ECU CITROEN C4 CACTUS 2017 User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2017, Model line: C4 CACTUS, Model: CITROEN C4 CACTUS 2017Pages: 256, PDF Size: 7.62 MB

Page 90 of 256

88

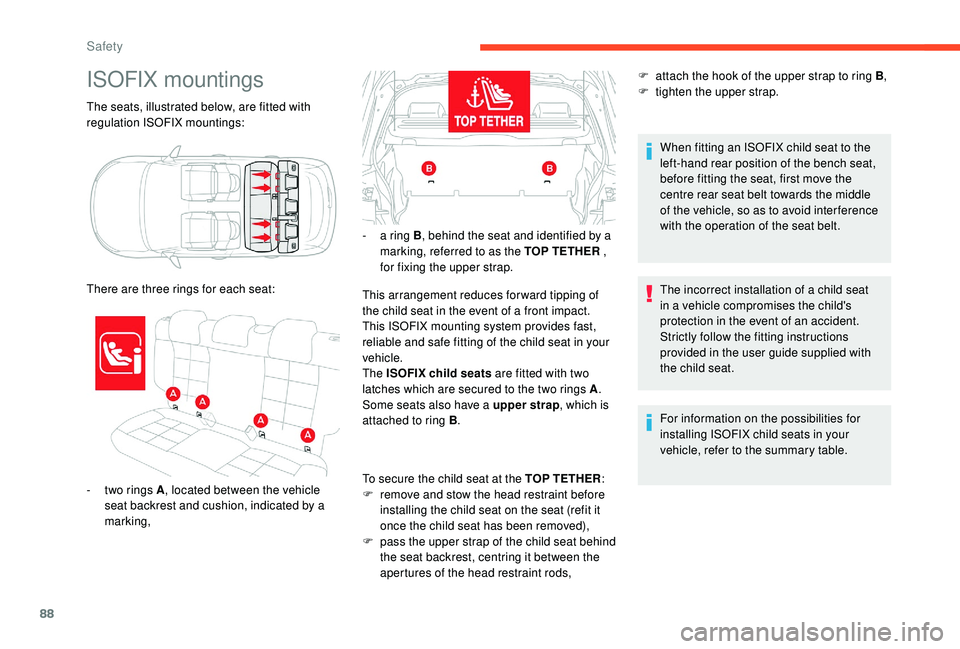

The seats, illustrated below, are fitted with

regulation ISOFIX mountings:

ISOFIX mountings

- two rings A, located between the vehicle

seat backrest and cushion, indicated by a

marking,

There are three rings for each seat:

-

a r

ing B

, behind the seat and identified by a

marking, referred to as the TOP TETHER ,

for fixing the upper strap.

This arrangement reduces forward tipping of

the child seat in the event of a front impact.

This ISOFIX mounting system provides fast,

reliable and safe fitting of the child seat in your

vehicle.

The ISOFIX child seats are fitted with two

latches which are secured to the two rings A .

Some seats also have a upper strap , which is

attached to ring B .

To secure the child seat at the TOP TETHER :

F r emove and stow the head restraint before

installing the child seat on the seat (refit it

once the child seat has been removed),

F

p

ass the upper strap of the child seat behind

the seat backrest, centring it between the

apertures of the head restraint rods, When fitting an ISOFIX child seat to the

left-hand rear position of the bench seat,

before fitting the seat, first move the

centre rear seat belt towards the middle

of the vehicle, so as to avoid inter ference

with the operation of the seat belt.

The incorrect installation of a child seat

in a vehicle compromises the child's

protection in the event of an accident.

Strictly follow the fitting instructions

provided in the user guide supplied with

the child seat.

For information on the possibilities for

installing ISOFIX child seats in your

vehicle, refer to the summary table.

F

a

ttach the hook of the upper strap to ring B

,

F

t

ighten the upper strap.

Safety

Page 91 of 256

89

Recommended ISOFIX

child seats

Also consult the installation notes from the

child seat's manufacturer to find out how

to install and remove the seat.

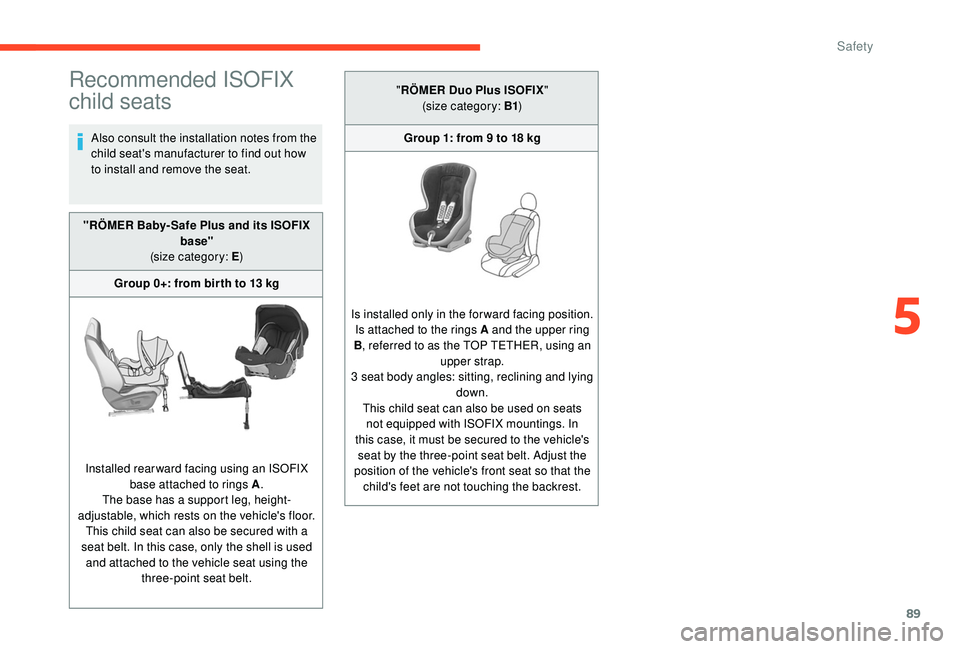

"RÖMER Baby- Safe Plus and its ISOFIX base"

(size category: E )

Group 0+: from bir th to 13 kg

Installed rearward facing using an ISOFIX base attached to rings A .

The base has a support leg, height-

adjustable, which rests on the vehicle's floor. This child seat can also be secured with a

seat belt. In this case, only the shell is used and attached to the vehicle seat using the three-point seat belt. "

RÖMER Duo Plus ISOFIX "

(size category: B1 )

Group 1: from 9 to 18 kg

Is installed only in the forward facing position. Is attached to the rings A and the upper ring

B , referred to as the TOP TETHER, using an

upper strap.

3 seat body angles: sitting, reclining and lying down.

This child seat can also be used on seats not equipped with ISOFIX mountings. In

this case, it must be secured to the vehicle's seat by the three-point seat belt. Adjust the

position of the vehicle's front seat so that the child's feet are not touching the backrest.

5

Safety

Page 92 of 256

90

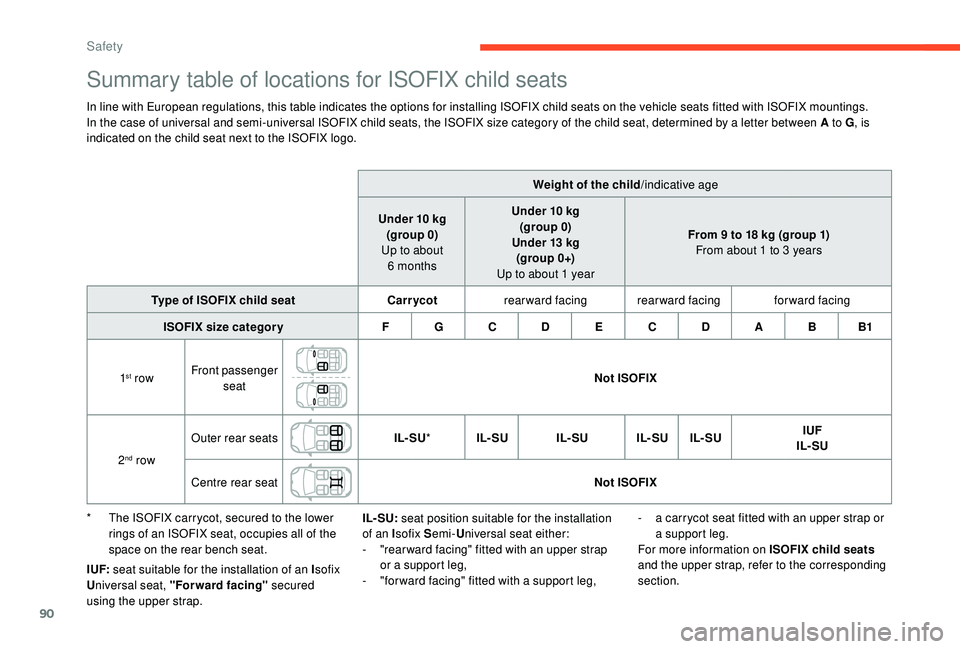

Summary table of locations for ISOFIX child seats

In line with European regulations, this table indicates the options for installing ISOFIX child seats on the vehicle seats fitted with ISOFIX mountings.

In the case of universal and semi-universal ISOFIX child seats, the ISOFIX size category of the child seat, determined by a letter between A to G, is

indicated on the child seat next to the ISOFIX logo.

Weight of the child/indicative age

Under 10 kg (group 0)

Up to about 6 months Under 10 kg

(group 0)

Under 13 kg (group 0+)

Up to about 1 year From 9 to 18 kg (group 1)

From about 1 to 3 years

Type of ISOFIX child seat Carr ycotrearward facing rearward facing forward facing

ISOFIX size categor y F G C D E C D A B B1

1

st row Front passenger

seat Not ISOFIX

2

nd row Outer rear seats

IL- SU* IL- SU IL- SU IL- SU IL- SU IUF

IL- SU

Centre rear seat Not ISOFIX

IL- SU: seat position suitable for the installation

of an I sofix S emi-Universal seat either:

-

"

rear ward facing" fitted with an upper strap

or a support leg,

-

"

for ward facing" fitted with a support leg,

*

T

he ISOFIX carrycot, secured to the lower

rings of an ISOFIX seat, occupies all of the

space on the rear bench seat. -

a c

arrycot seat fitted with an upper strap or

a support leg.

For more information on ISOFIX child seats

and the upper strap, refer to the corresponding

section.

I UF:

seat suitable for the installation of an I sofix

U niversal seat, "Forward facing" secured

using the upper strap.

Safety

Page 94 of 256

92

Advice

The incorrect installation of a child seat in a

vehicle compromises the child's protection in

the event of an accident.

Ensure that there is no seat belt or seat belt

buckle under the child seat, as this could

destabilise it.

Remember to fasten the seat belts or the

child seat harnesses keeping the slack

relative to the child's body to a minimum,

even for short journeys.

When installing a child seat using the seat

belt, ensure that the seat belt is tightened

correctly on the child seat and that it secures

the child seat firmly on the seat of your

vehicle. If your passenger seat is adjustable,

move it for wards if necessary.

At rear seating positions, always leave

sufficient space between the front seat and:

-

a "

rear ward facing" child seat,

-

t

he child's feet for a child seat fitted

"forward facing".

To do this, move the front seat for wards

and, if necessary, move its backrest into the

upright position.

For optimal installation of the "forward facing"

child seat, verify that its backrest is as close

as possible to the backrest of the vehicle

seat, if possible in contact with it. The head restraint must be removed

before installing a child seat with a

backrest on a passenger seat.

Ensure that the head restraint is stored or

attached securely to prevent it from being

thrown around the vehicle in the event of

sharp braking. Refit the head restraint when

the child seat is removed.

As a safety precaution, do not leave:

-

a c hild or children alone and unattended in

a vehicle,

-

a c

hild or an animal in a vehicle which

is exposed to the sun, with the windows

closed,

-

t

he keys within reach of children inside the

vehicle.

To prevent accidental opening of the doors

and rear windows, use the child lock.

Take care not to open the rear windows by

more than one third.

To protect young children from the rays of the

sun, fit side blinds on the rear windows.

Children in front

The legislation on carrying children on the

front passenger seat is specific to each

country. Refer to the legislation in force in

your country.

Deactivate the front passenger airbag when a

"rear ward facing" child seat is installed on the

front passenger seat.

Other wise, there is a risk of serious or fatal

injury to the child if the airbag is deployed.

Installing a booster seat

The chest part of the seat belt must be

positioned on the child's shoulder without

touching the neck.

Ensure that the lap part of the seat belt

passes correctly over the child's thighs.

We recommend using a booster seat with

a backrest equipped with a belt guide at

shoulder level.

Safety

Page 144 of 256

142

After refitting a front wiper blade

F Switch on the ignition.

F O perate the wiper stalk again to park the

wiper blades.

Replacement of wiper arms should be

carried out only by a CITROËN dealer or

in a qualified workshop.

Roof bars

For safety reasons and to avoid damaging

the roof, it is essential to use the

transverse bars approved for your vehicle.

Obser ve the fitting instructions and the

conditions of use in the guide supplied

with the roof bars.

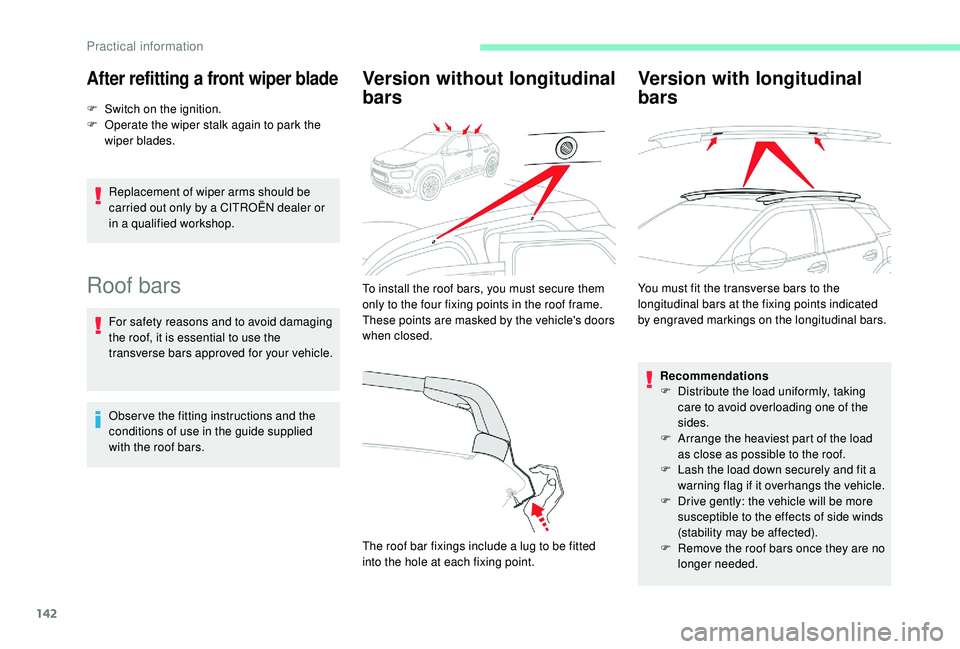

Version without longitudinal

bars

To install the roof bars, you must secure them

only to the four fixing points in the roof frame.

These points are masked by the vehicle's doors

when closed.

The roof bar fixings include a lug to be fitted

into the hole at each fixing point.

Version with longitudinal

bars

You must fit the transverse bars to the

longitudinal bars at the fixing points indicated

by engraved markings on the longitudinal bars.

Recommendations

F

D

istribute the load uniformly, taking

care to avoid overloading one of the

sides.

F

A

rrange the heaviest part of the load

as close as possible to the roof.

F

L

ash the load down securely and fit a

warning flag if it overhangs the vehicle.

F

D

rive gently: the vehicle will be more

susceptible to the effects of side winds

(stability may be affected).

F

R

emove the roof bars once they are no

longer needed.

Practical information

Page 156 of 256

154

Under-inflation detection

After repair of the tyre, the warning

lamp will remain on until the system is

reinitialised.

For more information on Tyre under-

inflation detection, refer to the

corresponding section.

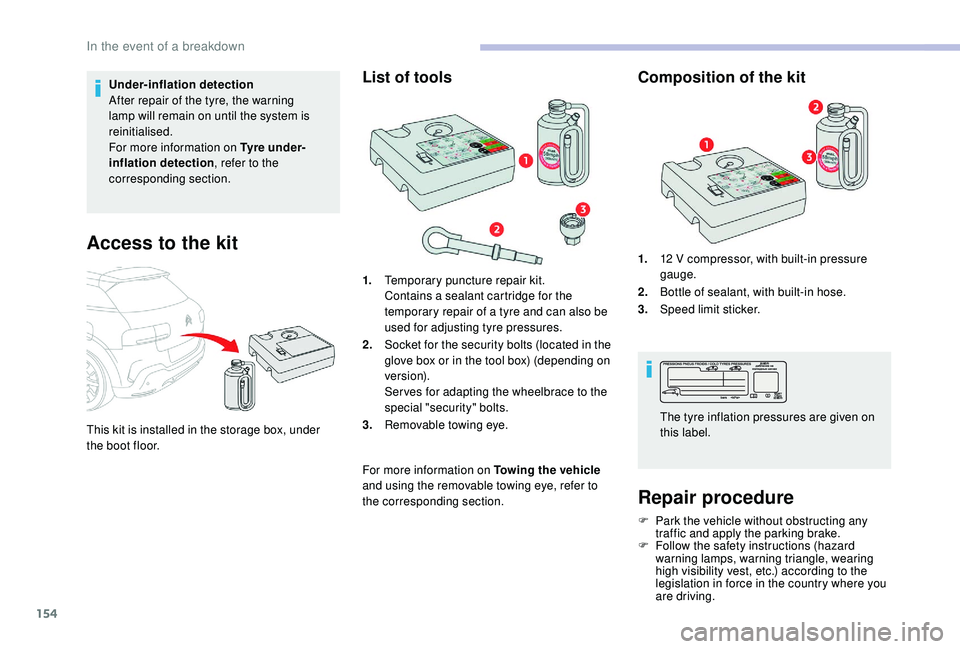

Access to the kit

This kit is installed in the storage box, under

the boot floor.

List of tools

1. Temporary puncture repair kit.

Contains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2. Socket for the security bolts (located in the

glove box or in the tool box) (depending on

ve r s i o n).

Ser ves for adapting the wheelbrace to the

special "security" bolts.

3. Removable towing eye.

For more information on Towing the vehicle

and using the removable towing eye, refer to

the corresponding section.

Composition of the kit

1. 12 V compressor, with built-in pressure

gauge.

2. Bottle of sealant, with built-in hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving. The tyre inflation pressures are given on

this label.

In the event of a breakdown

Page 157 of 256

155

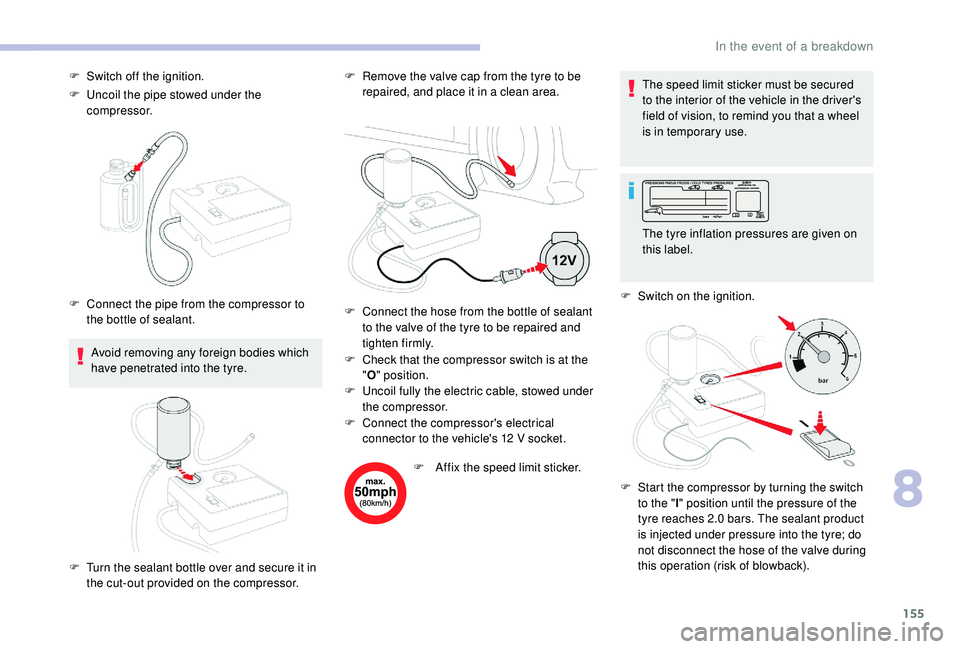

F Uncoil the pipe stowed under the compressor.

Avoid removing any foreign bodies which

have penetrated into the tyre. F

R

emove the valve cap from the tyre to be

repaired, and place it in a clean area.

F

C

heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

A

ffix the speed limit sticker.The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a wheel

is in temporary use.

F

S

witch on the ignition.

F

S

witch off the ignition.

F

C

onnect the pipe from the compressor to

the bottle of sealant.

F

T

urn the sealant bottle over and secure it in

the cut-out provided on the compressor. F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly.

F

C

onnect the compressor's electrical

connector to the vehicle's 12 V socket. The tyre inflation pressures are given on

this label.

F

S

tart the compressor by turning the switch

to the " l" position until the pressure of the

tyre reaches 2.0 bars. The sealant product

is injected under pressure into the tyre; do

not disconnect the hose of the valve during

this operation (risk of blowback).

8

In the event of a breakdown

Page 160 of 256

158

3.Wheel bolt cover removal tool.

To remove the alloy wheel bolt covers

or the central bolt cover (depending on

ve r s i o n).

4. Removable towing eye.

5. Socket for the security bolts (located in the

glove box or in the tool box) (depending on

country of sale).

Ser ves for adapting the wheelbrace to the

special "security" bolts.

For more information on To w i n g , refer to the

corresponding section.

All of these tools are specific to your

vehicle and can vary according to the level

of equipment.

Do not use them for any other purposes.

The jack should only be used to change a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact a CITROËN dealer or a qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

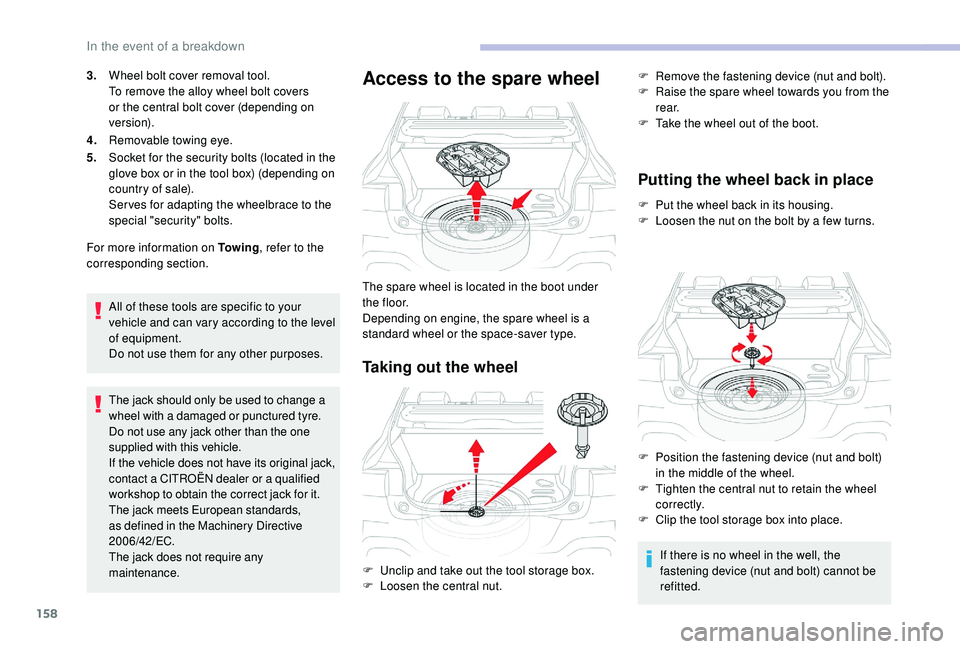

maintenance.Access to the spare wheel

Taking out the wheel Putting the wheel back in place

F Put the wheel back in its housing.

F

L oosen the nut on the bolt by a few turns.

If there is no wheel in the well, the

fastening device (nut and bolt) cannot be

refitted.

The spare wheel is located in the boot under

t h e f l o o r.

Depending on engine, the spare wheel is a

standard wheel or the space-saver type.

F

U

nclip and take out the tool storage box.

F

L

oosen the central nut. F

R

emove the fastening device (nut and bolt).

F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

F

P

osition the fastening device (nut and bolt)

in the middle of the wheel.

F

T

ighten the central nut to retain the wheel

c o r r e c t l y.

F

C

lip the tool storage box into place.

In the event of a breakdown

Page 161 of 256

159

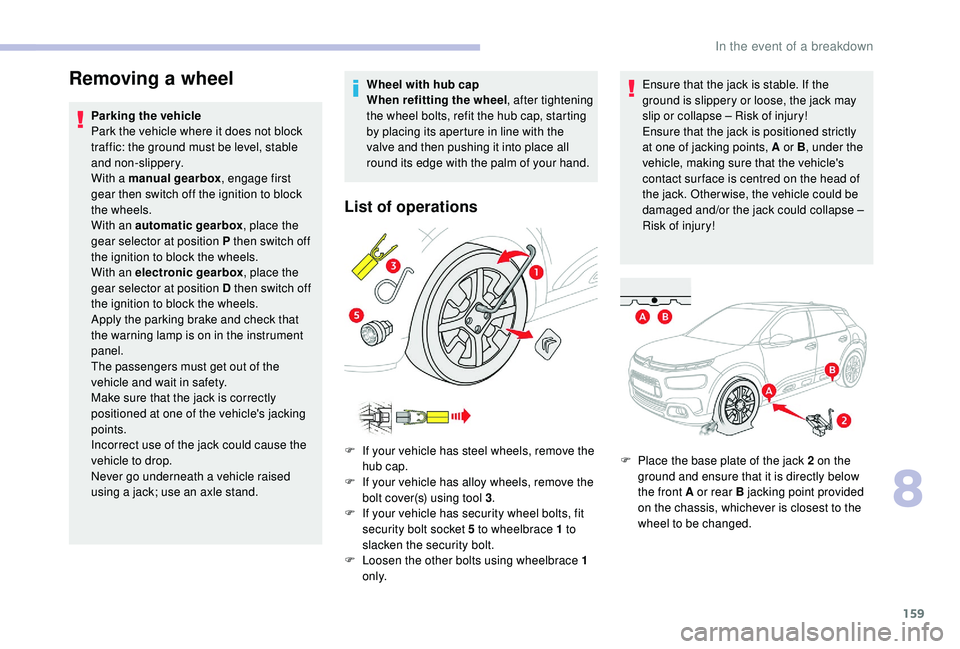

Removing a wheel

Parking the vehicle

Park the vehicle where it does not block

traffic: the ground must be level, stable

and non-slippery.

With a manual gearbox, engage first

gear then switch off the ignition to block

the wheels.

With an automatic gearbox , place the

gear selector at position P then switch off

the ignition to block the wheels.

With an electronic gearbox , place the

gear selector at position D then switch off

the ignition to block the wheels.

Apply the parking brake and check that

the warning lamp is on in the instrument

panel.

The passengers must get out of the

vehicle and wait in safety.

Make sure that the jack is correctly

positioned at one of the vehicle's jacking

points.

Incorrect use of the jack could cause the

vehicle to drop.

Never go underneath a vehicle raised

using a jack; use an axle stand. Wheel with hub cap

When refitting the wheel

, after tightening

the wheel bolts, refit the hub cap, starting

by placing its aperture in line with the

valve and then pushing it into place all

round its edge with the palm of your hand.

List of operations

F If your vehicle has steel wheels, remove the hub cap.

F

I

f your vehicle has alloy wheels, remove the

bolt cover(s) using tool 3 .

F

I

f your vehicle has security wheel bolts, fit

security bolt socket 5 to wheelbrace 1 to

slacken the security bolt.

F

L

oosen the other bolts using wheelbrace 1

o n l y. Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse – Risk of injury!

Ensure that the jack is positioned strictly

at one of jacking points, A or B

, under the

vehicle, making sure that the vehicle's

contact sur face is centred on the head of

the jack. Otherwise, the vehicle could be

damaged and/or the jack could collapse –

Risk of injury!

F P lace the base plate of the jack 2 on the

ground and ensure that it is directly below

the front A or rear B jacking point provided

on the chassis, whichever is closest to the

wheel to be changed.

8

In the event of a breakdown

Page 162 of 256

160

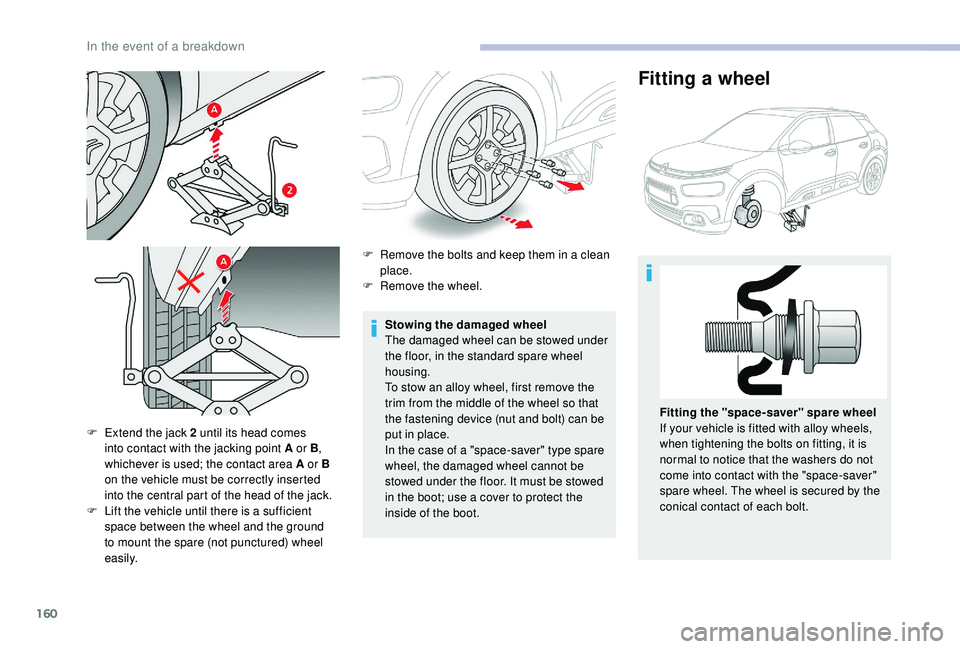

F Extend the jack 2 until its head comes into contact with the jacking point A or B ,

whichever is used; the contact area A or B

on the vehicle must be correctly inserted

into the central part of the head of the jack.

F

L

ift the vehicle until there is a sufficient

space between the wheel and the ground

to mount the spare (not punctured) wheel

easily. Stowing the damaged wheel

The damaged wheel can be stowed under

the floor, in the standard spare wheel

housing.

To stow an alloy wheel, first remove the

trim from the middle of the wheel so that

the fastening device (nut and bolt) can be

put in place.

In the case of a "space-saver" type spare

wheel, the damaged wheel cannot be

stowed under the floor. It must be stowed

in the boot; use a cover to protect the

inside of the boot.

Fitting a wheel

F Remove the bolts and keep them in a clean

place.

F

R

emove the wheel.

Fitting the "space-saver" spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it is

normal to notice that the washers do not

come into contact with the "space-saver"

spare wheel. The wheel is secured by the

conical contact of each bolt.

In the event of a breakdown