engine CITROEN CX 1988 User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1988, Model line: CX, Model: CITROEN CX 1988Pages: 648, PDF Size: 95.8 MB

Page 107 of 648

Toothed sector for locking the engine flywheel REMOVING/REFITTING THE TIMING

BUT, ON THE VEHICLE

---____ .-

Page 108 of 648

loosen, Fig II,

- valve rocket adjustrnr:nt screws (4) so as to reduce

the stresses irl the camshaft.

Fit: Fig. 111,

- tool 6012-T, once the engine flywheel protective

plate has been rernoved

Remove, Fig. IV:

- the HH wheelarch rubber sealing strtp,

- the al&l-nator belt and housing,

- crankshaft pulley (5),

- timing belt casing 161,

- tool

6012-T, Fig. III

Slacken, Fig. IV,

- the two XI-ews (7) and 18) securing the autornatlc

tensioner by a half turn,

Compress the tensioner spring and retighterl screws

(71 and 18).

Remove:

the timing belt. Crarlkshaft rotation, two pnss~ble rrrothotls

a) i-rlgage the irighest gear and tul n the clank-

shaft by means oi the road wheel OI the wheel i-tub

b) Rotate ti-le crankstlaft 1i1 the normal direction

of eqne rotation using the crankshaft pulley fixing

screw fitted with a ciistsnce piece

Position:

- the pistons at mid-point of their stroke

ith the crankshaft key placed horizontally).

djust the valve clearance

Inlet = 0.10 mm

Exhaust = 0.25 mm

Page 111 of 648

- crankshaft key horrrontally (with mark “c” stagge-

rred by 5’ upwards),

- mark “a” or “d” on camshaft,

- mark “b” on the rntermedrate shaft.

- Each timing mark on the belt must line up with the

tooth wheel marks.

Fit the belt (avoid contact with oil or grease).

Release, Fig. I and 111,

- tensioner roller screws (I 1 and 12) (let the spring act)

then tighten the screws.

Turn:

- the crankshaft 180’ clockwise.

Do not turn backwards

Release:

- the tensioner roller fixing screws then retrghten

starting with the upper screw (I ), Fig. I and Ill.

Turn:

- the crankshaft a further two turns clockwise.

Slacken, Fig. I and Ill:

- tensioner roller screws (1) and (21, (let the spring

react),

- then retighten starting with screw (I 1.

Fit:

- tool 6012-T., Fig. II. Install, Fig. lb:

the trming belt casing,

crankshaft pulley 13),

trghten screw (4)

to 8 mdaN on engine --r-829.A5

to 12.5 mdaN on engrne -+J6T.A5QQ

- the alternator belt and cover,

- the wheelarch rubber sealing strip.

Remove, Fig. II,

- tool 6012-T.

Fit:

- the cylinder head cover and gasket

ttightenrng torque: 0.6 mdaN).

Recouple:

- the accelerator control rod,

- the flexible hose,

- the cold start flap control cable.

Refit:

- the wheel,

Lower the vehicle to the ground.

NOTE:

- Camshaft toothed pulleys of engines 829.A5 and

J6T.A500 are identical but the fitment is different,

Fig. I.

- If, after carrying out the belt tensioning operation,

the timing belt is noisy when the engine is hot,

retension the belt with the engine hot.

Page 116 of 648

emove:

the I-oati Wi-l~~d,

- the wheelarch lrnrrng,

- the belt protectron covets

Position: Fig. I and II

the valves of cylrnder No. 1 rn the “rocking” ~OSI-

tion (look Into the engine 011 filler),

the flywheel wrth mar-ks- -alrgned,

- camsfraft gear wheel mark A opposite screw 12)

Loosen:

the nuts of the tensioners and compress the spring

of eacir tensloner. Hetighten the nuts.

Remove:

- injection pump belt,

- the trmrng belt

REFITTING

Fit, Fig. II:

the timrng belt- marks t-+-) and i-e-1 on the belt

should face the marks A and B on pinrons (there

are 35 pitches between A and B, passing around

the tensloner roller (I 1).

Loosen the nuts of the tensioner roller.

Install, Fig. III:

- tool 6Q28-T.K. on the roller

- the tool weight over the mark 2 of the rod, Fig 1V. Fitting the injection pump belt:

Run the engrne by 1 turn err the drrectrorr of rotation

until marks--- +- /Ino up, Fig. I

(wrth cylinder No 1 at the rnrtral trmrng

point)

Setting the pump to the injection point:

refer to Op @ MA. 146-011

Fit the InJectron purnf, drrvrng belt with the srde oppo-

site the roller, trght.

Slacken the roller nut. Let the roller- spring react

Tighten the rnut to 2 mdaN.

Rotate the engine by 2 turns in the direction of nor-

rnal rotation and check the pump timrng.

Remove the tools

Start the engine Warrn it up until the electric cooling

fans operate.

Retension the belt while the engine is hot, Fig. IV

Refit:

- the protectron covers,

- the wheelarch lining,

the road wheel

Page 119 of 648

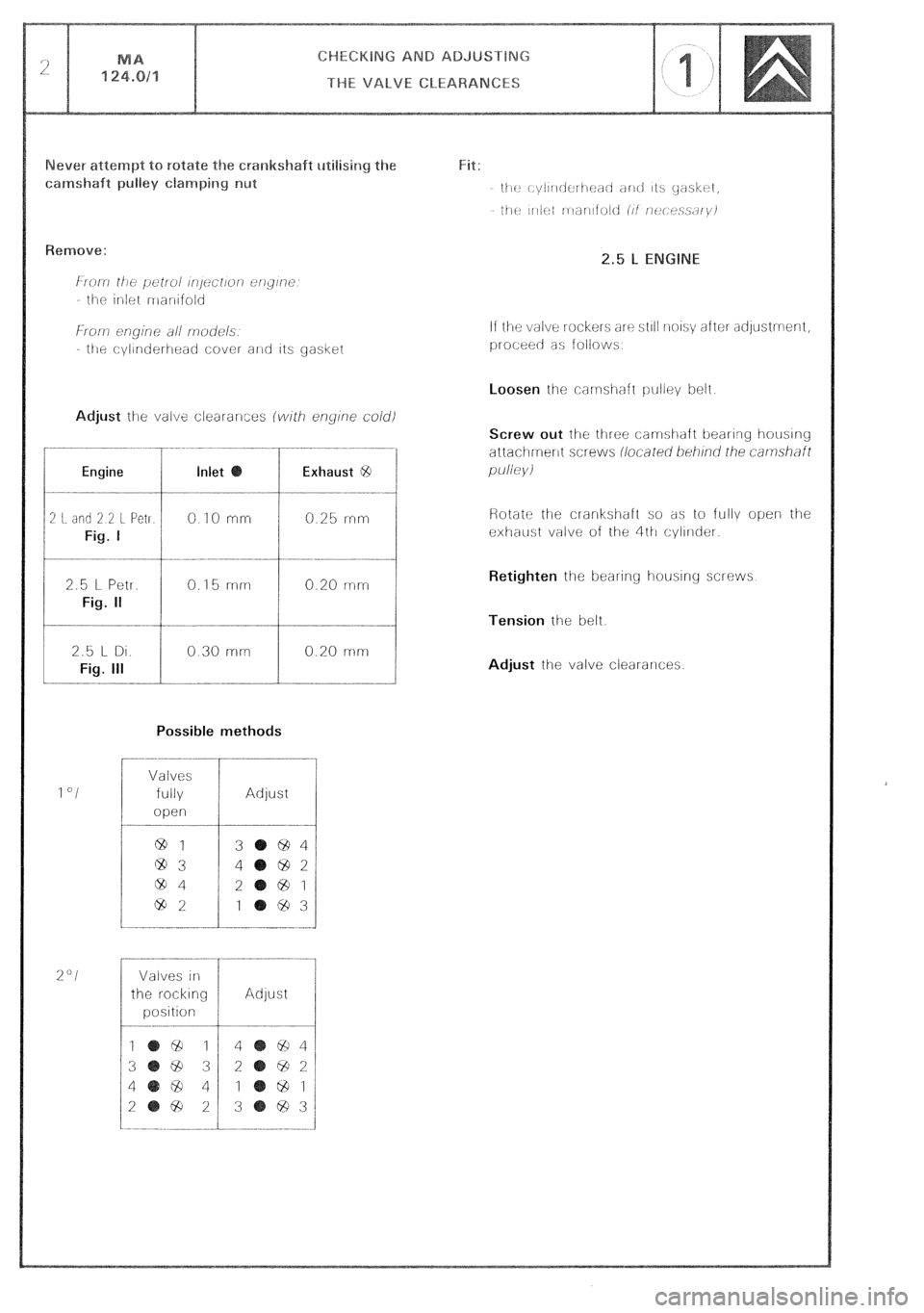

Engine Inlet Exhaust @

2 I. did 2 2 L Pet1

Fig. I

0 IO rnrr 0.25 rrirr

2.5 l- Petr.

Fig. II

0.15 mm 0.20 mm

Possible methods

1 “I

%“I

Valves

fully

open

64 1

@3

ciD4

69%

Adjust

3 694

4 692

2

@ 1

1 ‘83

Valves in

the r-ocklng

position Adjust If the valve rockers arc? sl~l! noIs\; after adystment,

proceec as follows

Screw out lhe three carmshaft bearing houslng

attachment screws iiocared beii/no’ rhe

carnshfl

pu//e)/i

Retighten

the beal-ing housing screws

Tension the belt.

Adjust the valve clearances.

Page 122 of 648

CHECKING AND ADJUSTING

THE ENGINE SUPPORT BRACKETS

-.~ ~.~ -.-... --- >

Page 132 of 648

ht into front exhaust pope (I ) the ball~joint (6) plus

joint

Tighter to 2.5 mdaN.

Ftt the turbine housing (51 vuith a seal

Engage clamp 141 oli the turbine 4 studs (3)

Slide a 5 rnn- thick shim between the sump and

pipe (I ) to allow for a clearance

M25/662, type engine: insert a seal between waste-

pipe 12) and the turbocharger.

Fit the 4 spacers and nuts to the turbine fixing studs (3).

Tighter to 2.5 mdaN in the order 1 - 2 - 3 - 4.

M25/648, type engine: position the clamp and the

seal of waste-pipe (2). Locate the 3 screws and nuts.

Tighten to 2.5 mdaN.

Adjust ball-jotnt support plate 17) fitted with flexible

lug (8) position, and hold It In an intermediate

pow

tion by means of 2 screws

Pile up RP distance pieces of various thicknesses bet-

ween the ball-joint and its flexible lug , ilefer to 1911.

Insert the ball-joint bolt (1 0).

Slacker ttre 2 ball-joint support plate screws (7) and

fit the other 2 attachment points without tightening Screw 111 ball-Joirnt t~old~ny down bolt (I 0) to 5 mdaN.

Do up ball Joint support plate (7) 4 attachment points

Page 147 of 648

- Remove the ileader tank cap

Refit the cap

Run

the engine at 2000 rprrl approx , until the cooling fan(s) has (have) cut In

NEVER OPEN THE CAP OF THE HEA

OPERATING. THE ELECTRIC COOLING FAN(S) IS (ARE)

Top up

the coolant tevel in the header tank

Page 157 of 648

GENERAL FEATURES OF THE CARBURATION

FITTING. Fig. I:

5. FIN the tamper-proof protective plug (a):

- load gun A,

- screw tool E onto gun A,

- position plug (a) in its housing on the carburettor (make sure it is fitted the right way round Fig. 111,

- actuate the gun until the plug is properly located.

EXHAUST EMISSION CONTROL

In order to comply with current regulations, the checking and adjustment of the exhaust emission from vehicles

with a petrol engine must, without fail, be performed after the following operations:

I. ENGINE REPLACEMENT.

II. CARBURETTOR REPLACEMENT.

Ill. WORK ON THE CARBURETTOR.

Replacement of parts of the carburettor.

Carburettor adjustment.

Work on the carburettor controls.

IV. WORK ON THE INLET MANIFOLD.

Replacement or removal of:

- the inlet manifold,

- the air filter,

- crankcase gas recirculation system

V. WORK ON THE ENGINE.

Rocker adjustment.

Replacement or removal of:

- the cylinder head,

- the camshaft,

- the rockers,

- the valves,

- the liners and pistons.

VI. WORK ON THE IGNITION.

Replacement or reconditioning of the distributor (wholly or partially)

Adjustment or replacement of the sparking plugs.

Adjustment of the ignition timing.

VII. WORK ON EXHAUST SYSTEM.

Replacement or removal of:

- the exhaust manifold,

- the silencer or any part of the exhaust.

VIII. WORK ON THE EMISSION CONTROL SYSTEM.

When the vehicle is fitted with a specific equipment (e.g. on vehicles of SWEDEN, AUSTRALlA or JAPAN type)

Page 160 of 648

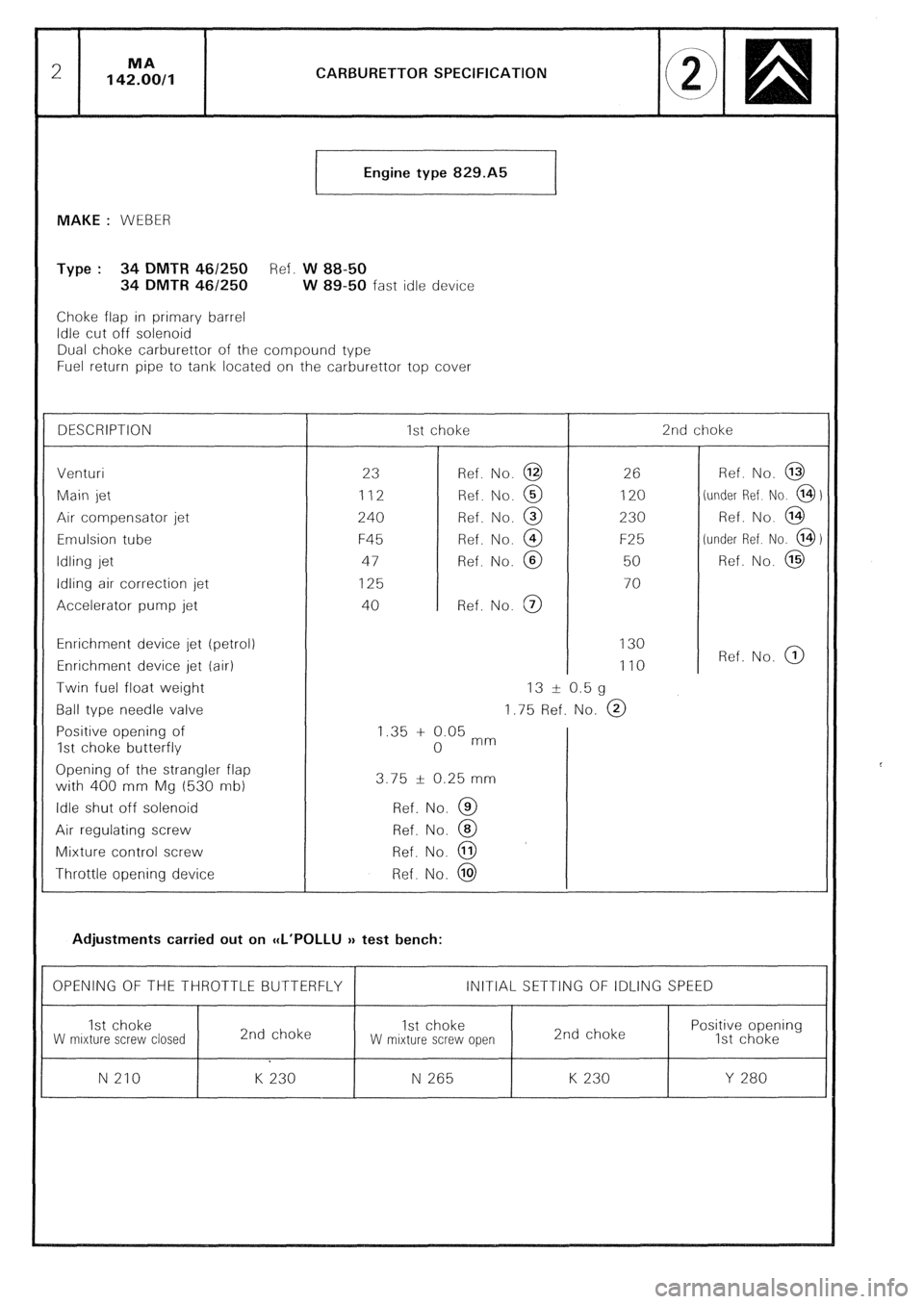

CARBURETTOR SPECIFICATION

Engine type 829.A5

t

MAKE : WEBER

Type : 34 DMTR 461250 Ref. W 88-50

34 DMTR 46/250 W 89-50 fast idle device

Choke flap in primary barrel

Idle cut off solenoid

Dual choke carburettor of the compound type

Fuel return pipe to tank located on the carburettor top cover

DESCRIPTION 1st choke 2nd choke

Venturi

23 Ref. No. @ 26 Ref. No. @

Main jet 112 Ref. No. @ 120 (under Ref No. @)

Air compensator jet

240 Ref. No. @ 230 Ref. No. @

Emulsion tube F45 Ref. No. @ F25 (under Ref. No. @)

Idling jet 47 Ref. No. @ 50 Ref. No. @

Idling air correction jet

125 70

Accelerator pump jet 40 Ref. No. @

Enrichment device jet (petrol) 130

Enrichment device jet (air) 110 Ref. No. @

Twin fuel float weight 13 -t 0.5 g

Ball type needle valve 1.75 Ref. No. @

Positive opening of 1.35 + 0.05 mm

1st choke butterfly 0

Opening of the strangler flap

with 400 mm Mg (530 nib) 3.75 f 0.25 mm

Idle shut off solenoid Ref. No. @

Air regulating screw Ref. No. @

Mixture control screw Ref. No. @

Throttle opening device Ref. No. @

Adjustments carried out on CCL’POLLU v test bench:

OPENING OF THE THROTTLE BUTTERFLY INITIAL SETTING OF IDLING SPEED

1st choke

2nd choke 1st choke Positive opening

W mrxture screw closed W mixture screw open 2nd choke

1st choke

N 210 K 230 N 265 K 230 Y 280