electrical Citroen CX 1985 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1985, Model line: CX, Model: Citroen CX 1985 1.GPages: 394

Page 320 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 510-00 b : A ..n A II it ~(~rttc~t7t 0 j lhv cJcctr.ical irlsldllntiari ( iront 9/

107 5 ) Op. MA. 510-00 b 9

ARRANGEMENT OF THE ELECTRICAL INSTALLATION

PRESENTATION OF THE DIAGRAMS

1. CIRCUIT DIAGRAM

a) Special feature

: The various circuits are presented in a functional way. therefore. where a unit is connected

to several circuits. its various sections are shown in cx exploded )) form on different vertical grid lines.

n

0 b) Method of identification, Identification marks are divided into three sections

<

- figures which identify components ( and not leads )

- letters LG, TB! AR. etc .~. identifying wiring harnessss,

- other letters ( Bc F. Gr, FN. Bl . . . ) identifying the colour of the extremity of the insulating sleeve.

:

r”

NOTE For the last group of identification marks. four cases may occur

marks on diagrams Bc. Bl. Ve. Gr . ..~

- No

slcc~rv ot) a lcad tbv colaur o{ which scrt‘vs as idvtltijirntiatt mark :

marks on diagrams F. Gr. F. Ve. F. Bc . . . .

- UnidetttijiGd lead : its position cannot give rise to any confusion. IMPORTANT

: Identification marks for components and wiring harnesses are arbitrary they have been chosen

for the sole purpose ‘of facilitating the use of the diagrams.

7’hr colour of tkc sl~~c~r~c~s aud tbcz IcJads arc the wly idcwtijicntiorl marks nctr,ally used ot1 the leads mak.fng

up the elcactric systc~nz 0 / th(z chicle. 2. WIRING DIAGRAM

This is a schematic diagram of the components. as they are fitted on the vehicle.

It indicates the layout of the leads, and the approximate location of the components

The method of identification is the same as for the circuit diagram.

Page 355 of 394

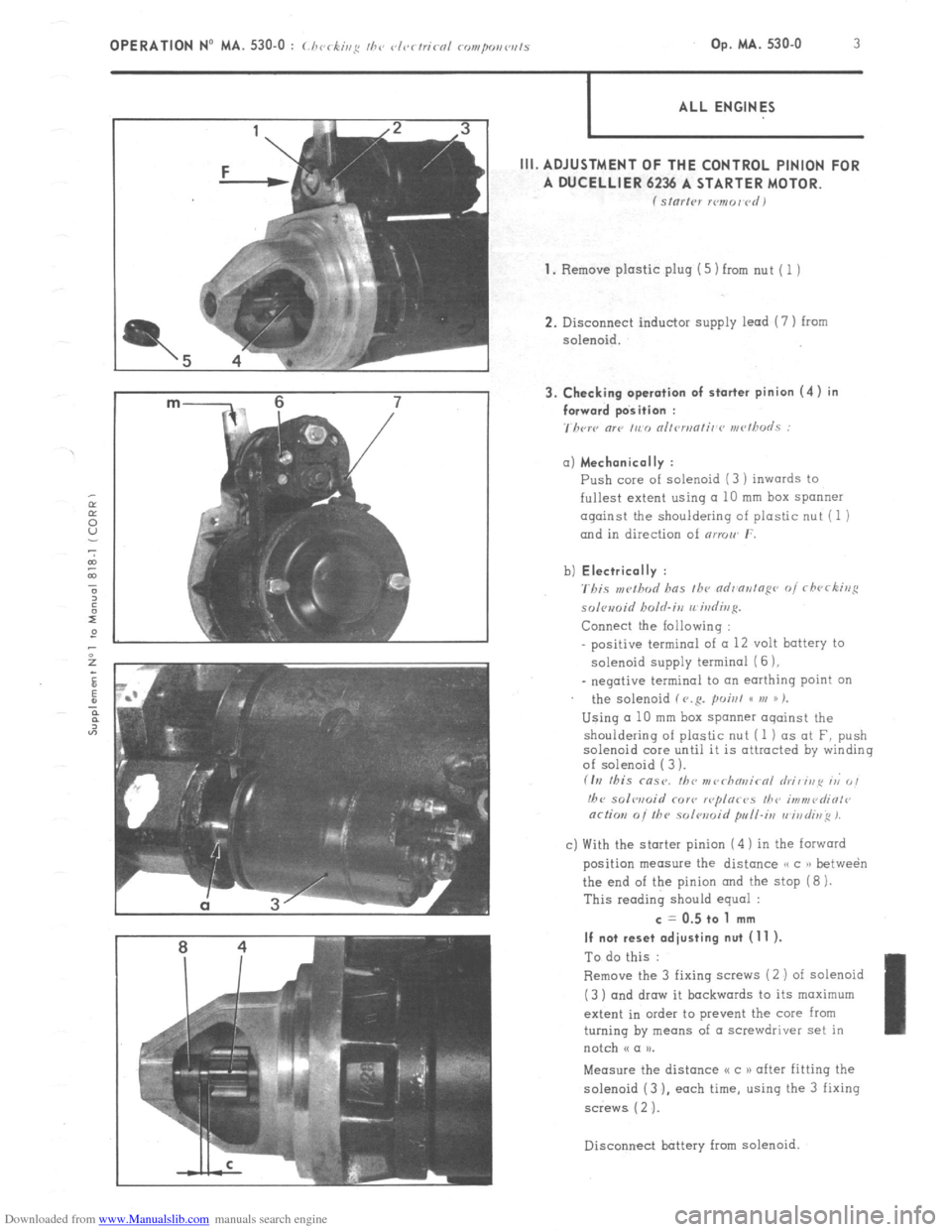

Downloaded from www.Manualslib.com manuals search engine m- 6 7 3. Checking operation of starter pinion (4) in

/ forward position :

7hcrc “lP ,,c,, nllrn,nli,~r~ rn<~~h”LS : OPERATION No MA. 530-O : (./ 1< ‘ ,,,g II,‘, vl<~rtricnl rompo,,w,ls , -k’ Op. MA. 530-O 3

ALL ENGINES

III. ADJUSTMENT OF THE CONTROL PINION FOR

A DUCELLIER 6236 A STARTER MOTOR.

f Sl”l’,Pl xmor~rdI

1.

Remove plastic plug (5) from nut ( 1 )

2. Disconnect inductor supply lead (7 ) from

solenoid. a) Mechanically :

Push core of solenoid (3 ) inwards to

fullest extent using a 10 mm box spanner

against the shouldering of plastic nut (1 )

and in direction of nrmw r.

b) Electrically :

'rbis ,w!hod has fh~ ndr'ontopr~ of rfwrking

solomid holrl.irz rrirdivg.

Connect the Iollowing :

positive terminal of (I 12 volt battery to

solenoid supply termina1 (6 ),

_ negative terminal to an earthing point on

the solenoid f V.R. poisl GC VI )) %

Using a 10 mm box spanner oqainst the

shouldering of plastic nut (1 ) as at F, push

solenoid core until it is attracted by winding

of solenoid ( 3 ).

fIrI this msr. fbc nr~~rhn~~irnl hi, irip ri 0,

!hc solwoid COY<, r<~plor<~s I/?<, i,,?“,<~diOl<~

or/ion 0i the solwoid pull-i,, vi,,di~~ 1.

c) With the starter pinion (4 ) in the forward

position measure the distance /, c )r betwe&

the end of the pinion and the stop (8 ).

This reading should equal : c = 0.5 to 1 mm

If not reset adjusting nut (11 ).

To do this :

Remove the 3 fixing saews (2 ) of solenoid

(3 ) and draw it backwards to its maximum

extent in order to prevent the core from

turning by means of a screwdriver set in

notch N a u.

Measure the distance I< c 1) after fitting the

solenoid (3 ). each time, using the 3 fixing

screws ( 2 ‘J.

Disconnect battery

from solenoid.

Page 359 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 560.0 : ~hrrkin~ o,,d oc/@s/i,,g I/><, wiurisrrrr,, wip’r. Op. MA. 560.0

1

Fi

m

0 CHECKING AND ADJUSTING THE WINDSCREEN WIPER.

FRONT WINDSCREEN WIPER MOTOR

CHARACTERISTICS.

Manufacturer DUCELLIER

Reference No. 4966 A

Field coils Ferrite

Armature : Endfloot (adjustable by means of stop-screw) : 0.2 mm

Nominal dia. of commutator :

24 mm

Min. dia. after machining : 23 mm

Brushes : Ref. No. :

CL 7239

Minimum length after wear : 5.5 mm

Ratio : .._...................................................................................................

44 1

Connection and circuit diagram as in Op. MA. 510 00.

ELECTRICAL CHECK. BOSCH

0390 346 127

Ferrite

0

23.2 mm

23 mm

1.394.320-058 059, 062

7.5 mm

49 1

1. First speed :

Nominal power : IO watts

Speed, under no load, at 13.5 volts = 50 rpm Corresponding current = I.8 A

Torque, motor locked, at 13.5 volts = 1.9 da Nm 7 13.74 ft.lb min. Corresponding current 18 A max.

Torque at 40 rpm and 13.5 volts = 0.2 do Nm (1.45 ft.lb) Correspondinq current = 5.5 A max.

- Torque ot 20 rpm and 13.5 volts = 1.07 da Nm (7.74 ft.lb) min Corresponding current = 13.2 A max.

2. Second speed :

Nominal power : 15 watts

Speed under no load at 13.5 volts = 70 rpm Corresponding current = 2.3 A

Torque motor locked at 13.5 volts = 1.5 do Nm (IO.85 ft.lb) min Corresponding current = 21 A max

Torque at 60 rpm and 13.5 volts = 0.2 da Nm (1.45 ft.lb) min Corresponding current = 7 A max

Torque ot 30 rpm and 13.5 volts = 0.9 da Nm (6.51 ft.lb) min Corresponding current = 14.7 A mrx.

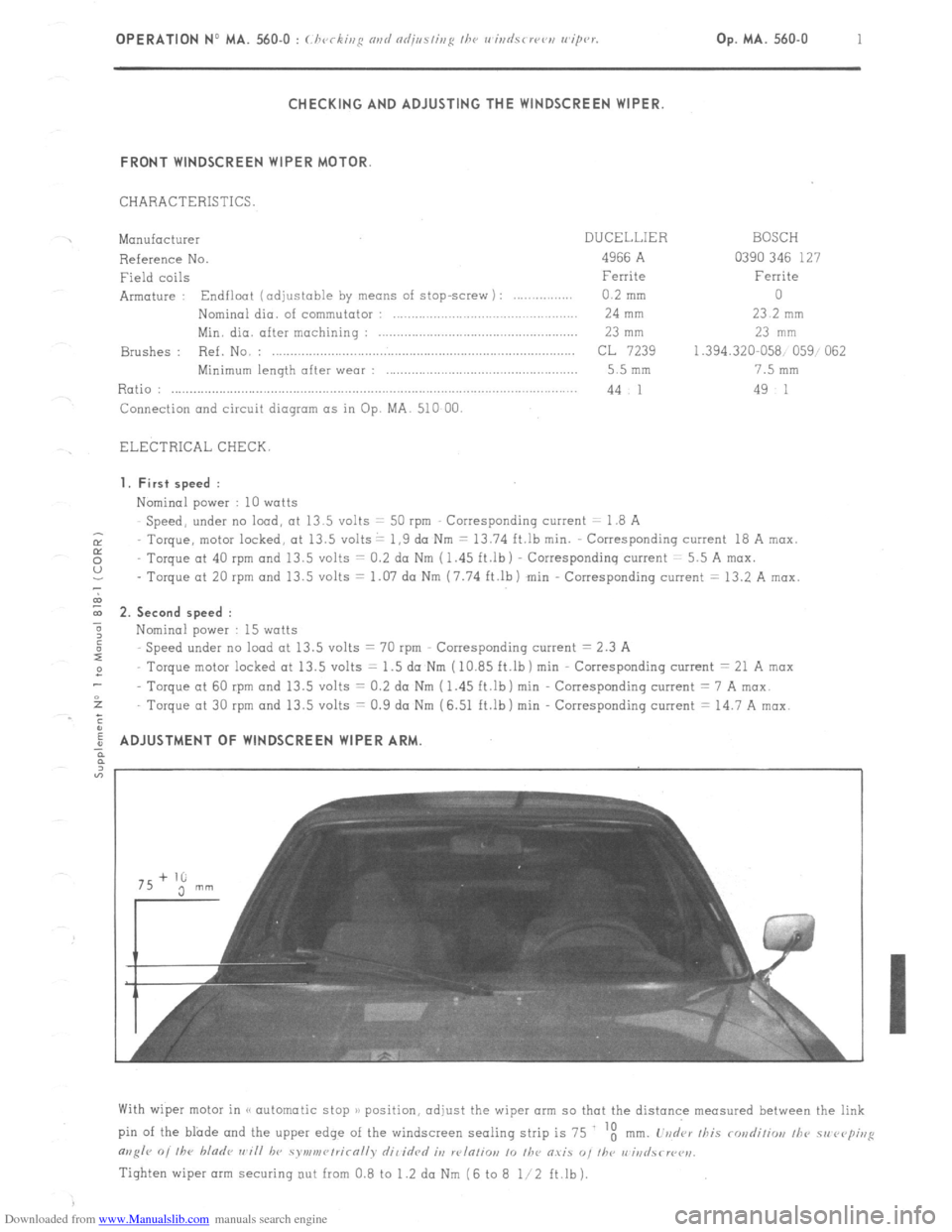

ADJUSTMENT OF WINDSCREEN WIPER ARM

With wiper motor in (< automatic stop )/ position, adjust the wiper arm so that the distance measured between the link

pin of the blade and the upper edge of the windscreen sealing strip is 75 ‘t

mm. L’vd‘ar /his rondiliw, /he 51, rvp;,,g

m,g/r 0, /he bladr ,,~i// hv symv,r~/rirn//v dil idrd it, w/n/io,, 10 /he O.YiS “, I/w r,‘iri

Tighten wiper arm securing out from 0.8 to 1.2 da Nm (6 to 8 l/2 ft.lb).