Citroen C4 DAG 2014.5 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2014.5, Model line: C4 DAG, Model: Citroen C4 DAG 2014.5 2.GPages: 340, PDF Size: 12.89 MB

Page 191 of 340

1010

189

C4-2_en_Chap10_verification_ed01-2014

F Obtain a bottle of AdBlue®. After first

checking

the

use-by

date, read

carefully

the instructions on use on

the

label

before

pouring

the

con

-

tents

of

the

bottle

into

your

vehicle's

AdBlue® tank.

Important: if your vehicle's AdBlue®

tank

is

completely

empty

-

which

is

confirmed

by

the

alert

displays

and

the

impossibility

of

starting

the

en

-

gine

-

you

must

add

at

least

3.8

li-

tres

(so

two

1.89

litre

bottles).

F After emptying the bottle, wipe away

any spilla ge around the tank

filler

using a damp cloth.

If

any

additive

is

split

or

splashed,

wash

immediately

with

cold

water

or

wipe

with

a

damp

cloth.

If

the

additive

has

crystallised,

clean

it

of

f

using

a

sponge

and

hot

water.

F

Refit

the

blue

cap

to

the

tank

and

turn

it

a

6th of a turn clockwise, to its stop.

F

Refit

the

black

plastic

blanking

plug,

clipping

it

in on the flap

F

Detach

the

cord

from

the

parcel

shelf

support

and

lower

the

boot

floor

. Never

dispose

of

AdBlue® ad-

ditive

bottles

in

the

household

waste.

Place

them

in

a

special

container

provided

this

purpose

or

take

them

to

your

dealer.

Important:

in the event of a

top-up

after a breakdown be-

cause of a lack of additive,

you

must

wait

around

5

minutes

before

switching

on

the

ignition,

without

opening the driver's

door, locking the vehicle or

introducing the key into the

ignition switch.

Switch

on

the

ignition,

then,

af

-

ter

10

seconds,

start

the

engine.

CHECKS

Page 192 of 340

1111

190

C4-2_en_Chap11_info-pratique_ed01-2014

TEMPORARY PUNCTURE REP

AIR KIT

Access to the kit

The speed limit sticker I must be affixed

to the vehicle's steering

wheel

to

remind

you

that

a

wheel

is

in temporary use.

Do

not

exceed

a

speed

of

50

mph

(80

km/h)

when

driving

with

a

tyre

repaired

using

this

type

of kit.

This

kit

is

installed

in

the

storage

box,

under

the

boot

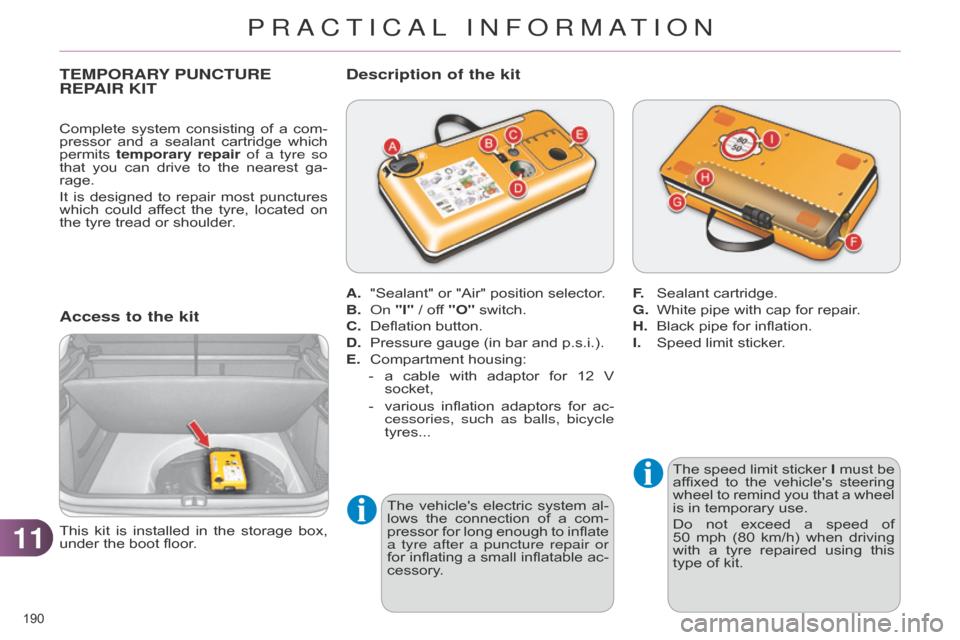

floor. A.

"Sealant"

or

"Air"

position

selector.

B.

o

n

"I"

/

off

"O"

switch.

C.

Deflation

button.

D.

Pressure

gauge

(in

bar

and

p.s.i.).

E.

Compartment

housing:

-

a

cable

with

adaptor

for

12

V

socket,

-

various

inflation

adaptors

for

ac

-

cessories, such as balls, bicycle

tyres...

Description of the kit

F. Sealant cartridge.

G.

White

pipe with cap for repair.

H.

Black

pipe for inflation.

I.

Speed

limit sticker.

Complete

system

consisting

of

a

com

-

pressor

and

a

sealant

cartridge

which

permits

temporary repair

of a tyre so

that

you

can

drive

to

the

nearest

ga

-

rage.

It

is

designed

to

repair

most

punctures

which

could

af

fect

the

tyre,

located

on

the

tyre

tread

or

shoulder.

The

vehicle's

electric

system

al

-

lows

the

connection

of

a

com

-

pressor

for

long

enough

to

inflate

a tyre after a puncture repair or

for

inflating

a

small

inflatable

ac

-

cessory.

PRACTICAL INFORMATION

Page 193 of 340

1111

191

C4-2_en_Chap11_info-pratique_ed01-2014

Repair procedure

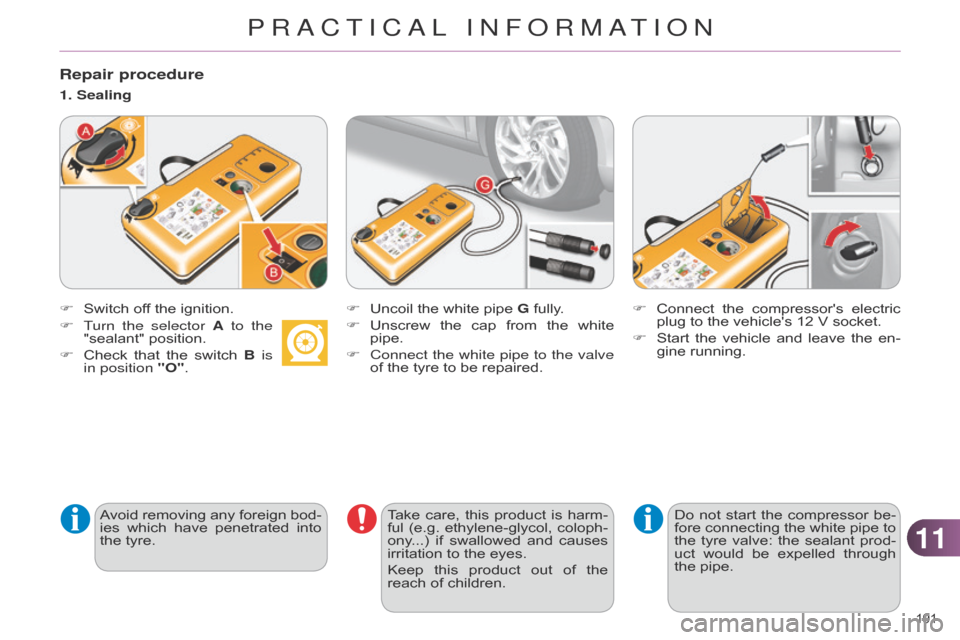

F Switch off the ignition.

Avoid

removing

any

foreign

bod

-

ies

which

have

penetrated

into

the

tyre.

1. Sealing

F Uncoil the white pipe G fully.

F

Unscrew

the

cap

from

the

white

pipe.

F

Connect

the white pipe to the valve

of

the tyre to be repaired.F

Connect the compressor's electric plug

to the vehicle's 12 V socket.

F

Start

the

vehicle

and

leave

the

en

-

gine

running.

Do

not

start

the

compressor

be

-

fore

connecting

the

white

pipe

to

the

tyre

valve:

the

sealant

prod

-

uct

would

be

expelled

through

the

pipe.

Take

care,

this

product

is

harm

-

ful

(e.g.

ethylene-glycol,

coloph

-

ony...)

if

swallowed

and

causes

irritation

to the eyes.

Keep

this

product

out

of

the

reach

of children.

F

T

urn the selector A to the

"sealant"

position.

F

Check

that

the

switch

B

is

in position "O".

PRACTICAL INFORMATION

Page 194 of 340

1111

192

C4-2_en_Chap11_info-pratique_ed01-2014

Tyre under-inflation detection

If

the

vehicle

is

fitted

with

tyre under-inflation

detection,

the

un

-

der-inflation

warning

lamp

will

re

-

main

on

after

the

wheel

has

been repaired

until

the

system

is

reini

-

tialised

by

a

CITROËN

dealer

or a

qualified workshop.

If

after

around

5

to

7

minutes

the

pressure

is

not

attained,

this

in

-

dicates

that

the

tyre

is

not

repair

-

able;

contact

a

CITROËN

dealer

or

a

qualified

workshop

for

as

-

sistance.

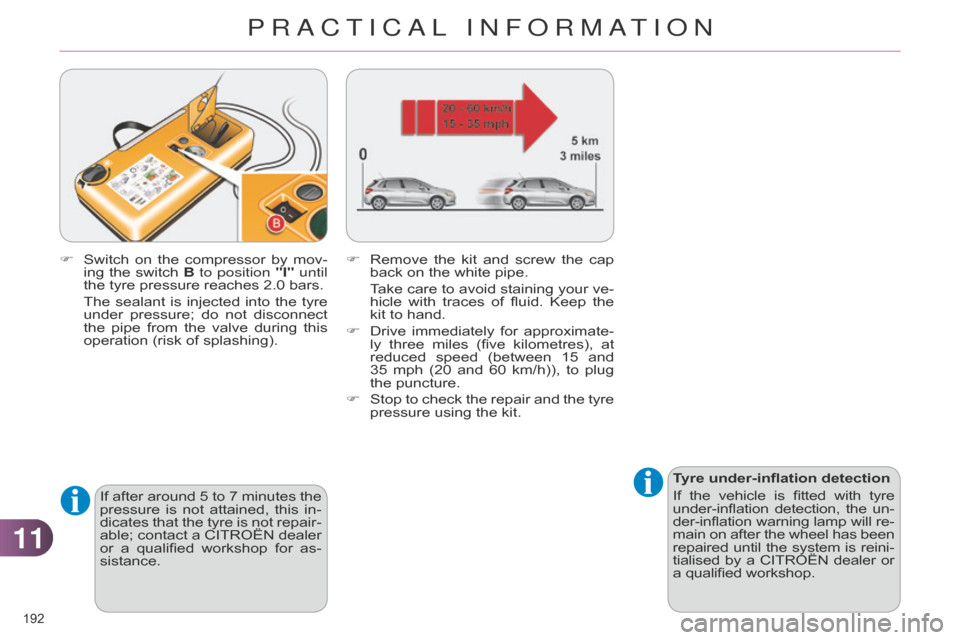

F

Switch

on

the

compressor

by

mov

-

ing

the

switch

B

to position

"I" until

the

tyre

pressure

reaches

2.0

bars.

The

sealant

is

injected

into

the

tyre

under

pressure;

do

not

disconnect

the

pipe

from

the

valve

during

this

operation

(risk

of

splashing).

F

Remove

the

kit

and

screw

the

cap

back

on

the

white

pipe.

T

ake

care

to

avoid

staining

your

ve

-

hicle

with

traces

of

fluid.

Keep

the

kit

to

hand.

F

Drive

immediately

for

approximate

-

ly

three

miles

(five

kilometres),

at

reduced

speed

(between

15

and

35

mph

(20

and

60

km/h)),

to

plug

the

puncture.

F

Stop

to

check

the

repair

and

the

tyre

pressure

using

the

kit.

PRACTICAL INFORMATION

Page 195 of 340

1111

193

C4-2_en_Chap11_info-pratique_ed01-2014

F Connect the compressor's electric plug

to the vehicle's 12 V socket.

F

Start

the

vehicle

again

and

leave

the

engine running.

As

soon

as

possible,

go

to

a

CITROËN

dealer

or

a

qualified

workshop.

Y

ou

must

inform

the

technician

that

you

have

used

this

kit.

After

inspection, the technician will

advise

you

on

whether

the

tyre

can

be

repaired

or

if

it

must

be

replaced.

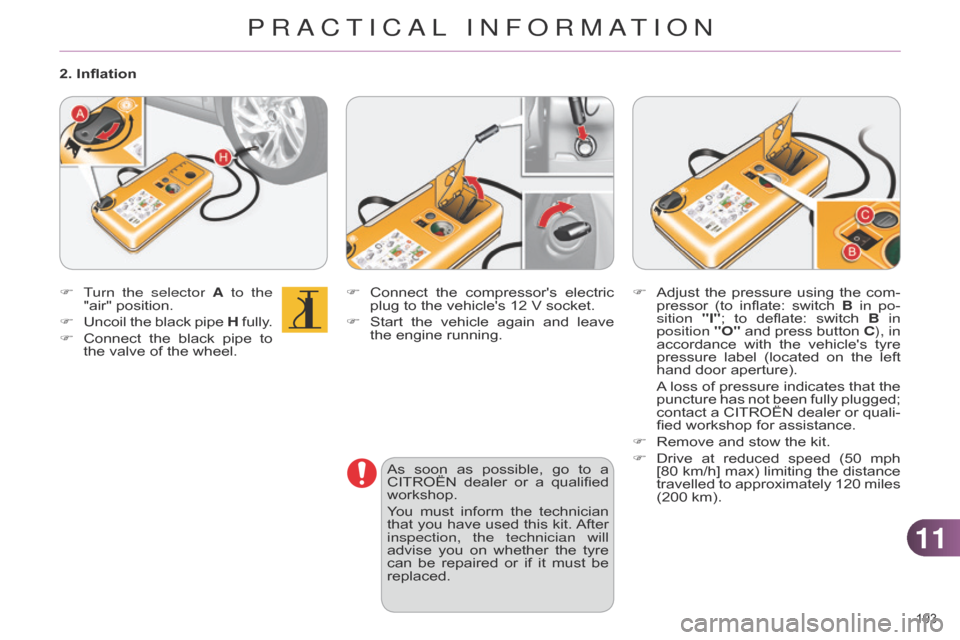

F

T

urn the selector A to the

"air"

position.

F

Uncoil

the

black

pipe

H

fully

.

F

Connect

the

black

pipe

to

the

valve

of

the

wheel.

2. Inflation

F Adjust the pressure using the com -

pressor (to inflate: switch B in po-

sition "I";

to

deflate:

switch

B

in

position "O"

and

press

button

C

), in

accordance

with

the

vehicle's

tyre

pressure

label

(located

on

the

left

hand

door aperture).

A loss

of

pressure

indicates

that

the

puncture

has

not

been

fully

plugged;

contact

a

CITROËN

dealer

or

quali

-

fied

workshop for assistance.

F

Remove

and stow the kit.

F

Drive

at

reduced

speed

(50

mph

[80

km/h]

max)

limiting

the

distance

travelled

to

approximately

120

miles

(200

km).

PRACTICAL INFORMATION

Page 196 of 340

1111

194

C4-2_en_Chap11_info-pratique_ed01-2014

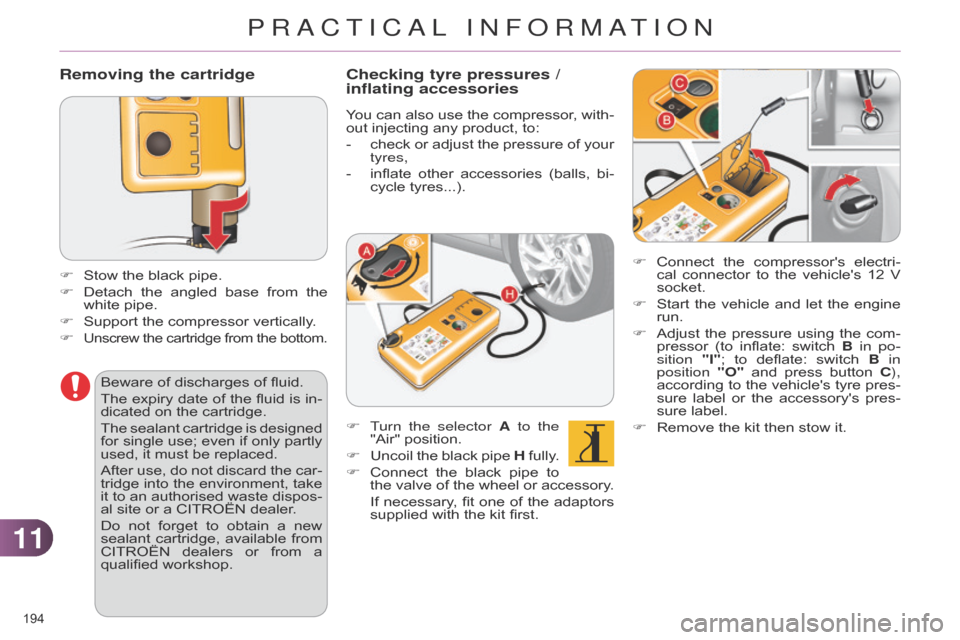

Removing the cartridge

F Stow the black pipe.

F

Detach

the

angled

base

from

the

white

pipe.

F

Support

the compressor vertically.

F

Unscrew the cartridge from the bottom.

F Connect the compressor's electri -

cal connector to the vehicle's 12 V

socket.

F

Start

the

vehicle

and

let

the

engine

run.

F

Adjust

the

pressure

using

the

com

-

pressor

(to

inflate:

switch

B

in po-

sition "I";

to

deflate:

switch

B

in

position "O"

and

press

button

C

),

according

to

the

vehicle's

tyre

pres

-

sure

label

or

the

accessory's

pres

-

sure

label.

F

Remove

the kit then stow it.

Beware

of

discharges

of

fluid.

The

expiry

date

of

the

fluid

is

in

-

dicated

on

the

cartridge.

The

sealant

cartridge

is

designed

for

single

use;

even

if

only

partly

used,

it

must

be

replaced.

After

use,

do

not

discard

the

car

-

tridge

into

the

environment,

take

it

to

an

authorised

waste

dispos

-

al

site

or

a

CITROËN

dealer.

Do

not

forget

to

obtain

a

new

sealant

cartridge,

available

from

CITROËN

dealers

or

from

a

qualified

workshop.

Checking tyre pressures /

inflating accessories

You can also use the compressor , with -

out injecting any product, to:

-

check

or

adjust

the

pressure

of

your

tyres,

-

inflate

other

accessories

(balls,

bi

-

cycle

tyres...).

F

T

urn the selector A to the

"Air"

position.

F

Uncoil

the

black

pipe

H

fully

.

F

Connect

the

black

pipe

to

the

valve

of

the

wheel

or

accessory

.

If

necessary

,

fit

one

of

the

adaptors

supplied

with the kit first.

PRACTICAL INFORMATION

Page 197 of 340

1111

195

C4-2_en_Chap11_info-pratique_ed01-2014

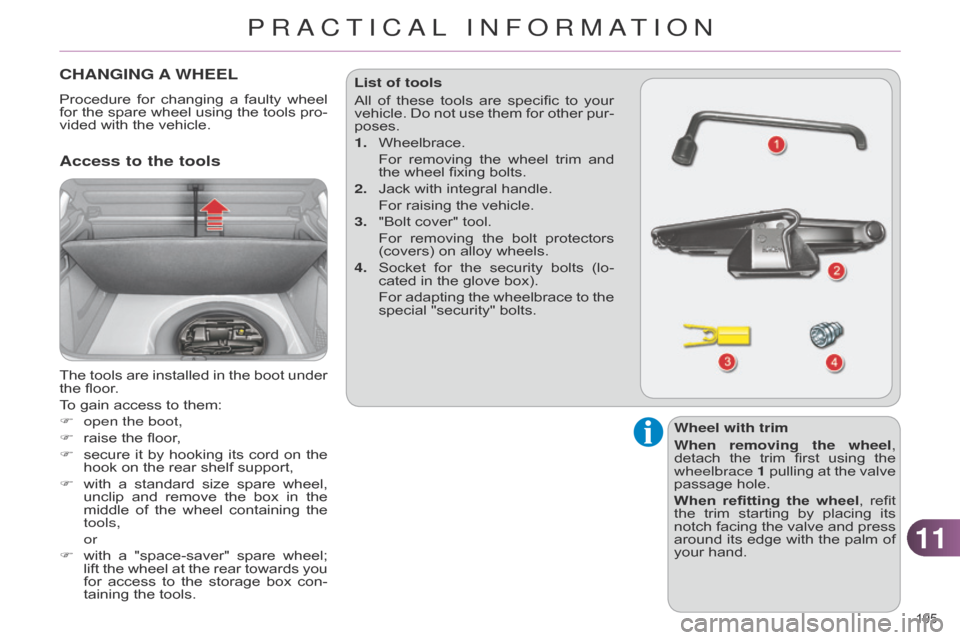

CHANGING A WHEEL

Procedure for changing a faulty wheel for

the spare wheel using the tools pro -

vided

with the vehicle.

Access to the tools

The tools are installed in the boot under the

floor.

To

gain access to them:

F

open the boot,

F

raise

the floor,

F

secure

it

by

hooking

its

cord

on

the

hook

on the rear shelf support,

F

with

a

standard

size

spare

wheel,

unclip

and

remove

the

box

in

the

middle

of

the

wheel

containing

the

tools,

or

F

with

a

"space-saver"

spare

wheel;

lift

the

wheel

at

the

rear

towards

you

for

access

to

the

storage

box

con

-

taining

the tools. List of tools

All

of

these

tools

are

specific

to

your

vehicle.

Do

not

use

them

for

other

pur

-

poses.

1.

Wheelbrace.

For

removing

the

wheel

trim

and

the

wheel fixing bolts.

2.

Jack

with integral handle.

For

raising the vehicle.

3.

"Bolt

cover" tool.

For

removing

the

bolt

protectors

(covers)

on alloy wheels.

4.

Socket

for

the

security

bolts

(lo

-

cated in the glove box).

For

adapting

the

wheelbrace

to

the

special

"security" bolts.

Wheel with trim

When removing the wheel,

detach

the

trim

first

using

the

wheelbrace 1

pullin

g

at

the

valve

passage

hole.

When refitting the wheel,

refit

the

trim

starting

by

placing

its

notch

facing

the

valve

and

press

around

its

edge

with

the

palm

of

your

hand.

PRACTICAL INFORMATION

Page 198 of 340

1111

196

C4-2_en_Chap11_info-pratique_ed01-2014

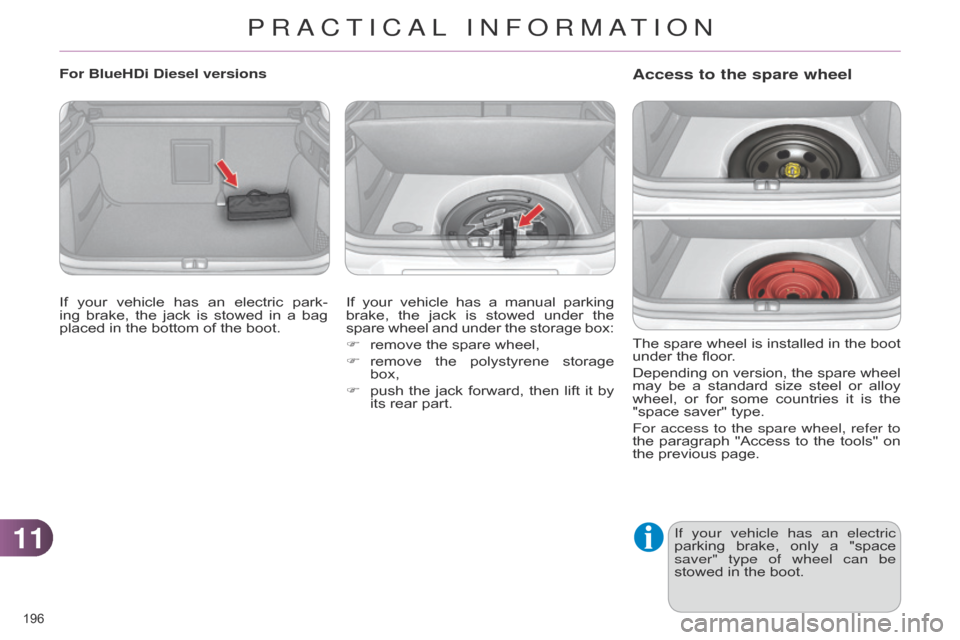

Access to the spare wheel

The spare wheel is installed in the boot under

the floor.

Depending

on

version,

the

spare

wheel

may

be

a

standard

size

steel

or

alloy

wheel,

or

for

some

countries

it

is

the

"space

saver" type.

For access to the spare wheel, refer to

the

paragraph

"Access

to

the

tools"

on

the

previous page.

If your vehicle has an electric

parking

brake,

only

a

"space

saver" type of wheel can be

stowed

in the boot.

For BlueHDi Diesel versions

If

your

vehicle

has

an

electric

park

-

ing

brake,

the

jack

is

stowed

in

a

bag

placed

in

the

bottom

of

the

boot. If

your

vehicle

has

a

manual

parking

brake,

the

jack

is

stowed

under

the

spare

wheel

and

under

the

storage

box:

F

remove

the

spare

wheel,

F

remove

the

polystyrene

storage

box,

F

push

the

jack

forward,

then

lift

it

by

its

rear

part.

PRACTICAL INFORMATION

Page 199 of 340

1111

197

C4-2_en_Chap11_info-pratique_ed01-2014

Putting the standard wheel back in

placeTyre under-inflation detection

The

spare

wheel

is

not

fitted

with

a

sensor

.

The

punctured

wheel

must

be

repaired

by

a

CITROËN

dealer

or aqualified workshop.

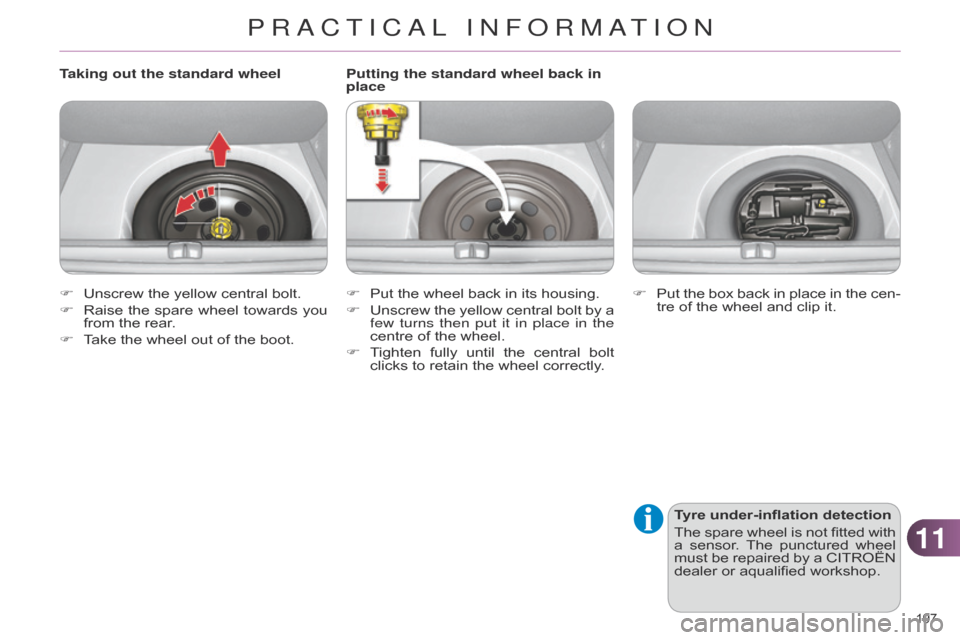

Taking out the standard wheel

F

Put

the wheel back in its housing.

F

Unscrew

the

yellow

central

bolt

by

a

few turns then put it in place in the

centre

of the wheel.

F

T

ighten

fully

until

the

central

bolt

clicks

to retain the wheel correctly.

F

Unscrew

the

yellow

central

bolt.

F

Raise

the

spare

wheel

towards

you

from

the

rear.

F

T

ake

the

wheel

out

of

the

boot. F

Put

the

box

back

in

place

in

the

cen

-

tre

of the wheel and clip it.

PRACTICAL INFORMATION

Page 200 of 340

1111

198

C4-2_en_Chap11_info-pratique_ed01-2014

Ensure that the jack is stable. If the

ground is slippery or loose,

the

jack

may

slip

or

drop

-

Risk

of

injury!

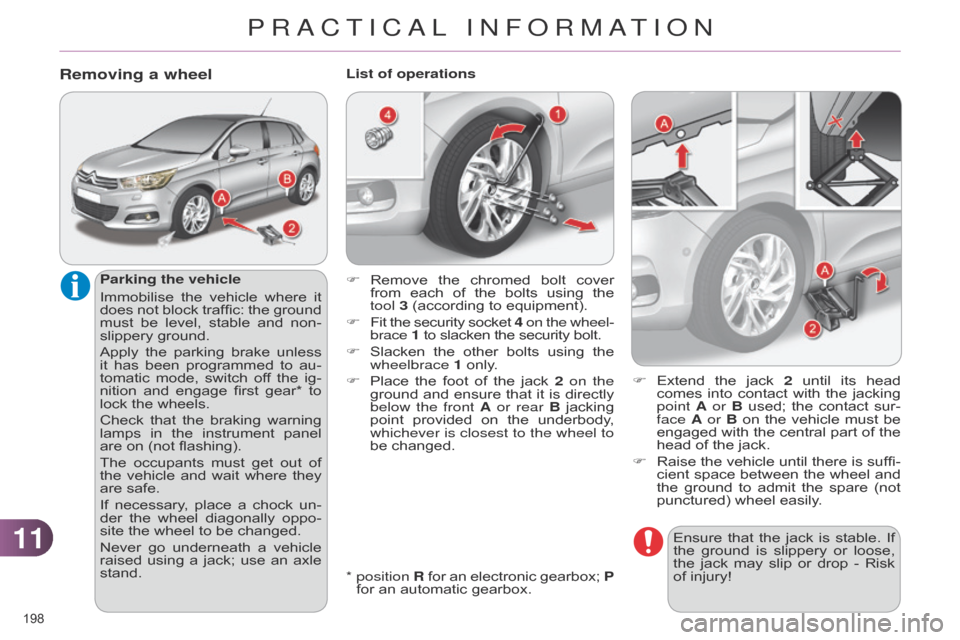

Removing a wheel

Parking the vehicle

Immobilise

the

vehicle

where

it

does

not

block

traffic:

the

ground

must

be

level,

stable

and

non-

slippery

ground.

Apply

the

parking

brake

unless

it

has

been

programmed

to

au

-

tomatic

mode,

switch

of

f

the

ig

-

nition

and

engage

first

gear*

to

lock

the wheels.

Check

that

the

braking

warning

lamps

in

the

instrument

panel

are

on (not flashing).

The

occupants

must

get

out

of

the

vehicle

and

wait

where

they

are

safe.

If

necessary

,

place

a

chock

un

-

der

the

wheel

diagonally

oppo

-

site

the wheel to be changed.

Never

go

underneath

a

vehicle

raised

using

a

jack;

use

an

axle

stand. *

position R

for

an

electronic

gearbox;

P

for

an automatic gearbox.

List of operations

F

Extend

the

jack

2

until

its

head

comes

into

contact

with

the

jacking

point A

or B

used;

the

contact

sur

-

face A or B

on

the

vehicle

must

be

engaged

with

the

central

part

of

the

head

of the jack.

F

Raise

the

vehicle

until

there

is

suffi

-

cient

space

between

the

wheel

and

the

ground

to

admit

the

spare

(not

punctured)

wheel easily.

F

Remove the chromed bolt cover from

each of the bolts using the

tool

3 (according to equipment).

F

Fit

the

security

socket

4 on the wheel

-

brace 1

to slacken the security bolt.

F

Slacken

the

other

bolts

using

the

wheelbrace

1 only.

F

Place

the

foot

of

the

jack

2

on the

ground

and

ensure

that

it

is

directly

below the front

A or rear B

jacking

point

provided

on

the

underbody

,

whichever is closest to the wheel to

be

changed.

PRACTICAL INFORMATION