CITROEN C6 2005 Owners Manual

Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 171 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 165

AXLES

SUSPENSION

STEERING

Tools.

[1]Pipe spanner: FACOM 18.17

[2]Set of 2 hoseclamps: 4153-T

[3] Pressure checking assembly:

[3a]Pressure g CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 165

AXLES

SUSPENSION

STEERING

Tools.

[1]Pipe spanner: FACOM 18.17

[2]Set of 2 hoseclamps: 4153-T

[3] Pressure checking assembly:

[3a]Pressure g](/img/9/57744/w960_57744-170.png)

Downloaded from www.Manualslib.com manuals search engine 165

AXLES

SUSPENSION

STEERING

Tools.

[1]Pipe spanner: FACOM 18.17

[2]Set of 2 hoseclamps: 4153-T

[3] Pressure checking assembly:

[3a]Pressure gauge: (-).0710.AZ

[3b]Checking tube: Pressure gauge to tap: (-).0710.B1

[3c]Checking tube: High pressure pipe to tap: (-).0710.B2

[3d]Checking tube: High pressure pump to tap: (-).0710.B3

[3e] 3-waytap: (-).0710.C

[4]Union: (-).0710.E1Z

[5]Union: (-).0710.E2Z

[6] Plug for checking sealing of the steering valve: (-).0410.N

Precautions to be taken.

Work with care to avoid entry of polluting particles.

NOTE:Correct operation of the system requires the LDSfluid and the hydraulic components

to be perfectly clean.

Check:

- The level of the LDSfluid (see procedure: drain-fill-bleed the suspension circuit).

- The condition of the piping and unions.

Using the tools.

Prepare the checking assembly [3], [4]and [5].

Remove the bracket (1).

Clamp the pipe at "a", using tool [2].

Uncouple and move aside the piping (2), using tool [1].

E5AP2PNDB1BP3GPD

CHECKING THE STEERING ASSISTANCE PRESSURE (ES9A ENGINE)

Angl-C6-page121-169-2005 4/02/05 17:31 Page 165

Page 172 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 166

AXLES

SUSPENSION

STEERING

Attach the tool [3a].

Do up:

- The union [5]on the pipe (2).

- The union [4]on the steering assistance pump.

Conn CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 166

AXLES

SUSPENSION

STEERING

Attach the tool [3a].

Do up:

- The union [5]on the pipe (2).

- The union [4]on the steering assistance pump.

Conn](/img/9/57744/w960_57744-171.png)

Downloaded from www.Manualslib.com manuals search engine 166

AXLES

SUSPENSION

STEERING

Attach the tool [3a].

Do up:

- The union [5]on the pipe (2).

- The union [4]on the steering assistance pump.

Connect the assembly [3]to the unions [4]and [5].

Tighten all the unions.

Remove the tool [2].

Open the tap [3e].

Start the engine and allow it to run for 5 seconds.

Stop the engine.

Move the steering several times in each direction.

Check that there are no leaks.

Checking the steering assistance pump pressure.

Start the engine.

Close the tap[3e]for 5 seconds.

Open the tap [3e].

Accelerate between 1200and 1500 rpm, the pressure should be: 115 ± 5 bars.

Stop the engine.

If the steering assistance pump pressure is correct, check the sealing of the valve.

B1BP3GQDB1BP3GRD

CHECKING THE STEERING ASSISTANCE PRESSURE (ES9A ENGINE)

Angl-C6-page121-169-2005 4/02/05 17:31 Page 166

Page 173 of 223

Downloaded from www.Manualslib.com manuals search engine 167

AXLES

SUSPENSION

STEERING

Checking the valve sealing.

Remove the exhaust line (3).

Move aside the heat shield from the steering mechanism.

Slacken the union (6)on the power steering ram.

Remove:

- The screw (4).

- The bracket (7).

Uncouple the two supply pipes (5)from the distributor valve, and move them aside.

Fit on the distributor valve the tool [6], tighten the screw to: 0,8 ± 0,1 m.daN.

Couple two pipes at the outlets of the pipes (5).

Move the steering slowly from lock to lock, to drain the ram.

Collect the LDSfluid in a tray.

Refit the exhaust line (3).

Open the tap [3e].

Start the engine.

Hold the engine speed between 1200and 1500 rpm.

Hold the steering at full lock to the right, then at full lock to the left.

The pressure should adjust to: 115 ± 5 bars.

B1JP08WDB3EP185D

CHECKING THE STEERING ASSISTANCE PRESSURE (ES9A ENGINE)

Angl-C6-page121-169-2005 4/02/05 17:31 Page 167

Page 174 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 168

AXLES

SUSPENSION

STEERING

Remove:

- The exhaust line (3).

- The tool [6].

Couple the two supply pipes (5)on the distributor valve.

Refit:

- CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 168

AXLES

SUSPENSION

STEERING

Remove:

- The exhaust line (3).

- The tool [6].

Couple the two supply pipes (5)on the distributor valve.

Refit:

-](/img/9/57744/w960_57744-173.png)

Downloaded from www.Manualslib.com manuals search engine 168

AXLES

SUSPENSION

STEERING

Remove:

- The exhaust line (3).

- The tool [6].

Couple the two supply pipes (5)on the distributor valve.

Refit:

- The bracket (7).

- The screw (4), tighten to 0,8 ± 0,1 m.daN.

Retighten the union (6)on the power steering ram; tighten to 1,4 ± 0,35 m.daN.

Refit the exhaust line (3).

Pinch the pipe at "a", using tool [2].

Remove:

- The assembly [3].

- The union [5]on the pipe (2).

- The union [4]on the steering assistance pump.

Couple the pipe (2), using tool [1].

Tighten the pipe (2)to 2 ± 0,2 m.daN.

Refit the bracket (1).

Bleed the hydraulic steering assistance circuit (see corresponding operation).

Top up the level of the LDS fluid (see procedure: drain-fill-bleed the suspension circuit).

B1JP08WDB3EP185D

CHECKING THE STEERING ASSISTANCE PRESSURE (ES9A ENGINE)

Angl-C6-page121-169-2005 4/02/05 17:31 Page 168

Page 175 of 223

Downloaded from www.Manualslib.com manuals search engine 169

AXLES

SUSPENSION

STEERING

Precautions to be taken.

Proceed with care so as to prevent any entry of polluting particles.

IMPERATIVE: Respect the safety and cleanliness requirements.

IMPERATIVE: Fill the LDS fluid reservoir with new fluid: TOTAL LDS.

Bleeding.

Check the level and top up the LDSfluid (see procedure: drain-fill-bleed the suspension circuit).

Apply a pressure of 0.5 barin the LDSfluid reservoir (using tool FACOM 920).

Start the engine.

Wait for the vehicle height to stabilise.

Move the steering in each direction, from lock to lock.

Stop the engine.

Check the level and top up the LDSfluid (see procedure: drain-fill-bleed the suspension circuit).

BLEEDING THE HYDRAULIC STEERING ASSISTANCE CIRCUIT

Angl-C6-page121-169-2005 4/02/05 17:31 Page 169

Page 176 of 223

Downloaded from www.Manualslib.com manuals search engine 170

BRAKES

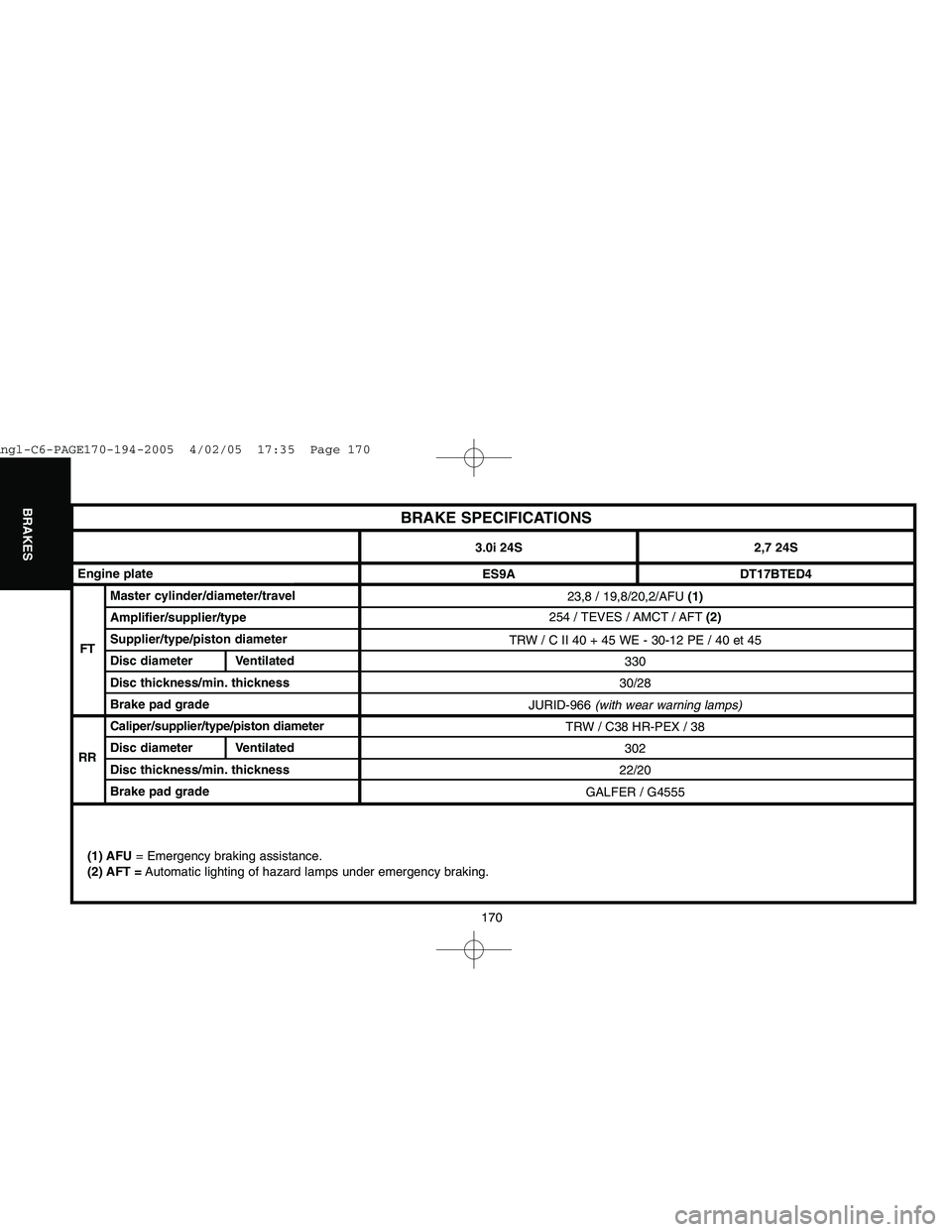

3.0i 24S 2,7 24S

ES9A DT17BTED4

23,8 / 19,8/20,2/AFU (1)

254 / TEVES / AMCT / AFT(2)

TRW / C II 40 + 45 WE - 30-12 PE / 40 et 45

330

30/28

JURID-966 (with wear warning lamps)

TRW / C38 HR-PEX / 38

302

22/20

GALFER / G4555

BRAKE SPECIFICATIONS

Master cylinder/diameter/travel

Amplifier/supplier/type

FTSupplier/type/piston diameter

Disc diameter Ventilated

Disc thickness/min. thickness

Brake pad grade

Caliper/supplier/type/piston diameter

RRDisc diameter Ventilated

Disc thickness/min. thickness

Brake pad grade

Engine plate(1) AFU= Emergency braking assistance.

(2) AFT =Automatic lighting of hazard lamps under emergency braking.

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 170

Page 177 of 223

Downloaded from www.Manualslib.com manuals search engine 171

BRAKES

B3FP7GED

BRAKING SYSTEM: GENERAL SPECIFICATIONS

Braking system

Braking circuit in the form of anX.

Disc brakes at the front and at the rear

(vehicles all types):

- The front brake discs are ventilated.

- The rear brake discs are ventilated.

Electric parking brake (FSE)acting via cables on the

rear wheels.

The compensator and main brake limiter functions are

assured by the ABS REFsystems.

ESPis fitted as standard on the entire range.

NOTE: - REF (EBD) =Electronic Brakeforce

Distribution.

- ESP =Electronic Stability Programme.

Braking circuit

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 171

Page 178 of 223

Downloaded from www.Manualslib.com manuals search engine 172

BRAKES

B3FP7GFC

BRAKING SYSTEM: GENERAL SPECIFICATIONSComponents Supplier Reference Observations

Hydraulic valve blockLocated on the front LH chassis member:

TRWESP 4regulation channels

ECUVSC 440

25-way connector

Integral to the hydraulic valve block

2-way blackconnector

Front wheel sensor The sensors, of inductive type, are fitted on the pivot

SIEMENSAir gap non-adjustable: 0.25 to 1.65 mm

VDO 2-way blackconnector

Rear wheel sensor The sensors, of inductive type, are fitted on the pivot

Air gap non-adjustable: 0.23 to 1.35 mm

Front pivot bearingThe hub has a bearing with integral magnetic wheel

NSK(48 pairs of poles)

Rear hub bearingThe rear hub-bearing has a radial ABS target

(48 pairsof poles)

ABS/ESP hydraulic valve block

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 172

Page 179 of 223

Downloaded from www.Manualslib.com manuals search engine 173

BRAKES

C5FP0T8C

BRAKING SYSTEM: GENERAL SPECIFICATIONS

(1)Electrically-controlled parking brake system(FSE)

(2)Parking brake cables

(3)Cable for manual unlocking of the electric parking brake (FSE).

WARNING: It is forbidden to open the electric parking brake system in After Sales. If a

malfunctioning of the electric parking brake is diagnosed, it is necessary to replace it.

Changing of the parking brake cables does not necessitate opening of the electric parking

brake system (see corresponding operation).

(4)Handle for manual unlocking of the electric parking brake (FSE)

(5)Switch for the electric parking brake (FSE)

If it is impossible to release the electric parking brake, a handle (4)located in the front central

armrest will mechanically unlock the electric parking brake.

Parking brake

B3FP7GDD

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 173

Page 180 of 223

Downloaded from www.Manualslib.com manuals search engine 174

BRAKES

TIGHTENING TORQUES: BRAKING SYSTEM

Front brakes

1 Front brake disc 1 ± 0,12 Yoke on brake caliper 3 ± 0,23 Unions on brake piping 4 ± 0,54 Front brake caliper 11,5 ± 1

5 Hydraulic valve block on intermediate support

0,8 ± 0,26 Intermediate support on support7 Front wheel sensor 0,8 ± 0,1

B3FP7HNDB3FP7HMD

B3FP7HPD

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 174