weight CITROEN CX 1988 Service Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1988, Model line: CX, Model: CITROEN CX 1988Pages: 648, PDF Size: 95.8 MB

Page 116 of 648

emove:

the I-oati Wi-l~~d,

- the wheelarch lrnrrng,

- the belt protectron covets

Position: Fig. I and II

the valves of cylrnder No. 1 rn the “rocking” ~OSI-

tion (look Into the engine 011 filler),

the flywheel wrth mar-ks- -alrgned,

- camsfraft gear wheel mark A opposite screw 12)

Loosen:

the nuts of the tensioners and compress the spring

of eacir tensloner. Hetighten the nuts.

Remove:

- injection pump belt,

- the trmrng belt

REFITTING

Fit, Fig. II:

the timrng belt- marks t-+-) and i-e-1 on the belt

should face the marks A and B on pinrons (there

are 35 pitches between A and B, passing around

the tensloner roller (I 1).

Loosen the nuts of the tensioner roller.

Install, Fig. III:

- tool 6Q28-T.K. on the roller

- the tool weight over the mark 2 of the rod, Fig 1V. Fitting the injection pump belt:

Run the engrne by 1 turn err the drrectrorr of rotation

until marks--- +- /Ino up, Fig. I

(wrth cylinder No 1 at the rnrtral trmrng

point)

Setting the pump to the injection point:

refer to Op @ MA. 146-011

Fit the InJectron purnf, drrvrng belt with the srde oppo-

site the roller, trght.

Slacken the roller nut. Let the roller- spring react

Tighten the rnut to 2 mdaN.

Rotate the engine by 2 turns in the direction of nor-

rnal rotation and check the pump timrng.

Remove the tools

Start the engine Warrn it up until the electric cooling

fans operate.

Retension the belt while the engine is hot, Fig. IV

Refit:

- the protectron covers,

- the wheelarch lining,

the road wheel

Page 160 of 648

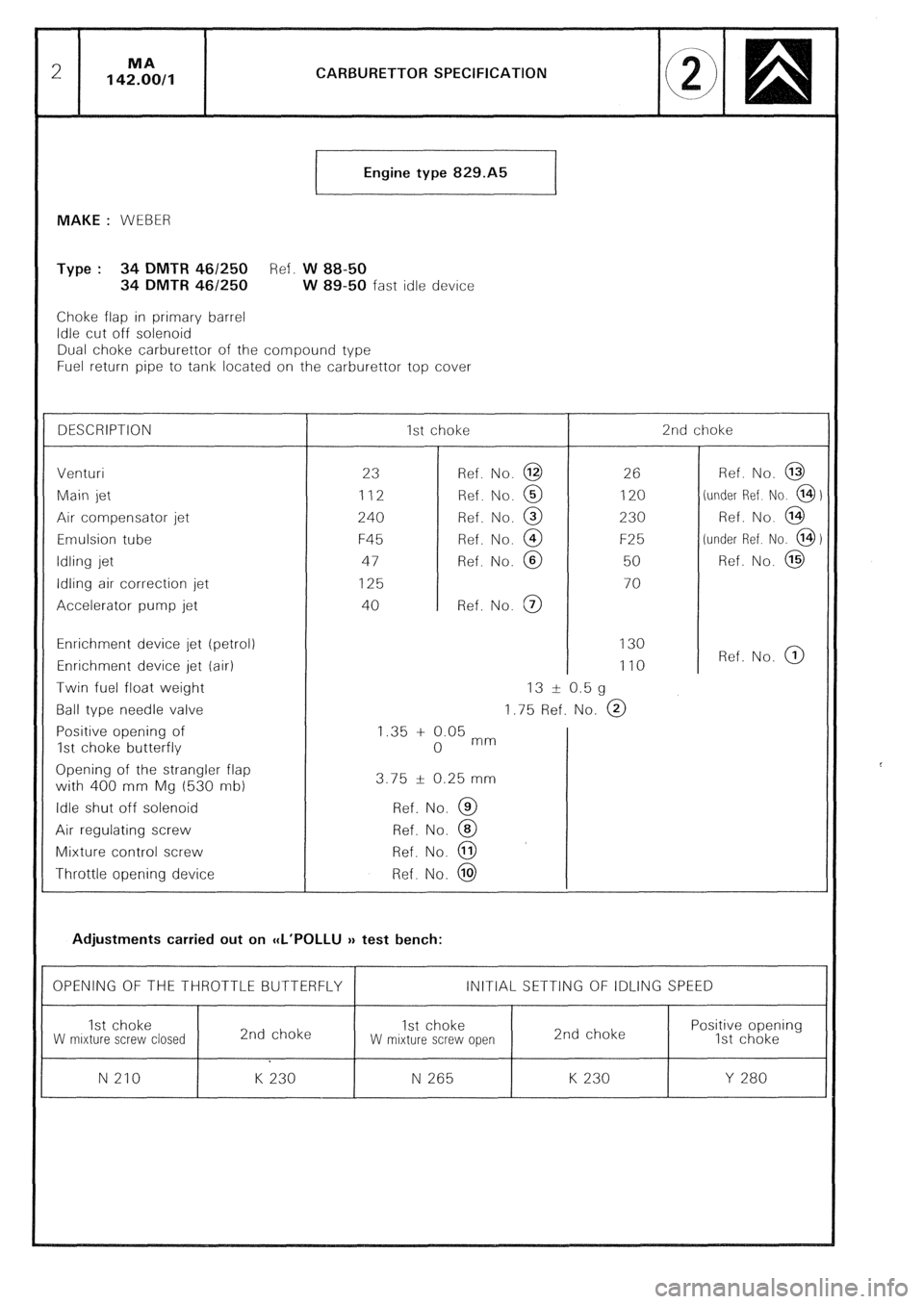

CARBURETTOR SPECIFICATION

Engine type 829.A5

t

MAKE : WEBER

Type : 34 DMTR 461250 Ref. W 88-50

34 DMTR 46/250 W 89-50 fast idle device

Choke flap in primary barrel

Idle cut off solenoid

Dual choke carburettor of the compound type

Fuel return pipe to tank located on the carburettor top cover

DESCRIPTION 1st choke 2nd choke

Venturi

23 Ref. No. @ 26 Ref. No. @

Main jet 112 Ref. No. @ 120 (under Ref No. @)

Air compensator jet

240 Ref. No. @ 230 Ref. No. @

Emulsion tube F45 Ref. No. @ F25 (under Ref. No. @)

Idling jet 47 Ref. No. @ 50 Ref. No. @

Idling air correction jet

125 70

Accelerator pump jet 40 Ref. No. @

Enrichment device jet (petrol) 130

Enrichment device jet (air) 110 Ref. No. @

Twin fuel float weight 13 -t 0.5 g

Ball type needle valve 1.75 Ref. No. @

Positive opening of 1.35 + 0.05 mm

1st choke butterfly 0

Opening of the strangler flap

with 400 mm Mg (530 nib) 3.75 f 0.25 mm

Idle shut off solenoid Ref. No. @

Air regulating screw Ref. No. @

Mixture control screw Ref. No. @

Throttle opening device Ref. No. @

Adjustments carried out on CCL’POLLU v test bench:

OPENING OF THE THROTTLE BUTTERFLY INITIAL SETTING OF IDLING SPEED

1st choke

2nd choke 1st choke Positive opening

W mrxture screw closed W mixture screw open 2nd choke

1st choke

N 210 K 230 N 265 K 230 Y 280