Rod CITROEN CX 1988 User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1988, Model line: CX, Model: CITROEN CX 1988Pages: 648, PDF Size: 95.8 MB

Page 94 of 648

- pressure regulator- and compressor holder nuts (1 )

(a//- condit/oning option).

- all the sfirms,

and put them rn place of the battery.

Uncouple the exhaust systern.

Normally aspirated engine with E. F. I..

Remove the 4 exhaust pipe nuts.

Turbo with E./Y/., Fig. II and 111

Remove:

- screw (2) and shims (31,

- flexrble pipe screws (7),

- nuts and spacers (4).

Release exhaust pipe (8) downwards.

Remove nuts (5) and flexible pipe (6). - adtustrng nuts (91,

- clutch control support screws (I 0).

Uncouple the power take off with double outlet,

Fig. V.

Fully loosen screw i 121, then retrghten it by two turns

to prevent the speedometer drive guide from being

pushed out.

Disengage the twin outlet power take off ( 1 1).

Remove oil gauge i 13).

Uncouple, Fig. V:

- heater hoses (I 6) and (I 71,

- fast idle air duct (I 5),

- petrol supply pipe (181,

- petrol return pipe (14).

Disconnect, Fig. VII:

- connectors (201,

- sensors (221,

- coils and suppressors (I 9),

- gear shift link rods (21 ).

Page 95 of 648

o&ion oi‘i tht: enginr:,

-T.bis (as shown on i/til.irial~oiii,

attaching bracket 6031-

nafu/a//y asp/rafed erg/m with E/7: bracket to bc: fit-

ted on the exhaust pipe, with one screw,

turbo with EN: fit the bracket to the pressure relief

valve outlet,

- tensioner 4061-T (siack).

Place sling 2517-T.bis. under tension, tensioner

4061-T being loosened, Fig. II.

Remove:

- screw (I 1 from the engine bearer, Fig. III.

- nut (3) and screws (4) from the gearbox mounting,

Fig. V (retrieve the shims),

- screw (2) from the torque rod; slacken the other

scl-ew, Fig. IV.

Slightly raise the power unit assembly

Screw tensioner 4061-T fully, Fig. VI and remove

the engine/gearbox assembly:

Before refitting the power unit assembly:

Check the condition of the engine mounting brac-

kets. Replace them if needed.

Adjustment to be tested,

(as per Op.0 MA 733.0/1) Fit the engine crankcase water dralrl plug, fltted with a

~~~in~ torque: 3 mda

Place sling 2517-T.bis, attaching bracket 6031 -T

and tensioner 4061-T; screw the tensioner fully In,

Fig. I and VI.

Engage the engine/gearbox assembly Into Its corr-

partment, Fig. VI.

l-oosen tensioner 4061-T, Fig. II.

Refit: (without tightening)

- engine support bracket

screw (I 1,

- torque rod screw (2)

- gearbox support plate (toyeTher with 1f.s shims).

Tighten:

- the engrne bearer to 10 mdaN, Fig. III

- the torque rod to 9 mdaN, Fig. IV

-. the gearbox support plate fixings, Fig. V:

screws (4): to 3 mdaN

nut (31: to 16.5 mdaN.

Insert the clutch cable into Its ball-joint. Tighten clutch

control support (5). Adjust the clutch , Fig. VII.

Locate, Fig. VIII.

the dual outlet power take off (61.

the oil gauge.

Page 97 of 648

le up the exhaust system. econnect, Fig. IV and V:

- connectors 11 I),

turaily aspirated engines w/th EN, fitted with

seals:

Tighten the flange to 1.6 mda

On the turbocharged engines with EH, fitted with

NEW nuts and seals:

Refit: Fig. I and II, - sensor (12) (with biue /dent mark),

- sensor (13) (with no ident mark),

- HT coil 191 cyls 1 and 4 (with yellow /dent mark),

HT coil i IO) cyls 2 and 3 (w/t/r fro markl,

- the suppressors,

- the reversing larnp switch wrring harness,

- the throttle spindle switch (141,

- knock sensor (I 8).

- flexible pipe (2) to the pressure release valve outlet,

- exhaust pipe (4) to the turbo, screws (31, distance

pieces (51,

- screw (6) and adjusting shims.

There should be a 5 mm clearance at least between

the exhaust pipe and the engine crankcase. Recouple, Fig. V and VI:

- the water hoses,

- air circurt pipes (151, (161, (17). (20) and (211,

- petrol circuit pipes (I 9),

- gear shift link rods,

- the accelerator cable.

Tighten, Fig. I and II:

- turbocharger nuts fin the correct sequence), Fig. II,

- flexible hose (2) screws (3) and nuts (I 1 to

2.5 mdaN,

- screw (6) to 5 mdaN. Fit:

- the driveshafts,

(See Op. @ MA 372-l/11

- the radiator,

- the bonnet,

- the battery,

Refit: Fig. Ill

- the pressure regulator and compressor holder (air

conditioning option) together with its shims; tigh-

ten nuts (7) to 5 mdaN. - the protection plate located under the spare

wheel.

Check the oil levels. Top up if necessary.

Vehicles with air-conditioning: Fill up the cooling circuit (wrth the heater open) and

carry out the bleeding operation.

- the compressor belt and protection cover,

- the pressure regulator accumulator, fitted with a

NEW seal,

- the HP pump outlet pope, fitted with a NEW sea/

and its fastenings (8),

- the pipe situated between the pressure regulator

and the brake accumulator, fitted with NEWseals,

- the HP pump rubber suction pipe,

- the horn. (As per Op @ MA 230.0/l/.

Bleed the front brakes.

(Refer to Op. MA 453.0/l/.

Check the gear change.

Lower the vehicle to the ground.

Page 99 of 648

and turn ti-re crankshafi irl the norrnai direct~or~ of

I otatiorj

Remove, Fig. I:

- the co~llrol cable frorn the cold start flap (I 1,

- hose

(21,

- the accelerator control rod and cable,

- cylinderhead cover (3).

Bring:

- the piston of cylinder No. 4 to TDC

(with the valves in the “rocking” position)

Make sure:

that mark “a” on the flywheel is facing the zero on

the clutch bell housing, Fig III.

Set:

the clearance of cylinder No. 1 inlet valve (4) to

1.50 mm, Fig II. Check:

cylinder 0. 1 valve clearance

The clearance should be of 0.30 to 0.75 mm.

Adjust:

the valve clearance:

INLET = 0.10 mm

EXHAUST = 0.25 mm

NOTE:

This check can be carried out with a dial gauge, as

shown on Fig. IV.

Fit:

the cyllnderhead cover and its gasket,

(tighten to 0.6 mdaN).

Recouple:

- the accelerator control rod and cable,

- the hoses,

- the control cable to the cold start flap.

Page 111 of 648

- crankshaft key horrrontally (with mark “c” stagge-

rred by 5’ upwards),

- mark “a” or “d” on camshaft,

- mark “b” on the rntermedrate shaft.

- Each timing mark on the belt must line up with the

tooth wheel marks.

Fit the belt (avoid contact with oil or grease).

Release, Fig. I and 111,

- tensioner roller screws (I 1 and 12) (let the spring act)

then tighten the screws.

Turn:

- the crankshaft 180’ clockwise.

Do not turn backwards

Release:

- the tensioner roller fixing screws then retrghten

starting with the upper screw (I ), Fig. I and Ill.

Turn:

- the crankshaft a further two turns clockwise.

Slacken, Fig. I and Ill:

- tensioner roller screws (1) and (21, (let the spring

react),

- then retighten starting with screw (I 1.

Fit:

- tool 6012-T., Fig. II. Install, Fig. lb:

the trming belt casing,

crankshaft pulley 13),

trghten screw (4)

to 8 mdaN on engine --r-829.A5

to 12.5 mdaN on engrne -+J6T.A5QQ

- the alternator belt and cover,

- the wheelarch rubber sealing strip.

Remove, Fig. II,

- tool 6012-T.

Fit:

- the cylinder head cover and gasket

ttightenrng torque: 0.6 mdaN).

Recouple:

- the accelerator control rod,

- the flexible hose,

- the cold start flap control cable.

Refit:

- the wheel,

Lower the vehicle to the ground.

NOTE:

- Camshaft toothed pulleys of engines 829.A5 and

J6T.A500 are identical but the fitment is different,

Fig. I.

- If, after carrying out the belt tensioning operation,

the timing belt is noisy when the engine is hot,

retension the belt with the engine hot.

Page 116 of 648

emove:

the I-oati Wi-l~~d,

- the wheelarch lrnrrng,

- the belt protectron covets

Position: Fig. I and II

the valves of cylrnder No. 1 rn the “rocking” ~OSI-

tion (look Into the engine 011 filler),

the flywheel wrth mar-ks- -alrgned,

- camsfraft gear wheel mark A opposite screw 12)

Loosen:

the nuts of the tensioners and compress the spring

of eacir tensloner. Hetighten the nuts.

Remove:

- injection pump belt,

- the trmrng belt

REFITTING

Fit, Fig. II:

the timrng belt- marks t-+-) and i-e-1 on the belt

should face the marks A and B on pinrons (there

are 35 pitches between A and B, passing around

the tensloner roller (I 1).

Loosen the nuts of the tensioner roller.

Install, Fig. III:

- tool 6Q28-T.K. on the roller

- the tool weight over the mark 2 of the rod, Fig 1V. Fitting the injection pump belt:

Run the engrne by 1 turn err the drrectrorr of rotation

until marks--- +- /Ino up, Fig. I

(wrth cylinder No 1 at the rnrtral trmrng

point)

Setting the pump to the injection point:

refer to Op @ MA. 146-011

Fit the InJectron purnf, drrvrng belt with the srde oppo-

site the roller, trght.

Slacken the roller nut. Let the roller- spring react

Tighten the rnut to 2 mdaN.

Rotate the engine by 2 turns in the direction of nor-

rnal rotation and check the pump timrng.

Remove the tools

Start the engine Warrn it up until the electric cooling

fans operate.

Retension the belt while the engine is hot, Fig. IV

Refit:

- the protectron covers,

- the wheelarch lining,

the road wheel

Page 209 of 648

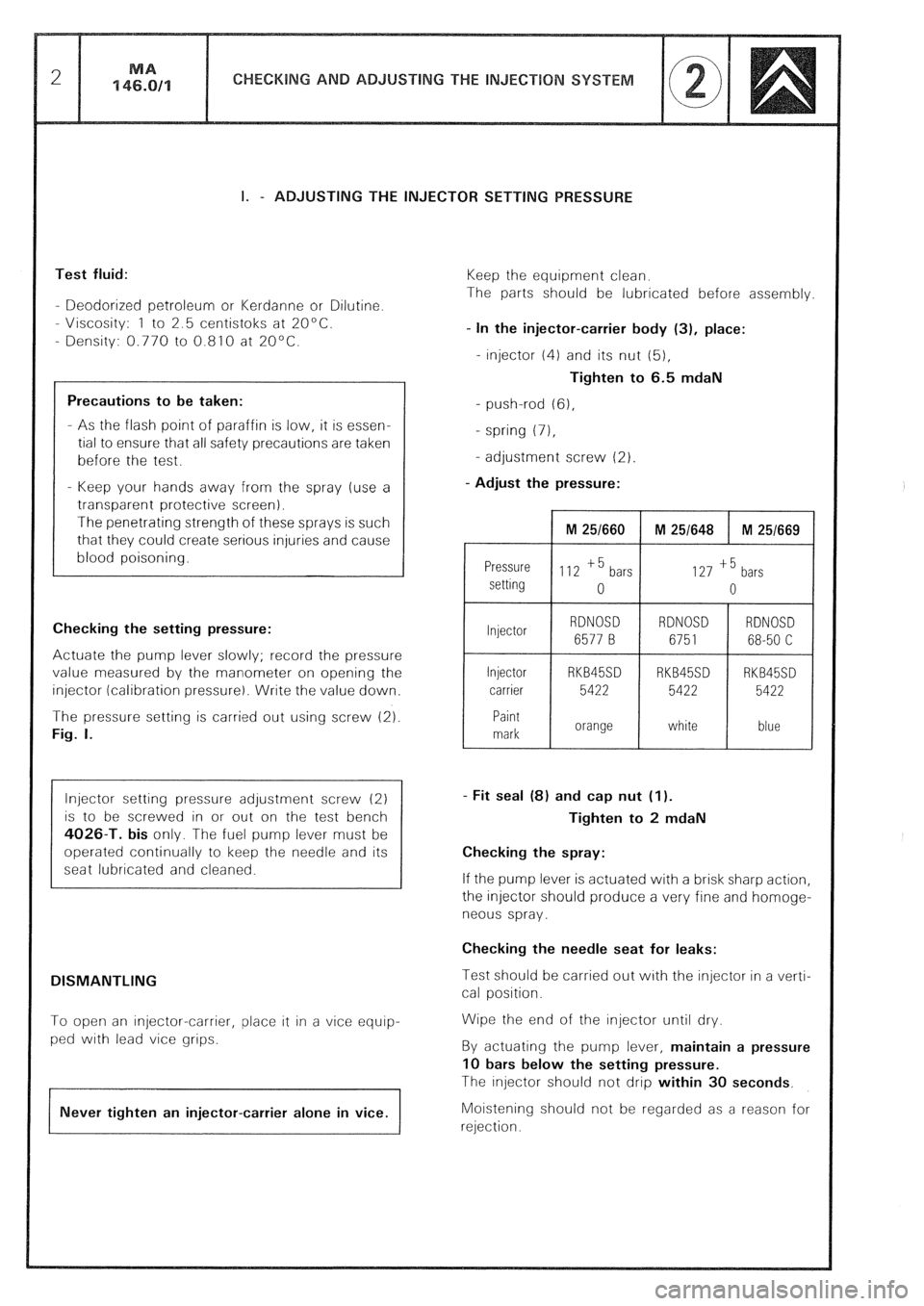

I. - ADJUSTING THE INJECTOR SETTING PRESSURE

Test fluid: Keep the equipment clean.

- Deodorized petroleum or Kerdanne or Dilutine. The parts should be lubricated before assembly.

- Viscosity: 1 to 2.5 centistoks at 2O’C.

- Density: 0.770 to 0.810 at 2O’C. - In the injector-carrier body (31, place:

- injector (4) and its nut (5),

Tighten to 6.5 mdaN

Precautions to be taken:

- push-rod (6),

- As the flash point of paraffin is low, it is essen-

- spring (7),

tial to ensure that all safety precautions are taken

before the test. - adjustment screw (2).

- Keep your hands away from the spray (use a - Adjust the pressure:

transparent protective screen).

The penetrating strength of these sprays is such

that they could create serious injuries and cause M 251660 M 251648 M 25/669

blood poisoning.

Pressure

112 t5 bars 127 t5 bars

setting

0 0

Checking the setting pressure: Injector RDNOSD RDNOSD RDNOSD

6577 B 6751 68-50 C

Actuate the pump lever slowly; record the pressure

value measured by the manometer on opening the Injector RKB45SD RKB45SD RKB45SD

Injector (calibration pressure). Write the value down. carrier 5422 5422 5422

The pressure setting is carried out using screw (2). Paint

Fig. I. mark orange white blue

Injector setting pressure adjustment screw (2)

is to be screwed in or out on the test bench

operated continually to keep the needle and its

If the pump lever is actuated with a brisk sharp action,

the injector should produce a very fine and homoge-

neous spray.

Checking the needle seat for leaks:

DISMANTLING Test should be carried out with the injector in a verti-

cal position.

To open an injector-carrier, place it in a vice equip- Wipe the end of the injector until dry.

ped with lead vice grips.

By actuating the pump lever, maintain a pressure

10 bars below the setting pressure.

The injector should not drip within 30 seconds,

Never tighten an injector-carrier alone in vice. Moistening should not be regarded as a reason for

rejection.

Page 213 of 648

CHECKING AND ADJUSTING

THE INJECTION SYSTEM

III. - ADJUSTING THE ROTO-DIESEL INJECTION PUMP CONTROLS

DPC type pump from engine M 25/648, Fig. I

DPA type pump from engine M 25/660, Fig. II

Checking the fast-idle control

Ensure that lever (7) is against its stop, by pushing

it in the direction of arrow (-).

If not, adjust tension of cab/e by means of cable end

clamp (6). Complete tightening of cable using sheath

tensioner (41.

Checking the fast-idle control

Make sure that the cable is slack.

If not, check the operation of the thermal sensor (101

located on the water outlet duct: the cable must ope-

rate over a range of 6 mm between its “ENGINE

COLD” and “ENGINE WARM” positions.

Adjusting the accelerator control

Engine stopped:

Fully depress the accelerator pedal.

Check that lever (I) is against stop (2).

If not, move pin (3) of accelerator cable.

Make sure that, at idle, lever (I) is against stop (5).

Adjusting the anti-stalling device

Engine running:

Insert a 1.5 mm thick shim (DPC pump, Fig. I)

2 mm thick shim (DPA pump, Fig. II)

between lever (I) and stop-screw (5) at “b”.

Place a 3 mm dia. rod through the hole in lever (7)

at “a” by pushing STOP lever (9) outwards. Set the engine speed to:

800 t 50 rpm (DPC pump)

800 f 25 rpm (DPA pump)

by turning stop screw (5).

Remove the 3 mm dia. rod and the shim

Adjust the idling speed to:

800 + 25 rpm

by turning stop screw (8).

Checking the engine deceleration:

Accelerate the engine to 3.000 rpm, then release the

accelerator lever sharply.

- if the deceleration is too fast (engine often stalling),

unscrew stop-screw (5) by 114 turn,

- if the deceleration is too slow (poor engine braking),

screw up stop-screw (51 by l/4 turn.

In both cases, check the idling speed and adjust if

necessary.

If the malfunction continues to exist, carry out the

adjustments again.

Check the efficiency of the mechanically operated

STOP control (9).

Note: The setting figures are identical if the vehicle

is equipped with air-conditioning and the adjustments

are to be effected with the air-conditioning off.

Page 286 of 648

FRONT MA

412.1/l 1

RECOMMENDED TOOLS

6303-T.

Upper arm shaft extractor. 6320-T.

Anti-roll bar link rod extractor 6602-T.

Set of three stands.

REMOVING AND REFITTING

AN UPPER WHEEL ARM

8531-8532

Page 287 of 648

REMOVING AND REFITTING

AN UPPER WHEEL ARM

REMOVAL

Raise and support the front of the vehicle on stands

6602-T.

Depressurize the hydraulic circuit.

Set the height control lever to the (( low )) position

Remove, Fig. I :

- the wheel,

- the suspension cylinder pivot retaining pin (I 1,

- the anti-roll bar link rod nut (2).

Uncouple ball-joint (3) from the anti-roll bar link rod

using puller 6320-T. Fig. II.

Screw up the tool nut in the ball-joint stem. Fit the

tool cross piece and pin.

Extract, Fig. Ill,

- the nut from upper ball-joint (4).

Disconnect the upper ball-joint.

NOTE:

If the vehicle is fitted with the ABS, the removal of

the upper ball-joint nut requires pushing back the

transmission.

Remove:

- the pin, C

- the nut lock,

- the drive-shaft nut.

Fig. IV

- nut (51,

Fig. V

- the spindle with extractor 6303-T.

Remark: An adjustment shim may be found between

the arm and the front face of the subframe. REFITTING

The LH wheel arm is different from the RH one. Boss

u a )a should be directed towards the rear of the

vehicle when the wheel arm has been fitted.

Reinstall, Fig. V :

- the arm fitted with its thrust cups (7)

frhe thinner cup facing rearwardsl,

- the adjustment shim (6) found on dismantling, facing

forward.

Engage the spindle ; place a new NYLSTOP nut.

Tighten to 12.5 mdaN

Recouple the upper ball-joint.

Tighten the new NYLSTOP nut to 7 mdaN

Reconnect the anti-roll bar link rod (wipe the ball-joint

fixing but do nor use solventl.

Tighten the new NYLSTOP nut to 4.7 mdaN

Refit the suspension cylinder pivot and pin.

Vehicles equipped with the ABS:

Fit the drive-shaft nut (with the faces and threads

lubricated).

Tighten to 37.5 mdaN.

Replace:

- the nut lock,

- the pin,

- the road wheel