spare wheel CITROEN C4 PICASSO 2022 User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2022, Model line: C4 PICASSO, Model: CITROEN C4 PICASSO 2022Pages: 316, PDF Size: 10.36 MB

Page 174 of 316

172

Deactivation of the system is recommended in

the following situations:

-

d

riving on a road sur face in poor condition,

-

p

oor weather conditions,

-

d

riving on slippery sur faces (ice).

Activation/Deactivation

Activation and deactivation of the system is

done in the Driving menu of the touch screen.

Select the " Driving functions " then the "Lane

assist " tab.

The system state remains in memory when the

ignition is switched off.

Malfunction

Operating limits

The system goes into standby automatically in

the following cases:

-

E

SC deactivated or operation triggered,

-

s

peed below 40 mph (65 km/h) or greater

than 112

mph (180 km/h),

-

c

onnected electrically to a

trailer,

-

u

se of the "space-saver" spare

wheel detected (as detection is not

immediate, deactivation of the system is

recommended),

-

d

ynamic driving style detected, pressure on

the brake or accelerator pedal,

-

d

riving where there are no lane markings,

-

a

ctivation of the direction indicators,

-

c

rossing the inside line on a bend,

-

d

riving in a tight corner,

-

i

nactivity by the driver detected during

correction. The following situations may interfere with

the operation of the system or prevent it

working:

-

c

onditions of poor visibility (inadequate

street lighting, snowfall, rain, fog),

-

d

azzle (headlamps of an oncoming

vehicle, low sun, reflections on a

damp

road, leaving a

tunnel, alternating

shade and light),

-

w

indscreen area located in front of the

camera: dirty, misted, frost-covered,

snow-covered, damaged or covered by

a

s t i c ke r,

-

l

ane markings worn, hidden (snow,

mud) or multiple (roadworks, etc.),

-

r

unning close to the vehicle in front

(the lane markings may not be

detected),

-

r

oads that are narrow, winding, etc.

Risk of undesirable operation

The system is not intended for driving in the

following situations:

-

d

riving on a speed circuit,

-

d

riving with a trailer,

-

d

riving on a rolling stand,

-

d

riving on unstable sur faces.

In the event of a

fault with the system, you are

alerted by the illumination of these warning

lamps in the instrument panel, accompanied by

the display of a

message and an audible signal.

Have the system checked by a

CITROËN

dealer or a

qualified workshop.

Driving

Page 193 of 316

191

Misfuel prevention (Diesel)

(Depending on the country of sale.)

Mechanical device which prevents filling the

tank of a Diesel vehicle with petrol. It helps

avoid the risk of engine damage that can result

from filling with the wrong fuel.

Operation

It remains possible to use a fuel can to fill

t he tank.

In order to ensure a

good flow of fuel,

do not place the nozzle of the fuel can in

direct contact with the flap of the misfuel

prevention device and pour slowly. Travelling abroad

As Diesel fuel pump nozzles may be

different in other countries, the presence

of the misfuel prevention device may make

refuelling impossible.

Not all Diesel vehicles are fitted with

misfuel protection, so before travelling

abroad, we recommend that you check

with the CITROËN dealer network,

whether your vehicle is suitable for the

fuel pumps in the country in which you

intend to travel.

When a petrol filler nozzle is introduced into

the fuel filler neck of a Diesel vehicle, it comes

into contact with the flap. The system remains

closed and prevents filling.

Do not persist but introduce a Diesel type

filler nozzle.

Snow chains

In wintry conditions, snow chains

improve traction as well as the

behaviour of the vehicle when

braking.

Snow chains must be fitted only to the

front wheels. They must never be fitted to

"space-saver" type spare wheels.

Take account of the legislation in force in

your country on the use of snow chains

and the maximum authorised speed.

Installation tips

F If you have to fit the chains during a journey,

stop the vehicle on a flat sur face on the side

of the road.

F

A

pply the parking brake and position any

wheel chocks under the wheels to prevent

movement of your vehicle.

F

F

it the chains following the instructions

provided by the manufacturer.

F

M

ove off gently and drive for a few

moments, without exceeding 31

mph

(50

km/h).

F

S

top your vehicle and check that the snow

chains are correctly tightened.

It is strongly recommended that before

you leave, you practise fitting the snow

chains on a

level and dry sur face.

Avoid driving with snow chains on roads

that have been cleared of snow to avoid

damaging your vehicle's tyres and the

road sur face. If your vehicle is fitted with

alloy wheels, check that no part of the

chain or its fixings is in contact with the

wheel rim.

7

Practical information

Page 205 of 316

203

Manual gearbox

The gearbox does not require any

maintenance (no oil change).

Automatic gearbox

The gearbox does not require any

maintenance (no oil change).

Brake pads

Brake wear depends on the style

of driving, particularly in the case

of vehicles used in town, over short

distances. It may be necessary to

have the condition of the brakes

checked, even between vehicle

services.

Unless there is a

leak in the circuit, a drop in

the brake fluid level indicates that the brake

pads are worn.

Brake disc wear

For information on checking brake

disc wear, contact a CITROËN

dealer or a

qualified workshop.

Electric parking brake

This system does not require any

specific check. However, in the

event of a problem, have the system

checked by a

CITROËN dealer or

a

qualified workshop.

For more information on the Electric

parking brake , refer to the corresponding

section.

Wheels and tyres

The pressure must be checked on

all tyres, including the spare wheel,

when the tyres are "cold", at least

once a

month and before a long

j o u r n ey. The pressures given on the tyre pressure label

are valid for "cold" tyres. If you have driven for

more than 10

minutes or more than 6 miles

(10 kilometres) at more than 31 mph (50 km/h),

0.3 bar (30 kPa) should be added to the values

given on the label.

Under-inflation increases fuel consumption.

Non-compliant tyre pressure causes premature

wear on tyres and has an adverse effect on the

vehicle's road holding – Risk of an accident!

Driving with worn or damaged tyres reduces

braking efficiency and control of the vehicle's

steering. Regular inspections of the condition

of tyres (tread and sides) and rims are

recommended as well as making sure that

valves are fitted.

Using different size wheels and tyres from

those specified can affect the lifetime of tyres,

wheel rotation, ground clearance and the

speedometer reading and have an adverse

effect on road holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

7

Practical information

Page 213 of 316

211

F Check that the compressor switch is at the "O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

Only the 12

V socket located at the front

of the vehicle can be used to power the

compressor. F

S

tart the compressor by placing the switch

at position " I" and adjust the pressure to the

value shown on the vehicle's tyre pressure

label. To deflate: press the black button

located on the compressor pipe, near the

valve connection.

If a pressure of 2 bars is not reached after

7 minutes, this indicates that the tyre is

not repairable; contact a CITROËN dealer

or a

qualified workshop for assistance.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 125

miles (200 km)

with the repaired tyre; see a

CITROËN

dealer or a

qualified workshop to change

the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-

inflation detection , refer to the

corresponding section.

F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f i r m l y.

F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

F

S

witch on the ignition.

The tyre inflation pressures are given on

this label.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

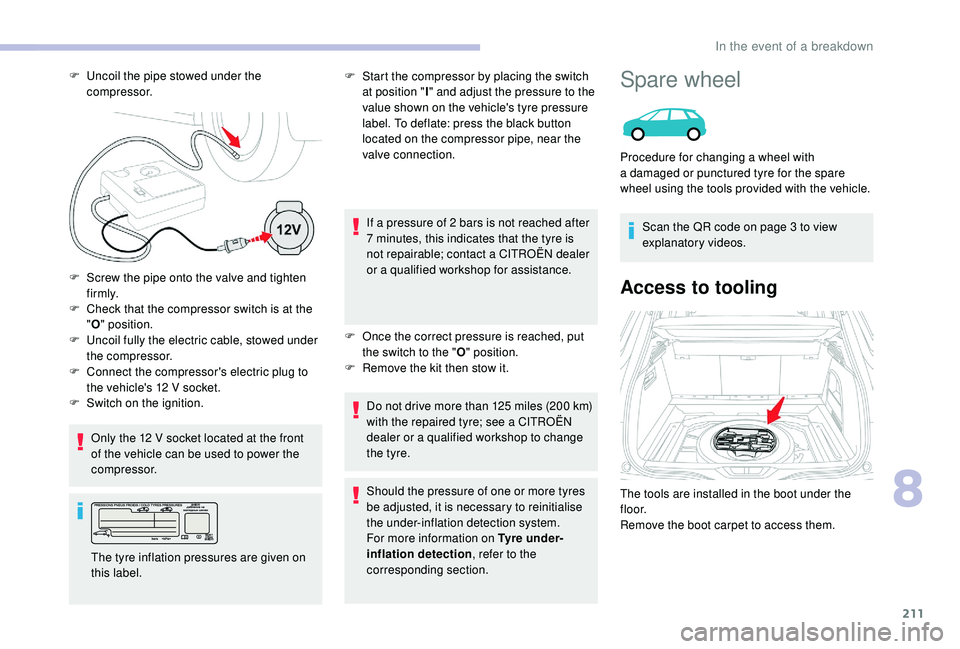

Access to tooling

Procedure for changing a wheel with

a damaged or punctured tyre for the spare

wheel using the tools provided with the vehicle.

The tools are installed in the boot under the

f l o o r.

Remove the boot carpet to access them.

8

In the event of a breakdown

Page 214 of 316

212

List of tools

(Depending on equipment.)4.

Wheel bolt cover removal tool.

Removes the wheel bolt covers on alloy

wheels.

5. Socket for the security bolts (located in

the glove box).

For adapting the wheelbrace to the special

"security" bolts.

6. Towing eye and tool to open the front

protective cover.

1. Wheelbrace.

For removing the wheel trim and the wheel

fastening bolts.

2. Chock to immobilise the vehicle (except

versions with manual gearbox).

3. Jack with integrated handle.

Used to raise the vehicle. For more information on To w i n g

, refer to the

corresponding section.

All of these tools are specific to your

vehicle and may vary according to the

level of equipment.

Do not use them for any other purposes.

The jack must only be used to change

a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact a

CITROËN dealer or a qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

Access to the spare wheel

The spare wheel is located in the boot, under

t h e f l o o r.

Taking out the wheel

F Loosen the central nut.

F R emove the fastening device (nut and bolt).

F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

In the event of a breakdown

Page 215 of 316

213

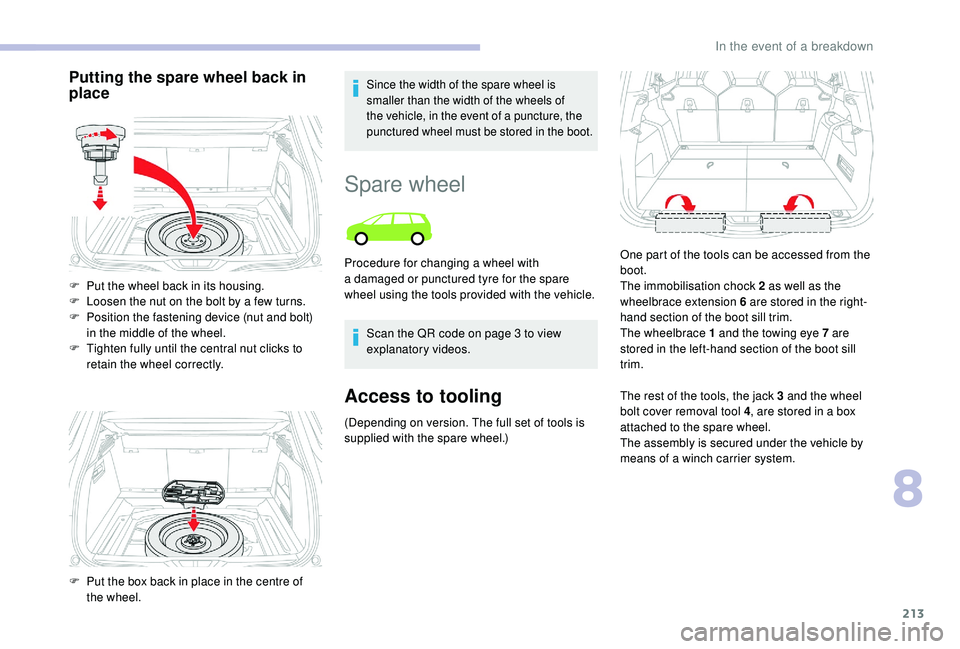

Putting the spare wheel back in

placeSince the width of the spare wheel is

smaller than the width of the wheels of

the vehicle, in the event of a puncture, the

punctured wheel must be stored in the boot.

F Put the wheel back in its housing.

F L oosen the nut on the bolt by a few turns.

F

P

osition the fastening device (nut and bolt)

in the middle of the wheel.

F

T

ighten fully until the central nut clicks to

retain the wheel correctly.

F

P

ut the box back in place in the centre of

the wheel.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

Access to tooling

(Depending on version. The full set of tools is

supplied with the spare wheel.) The rest of the tools, the jack 3

and the wheel

bolt cover removal tool 4 , are stored in a box

attached to the spare wheel.

The assembly is secured under the vehicle by

means of a

winch carrier system.

Procedure for changing a

wheel with

a damaged or punctured tyre for the spare

wheel using the tools provided with the vehicle. One part of the tools can be accessed from the

boot.

The immobilisation chock 2 as well as the

wheelbrace extension 6 are stored in the right-

hand section of the boot sill trim.

The wheelbrace 1 and the towing eye 7 are

stored in the left-hand section of the boot sill

trim.

8

In the event of a breakdown

Page 216 of 316

214

List of tools

(Depending on version. The full set of tools is

supplied with the spare wheel.)

1.Wheelbrace.

For removing the wheel trim and removing

the wheel bolts.

2. Chock to immobilise the vehicle (except

for versions with manual gearbox).

3. Jack with integrated handle.

Used to raise the vehicle. 4.

Wheel bolt cover removal tool.

Removes the wheel bolt covers on alloy

wheels.

5. Socket for wheel security bolts (stored in

the glove box).

For adapting the wheelbrace to the special

"security" bolts.

6. Wheelbrace extension.

For slackening/tightening the spare wheel

winch cable carrier nut.

7. Towing eye and tool to open the front

protective cover.

For more information on To w i n g , refer to the

corresponding section.

All of these tools are specific to your

vehicle and may vary according to the

level of equipment.

Do not use them for any other purposes.

The jack must only be used to change

a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact a

CITROËN dealer or a qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

Wheel with wheel trim

When removing the wheel , first remove the

trim using the wheelbrace 1 by pulling at the

valve aperture.

When refitting the wheel , refit the trim

starting by placing its notch facing the valve

and press around its edge with the palm of your

hand.

Access to the spare wheel

(Depending on version.)

Only a "space-saver" type spare wheel

may be fixed underneath the vehicle.

The spare wheel is supported by a

winch

carrier system underneath the vehicle.

In the event of a breakdown

Page 217 of 316

215

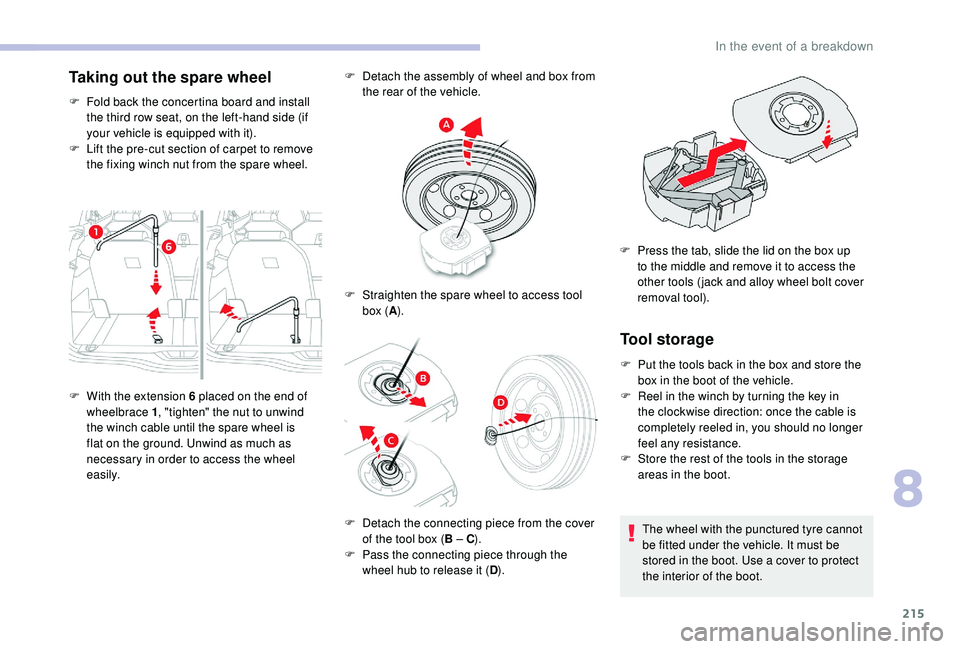

Taking out the spare wheel

F Fold back the concertina board and install the third row seat, on the left-hand side (if

your vehicle is equipped with it).

F

L

ift the pre-cut section of carpet to remove

the fixing winch nut from the spare wheel. F

D

etach the assembly of wheel and box from

the rear of the vehicle.

Tool storage

F Put the tools back in the box and store the box in the boot of the vehicle.

F

R

eel in the winch by turning the key in

the clockwise direction: once the cable is

completely reeled in, you should no longer

feel any resistance.

F

S

tore the rest of the tools in the storage

areas in the boot.

The wheel with the punctured tyre cannot

be fitted under the vehicle. It must be

stored in the boot. Use a

cover to protect

the interior of the boot.

F

W

ith the extension 6 placed on the end of

wheelbrace 1 , "tighten" the nut to unwind

the winch cable until the spare wheel is

flat on the ground. Unwind as much as

necessary in order to access the wheel

easily. F

S

traighten the spare wheel to access tool

box ( A).

F

D

etach the connecting piece from the cover

of the tool box ( B – C).

F

P

ass the connecting piece through the

wheel hub to release it ( D). F

P

ress the tab, slide the lid on the box up

to the middle and remove it to access the

other tools ( jack and alloy wheel bolt cover

removal tool).

8

In the event of a breakdown

Page 218 of 316

216

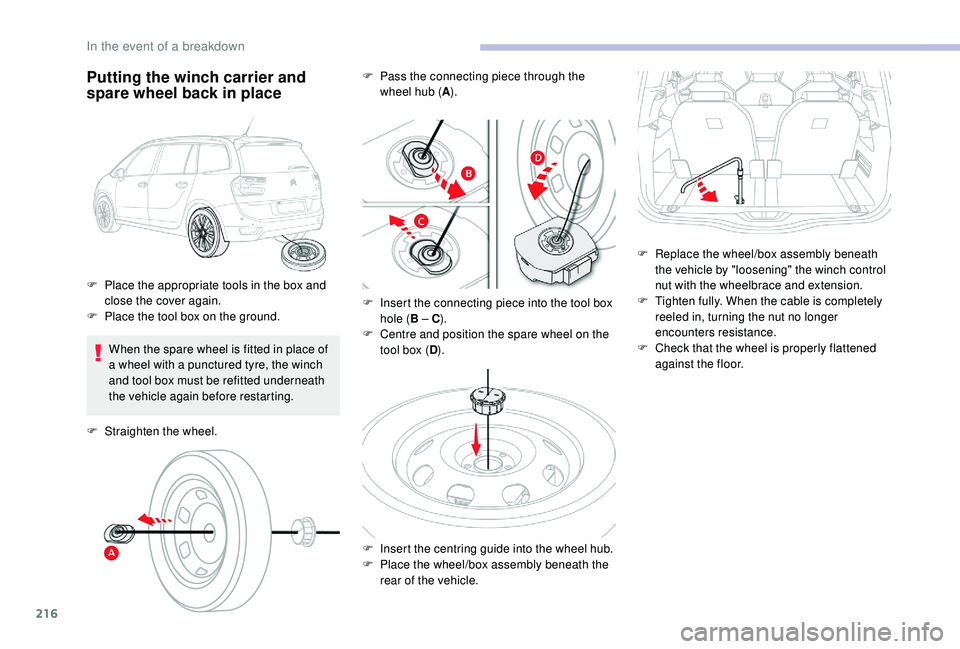

Putting the winch carrier and

spare wheel back in place

When the spare wheel is fitted in place of

a wheel with a punctured tyre, the winch

and tool box must be refitted underneath

the vehicle again before restarting.

F

S

traighten the wheel.

F

P

lace the appropriate tools in the box and

close the cover again.

F

P

lace the tool box on the ground. F

P

ass the connecting piece through the

wheel hub ( A).

F

I

nsert the connecting piece into the tool box

hole ( B – C).

F C entre and position the spare wheel on the

tool box ( D).

F

I

nsert the centring guide into the wheel hub.

F

P

lace the wheel/box assembly beneath the

rear of the vehicle. F

R

eplace the wheel/box assembly beneath

the vehicle by "loosening" the winch control

nut with the wheelbrace and extension.

F

T

ighten fully. When the cable is completely

reeled in, turning the nut no longer

encounters resistance.

F C heck that the wheel is properly flattened

against the floor.

In the event of a breakdown

Page 220 of 316

218

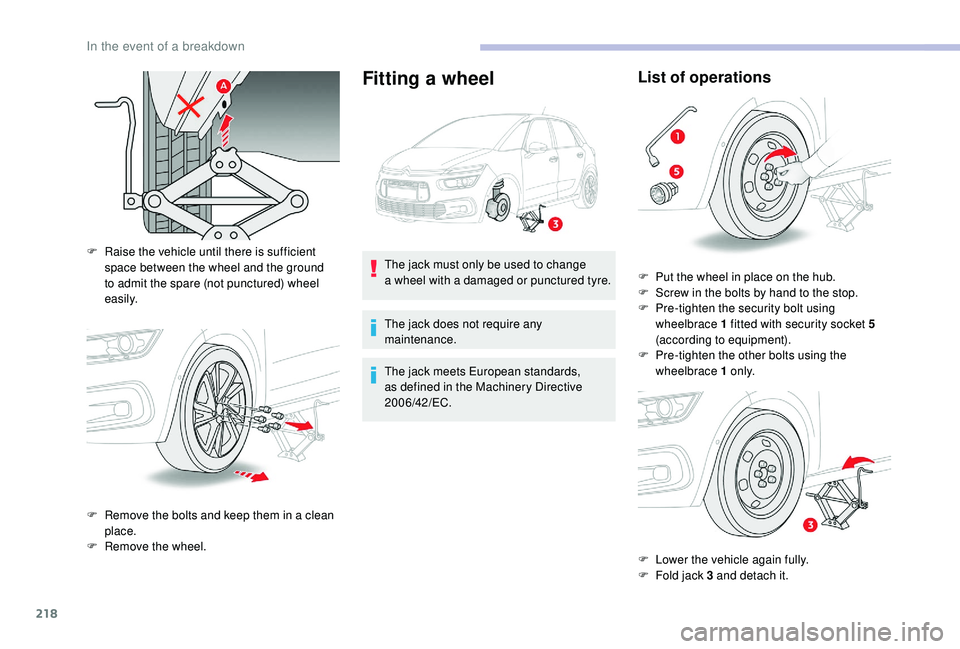

Fitting a wheel

F Raise the vehicle until there is sufficient

space between the wheel and the ground

to admit the spare (not punctured) wheel

easily.

F

R

emove the bolts and keep them in a clean

place.

F

R

emove the wheel. The jack must only be used to change

a

wheel with a damaged or punctured tyre.

The jack does not require any

maintenance.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts by hand to the stop.

F

P

re-tighten the security bolt using

wheelbrace 1

fitted with security socket 5

(according to equipment).

F

P

re-tighten the other bolts using the

wheelbrace 1

o n l y.

F

L

ower the vehicle again fully.

F

F

old jack 3 and detach it.

In the event of a breakdown