lock CITROEN C6 2005 Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 93 of 223

Downloaded from www.Manualslib.com manuals search engine 87

INJECTION

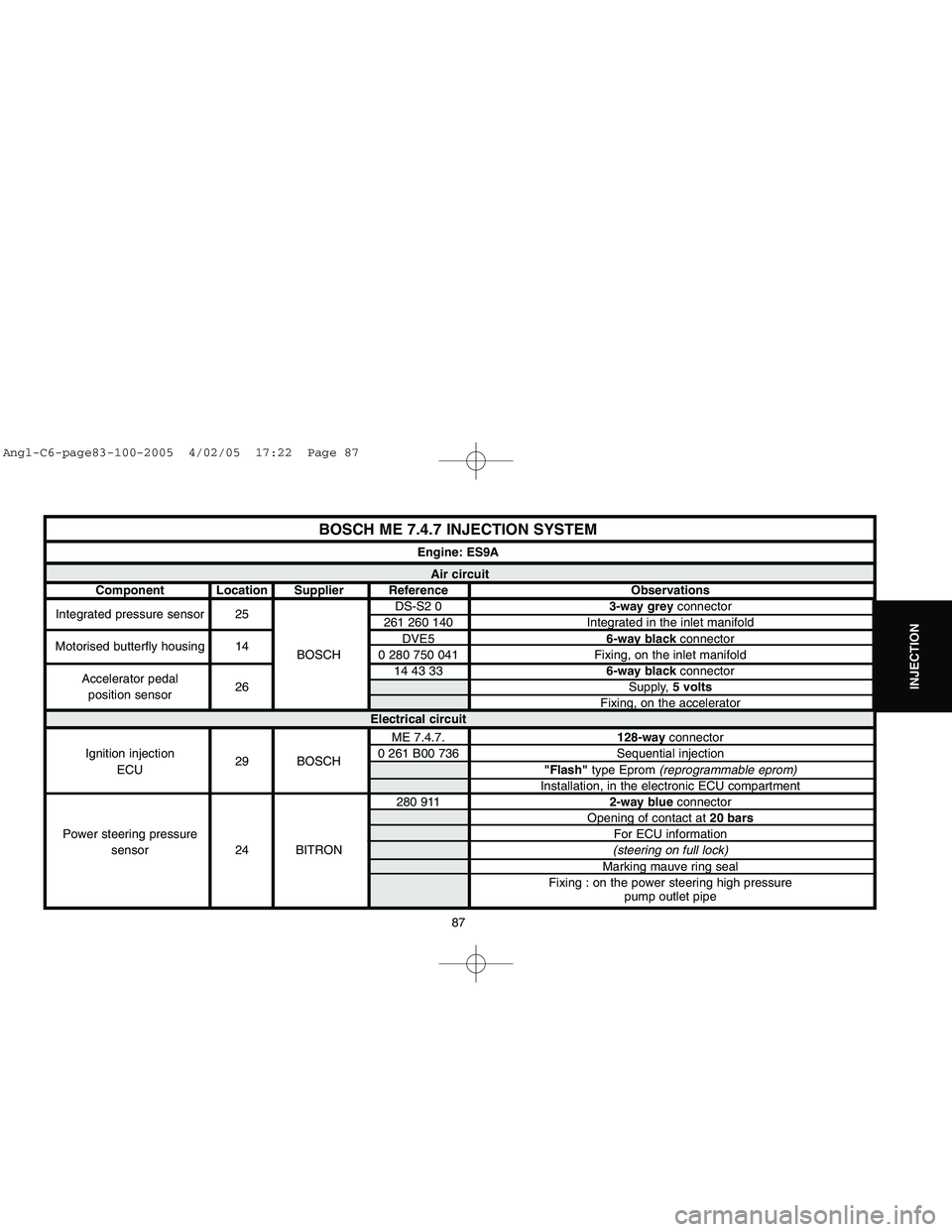

BOSCH ME 7.4.7 INJECTION SYSTEM

Engine: ES9AAir circuit

Component Location Supplier Reference Observations

Integrated pressure sensor 25DS-S2 03-way greyconnector

261 260 140 Integrated in the inlet manifold

Motorised butterfly housing 14DVE56-way blackconnector

BOSCH 0 280 750 041 Fixing, on the inlet manifold

Accelerator pedal 14 43 336-way blackconnector

position sensor26 Supply, 5 volts

Fixing, on the accelerator

Electrical circuit

ME 7.4.7.128-wayconnector

Ignition injection

29 BOSCH0 261 B00 736 Sequential injection

ECU"Flash"type Eprom (reprogrammable eprom)

Installation, in the electronic ECU compartment

280 9112-way blueconnector

Opening of contact at 20 bars

Power steering pressureFor ECU information

sensor 24 BITRON(steering on full lock)

Marking mauve ring seal

Fixing : on the power steering high pressure

pump outlet pipe

Angl-C6-page83-100-2005 4/02/05 17:22 Page 87

Page 94 of 223

Downloaded from www.Manualslib.com manuals search engine 88

INJECTION

BOSCH ME 7.4.7 INJECTION SYSTEM

Engine: ES9AElectrical circuit

Component Location Supplier Reference Observations

Inlet air temperature sensor 27 JAEGER 402 084 012-way greyconnector

Fixing: on the air filter inlet duct

Camshaft position

13 ELECTRICFIL14 43 2514 43 3-way grey connector

sensor25

Fixing: on the inlet camshaft bearing cap cover

3-way green connector

Knock sensor 23 BOSCH 0 261 231 10 Fixing: on the central part of the «V»of the engine block

Essential to respect tightening torque: 2 ± 0,5 m.daN

DAV 402 243 032-way greenconnector

Engine coolant temperature 22Fixing: on the coolant outlet housing

sensor

14 43 32Tightening torque:

ELECTRICFILTighten to: 2 ± 0,2 m.daN

Engine speed sensor 12 14 43 282-way blackconnector

Fixing: on the gearbox clutch housing

Angl-C6-page83-100-2005 4/02/05 17:22 Page 88

Page 98 of 223

Downloaded from www.Manualslib.com manuals search engine 92

INJECTION

SAFETY REQUIREMENTS: HDi DIRECT INJECTION SYSTEM

Safety requirements.

Preamble.

All interventions on the injection system must be carried out to conform

with the following requirements and regulations:

- Competent health authorities.

- Accident prevention.

- Environmental protection.

WARNING: Repairs must be carried out by specialised personnel

informed of the safety requirements and of the precautions to be

taken.

Safety requirements.

IMPERATIVE: Take into account the very high pressures in the high

pressure fuel circuit (1600 bars), and respect the requirements

below:

- No smoking in proximity to the high pressure circuit when work is being

carried out.

- Avoid working close to flame or sparks.

Engine running:

- Do not work on the high pressure fuel circuit.

- Always stay clear of the trajectory of any possible jet of fuel, which could

cause serious injuries.

- Do not place your hand close to any leak in the high pressure fuel circuit.After the engine has stopped, wait 30 secondsbefore any intervention.

NOTE:This waiting time is necessary in order to allow the high pressure

fuel circuit to return to atmospheric pressure.

Cleanliness requirements.

Preliminary operations.

IMPERATIVE: The technician should wear clean overall.

Before working on the injection system, it may be necessary to

clean the apertures of the following sensitive componen (refer to

corresponding procedures):

- Fuel filter.

- Fuel high pressure pump.

- Fuel high pressure common injection rail.

- Fuel high pressure pipes

- Diesel injector carriers.

IMPERATIVE: After dismantling, immediately block the apertures of

sensitive components with plugs, to avoid the entry of impurities.

Work area:

- The work area must be clean and free of clutter.

- Components being worked on must be protected from dust.

Angl-C6-page83-100-2005 4/02/05 17:22 Page 92

Page 110 of 223

Downloaded from www.Manualslib.com manuals search engine 104

CLUTCH

GEARBOX

TRANSMISSION

PRECAUTIONS TO BE TAKEN : AM6 AUTOMATIC GEARBOX

Towing.

The front of the vehicle must be raised in order to be towed.

If the front of the vehicle cannot be raised.

IMPERATIVE:

- Put gear lever in position «N».

- Do not add any oil.

- Do not exceed 70 km/h (45 mph)over a distance of 100 km (60 miles)

maximum.

Driving.

Never drive with the ignition switched off.

NOTE:The automatic gearbox is only lubricated when the engine is

running.

Repairs on electrical components.

Do not disconnect:

- The battery when the engine is running.

- The ECU when the ignition is switched on.

Before reconnecting a switch, check:

- The condition of the various contacts (for deformation, corrosion etc.)

- The presence and condition of the mechanical locking.When performing electrical checks:

- The battery should be correctly charged.

- Never use a voltage source higher than 16V.

- Never use a test lamp.

Repairs on mechanical components.

Never place the gearbox on the ground without protection.

Do not use the unions on the gearbox as handles for moving the

gearbox.

It is imperative

that the converter retaining peg should be in place

when removing the gearbox.

It is imperativeto use the centring pegs to couple the gearbox on the

engine.

Remove the converter retaining peg before coupling the gearbox on

the engine.

Engines: ES9A - DT17BTED4Precautions to be taken

Angl-C6-page101-120-2005 4/02/05 17:25 Page 104

Page 112 of 223

Downloaded from www.Manualslib.com manuals search engine 106

CLUTCH

GEARBOX

TRANSMISSION

Engines: ES9A - DT17BTED4

1 Automatic gearbox heat exchanger 4,2 ± 0,42 Hydraulic valve block casing 1,5 ± 0,23 Filler plug 4 ± 0,4

Torque converter screw [(ES9 3 screw) (DT17 6 screw)]

4Pre-tightening2 ± 0,2

Slackening100°

Tightening6 ± 0,6

5 Sleeve stop 3,5 ± 0,36 Gearbox support 5,5 ± 0,57 Engine speed sensor (ES9J4) 0,8 ± 0,18 Fixing of gearbox on cylinder block 6 ± 0,69 Closing panel fixing 2 ± 0,2

B2CP42XD

AM6 GEARBOX: TIGHTENING TORQUES

B2CP42WD

Angl-C6-page101-120-2005 4/02/05 17:25 Page 106

Page 113 of 223

Downloaded from www.Manualslib.com manuals search engine 107

CLUTCH

GEARBOX

TRANSMISSION

Engines: ES9A - DT17BTED4

12 Oil induction cover 1 ± 0,111 Hydraulic valve block (in the order indicated) 1 ± 0,112 Oil temperature sensor tightening plate 1 ± 0,113 ECU screws 2,5 ± 0,214 Oil drain and overflow plug 1 ± 0,115 Oil level plug 4,8 ± 0,5

B2CP42ZD

AM6 GEARBOX: TIGHTENING TORQUES

B2CP42YD

Angl-C6-page101-120-2005 4/02/05 17:25 Page 107

Page 114 of 223

Downloaded from www.Manualslib.com manuals search engine 108

CLUTCH

GEARBOX

TRANSMISSION

AM6 GEARBOX CONTROLSThe gear selector is guided by the shape of the stepped gate and by a retaining spring which

pulls it to the left hand side.

The gear control has 5 positions:

- Position "P": parking (locking and immobilisation of the vehicle).

- Position "R": reverse gear.

- Position "N": neutral.

- Position "D": drive (for use of the 6 gearsin autoadaptive automatic operation).

- Position "M": manual (this position allows the driver to select his gears in one-touch mode by

pulling "M -"or pushing "M +"on the gear selector).

NOTE:Only positions "P"or "N"authorise starting of the engine.

In position "M", the selection is enabled by an electronic sensor located close to the gear

selector:

- The variation of flux necessary to affect the sensor cells is obtained by a magnet on the lever

opposite the cells, provoking the changes of status.

- The information on this is transmitted to the gearbox ECU.

B2CP430D

Engines: ES9A - DT17BTED4

Angl-C6-page101-120-2005 4/02/05 17:25 Page 108

Page 115 of 223

Downloaded from www.Manualslib.com manuals search engine 109

CLUTCH

GEARBOX

TRANSMISSION

AM6 GEARBOX CONTROLSNOTE:The vehicle is equipped with «shift lock». It is necessary to switch on the ignition and

press the brake pedal to release the selection lever from position "P".

The switch "a"positioned on the gear control panel allows the driver to choose one of the

following 3 driving programmes:

- Normal programme:The normal programme operates in the absence of any other selection

being made (auto-adaptive mode ; eco law).

- Sport programme:The sport programme permits a more dynamic driving style, with greater

performances and acceleration.

- Snow programme:The snow programme facilitates moving off and traction on ground that

has limited adhesion.

To revert to the normalprogramme, you have to press a second timeon the sportor snow

switch.

B2CP430D

Engines: ES9A - DT17BTED4

Angl-C6-page101-120-2005 4/02/05 17:25 Page 109

Page 116 of 223

Downloaded from www.Manualslib.com manuals search engine 110

CLUTCH

GEARBOX

TRANSMISSION

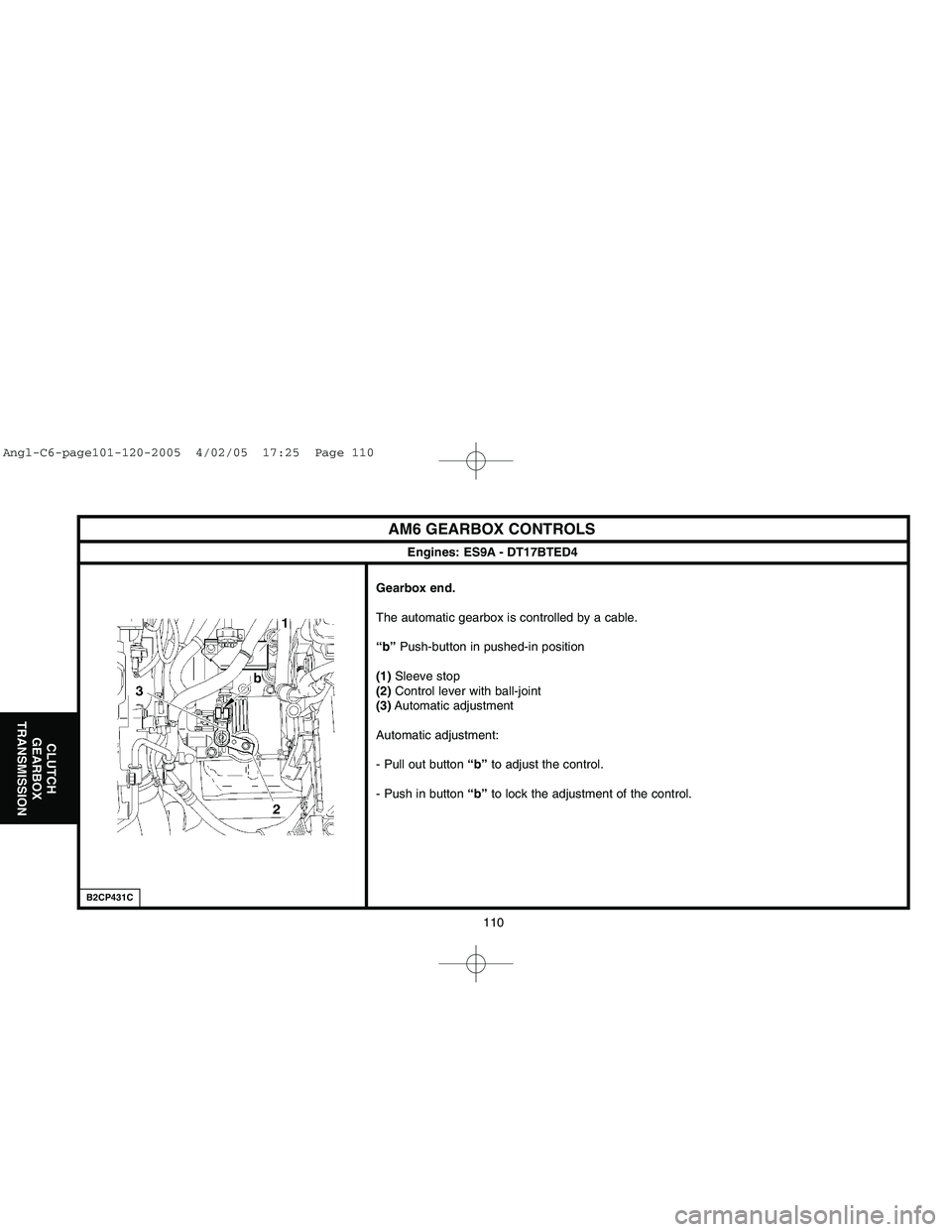

AM6 GEARBOX CONTROLSGearbox end.

The automatic gearbox is controlled by a cable.

“b”Push-button in pushed-in position

(1)Sleeve stop

(2) Control lever with ball-joint

(3)Automatic adjustment

Automatic adjustment:

- Pull out button “b”to adjust the control.

- Push in button “b”to lock the adjustment of the control.

B2CP431C

Engines: ES9A - DT17BTED4

Angl-C6-page101-120-2005 4/02/05 17:25 Page 110

Page 117 of 223

Downloaded from www.Manualslib.com manuals search engine 111

CLUTCH

GEARBOX

TRANSMISSION

AM6 GEARBOX CONTROLS: «SHIFT LOCK» FUNCTIONIMPERATIVE: Respect the safety and cleanliness requirements, with reference to the brochure:

«Recommendations-Precautions».

The «shift lock»is a system that locks the gear selection lever in position «P».

Unlocking the «SHIFT LOCK»(normal operation).

Switch on the ignition.

Press the brake pedal and keep it pressed.

Move the gear selection lever out of position «P».

Unlocking the «SHIFT LOCK» (with an operating fault).

Should it be impossible to unlock the «shift lock»with the «Normal operation»method.

The fault may originate from one of the following components:

- «Shift lock».

- Gear lever position switch.

- Automatic gearbox ECU.

- Electrical harness.

- Battery voltage.

Operations to be performed.

Unclip the cover (1).

Unlock the «shift lock»by pressing at "a"with the aid of a screwdriver (screwdriver with a minimum length of

150 mm).

Move the gear selection lever out of position "P".

C5FP0RCD

Engines: ES9A - DT17BTED4

C5FP0RBC

Angl-C6-page101-120-2005 4/02/05 17:25 Page 111