Citroen CX 1982 1.G Repair Manual

Manufacturer: CITROEN, Model Year: 1982, Model line: CX, Model: Citroen CX 1982 1.GPages: 394

Page 51 of 394

Downloaded from www.Manualslib.com manuals search engine Supplement No. 1 to Manual 818-1 (CORR )

Page 52 of 394

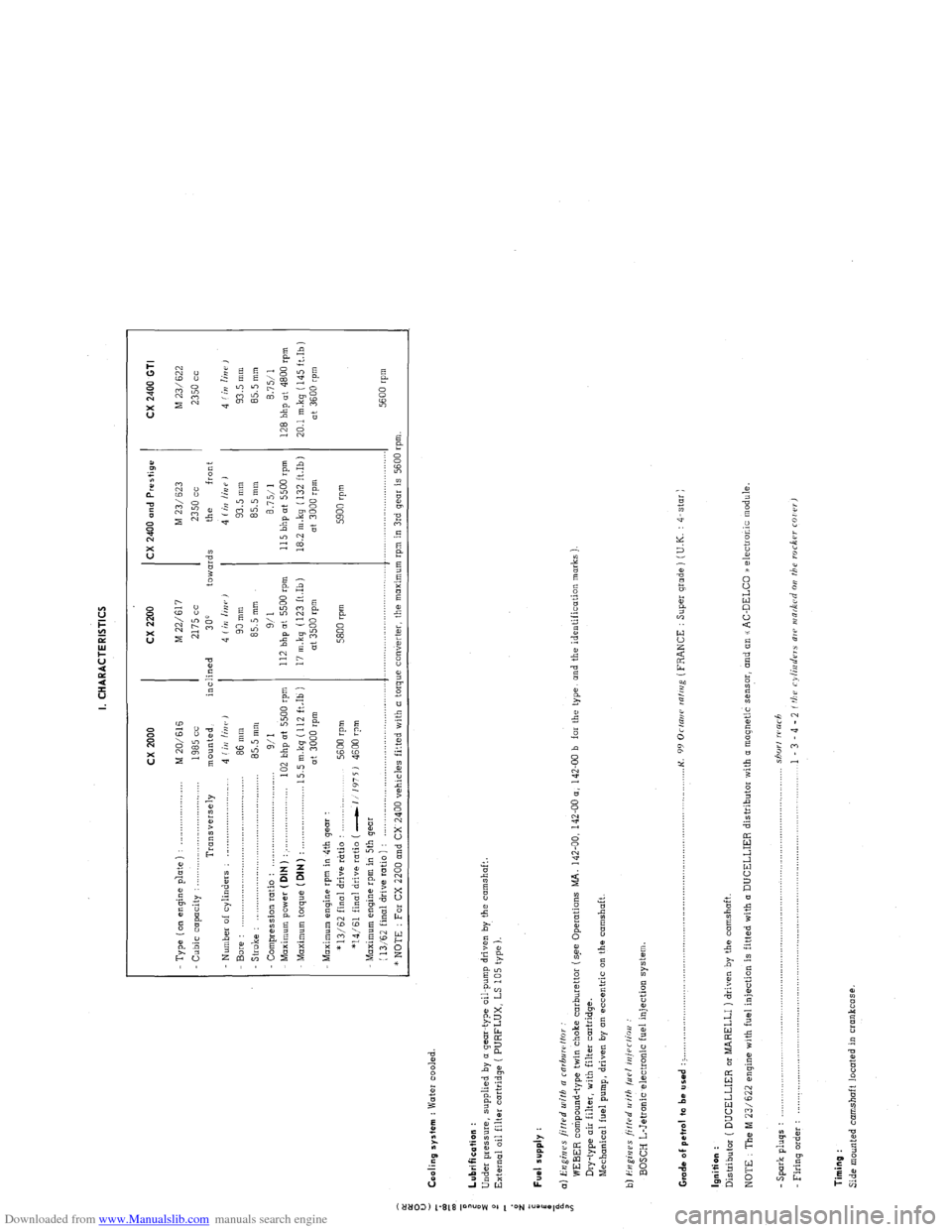

Downloaded from www.Manualslib.com manuals search engine I. CHARACTERISTICS

:

0

u

5 Cooling system : Water cooled.

z

T cx 2000 cx 2200 CX 2400 and Prestige

CX 2400 GTI

- Type ( on engine p’late ) : _..._................... M 20/616 M 22/617 M 23/ 623

M 23/622

Cubic capacity : . . .._......_...............

1985 cc 2175 cc 2350 cc 2350 cc

Transversely mounted, inclined

300 towards the front

Number of cylinders : _........................... 4 (iI/ linr, J 4 Iin linr,)

4 (irr /iUP J 4 f in lin i’ ,

Bore : 86 mm 90 mm 93.5 mm 93.5 mm

- Stroke : .,.,,_,.,.,....____.,.. .._._.....................

85.5 mm 85.5 mm 85.5 mm

85.5 mm

Compression ratio :

9/I 9/l 8.7511 8.7511

Maximum power ( DIN ) : . . . .._................... 102 bhp at 5500 rpm 112 bhp at 5500 rpm 115 bhp ot 5500 rpm

128 bhp at 4800 rpm

Maximum torque (DIN)

: . . 15.5 m.kg (112 ft.Ib ) 17 m.kq (123 ft.Ib) 18.2 m.kg ( 132 ft.Ib)

20.1 mkq (145 ft.Ib)

at 3000 rpm at 3500 rpm at 3000 rpm

at 3600 rpm

Maximum engine rpm in 4th gear :

* 13/62 final drive rtrtio :

5600 rpm 5800 rpm 5900 rpm

*14/61 final drive ratio ( -1 1’175 J 4600 rpm

Maximum engine rpm in 5th gear

(

13,‘62 final drive ratio ) : ,._............,..,........,....,.,........,..,.,..... .._.........,................ .._..._...................

5600 rpm

* NOTE : For CX 2200 and CX 2400 vehicles fitted with a torque converter, the maximum rpm in 3rd gear is 5600 rpm.

: Lubrification :

i

Under pressure, supplied by o gear-type oil-pump driven by the camshaft.

2

External oil filter cartridge ( PURFLUX, LS 105 type ).

d

z

;

i Fuel supply :

a

i a) Engines fitted u~ifh a rnrbuwffor

WEBER compound-type twin choke carburettor (s.ee Operations MA. 142-00, 142-00 a, 142-00 b far the type, and the identification marks )

Dry-type air filter, with filter cartridge.

Mechanical fuel pump, driven by on eccentric on the camshaft.

b) i?ugi,jes ji/f.rd II ith /LIP/ iniPr/ioo :

BOSCH L-Jetronic electronic fuel injection system

Grade of pet,ol to be used : > ._,,,,.,_.._,,,,,.,......... . .._...o....._............................................. K.

99 Orrani ralrrig (FRANCE : Super grade ) (U.K. : 4-star )

Ignition :

Distributor ( DUCELLIER or MARELLI ) driven by the camshaft.

NOTE : The M 23/622 engine with fuel injection is fitted with (I DUCELLIER distributor with a magnetic sensor, and an u AC-DELCO /a electronic module.

- Spark pluqs : .................................................................................................................................... shorf warh

Firing o&r : .................................................................................................................................... 1 - 3 - 4 - 2 f tbu cylinders ale INR&Cd 011 the roc6w COI rr,

Timing :

Side mounted camshaft located in crankcase.

Page 53 of 394

Downloaded from www.Manualslib.com manuals search engine

Page 54 of 394

Downloaded from www.Manualslib.com manuals search engine

Page 55 of 394

Downloaded from www.Manualslib.com manuals search engine 4 OPERATION No MA. 100-00 : ChargctrJristics and special jeattlws of the engine. II. PARTICULAR FEATURES.

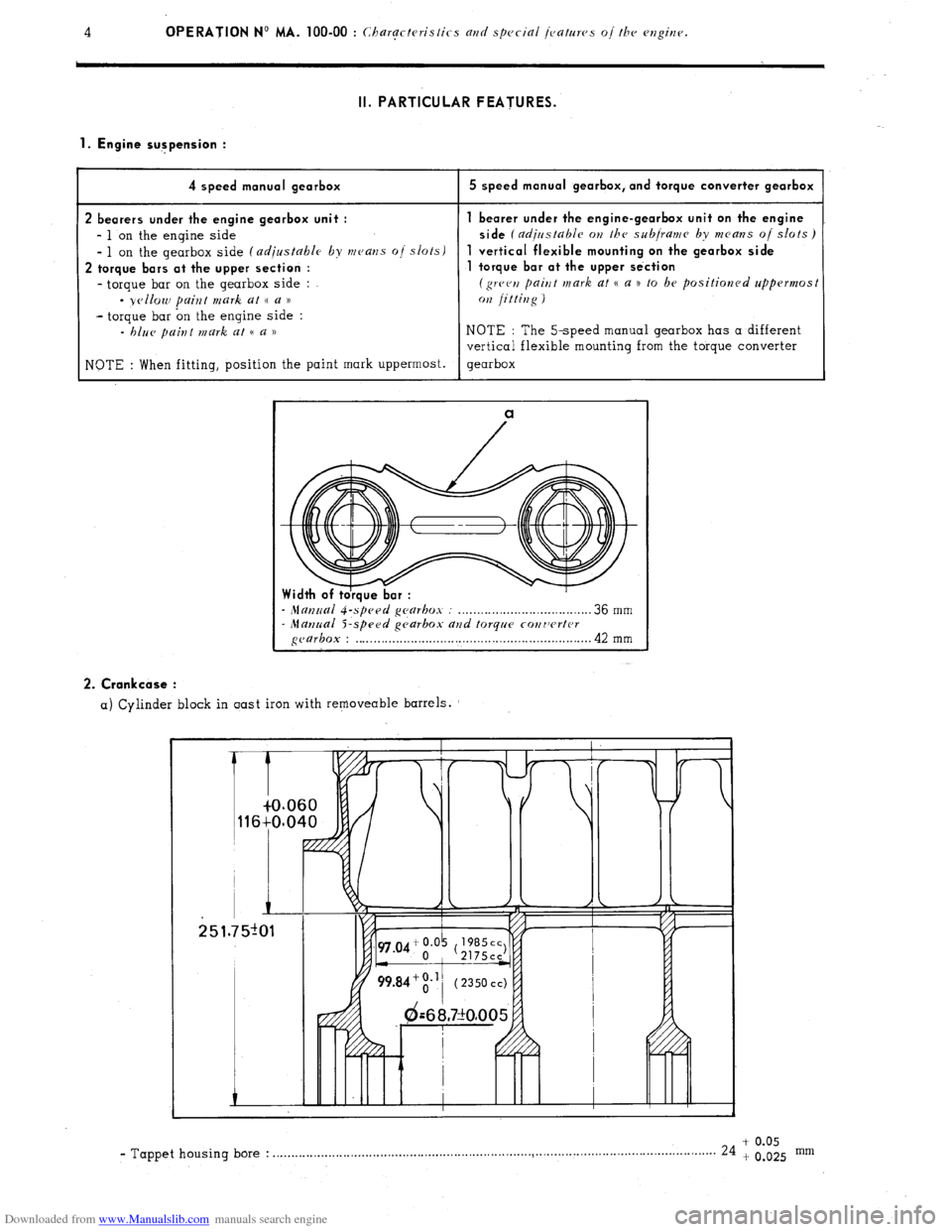

1. Engine sugpension :

4 speed manual gearbox

2 bearers under the engine gearbox unit :

- 1 on the engine side

- 1 on the gearbox side (adjustable by means o/ slots)

2 torque bars at the upper section :

- torque bar on the gearbox side :

- yellow paint mark at (( a ))

- torque bar on the engine side :

- blue paint mark at (( a ))

NOTE : When fitting, position the paint mark uppermost.

5 speed manual gearbox, and torque converter gearbox

bearer under the engine-gearbox unit on the engine

side

(adirrstable OH the subjranra by means oj slots)

vertical flexible mounting on the gearbox side

torque bar at the upper se‘ction

(green paint mark at CC a n to be positioned uppermost

072 jittiug )

NOTE : The 5-speed manual gearbox has a different

vertical flexible mounting from the torque converter

gearbox

a

- Mat7~ral gearbox : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 mm - Manual S-speed gc,arbox and torque cowrvrtcr gearbox : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 mm 2. Crankcase :

a) Cylinder block in oast iron with removeable barrels.

+ 0.05 - Tappet housing bore : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.................................................

24 + 0.025 mm

Page 56 of 394

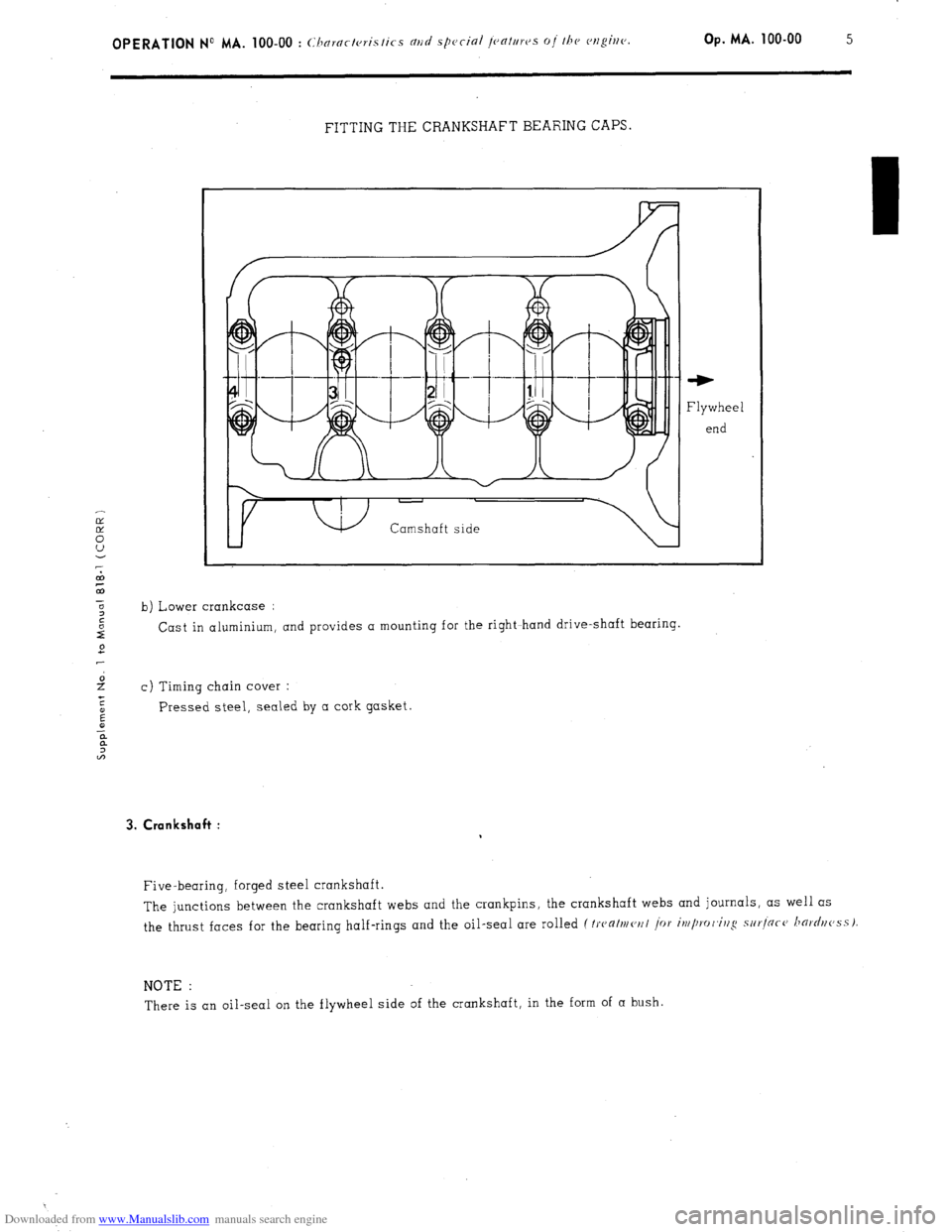

Downloaded from www.Manualslib.com manuals search engine FITTING THE CRANKSHAFT BEARING CAPS

Camshaft side Camshaft side ‘W

Flywheel

end

b) Lower crankcase :

Cast in aluminium, and provides a mounting for the right~hand drive-shaft bearing.

c) Timing chain cover :

Pressed steel, sealed by a cork gasket. 3. Crankshaft :

Five-bearing, forged steel crankshaft.

The junctions between the crankshaft webs and the crankpins, the crankshaft webs and journals, as well as

the thrust faces for the bearing half-rings and the oil-seal are rolled

(Iwalmc,r/l i~r iw/lro/~ir/g sur]ncc~ horr/r/c,ssI

NOTE :

There is an oil-seal on the flywheel side of the crankshaft, in the form of a bush.

Page 57 of 394

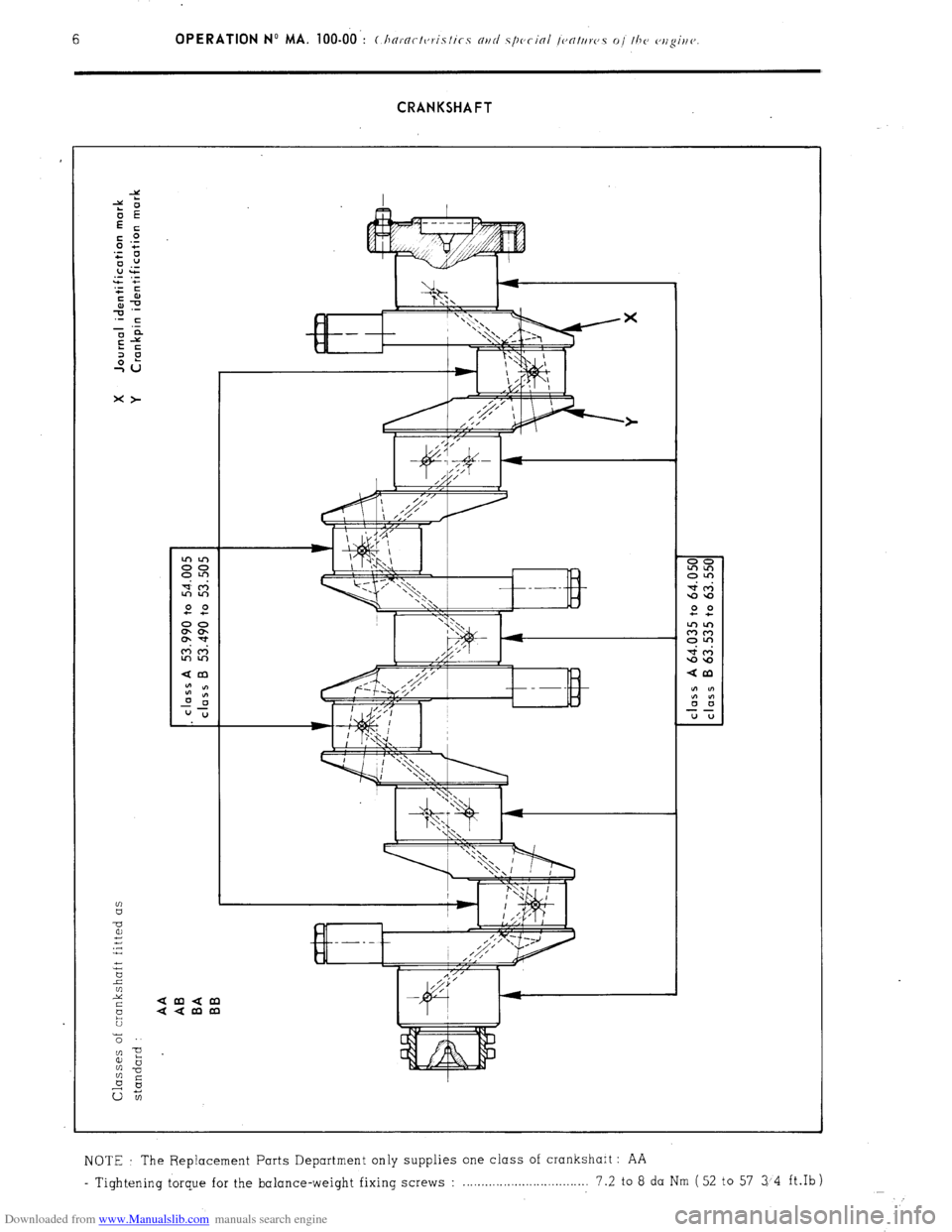

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT

?c

2

2 amam

aamm

t;

z

NOTE The Replacement Parts Department only supplies one class of crankshaft : AA

- Tight.ening torque for the balance-weight fixing screws : 7.2 to 8 da Nm (52 to 57 34 ft.Ib)

Page 58 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 100-00 7

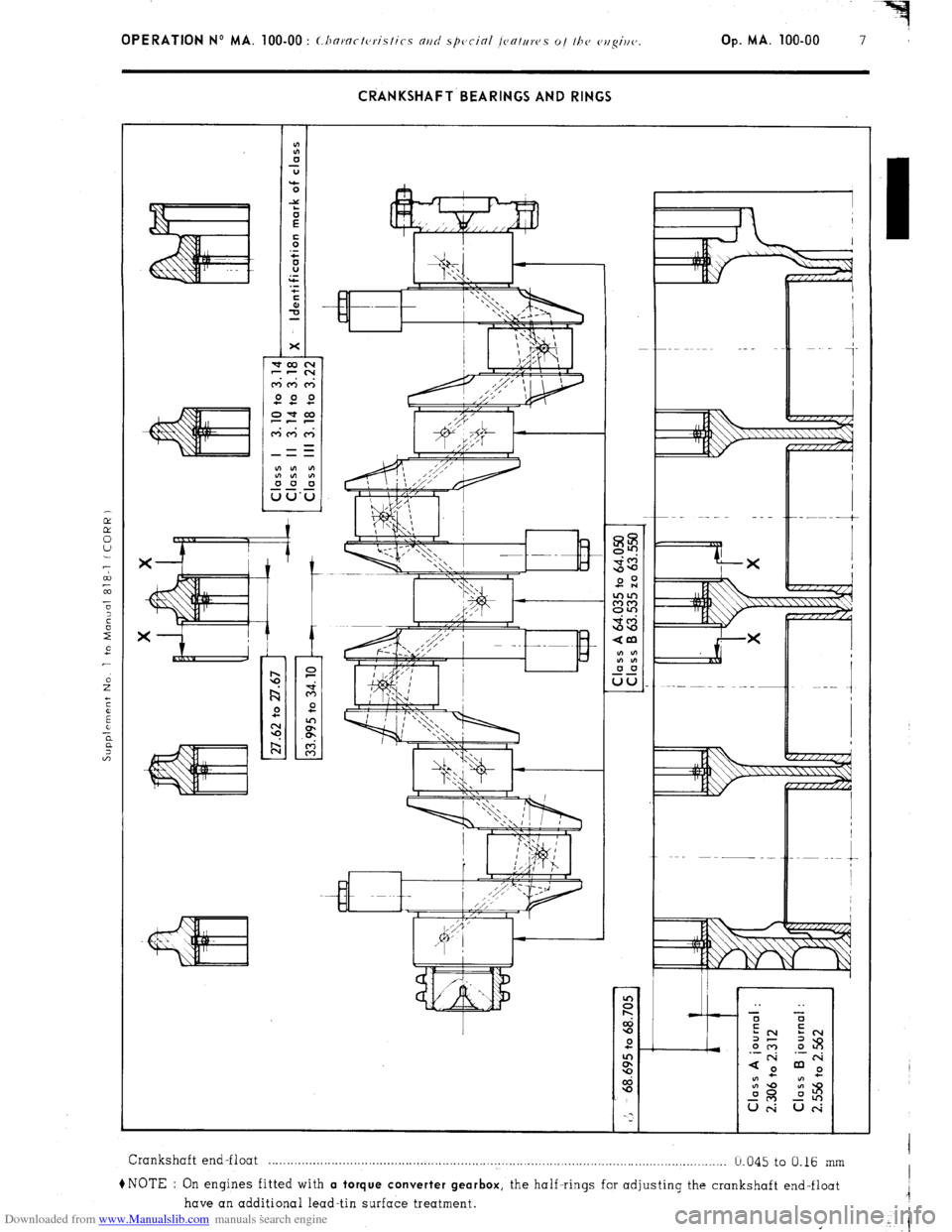

CRANKSHAFT BEARINGS AND RINGS

Crankshaft end-float . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....

b.045 to 0.16 mm

+NOTE : On engines fitted with a torque converter gearbox,

the half-rings for adjusting the crankshaft end-float

have an additional lead-tin surface treatment.

Page 59 of 394

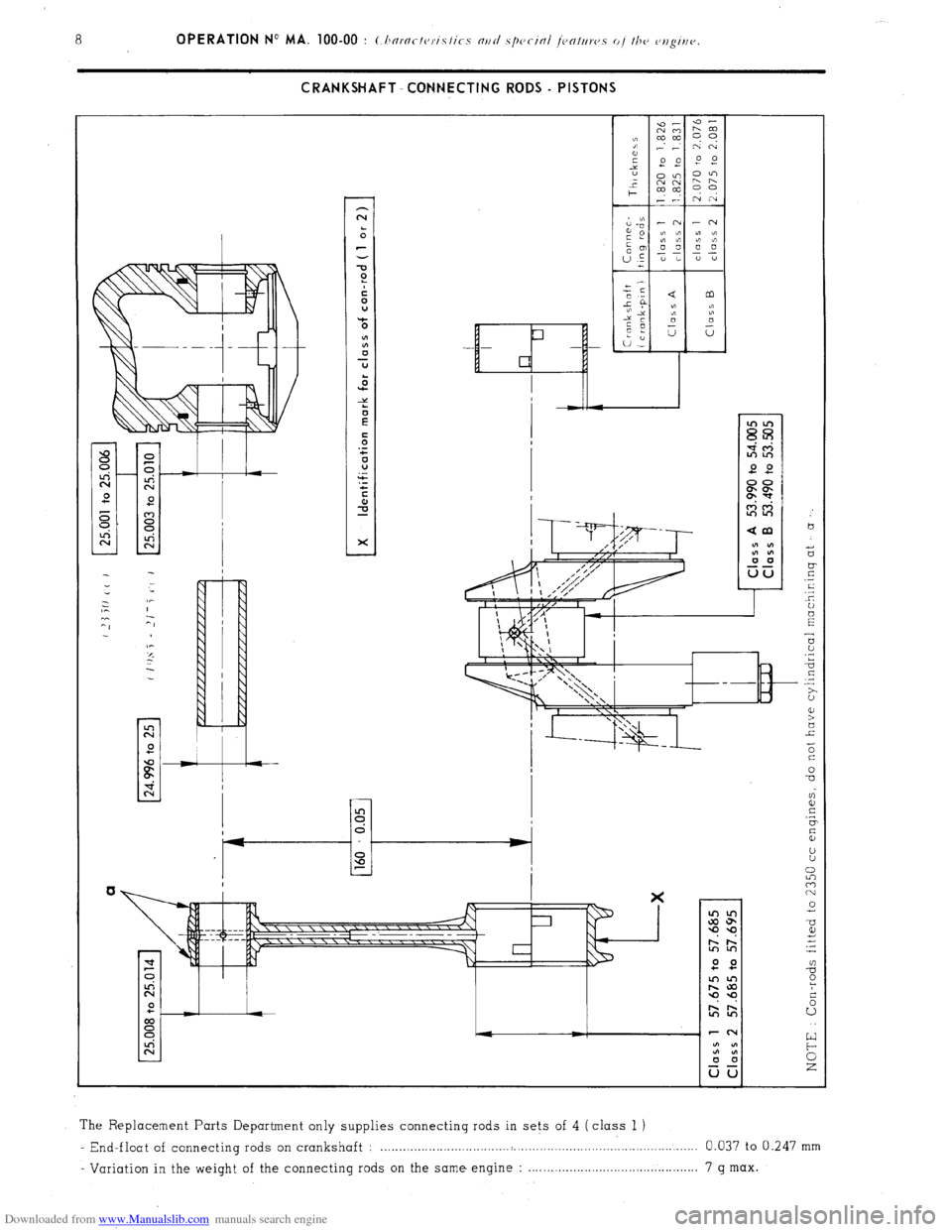

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT- CONNECTING RODS - PISTONS

The Replacement Parts Department only supplies connecting rods in sets of 4 (class 1 ) End-float of connecting rods on crankshaft : .._....,....._._.___...............: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.037

to 0.247 mm

- Variation in the weight of the connecting rods on the same engine : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 g max.

Page 60 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 100-00 : (:hnractc,ri.stics arid specinl j(,atrlres o,/ the> cl,gi?lcJ. Op. MA. 100-00 1

9

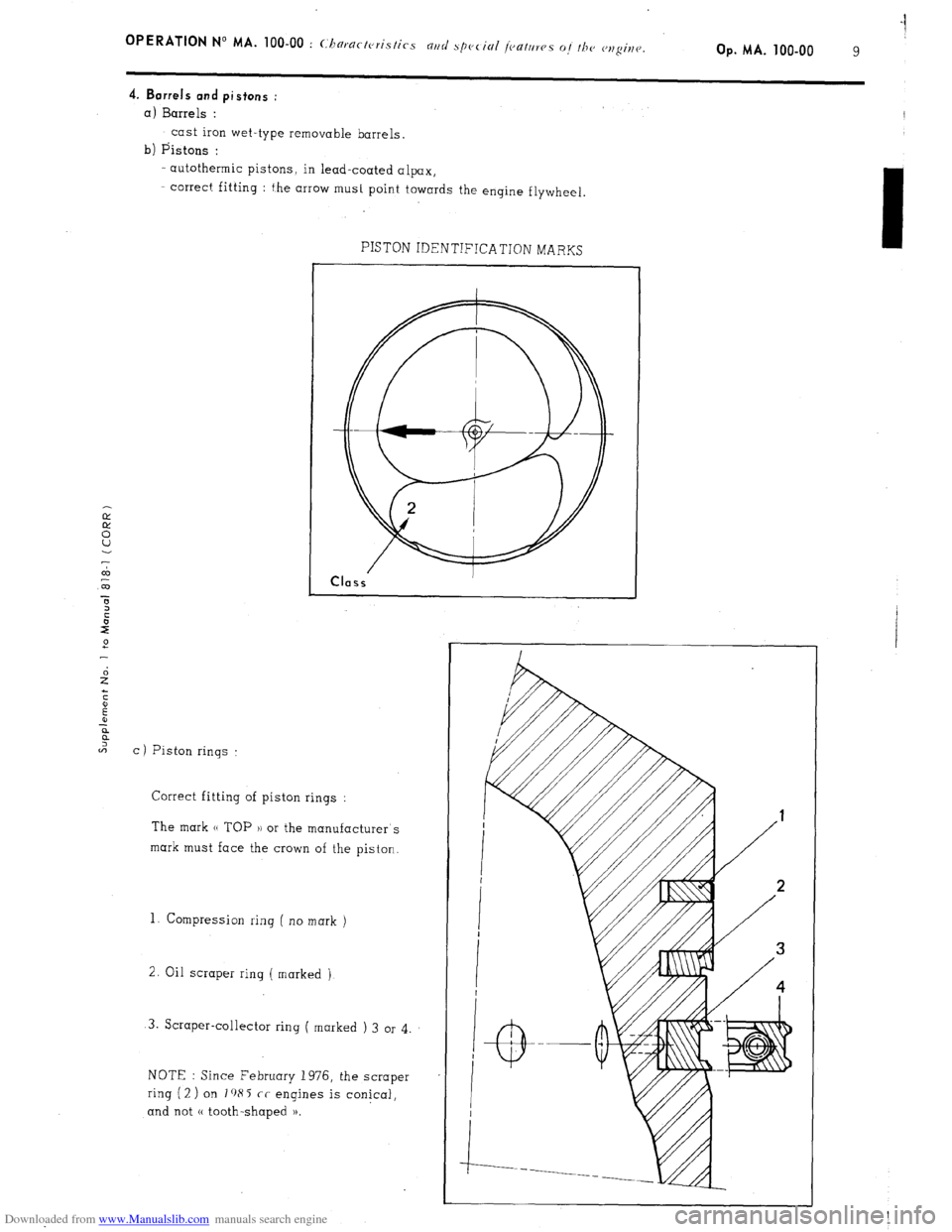

4. Barrels and pistons :

a)

Barrels :

cast iron wet-type removable barrels.

b) Pistons :

-- autothermic pistons, in lead-coated alpax,

- correct fitting : the arrow must point towards the engine flywheel

7

co

m

C ) Piston rings : PISTON IDENTIFICATION MARKS

Correct fitting of piston rings :

The mark (( TOP 1) or the manufacturer’s

mark must face the crown of the piston.

1. Compression ring ( no mark )

2. Oil scraper ring ( marked )

3. Scraper-collector ring ( marked ) 3 or 4

NOTE : Since February 1976, the scraper

ring (2 ) on I a85 cc engines is conical,

and not (( tooth-shaped )).