boot Citroen C4 DAG 2014.5 2.G Owner's Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2014.5, Model line: C4 DAG, Model: Citroen C4 DAG 2014.5 2.GPages: 340, PDF Size: 12.89 MB

Page 185 of 340

1010

183

C4-2_en_Chap10_verification_ed01-2014

ADBLUE® ADDITIVE AND SCR SYSTEM

FOR

B

LUE HD I D IESEL

ENGINES

To assure respect for the environment and

conformity with the new Euro 6

emissions

standard,

without

adversely

af

fecting

the

performance

or

fuel

con

-

sumption

of

Diesel

engines,

CITROËN

has

taken

the

decision

to

equip

its

ve

-

hicles

with

an

ef

fective

system

that

associates SCR (Selective Catalytic

Reduction)

with

a

particle

filter

(F

AP)

for

the treatment of exhaust gases.

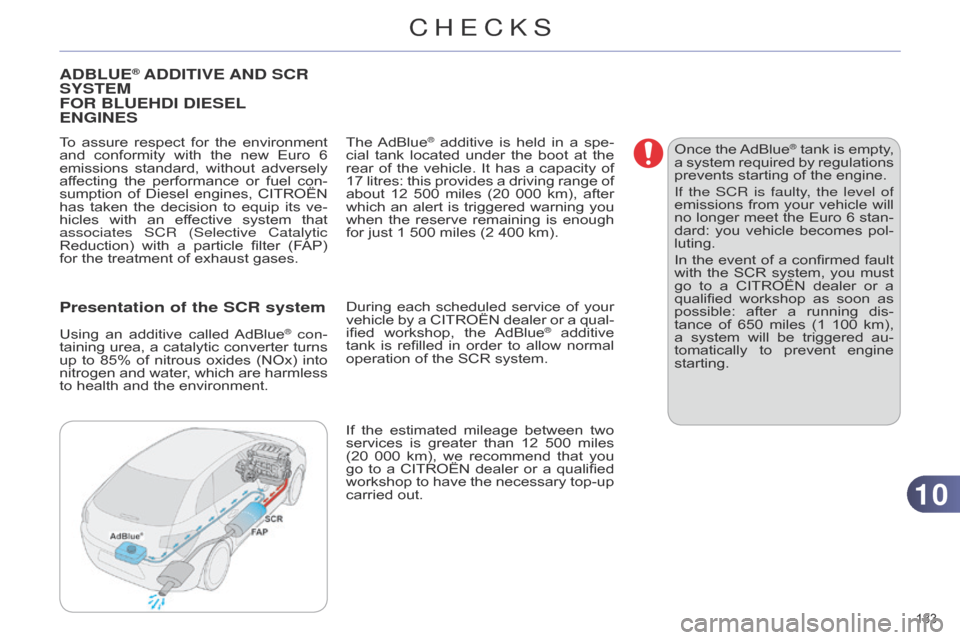

Presentation of the SCR system

Using an additive called AdBlue® con-

taining

urea,

a

catalytic

converter

turns

up

to

85%

of

nitrous

oxides

(NOx)

into

nitrogen

and

water

,

which

are

harmless

to

health

and

the

environment. The

AdBlue® additive

is held in a spe -

cial

tank

located under the boot at the

rear

of

the

vehicle.

It

has

a

capacity

of

17

litres:

this

provides

a

driving

range

of

about

12

500

miles

(20

000

km),

after

which

an

alert

is

triggered

warning

you

when

the

reserve

remaining

is

enough

for

just

1

500 miles (2 400 km).

During

each

scheduled

service

of

your

vehicle

by

a

CITROËN

dealer

or

a

qual

-

ified

workshop,

the

AdBlue® additive tank

is

refilled

in

order

to

allow normal

operation

of

the

SCR

system.

If

the

estimated

mileage

between

two

services

is

greater

than

12

500

miles

(20

000

km),

we

recommend

that

you

go

to

a

CITROËN

dealer

or

a

qualified

workshop

to

have

the

necessary

top-up

carried

out. Once

the

AdBlue® tank is

empty , a

system

required

by regulations

prevents

starting

of the engine.

If the SCR

is faulty, the level of

emissions

from

your

vehicle

will

no

longer

meet

the

Euro

6

stan

-

dard:

you

vehicle

becomes

pol

-

luting.

In

the

event

of

a

confirmed

fault

with

the

SCR

system,

you

must

go

to

a

CITROËN

dealer

or

a

qualified

workshop

as

soon

as

possible:

after

a

running

dis

-

tance

of

650

miles

(1

100

km),

a

system

will

be

triggered

au

-

tomatically

to

prevent

engine

starting.

CHECKS

Page 190 of 340

1010

188

C4-2_en_Chap10_verification_ed01-2014

Recommendations on storage

AdBlue® freezes at about -1 1°C and deteriorates

above 25°C. It is recom -

mended

that

bottles

be

stored

in

a

cool

area

and

protected

from

direct

sunlight.

Under

these

conditions,

the

additive

can

be

kept for at least a year.

If

the

additive

has

frozen,

can

be

used

once

it

has completely thawed out.

Never

store

bottles

of

AdBlue® in

your

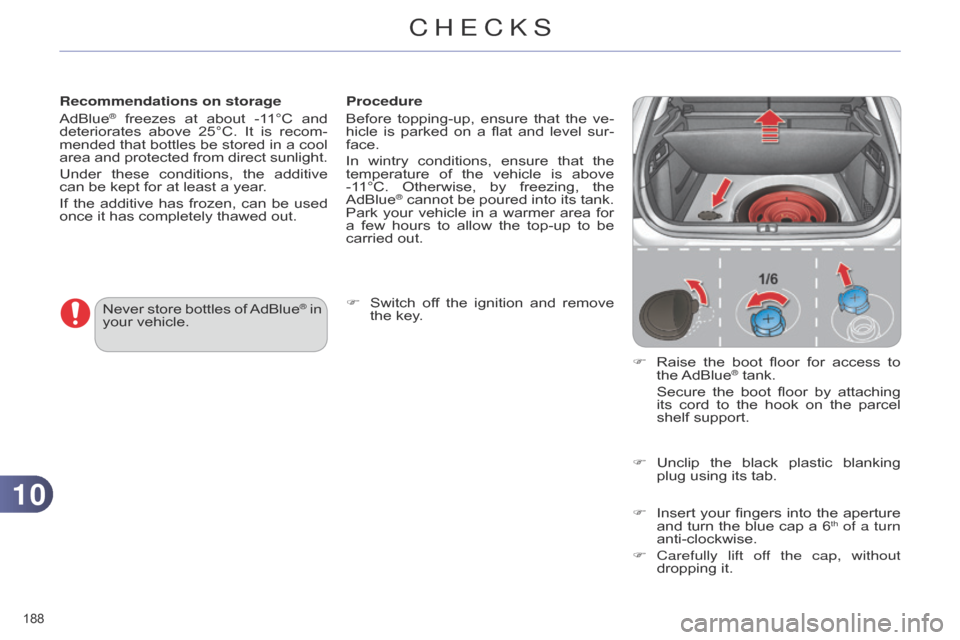

vehicle. Procedure

Before

topping-up,

ensure

that

the

ve

-

hicle

is

parked

on

a

flat

and

level

sur

-

face.

In

wintry

conditions,

ensure

that

the

temperature

of

the

vehicle

is

above

-1

1°C.

Otherwise,

by

freezing,

the

AdBlue® cannot

be poured into its tank. Park

your vehicle in a warmer area for

a

few

hours

to

allow

the

top-up

to

be

carried

out.

F

Switch

of

f

the

ignition

and

remove

the

key. F

Raise

the

boot

floor

for

access

to

the

AdBlue® tank.

Secure

the

boot

floor

by

attaching

its

cord

to

the

hook

on

the

parcel

shelf

support.

F

Unclip

the

black

plastic

blanking

plug

using

its tab.

F

Insert

your

fingers

into

the

aperture

and

turn

the

blue

cap

a

6th of a turn

anti-clockwise.

F

Carefully

lift off the cap, without

dropping

it.

CHECKS

Page 191 of 340

1010

189

C4-2_en_Chap10_verification_ed01-2014

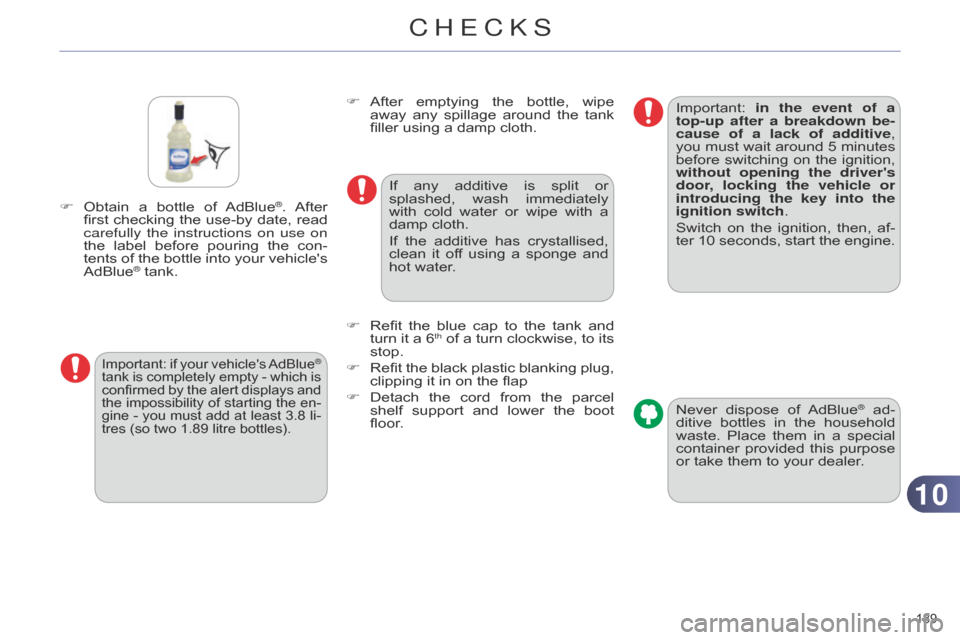

F Obtain a bottle of AdBlue®. After first

checking

the

use-by

date, read

carefully

the instructions on use on

the

label

before

pouring

the

con

-

tents

of

the

bottle

into

your

vehicle's

AdBlue® tank.

Important: if your vehicle's AdBlue®

tank

is

completely

empty

-

which

is

confirmed

by

the

alert

displays

and

the

impossibility

of

starting

the

en

-

gine

-

you

must

add

at

least

3.8

li-

tres

(so

two

1.89

litre

bottles).

F After emptying the bottle, wipe away

any spilla ge around the tank

filler

using a damp cloth.

If

any

additive

is

split

or

splashed,

wash

immediately

with

cold

water

or

wipe

with

a

damp

cloth.

If

the

additive

has

crystallised,

clean

it

of

f

using

a

sponge

and

hot

water.

F

Refit

the

blue

cap

to

the

tank

and

turn

it

a

6th of a turn clockwise, to its stop.

F

Refit

the

black

plastic

blanking

plug,

clipping

it

in on the flap

F

Detach

the

cord

from

the

parcel

shelf

support

and

lower

the

boot

floor

. Never

dispose

of

AdBlue® ad-

ditive

bottles

in

the

household

waste.

Place

them

in

a

special

container

provided

this

purpose

or

take

them

to

your

dealer.

Important:

in the event of a

top-up

after a breakdown be-

cause of a lack of additive,

you

must

wait

around

5

minutes

before

switching

on

the

ignition,

without

opening the driver's

door, locking the vehicle or

introducing the key into the

ignition switch.

Switch

on

the

ignition,

then,

af

-

ter

10

seconds,

start

the

engine.

CHECKS

Page 192 of 340

1111

190

C4-2_en_Chap11_info-pratique_ed01-2014

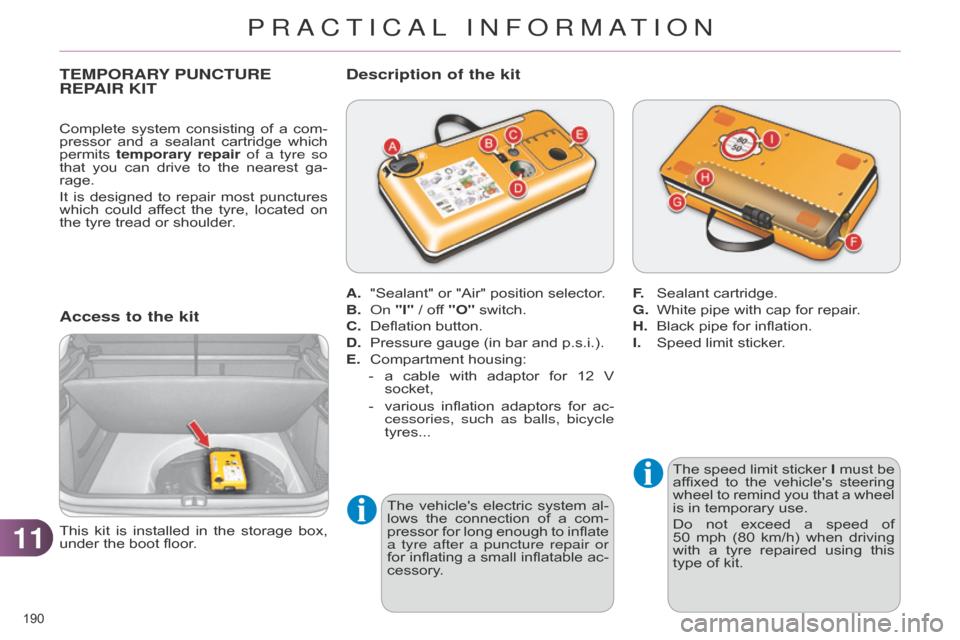

TEMPORARY PUNCTURE REP

AIR KIT

Access to the kit

The speed limit sticker I must be affixed

to the vehicle's steering

wheel

to

remind

you

that

a

wheel

is

in temporary use.

Do

not

exceed

a

speed

of

50

mph

(80

km/h)

when

driving

with

a

tyre

repaired

using

this

type

of kit.

This

kit

is

installed

in

the

storage

box,

under

the

boot

floor. A.

"Sealant"

or

"Air"

position

selector.

B.

o

n

"I"

/

off

"O"

switch.

C.

Deflation

button.

D.

Pressure

gauge

(in

bar

and

p.s.i.).

E.

Compartment

housing:

-

a

cable

with

adaptor

for

12

V

socket,

-

various

inflation

adaptors

for

ac

-

cessories, such as balls, bicycle

tyres...

Description of the kit

F. Sealant cartridge.

G.

White

pipe with cap for repair.

H.

Black

pipe for inflation.

I.

Speed

limit sticker.

Complete

system

consisting

of

a

com

-

pressor

and

a

sealant

cartridge

which

permits

temporary repair

of a tyre so

that

you

can

drive

to

the

nearest

ga

-

rage.

It

is

designed

to

repair

most

punctures

which

could

af

fect

the

tyre,

located

on

the

tyre

tread

or

shoulder.

The

vehicle's

electric

system

al

-

lows

the

connection

of

a

com

-

pressor

for

long

enough

to

inflate

a tyre after a puncture repair or

for

inflating

a

small

inflatable

ac

-

cessory.

PRACTICAL INFORMATION

Page 197 of 340

1111

195

C4-2_en_Chap11_info-pratique_ed01-2014

CHANGING A WHEEL

Procedure for changing a faulty wheel for

the spare wheel using the tools pro -

vided

with the vehicle.

Access to the tools

The tools are installed in the boot under the

floor.

To

gain access to them:

F

open the boot,

F

raise

the floor,

F

secure

it

by

hooking

its

cord

on

the

hook

on the rear shelf support,

F

with

a

standard

size

spare

wheel,

unclip

and

remove

the

box

in

the

middle

of

the

wheel

containing

the

tools,

or

F

with

a

"space-saver"

spare

wheel;

lift

the

wheel

at

the

rear

towards

you

for

access

to

the

storage

box

con

-

taining

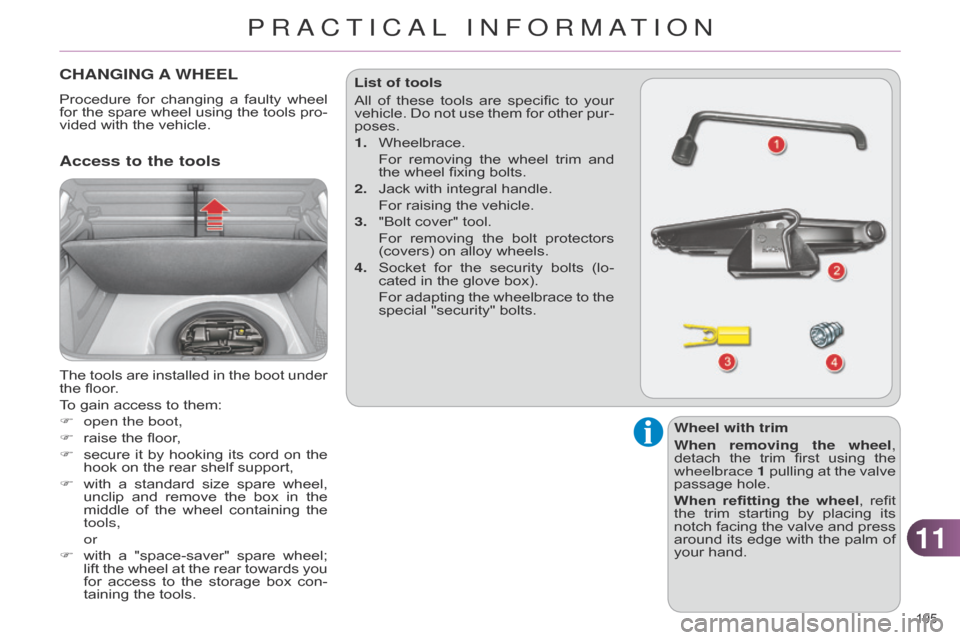

the tools. List of tools

All

of

these

tools

are

specific

to

your

vehicle.

Do

not

use

them

for

other

pur

-

poses.

1.

Wheelbrace.

For

removing

the

wheel

trim

and

the

wheel fixing bolts.

2.

Jack

with integral handle.

For

raising the vehicle.

3.

"Bolt

cover" tool.

For

removing

the

bolt

protectors

(covers)

on alloy wheels.

4.

Socket

for

the

security

bolts

(lo

-

cated in the glove box).

For

adapting

the

wheelbrace

to

the

special

"security" bolts.

Wheel with trim

When removing the wheel,

detach

the

trim

first

using

the

wheelbrace 1

pullin

g

at

the

valve

passage

hole.

When refitting the wheel,

refit

the

trim

starting

by

placing

its

notch

facing

the

valve

and

press

around

its

edge

with

the

palm

of

your

hand.

PRACTICAL INFORMATION

Page 198 of 340

1111

196

C4-2_en_Chap11_info-pratique_ed01-2014

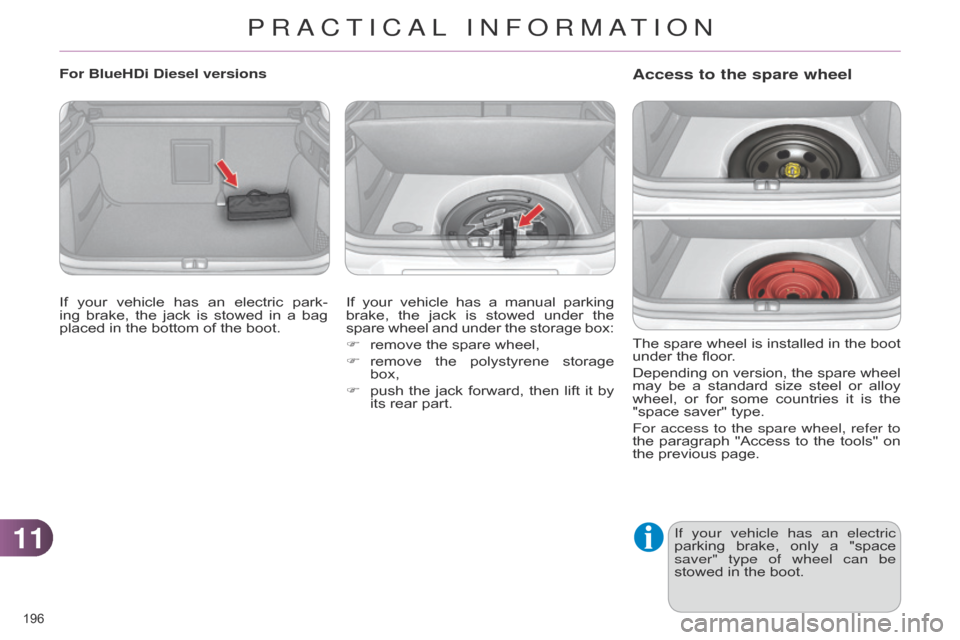

Access to the spare wheel

The spare wheel is installed in the boot under

the floor.

Depending

on

version,

the

spare

wheel

may

be

a

standard

size

steel

or

alloy

wheel,

or

for

some

countries

it

is

the

"space

saver" type.

For access to the spare wheel, refer to

the

paragraph

"Access

to

the

tools"

on

the

previous page.

If your vehicle has an electric

parking

brake,

only

a

"space

saver" type of wheel can be

stowed

in the boot.

For BlueHDi Diesel versions

If

your

vehicle

has

an

electric

park

-

ing

brake,

the

jack

is

stowed

in

a

bag

placed

in

the

bottom

of

the

boot. If

your

vehicle

has

a

manual

parking

brake,

the

jack

is

stowed

under

the

spare

wheel

and

under

the

storage

box:

F

remove

the

spare

wheel,

F

remove

the

polystyrene

storage

box,

F

push

the

jack

forward,

then

lift

it

by

its

rear

part.

PRACTICAL INFORMATION

Page 199 of 340

1111

197

C4-2_en_Chap11_info-pratique_ed01-2014

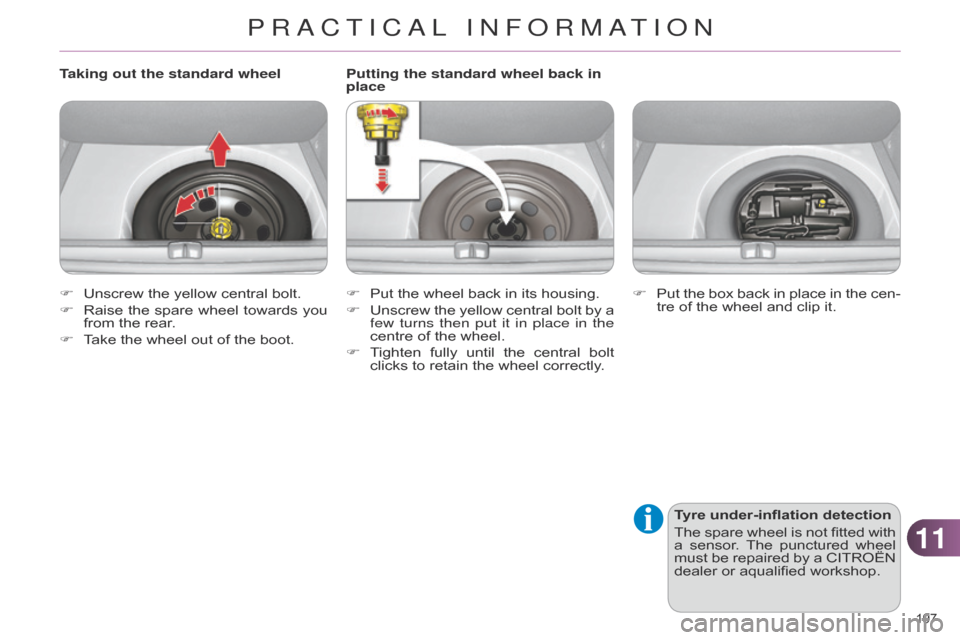

Putting the standard wheel back in

placeTyre under-inflation detection

The

spare

wheel

is

not

fitted

with

a

sensor

.

The

punctured

wheel

must

be

repaired

by

a

CITROËN

dealer

or aqualified workshop.

Taking out the standard wheel

F

Put

the wheel back in its housing.

F

Unscrew

the

yellow

central

bolt

by

a

few turns then put it in place in the

centre

of the wheel.

F

T

ighten

fully

until

the

central

bolt

clicks

to retain the wheel correctly.

F

Unscrew

the

yellow

central

bolt.

F

Raise

the

spare

wheel

towards

you

from

the

rear.

F

T

ake

the

wheel

out

of

the

boot. F

Put

the

box

back

in

place

in

the

cen

-

tre

of the wheel and clip it.

PRACTICAL INFORMATION

Page 202 of 340

1111

200

C4-2_en_Chap11_info-pratique_ed01-2014

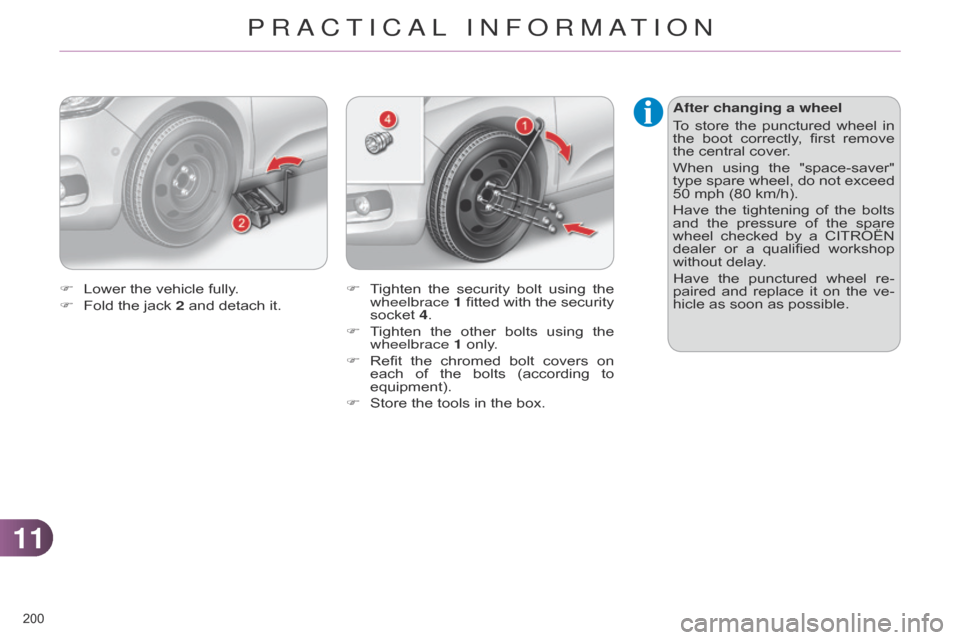

After changing a wheel

To

store

the

punctured

wheel

in

the

boot

correctly

,

first

remove

the

central cover.

When

using

the

"space-saver"

type

spare

wheel,

do

not

exceed

50

mph (80 km/h).

Have

the

tightening

of

the

bolts

and

the

pressure

of

the

spare

wheel

checked

by

a

CITROËN

dealer

or

a

qualified

workshop

without

delay.

Have

the

punctured

wheel

re

-

paired

and

replace

it

on

the

ve

-

hicle

as soon as possible.

F

T

ighten

the

security

bolt

using

the

wheelbrace 1

fitted

with

the

security

socket

4.

F

T

ighten

the

other

bolts

using

the

wheelbrace

1

only.

F

Refit

the

chromed

bolt

covers

on

each

of

the

bolts

(according

to

equipment).

F

Store

the

tools

in

the

box.

F

Lower

the

vehicle

fully.

F

Fold

the

jack

2

and

detach

it.

PRACTICAL INFORMATION

Page 208 of 340

1111

206

C4-2_en_Chap11_info-pratique_ed01-2014

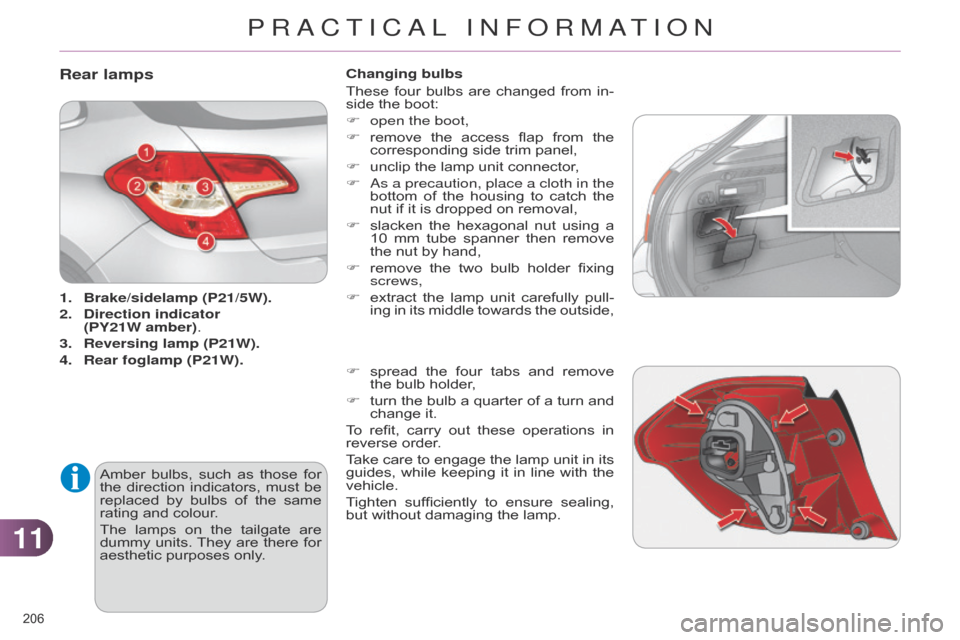

Rear lamps

1. Brake/sidelamp (P21/5W).

2.

Direction

indicator

(PY21W amber).

3.

Reversing lamp (P21W).

4.

Rear

foglamp (P21W).

Amber

bulbs,

such

as

those

for

the

direction

indicators,

must

be

replaced

by

bulbs

of

the

same

rating

and colour.

The

lamps

on

the

tailgate

are

dummy

units.

They

are

there

for

aesthetic

purposes only.Changing bulbs

These

four

bulbs

are

changed

from

in

-

side the boot:

F

open the boot,

F

remove

the

access

flap

from

the

corresponding

side trim panel,

F

unclip

the lamp unit connector,

F a s a precaution, place a cloth in the

bottom

of

the

housing

to

catch

the

nut

if it is dropped on removal,

F

slacken

the

hexagonal

nut

using

a

10

mm

tube

spanner

then

remove

the

nut by hand,

F

remove

the

two

bulb

holder

fixing

screws,

F

extract the lamp unit carefully pull -

ing in its middle towards the outside,

F

spread

the

four

tabs

and

remove

the

bulb holder,

F

turn

the

bulb

a

quarter

of

a

turn

and

change

it.

To

refit,

carry

out

these

operations

in

reverse

order.

Take

care

to

engage

the

lamp

unit

in

its

guides,

while

keeping

it

in

line

with

the

vehicle.

T

ighten

sufficiently

to

ensure

sealing,

but

without damaging the lamp.

PRACTICAL INFORMATION

Page 211 of 340

1111

209

C4-2_en_Chap11_info-pratique_ed01-2014

Dashboard fuses

The fuseboxes are located in the lower dashboard

(left-hand side).

Access to the fuses

F

Refer

to

the

paragraph

"Access

to

the

tools". Fuse tables

Fusebox 1

Fuse N° Rating Functions

F8 3 AAlarm

siren, alarm ECU.

F13 10 A12

V socket.

F14 10 A12

V socket in boot.

F16 3 ALighting

for the large multifunctional storage unit,

rear

map reading lamps, glove box illumination.

F17 3 ASun

visor illumination, front map reading lamps.

F28 15 AAudio

system, radio (after-market).

F30 20 ARear

wiper.

F32 10 AHi-Fi

amplifier.

PRACTICAL INFORMATION