR

B1HP22LD

C4

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 146

Page 212 of 462

Downloaded from www.Manualslib.com manuals search engine 206

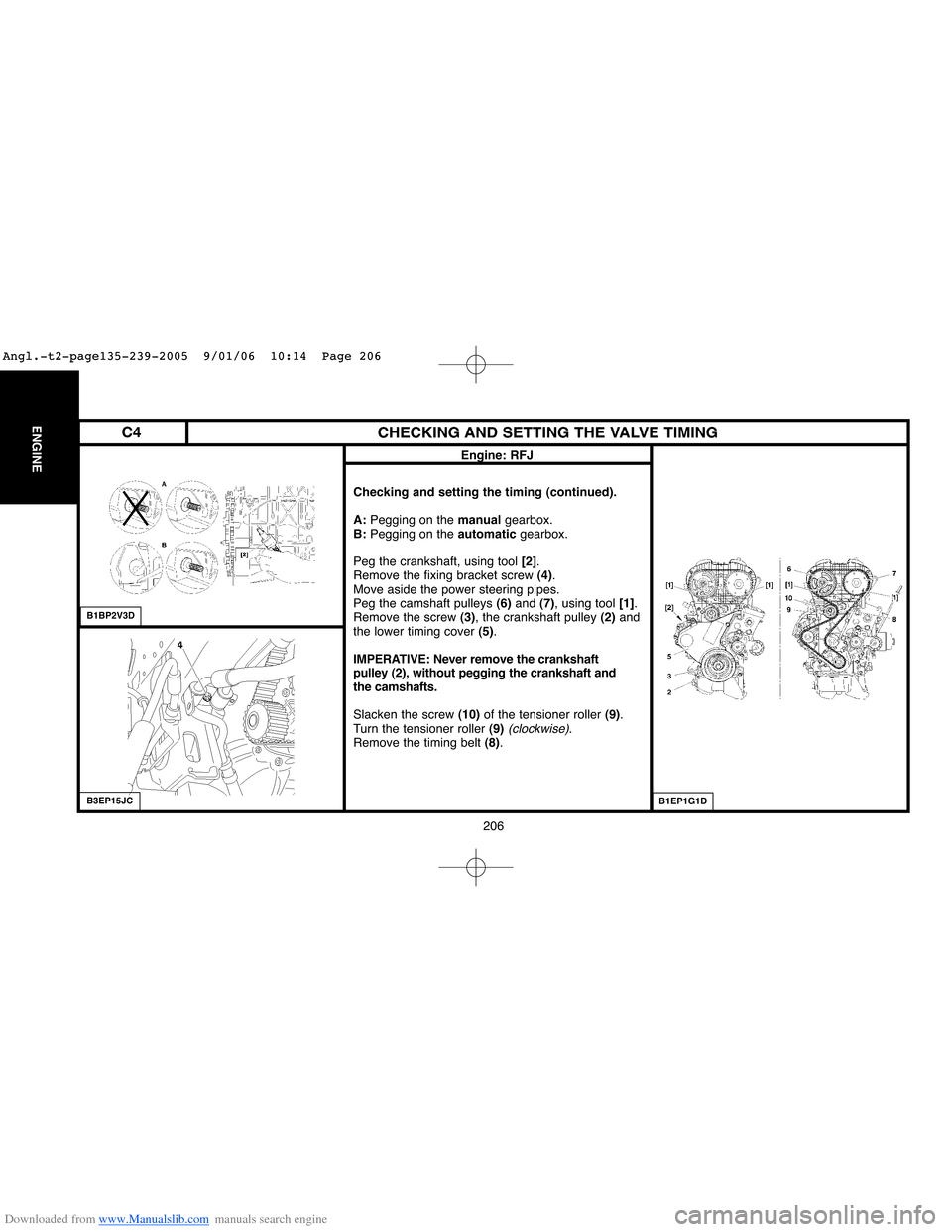

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFJ

Checking and setting the timing (continued).

A:Pegging on the manual gearbox.

B:Pegging on the automaticgearbox.

Peg the crankshaft, using tool [2].

Remove the fixing bracket screw (4).

Move aside the power steering pipes.

Peg the camshaft pulleys (6)and (7), using tool [1].

Remove the screw (3), the crankshaft pulley (2)and

the lower timing cover (5).

IMPERATIVE: Never remove the crankshaft

pulley (2), without pegging the crankshaft and

the camshafts.

Slacken the screw (10)of the tensioner roller (9).

Turn the tensioner roller (9)

(clockwise).

Remove the timing belt (8).

B1BP2V3D

B1EP1G1DB3EP15JC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 206

Page 219 of 462

Downloaded from www.Manualslib.com manuals search engine 213

ENGINE

213

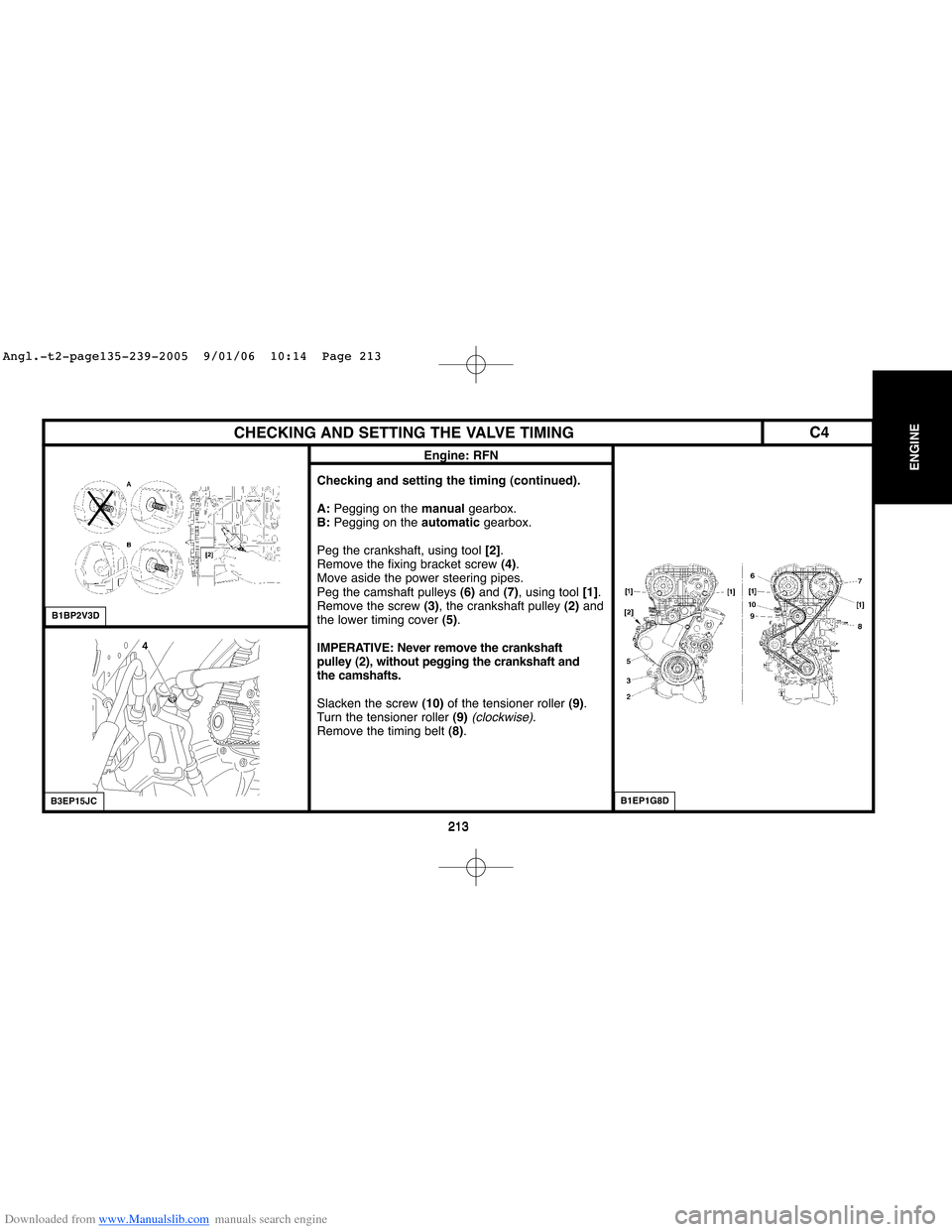

CHECKING AND SETTING THE VALVE TIMING

Engine: RFN

Checking and setting the timing (continued).

A:Pegging on the manualgearbox.

B:Pegging on the automatic gearbox.

Peg the crankshaft, using tool [2].

Remove the fixing bracket screw (4).

Move aside the power steering pipes.

Peg the camshaft pulleys (6)and (7), using tool [1].

Remove the screw (3), the crankshaft pulley (2)and

the lower timing cover (5).

IMPERATIVE: Never remove the crankshaft

pulley (2), without pegging the crankshaft and

the camshafts.

Slacken the screw (10)of the tensioner roller (9).

Turn the tensioner roller (9)

(clockwise).

Remove the timing belt (8).

B1BP2V3D

B3EP15JCB1EP1G8D

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 213

Page 232 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 226

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

[3 Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 226

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

[3](/img/9/4138/w960_4138-231.png)

Downloaded from www.Manualslib.com manuals search engine 226

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

[3] Timing belt retaining pin: (-) 0189.K

[4]Adaptor for angular tightening: 4069-T

[5]Hub immobilising tool: (-).0189.S

[5a] : (-).0189.S1

[5b] : (-).0189.S2

Pliers for removing plastic pins: 7504-T

IMPERATIVE: Respect the safety and cleanliness requirements.

Checking and setting the timing.

Removing.

Disconnect the negative terminal of the battery

(see corresponding operation).

Raise and support the vehicle, front wheels hanging.

Remove the auxiliaries drive belt

(see corresponding operation).

Unclip and move aside the fuel supply hose from the timing cover.

Remove the screw (1).

Move aside the power steering pipes.

Turn the engine by means of the screw (4)of the crankshaft pinion (3)to bring it to the pegging position.

B3EP15YC

B1BP36YC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 226

Page 240 of 462

Downloaded from www.Manualslib.com manuals search engine 234

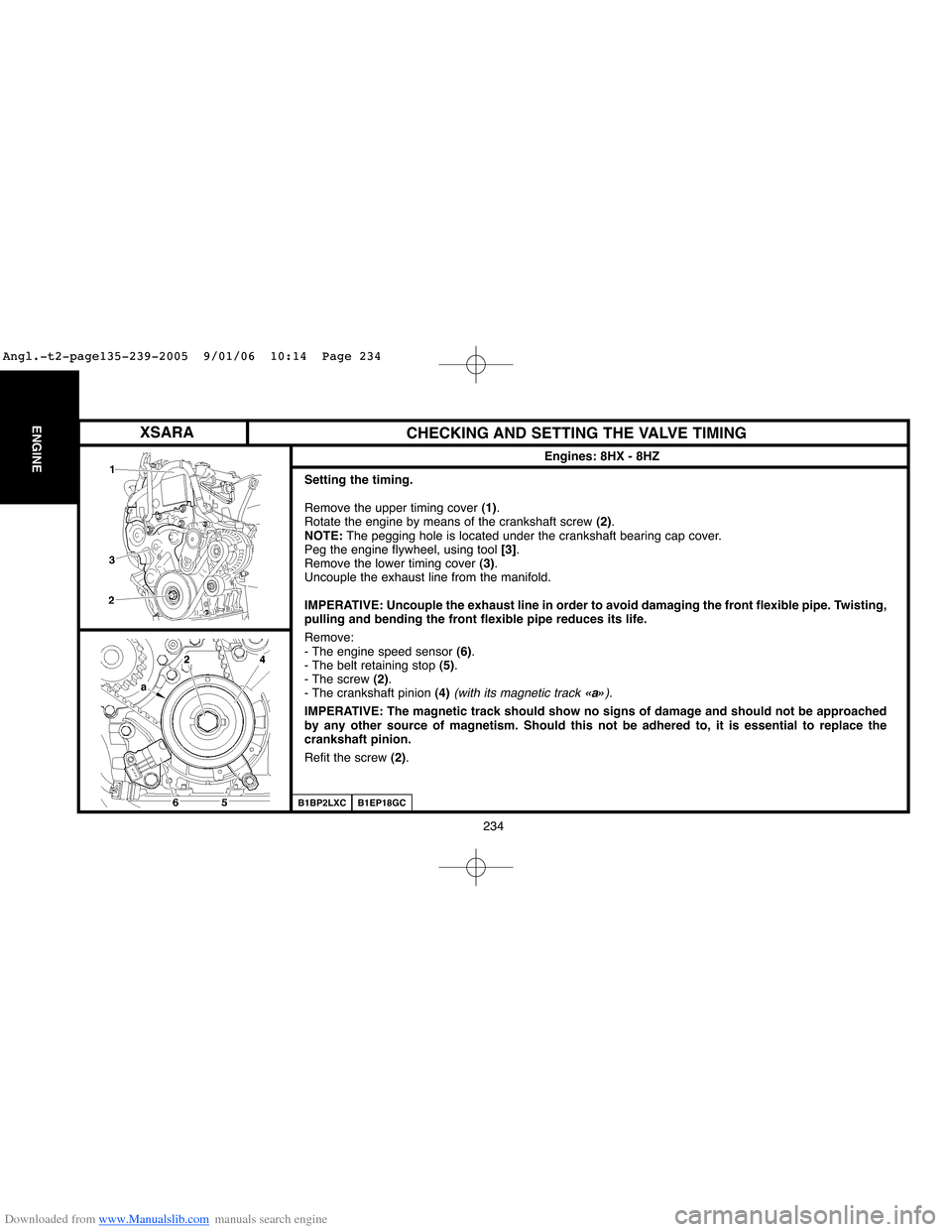

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 8HX - 8HZ

B1EP18GC

Setting the timing.

Remove the upper timing cover (1).

Rotate the engine by means of the crankshaft screw (2).

NOTE:The pegging hole is located under the crankshaft bearing cap cover.

Peg the engine flywheel, using tool [3].

Remove the lower timing cover (3).

Uncouple the exhaust line from the manifold.

IMPERATIVE: Uncouple the exhaust line in order to avoid damaging the front flexible pipe. Twisting,

pulling and bending the front flexible pipe reduces its life.

Remove:

- The engine speed sensor (6).

- The belt retaining stop (5).

- The screw (2).

- The crankshaft pinion (4)

(with its magnetic track «a»).

IMPERATIVE: The magnetic track should show no signs of damage and should not be approached

by any other source of magnetism. Should this not be adhered to, it is essential to replace the

crankshaft pinion.

Refit the screw (2).

B1BP2LXC

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 234

Page 246 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 240

ENGINECHECKING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Tools.

[1]Flywheel setting peg: (-).0194.C

[2] Camshaft setting peg: (-).0194.B

[3 Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 240

ENGINECHECKING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Tools.

[1]Flywheel setting peg: (-).0194.C

[2] Camshaft setting peg: (-).0194.B

[3](/img/9/4138/w960_4138-245.png)

Downloaded from www.Manualslib.com manuals search engine 240

ENGINECHECKING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Tools.

[1]Flywheel setting peg: (-).0194.C

[2] Camshaft setting peg: (-).0194.B

[3] Crankshaft setting peg: (-).0194.A

IMPERATIVE: Respect the safety and cleanliness requirements specific to High pressure Diesel

injection (HDi) engine versions.

Checking and setting the timing.

Raise and support the vehicle, wheels hanging.

Disconnect the battery.

Uncouple:

- The fuel supply unions (1).

- The air/air heat exchanger inlet and outlet pipes (3).

- The exhaust line at the catalytic converter flexible pipe.

- Disconnect the connecteur at «a».

Remove the accessories drive belt

(see corresponding operation).

Support the engine with a roller jack equipped with a block.

Remove the four screws (5), the three screws (4)and the engine supports (3).

B1BP38TD

B1BP38UD

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 240