wheel CITROEN C6 2005 Owners Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 6 of 223

Downloaded from www.Manualslib.com manuals search engine AXLES - SUSPENSION - STEERING

Wheels and tyres121 - 124

Checking and adjusting the vehicle height125 - 128

Values for checking and adjusting

the axle geometries129 - 133

Front axle134 - 135

Front axle tightening torques136 - 139

Rear axle140 - 141

Rear axle tightening torques142 - 143

Active suspension with variable damping144 - 149

Suspension tightening torques150 - 154

Draining-filling-bleeding

the hydraulic steering/suspension circuit155 - 158

Power steering specifications159 - 162

Power steering tightening torques163 - 164

Checking the steering assistance

pressure (ES9A engine)165 - 168

Bleeding the hydraulic steering

assistance circuit169AIR CONDITIONING

Quantities: aircon system R134.a 203

Special features: air conditioning circuit 204 - 205

Pollen filter206

Checking the compressor oil level207 - 208

Checking the efficiency of

the air conditioning circuit209 - 215

Air conditioning circuit: ES9A216

Air conditioning circuit: DT17217

CONTENTS

BRAKES

Brake specifications170

Braking system: general specifications171 - 173

Braking system: tightening torques174 - 177

Values for checking and adjusting

the braking system178

General feataures of

the electric parking brake179 - 189

Brake fluid checks190

Drain-fill-bleed the braking system191 - 194

HYDRAULICS

Safety requirements:

active suspension with variable damping195 - 197

Suspension spheres: general specifications 198

Suspension spheres:

specification - identification199 - 200

Depressurising the hydraulic

suspension circuit201 - 202

Angl-C6-Index-2005 4/02/05 17:10 Page IV

Page 12 of 223

Downloaded from www.Manualslib.com manuals search engine 6

GENERAL

GENERAL SPECIFICATION: DIMENSIONS

ODM =Vehicle in running order (vehicle empty, levels topped up).

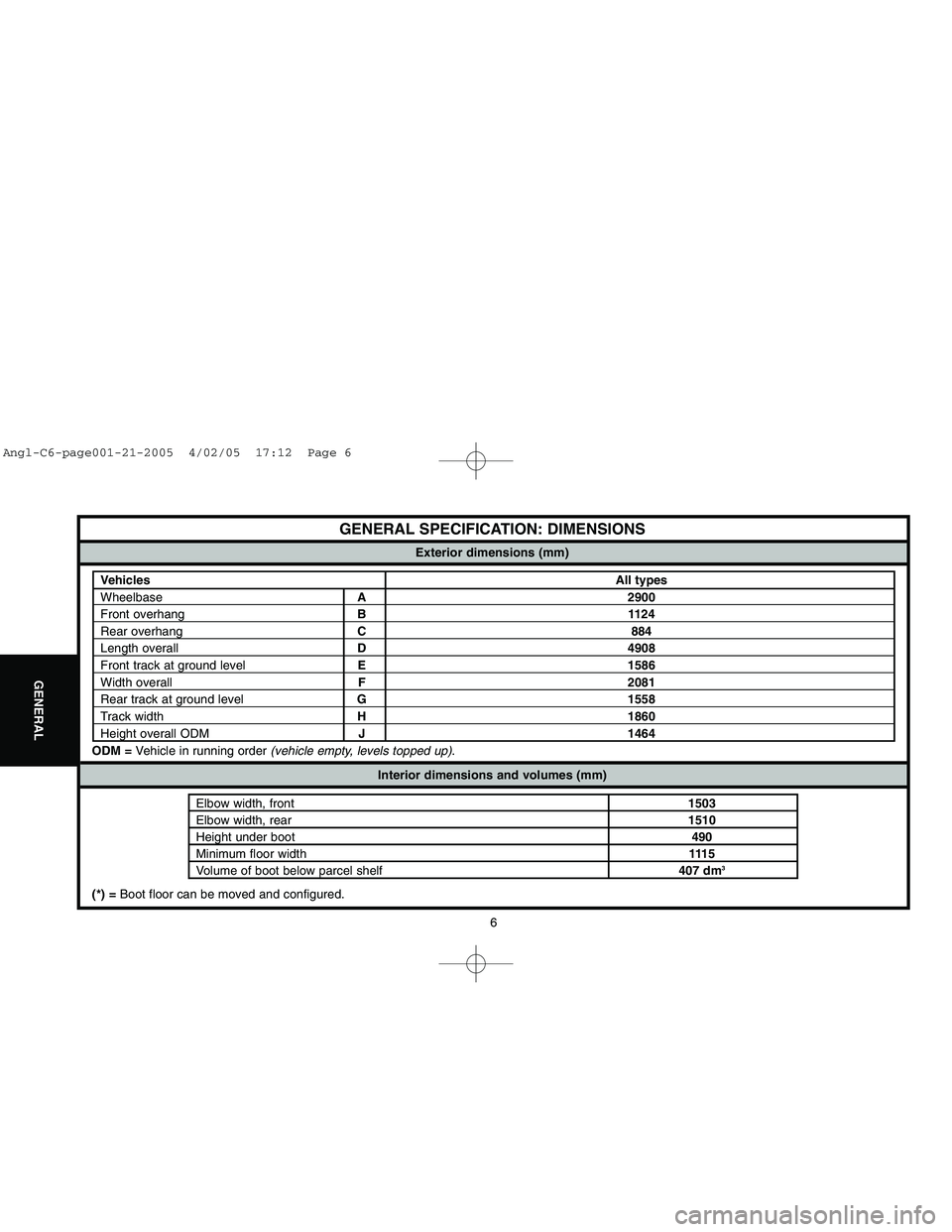

Exterior dimensions (mm)

VehiclesAll types

WheelbaseA 2900Front overhangB 1124Rear overhangC 884Length overallD 4908Front track at ground levelE 1586Width overallF 2081Rear track at ground levelG 1558Track widthH 1860

Height overall ODMJ 1464

Interior dimensions and volumes (mm)

Elbow width, front1503Elbow width, rear1510Height under boot490Minimum floor width111 5

Volume of boot below parcel shelf407 dm

3

(*) = Boot floor can be moved and configured.

Angl-C6-page001-21-2005 4/02/05 17:12 Page 6

Page 15 of 223

Downloaded from www.Manualslib.com manuals search engine 9

GENERAL

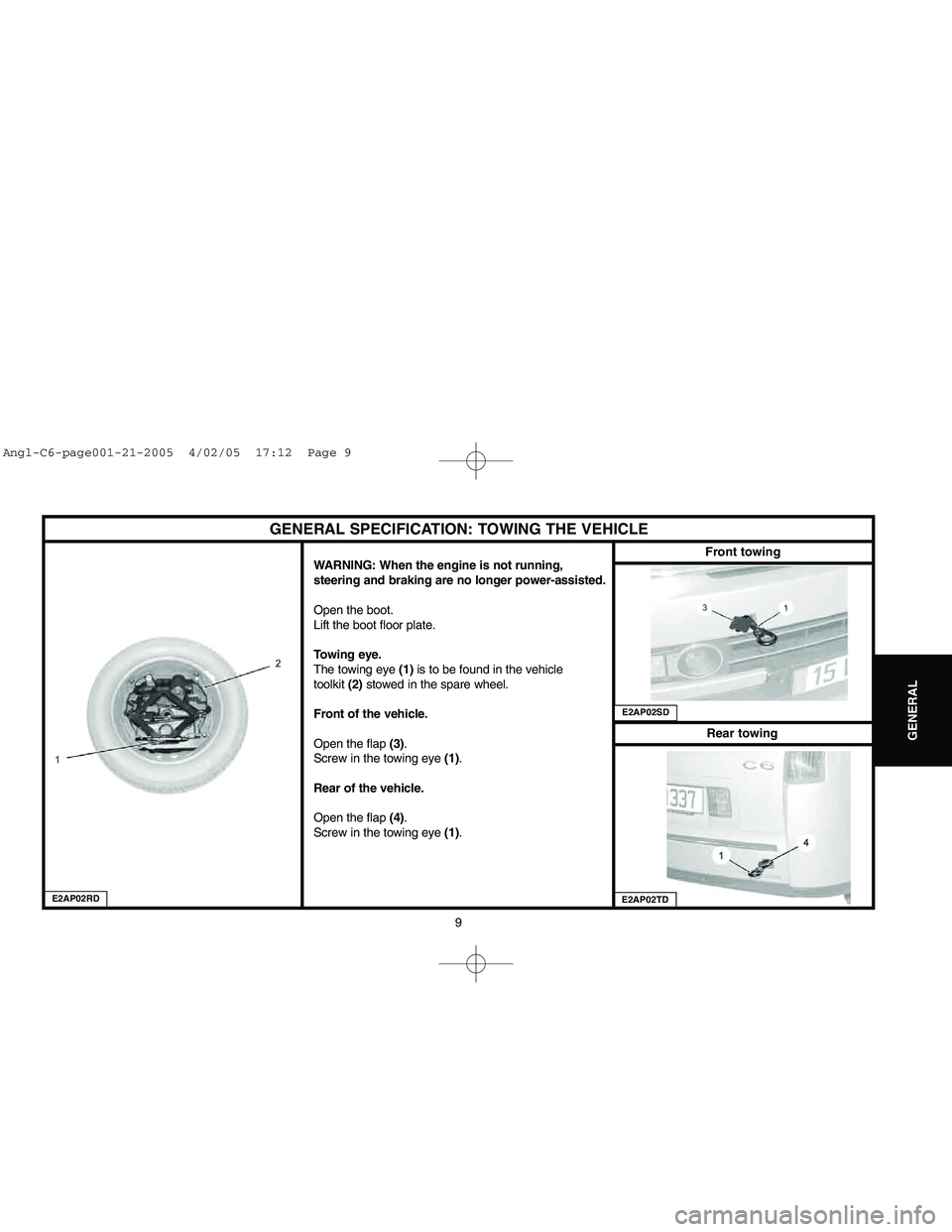

GENERAL SPECIFICATION: TOWING THE VEHICLE

WARNING: When the engine is not running,

steering and braking are no longer power-assisted.

Open the boot.

Lift the boot floor plate.

Towing eye.

The towing eye (1)is to be found in the vehicle

toolkit (2)stowed in the spare wheel.

Front of the vehicle.

Open the flap (3).

Screw in the towing eye (1).

Rear of the vehicle.

Open the flap (4).

Screw in the towing eye (1).

E2AP02RD

Front towingRear towing

E2AP02SDE2AP02TD

Angl-C6-page001-21-2005 4/02/05 17:12 Page 9

Page 16 of 223

Downloaded from www.Manualslib.com manuals search engine 10

GENERAL

GENERAL SPECIFICATION: TOWING THE VEHICLE

Vehicle with automatic gearbox.

IMPERATIVE: Never tow the vehicle with the wheels hanging (towing by the wheels).

Towing:

- It is necessary to raise the front of the vehicle, in order to tow it.

- If it is not possible to raise the front of the vehicle.

- It is essential to place the selection lever in position "N".

- Do not add any oil.

- Do not exceed a speed of 70 km/h(45 mph)on a journey of 100 Km (60 miles).

- Never tow the vehicle backwards.

- Check that the parking brake is released.

Driving:

- Never drive with the ignition switched off.

NOTE: The automatic gearbox is only lubricated when the engine is running.

Never push the vehicle to attempt to start it (impossible with an automatic gearbox).

Angl-C6-page001-21-2005 4/02/05 17:12 Page 10

Page 18 of 223

Downloaded from www.Manualslib.com manuals search engine 12

GENERAL

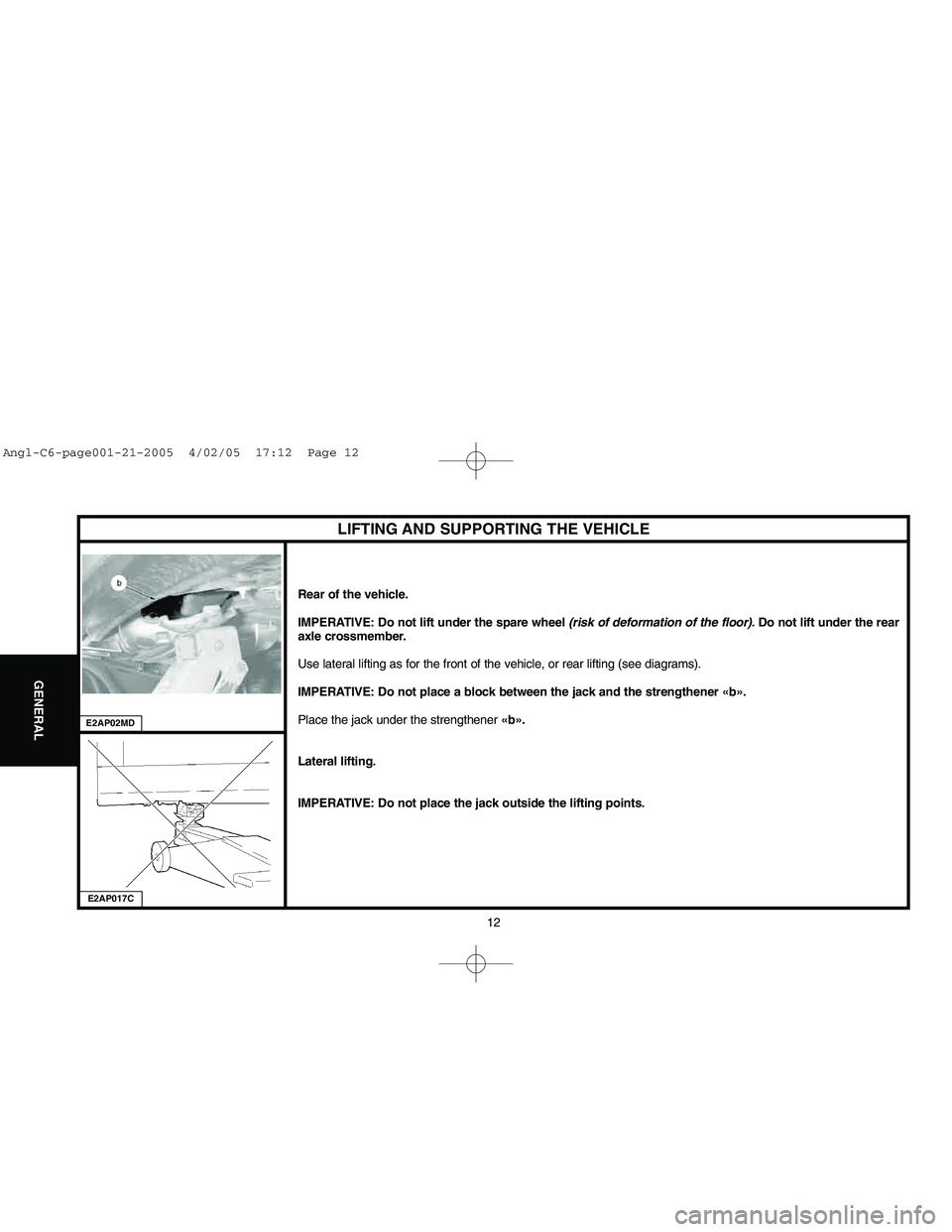

LIFTING AND SUPPORTING THE VEHICLE

Rear of the vehicle.

IMPERATIVE: Do not lift under the spare wheel (risk of deformation of the floor). Do not lift under the rear

axle crossmember.

Use lateral lifting as for the front of the vehicle, or rear lifting (see diagrams).

IMPERATIVE: Do not place a block between the jack and the strengthener «b».

Place the jack under the strengthener «b».

Lateral lifting.

IMPERATIVE: Do not place the jack outside the lifting points.

E2AP017CE2AP02MD

Angl-C6-page001-21-2005 4/02/05 17:12 Page 12

Page 19 of 223

Downloaded from www.Manualslib.com manuals search engine 13

GENERAL

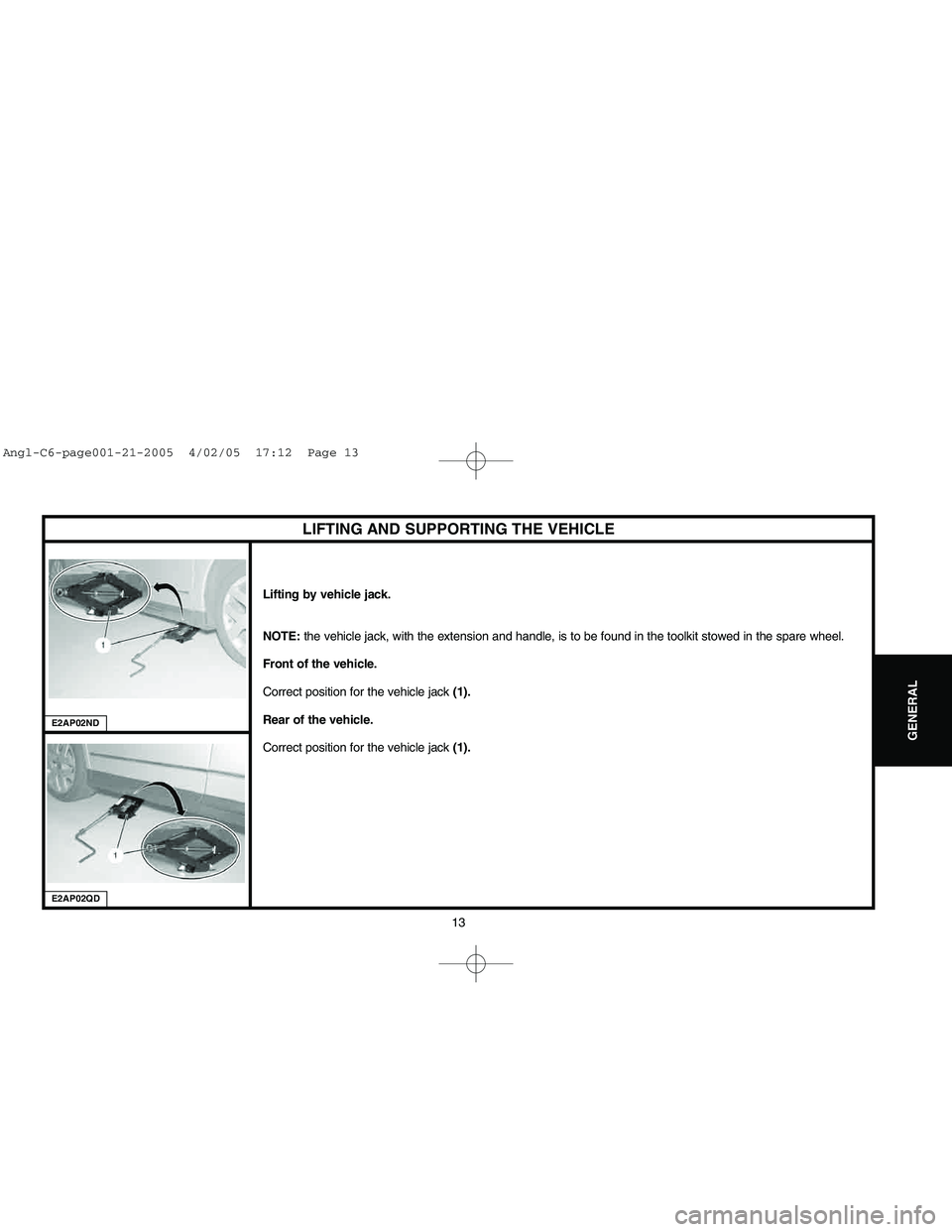

LIFTING AND SUPPORTING THE VEHICLE

Lifting by vehicle jack.

NOTE: the vehicle jack, with the extension and handle, is to be found in the toolkit stowed in the spare wheel.

Front of the vehicle.

Correct position for the vehicle jack(1).

Rear of the vehicle.

Correct position for the vehicle jack (1).

E2AP02QDE2AP02ND

Angl-C6-page001-21-2005 4/02/05 17:12 Page 13

Page 31 of 223

Downloaded from www.Manualslib.com manuals search engine 25

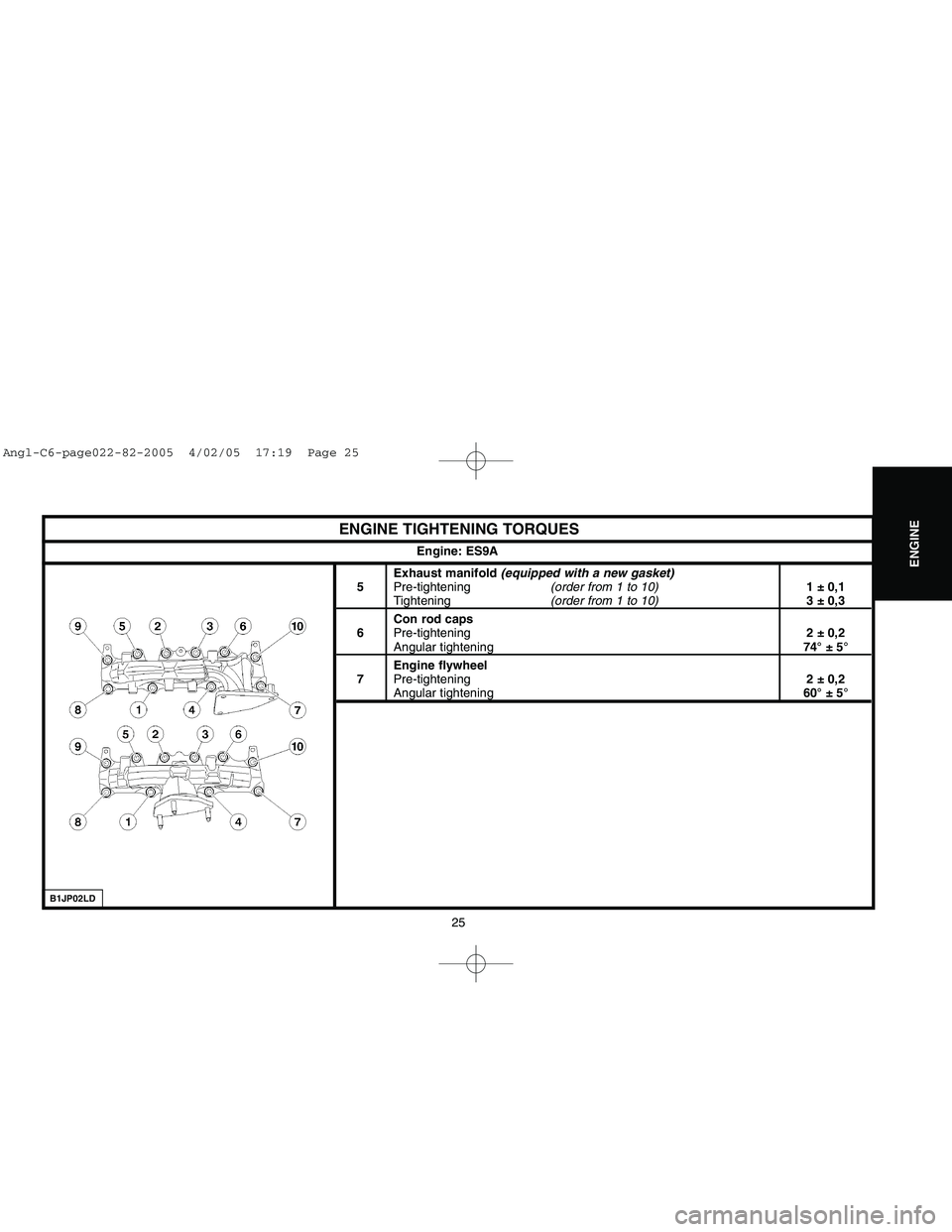

ENGINE

ENGINE TIGHTENING TORQUES

Exhaust manifold (equipped with a new gasket)

5Pre-tightening(order from 1 to 10)1 ± 0,1Tightening(order from 1 to 10)3 ± 0,3

Con rod caps

6Pre-tightening2 ± 0,2Angular tightening74° ± 5°

Engine flywheel

7Pre-tightening2 ± 0,2Angular tightening60° ± 5° Engine: ES9A

B1JP02LD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 25

Page 41 of 223

Downloaded from www.Manualslib.com manuals search engine 35

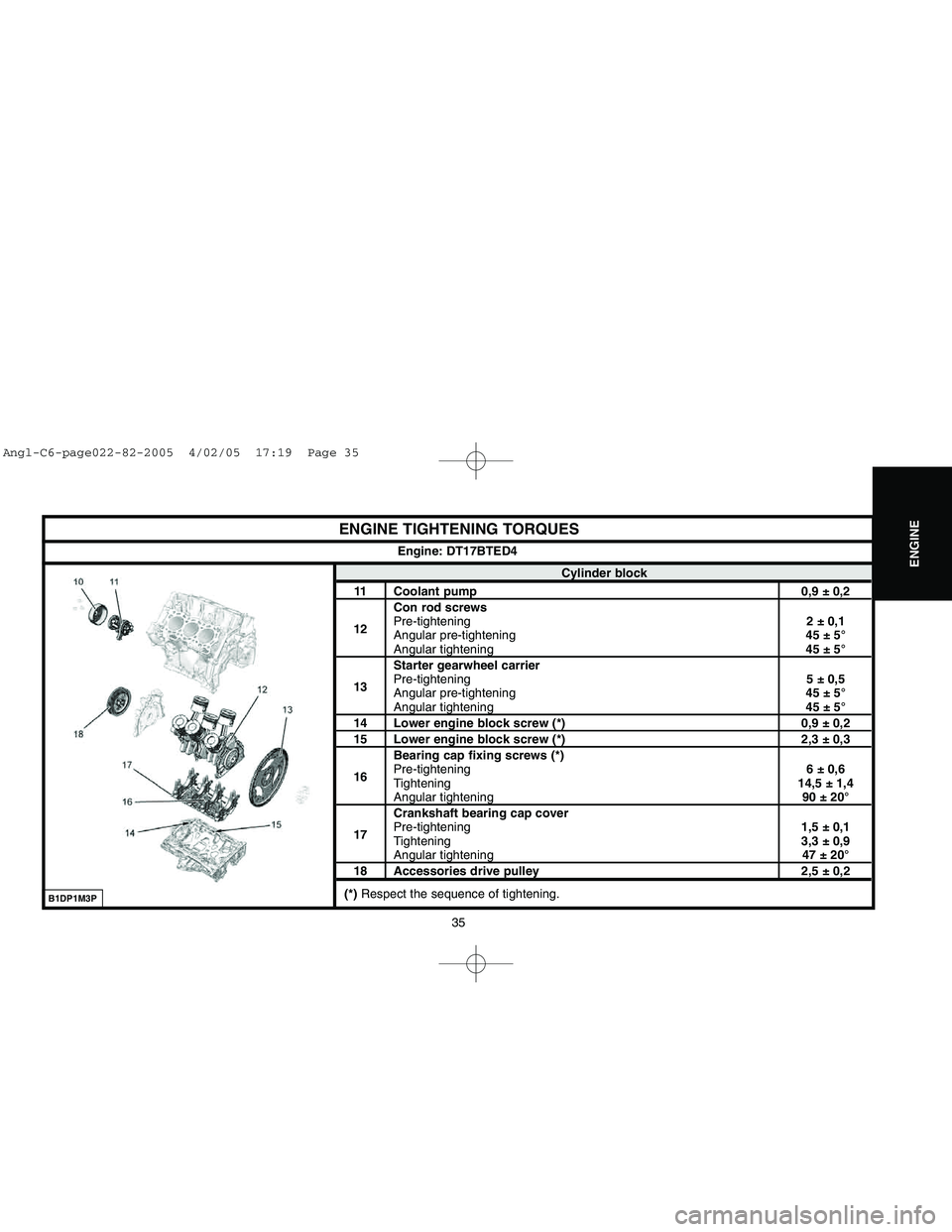

ENGINE

ENGINE TIGHTENING TORQUES

Cylinder block

11 Coolant pump 0,9 ± 0,2

Con rod screws

12Pre-tightening2 ± 0,1

Angular pre-tightening 45 ± 5°

Angular tightening45 ± 5°

Starter gearwheel carrier

13Pre-tightening5 ± 0,5

Angular pre-tightening 45 ± 5°Angular tightening45 ± 5°

14 Lower engine block screw (*) 0,9 ± 0,215 Lower engine block screw (*) 2,3 ± 0,3

Bearing cap fixing screws (*)

16Pre-tightening6 ± 0,6

Tightening14,5 ± 1,4

Angular tightening90 ± 20°

Crankshaft bearing cap cover

17Pre-tightening1,5 ± 0,1

Tightening3,3 ± 0,9Angular tightening 47 ± 20°

18 Accessories drive pulley 2,5 ± 0,2

(*) Respect the sequence of tightening.Engine: DT17BTED4

B1DP1M3P

Angl-C6-page022-82-2005 4/02/05 17:19 Page 35

Page 54 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 48

ENGINE

B1BP3BSD

AUXILIARY EQUIPMENT DRIVE BELT

Engine: ES9A

Tool.

[1] 2 mmdiameter peg: (-).0188-Q1

Removing.

Remove:

- The under-engine sou CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 48

ENGINE

B1BP3BSD

AUXILIARY EQUIPMENT DRIVE BELT

Engine: ES9A

Tool.

[1] 2 mmdiameter peg: (-).0188-Q1

Removing.

Remove:

- The under-engine sou](/img/9/57744/w960_57744-53.png)

Downloaded from www.Manualslib.com manuals search engine 48

ENGINE

B1BP3BSD

AUXILIARY EQUIPMENT DRIVE BELT

Engine: ES9A

Tool.

[1] 2 mmdiameter peg: (-).0188-Q1

Removing.

Remove:

- The under-engine sound-deadening.

- The front RH wheel.

- The RH splash-shield.

- The air duct (linking the air distributor heat exchanger).

Compress the dynamic tensioner roller (1)to free the pegging hole at "a".

Peg the dynamic tensioner roller at "a", using tool [1].

WARNING: Do not compress the dynamic tensioner roller completely (risk

of damage).

WARNING: Mark the direction of fitting of the auxiliary equipment drive belt

if for re-use.

Disengage the auxiliary equipment drive belt from the various pulleys, commencing

at "b"(coolant pump pulley).

Remove:

- The screws (2)and (4).

- The dynamic tensioner roller (1).

- The auxiliary equipment drive belt (3).

ESSENTIAL: Check that the tensioner and guide rollers as well as the

coolant pump can turn freely (without play, without tight spots and without

projections of grease).

Angl-C6-page022-82-2005 4/02/05 17:19 Page 48

Page 55 of 223

Downloaded from www.Manualslib.com manuals search engine 49

ENGINE

B1BP3BVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: DT17BTED4

Refitting.

WARNING: If re-using the auxiliary equipment drive belt, refit it respecting its direction of

fitting.

Fit the auxiliary equipment drive belt.

ESSENTIAL: Make sure that the auxiliaries drive belt is correctly positioned in the

grooves of the various pulleys.

Refit:

- The dynamic tensioner roller (1)by engaging the belt on the roller.

- The screws (2)and (4).

Tighten:

- Screw (2) : 5 ± 0,5.

- Screw (4) : 2,3 ± 0,2.

Compress the dynamic tensioner roller.

Remove tool [1].

ESSENTIAL: Make sure that the auxiliaries drive belt is correctly positioned in the

grooves of the various pulleys.

Refit:

- The air duct(linking the air distributor heat exchanger).

- The RH splash-shield.

- The front RH wheel.

- The under-engine sound-deadening.

Angl-C6-page022-82-2005 4/02/05 17:19 Page 49