ESP Citroen C5 2000 (DC/DE) / 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2000, Model line: C5, Model: Citroen C5 2000 (DC/DE) / 1.GPages: 259, PDF Size: 2.29 MB

Page 83 of 259

![Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

80

CHECKING AND SETTING THE VALVE TIMING

Engines : RHY - RHZ

Tools

[1]Belt tension measuring instrument : 4122-T

[2] Tension lever: (-). Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

80

CHECKING AND SETTING THE VALVE TIMING

Engines : RHY - RHZ

Tools

[1]Belt tension measuring instrument : 4122-T

[2] Tension lever: (-).](/img/9/4134/w960_4134-82.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE

80

CHECKING AND SETTING THE VALVE TIMING

Engines : RHY - RHZ

Tools

[1]Belt tension measuring instrument : 4122-T

[2] Tension lever: (-).188.J2

[3]Engine flywheel peg: (-).188.X

[4]Belt retaining pin: (-).0188.K

[5]Camshaft pinion peg: (-).0188.M

[6]Engine flywheel lock: (-).0188.F

[7]Set of blocking plugs: (-).0188.T

[8] Crankshaft pulley extractor: (-).0188.P

Checking the setting of the valve timing.

Peg :

- The engine flywheel, using tool [3]. (From under the vehicle).

- The camshaft, using tool [5].

WARNING :On removing screws (6), (7), (9), and (5) of the timing cover, refit the

screw(5) equipped with a spacer (thickness :17 mm).

Tighten to 1,5 ± 0,1m.daN.

(The screw (5)is one of the screws fixing and sealing the water pump).

WARNING : Should it be impossible to peg the camshaft, check that the offset

between the camshaft pinion hole and the pegging hole is not more than 1 mm,

with the help of a mirror «a» and a Ø 7 mm screw.

B1BP282CB1BP1YSCB1EP152DB1EP14AC

IMPERATIVE : If pegging is impossible, restart the adjusting.

(See corresponding operation).

Page 88 of 259

![Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

85

TOOLS

[1] Belt tension measuring instrument: 4122-T

[2] Engine flywheel peg: (-).0188.X.

[3]Tension lever: (-).0188.Y.

[4]Belt compre Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

85

TOOLS

[1] Belt tension measuring instrument: 4122-T

[2] Engine flywheel peg: (-).0188.X.

[3]Tension lever: (-).0188.Y.

[4]Belt compre](/img/9/4134/w960_4134-87.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE

85

TOOLS

[1] Belt tension measuring instrument: 4122-T

[2] Engine flywheel peg: (-).0188.X.

[3]Tension lever: (-).0188.Y.

[4]Belt compression spring: (-).0188.K.

[5]Camshaft pinion peg: (-).0188.M.

[6] Engine flywheel lock: (-).0188.F.

[7]Set of blocking plugs: (-).0188.T.

IMPERATIVE : Respect the safety and cleanliness recommendations

specific to high pressure diesel injection (HDi) engines.

Checking the setting of the valve timing.

- Turn the crankshaft(normal direction of rotation)and line up the black

markings on the chain (b) and (c)with the teeth marked (a) and (d)of the

camshaft drive pinions (40 turns max. of the camshaft).

CHECKING AND SETTING THE VALVE TIMING

Engine : 4HX

B1EP159D

Page 89 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

86

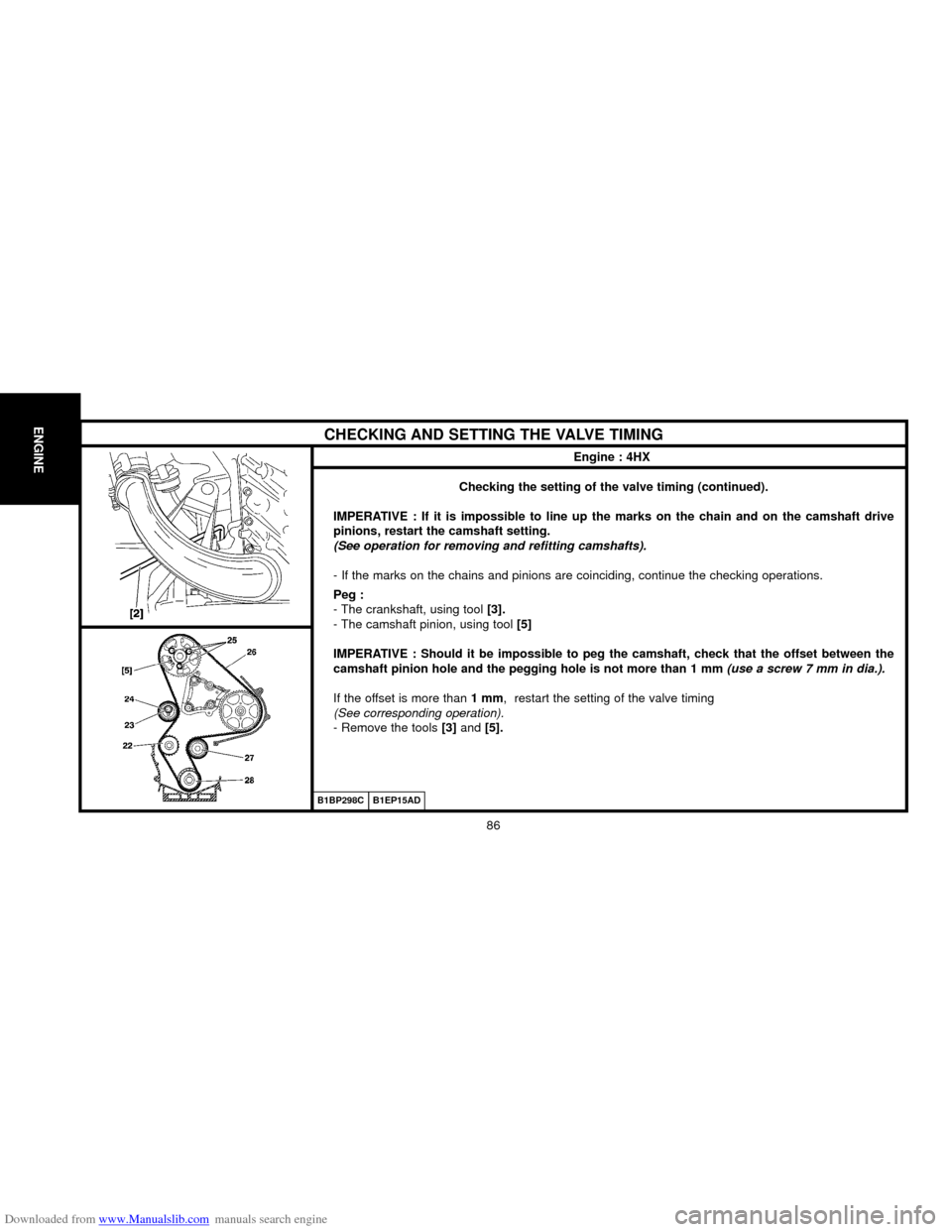

Checking the setting of the valve timing (continued).

IMPERATIVE : If it is impossible to line up the marks on the chain and on the camshaft drive

pinions, restart the camshaft setting.

(See operation for removing and refitting camshafts).

- If the marks on the chains and pinions are coinciding, continue the checking operations.

Peg :

- The crankshaft, using tool [3].

- The camshaft pinion, using tool [5]

IMPERATIVE : Should it be impossible to peg the camshaft, check that the offset between the

camshaft pinion hole and the pegging hole is not more than 1 mm (use a screw 7 mm in dia.).

If the offset is more than 1 mm, restart the setting of the valve timing

(See corresponding operation).

- Remove the tools [3] and [5].

CHECKING AND SETTING THE VALVE TIMING

Engine : 4HX

B1EP15ADB1BP298C

Page 100 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

97

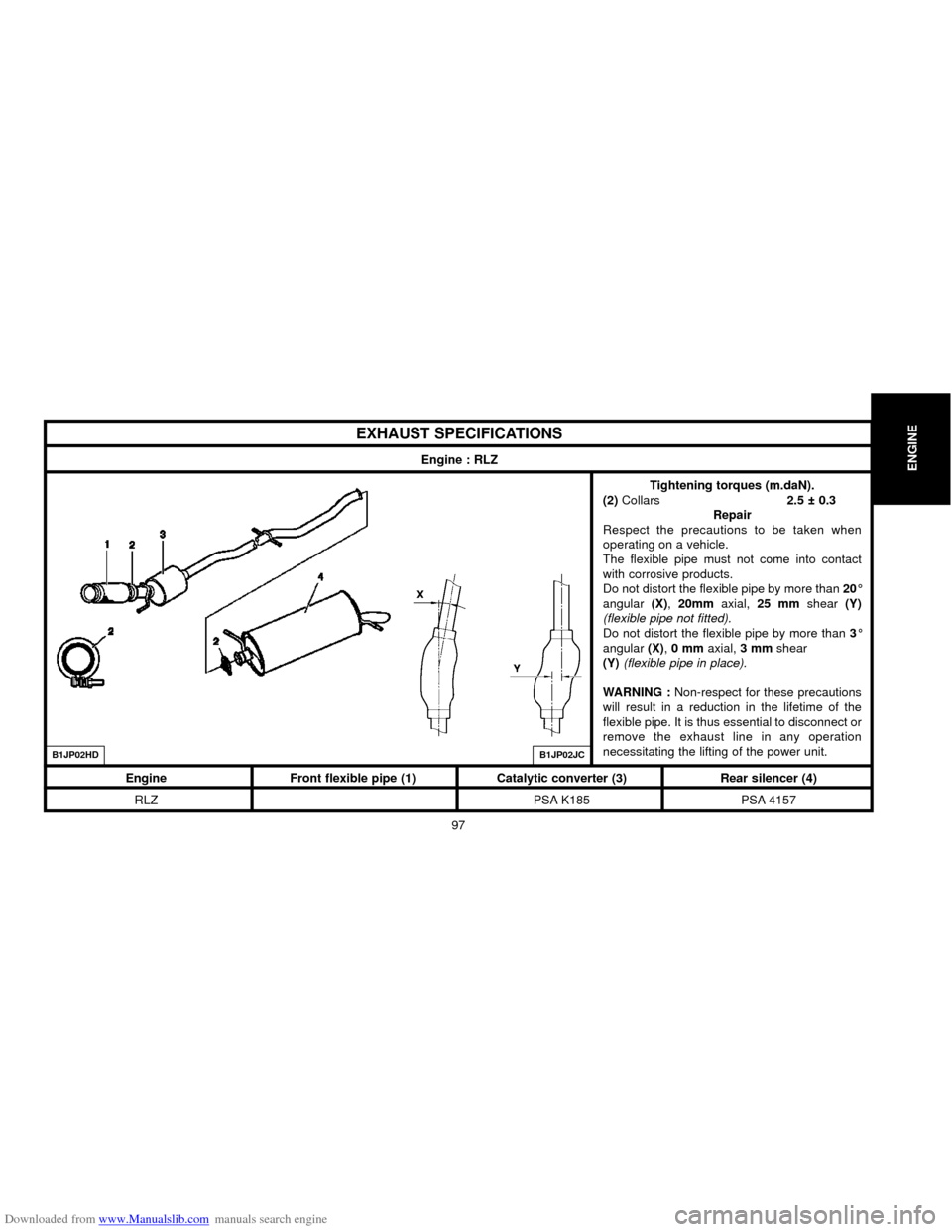

EXHAUST SPECIFICATIONS

Engine : RLZ

Tightening torques (m.daN).

(2) Collars2.5 ± 0.3

Repair

Respect the precautions to be taken when

operating on a vehicle.

The flexible pipe must not come into contact

with corrosive products.

Do not distort the flexible pipe by more than20°

angular (X), 20mmaxial, 25 mmshear(Y)

(flexible pipe not fitted).

Do not distort the flexible pipe by more than3°

angular (X), 0 mmaxial, 3 mmshear

(Y) (flexible pipe in place).

WARNING : Non-respect for these precautions

will result in a reduction in the lifetime of the

flexible pipe. It is thus essential to disconnect or

remove the exhaust line in any operation

necessitating the lifting of the power unit.

Engine Front flexible pipe (1) Catalytic converter (3) Rear silencer (4)

RLZ PSA K185 PSA 4157

B1JP02HDB1JP02JC

Page 101 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

98

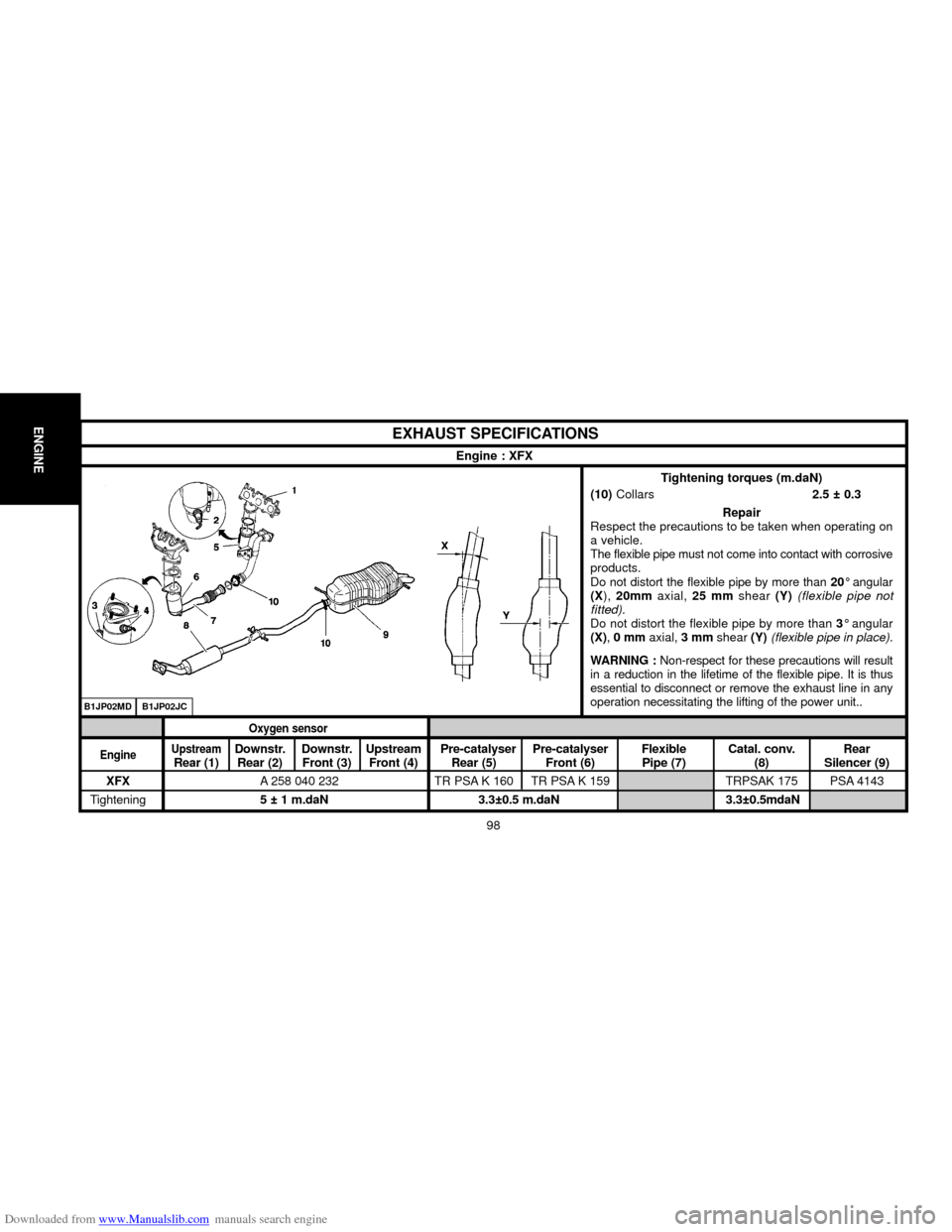

EXHAUST SPECIFICATIONS

Engine : XFX

Tightening torques (m.daN)

(10)Collars 2.5 ± 0.3

Repair

Respect the precautions to be taken when operating on

a vehicle.

The flexible pipe must not come into contact with corrosive

products.

Do not distort the flexible pipe by more than20°angular

(X),20mmaxial, 25 mmshear (Y)(flexible pipe not

fitted).

Do not distort the flexible pipe by more than 3°angular

(X), 0 mmaxial, 3 mmshear(Y)(flexible pipe in place).

WARNING : Non-respect for these precautions will result

in a reduction in the lifetime of the flexible pipe. It is thus

essential to disconnect or remove the exhaust line in any

operation necessitating the lifting of the power unit..

Oxygen sensor

EngineUpstream

Downstr. Downstr. Upstream Pre-catalyser Pre-catalyser Flexible Catal. conv. Rear

Rear (1) Rear (2) Front (3) Front (4) Rear (5) Front (6) Pipe (7) (8) Silencer (9)

XFXA 258 040 232 TR PSA K 160 TR PSA K 159 TRPSAK 175 PSA 4143

Tightening5 ± 1 m.daN 3.3±0.5 m.daN 3.3±0.5mdaN

B1JP02MDB1JP02JC

Page 102 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

99

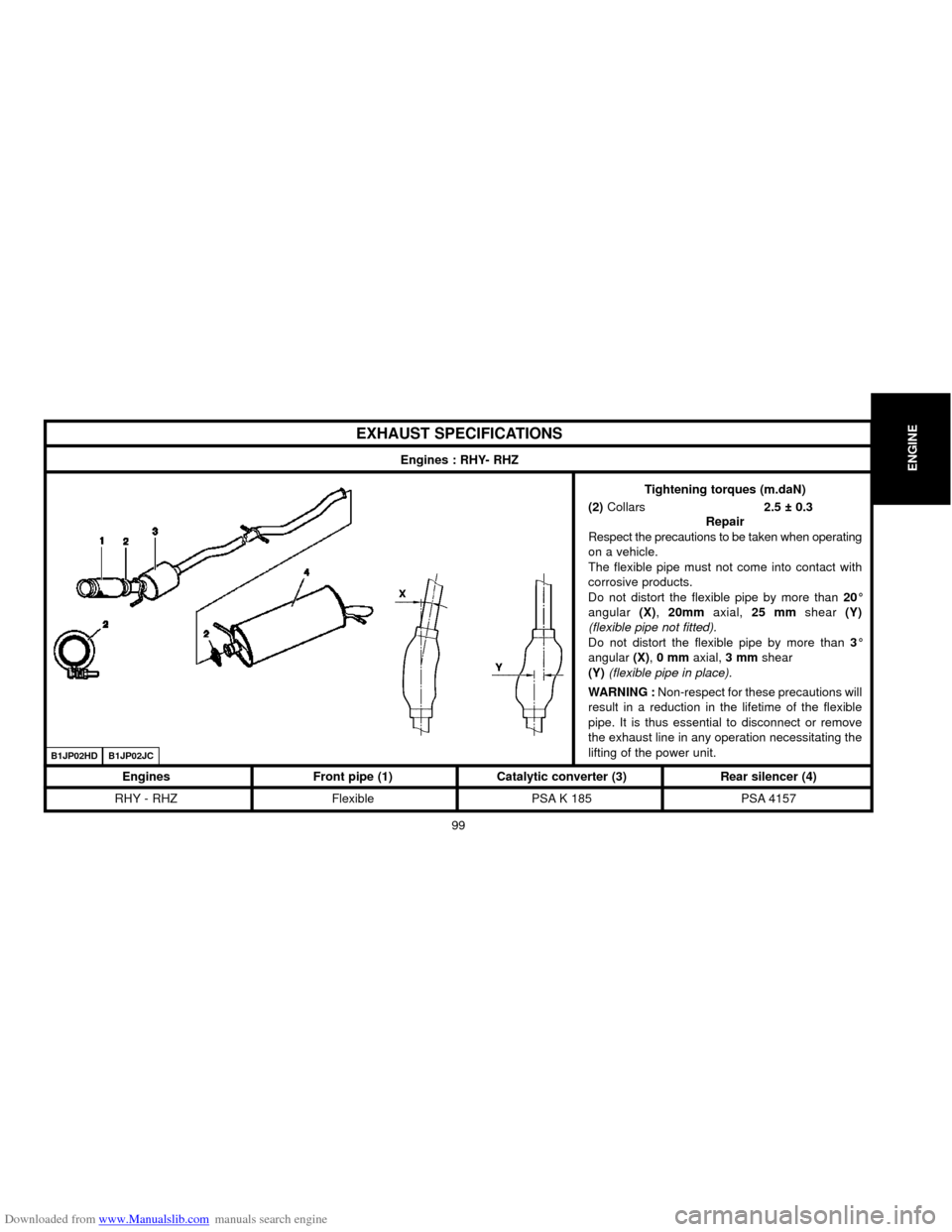

EXHAUST SPECIFICATIONS

Engines : RHY- RHZ

Tightening torques (m.daN)

(2) Collars2.5 ± 0.3

Repair

Respect the precautions to be taken when operating

on a vehicle.

The flexible pipe must not come into contact with

corrosive products.

Do not distort the flexible pipe by more than20°

angular (X), 20mmaxial, 25 mmshear (Y)

(flexible pipe not fitted).

Do not distort the flexible pipe by more than 3°

angular(X), 0 mmaxial, 3 mmshear

(Y)(flexible pipe in place).

WARNING :Non-respect for these precautions will

result in a reduction in the lifetime of the flexible

pipe. It is thus essential to disconnect or remove

the exhaust line in any operation necessitating the

lifting of the power unit.

Engines Front pipe (1) Catalytic converter (3) Rear silencer (4)

RHY - RHZ Flexible PSA K 185 PSA 4157

B1JP02HDB1JP02JC

Page 103 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

100

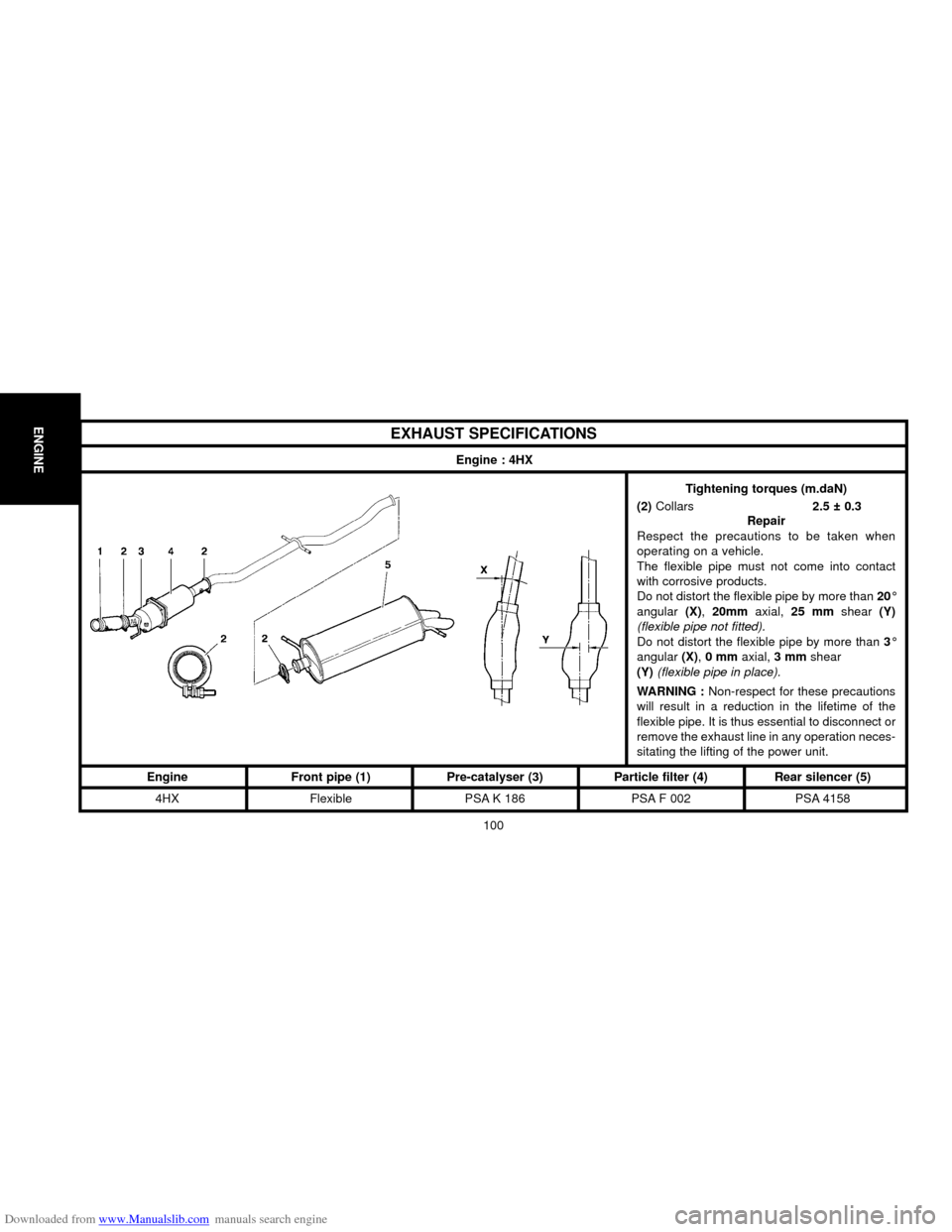

EXHAUST SPECIFICATIONS

Engine : 4HX

Tightening torques (m.daN)

(2) Collars 2.5 ± 0.3

Repair

Respect the precautions to be taken when

operating on a vehicle.

The flexible pipe must not come into contact

with corrosive products.

Do not distort the flexible pipe by more than20°

angular (X), 20mm axial, 25 mmshear (Y)

(flexible pipe not fitted).

Do not distort the flexible pipe by more than 3°

angular (X),0 mmaxial, 3 mmshear

(Y)(flexible pipe in place).

WARNING :Non-respect for these precautions

will result in a reduction in the lifetime of the

flexible pipe. It is thus essential to disconnect or

remove the exhaust line in any operation neces-

sitating the lifting of the power unit.

Engine Front pipe (1) Pre-catalyser (3) Particle filter (4) Rear silencer (5)

4HX Flexible PSA K 186 PSA F 002 PSA 4158

Page 111 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

108

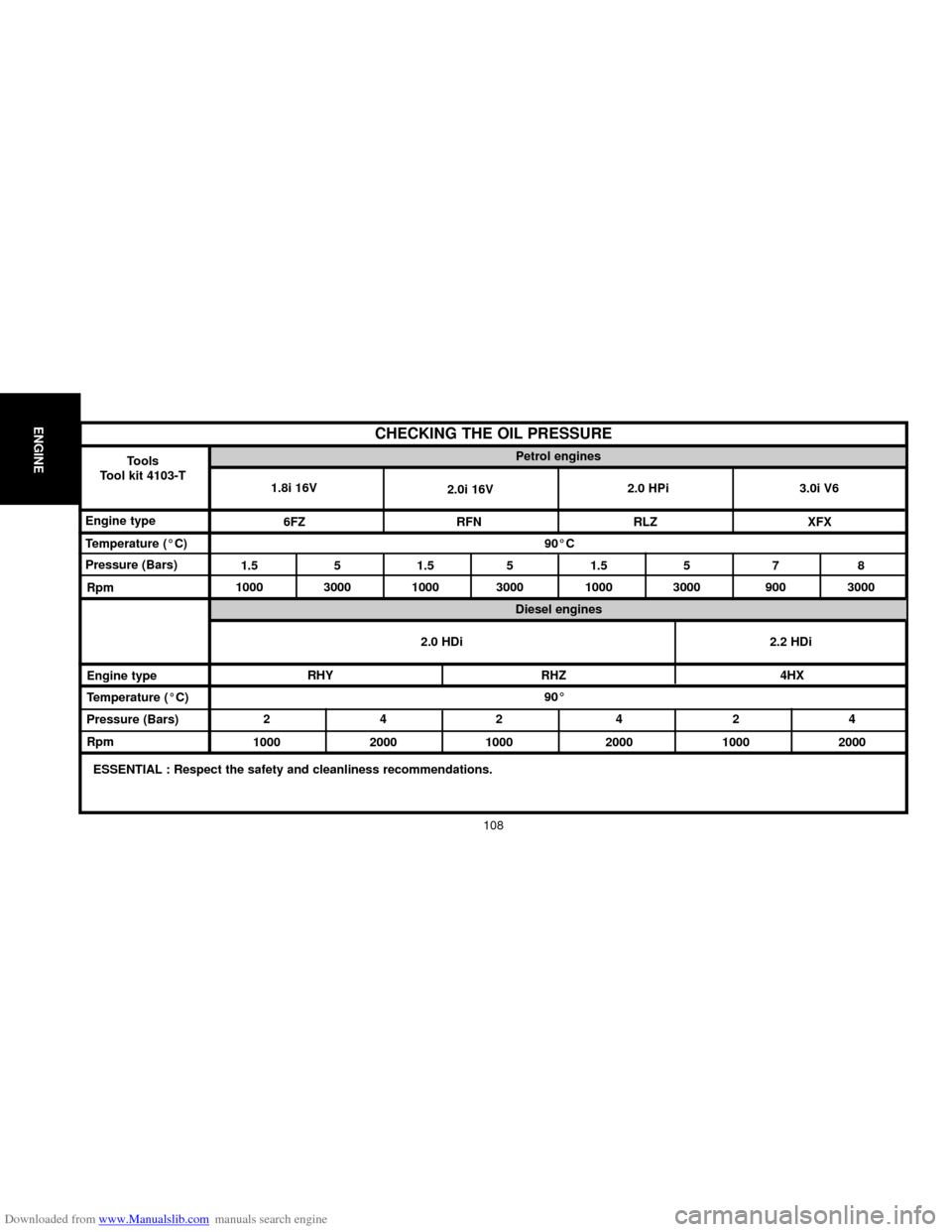

CHECKING THE OIL PRESSURE

Engine type

Temperature (°C)

Pressure (Bars)

Rpm

Engine type

Temperature (°C)

Pressure (Bars)

Rpm6FZ RFN RLZ XFX

90°C

1.5 5 1.5 5 1.5 5 7 8

1000 3000 1000 3000 1000 3000 900 3000

Diesel engines 1.8i 16V

2.0 HDi 2.2 HDi2.0i 16V2.0 HPi3.0i V6 Petrol engines

Tools

Tool kit 4103-T

RHY RHZ 4HX

90°

242 424

1000 2000 1000 2000 1000 2000

ESSENTIAL : Respect the safety and cleanliness recommendations.

Page 112 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

109

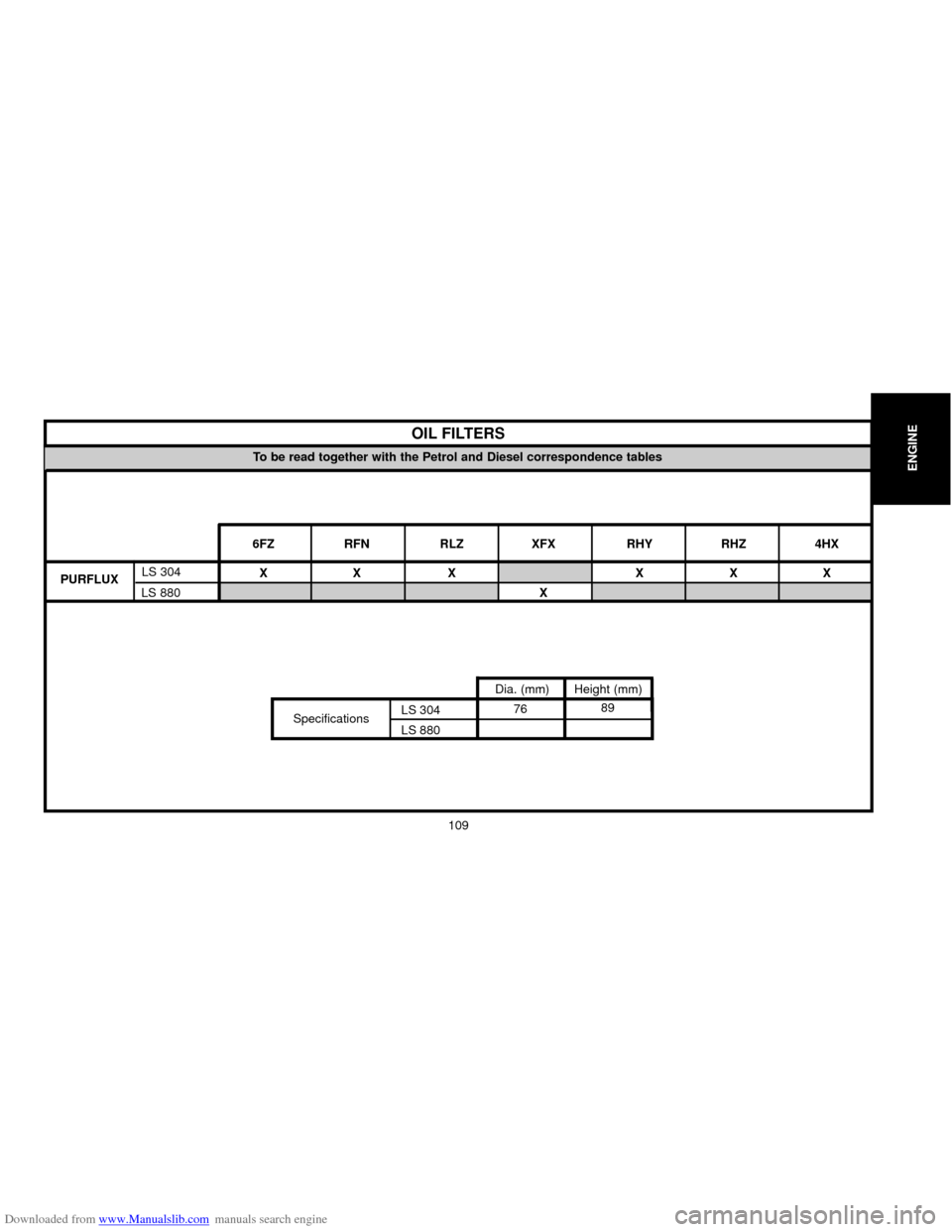

To be read together with the Petrol and Diesel correspondence tables

OIL FILTERS

PURFLUXLS 304

LS 880

SpecificationsDia. (mm)Height (mm)

LS 880 LS 3047689

6FZ RFN RLZ XFX RHY RHZ 4HX

XX X X XX

X

Page 113 of 259

![Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

110

FILLING AND BLEEDING THE COOLING CIRCUIT

TOOLS

[1] Filling cylinder: 4520-T

[2]Adaptor for filling cylinder: 4222-T.

ESSENTIAL : Res Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

110

FILLING AND BLEEDING THE COOLING CIRCUIT

TOOLS

[1] Filling cylinder: 4520-T

[2]Adaptor for filling cylinder: 4222-T.

ESSENTIAL : Res](/img/9/4134/w960_4134-112.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE

110

FILLING AND BLEEDING THE COOLING CIRCUIT

TOOLS

[1] Filling cylinder: 4520-T

[2]Adaptor for filling cylinder: 4222-T.

ESSENTIAL : Respect the safety and cleanliness recommendations.

- The draining and refilling operations can be carried out by means of a WINN’S coolant replacement

apparatus or similar; it is essential to follow the instructions when using this apparatus.

Filling and bleeding

- Fit the cylinder adaptor [2] 4222-Tand the filling cylinder [1] 4520 -T.

- Use the coolant to ensure protection between - 15°Cand - 37°C.

- Slowly fill the system.

NOTE :Keep the cylinder filled up (visible level).

- Close each bleed screw as soon as the coolant flows without air bubbles.

- Start the engine : Engine speed 1500 rpm.

- Maintain this speed until the third cooling cycle (cooling fans have cut in and cut out).

- Stop the engine and allow it to cool down.

- Remove the filling cylinder [1] 4520-T and the adaptor [2] 4222-T.

- Top up the system to the maximum mark, with the engine cold.

- Refit the filler cap.

E5AP1GNCB1GP00AC