ignition Citroen DS3 2014 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2014, Model line: DS3, Model: Citroen DS3 2014 1.GPages: 376, PDF Size: 12.55 MB

Page 200 of 376

DS3_en_Chap10_info-pratiques_ed01-2014

Freezing of the AdBlue®

additive

The adblue® additive freezes at

temperatures below around -11°C.

The

SCR

system includes a heater for

t

he

a

d

blu

e

® tank.

I

n

exceptional circumstances (vehicle

k

ept

for

a

long period at temperatures

t

hat

are

constantly below -15°C), an

e

missions

control system fault alert

m

ay

be

related to freezing of the

a

d

blu

e

® in your vehicle.

P

ark

your vehicle in a warmer area for

a

few

hours until the additive becomes

li

quid

a

gain.

The

emissions alert does not go off

i

mmediately, it will occur after several

m

ile

of

running.

You

have

exceeded

the

authorised

d

riving

limit:

the

starting

prevention

s

ystem

inhibits

engine

starting.

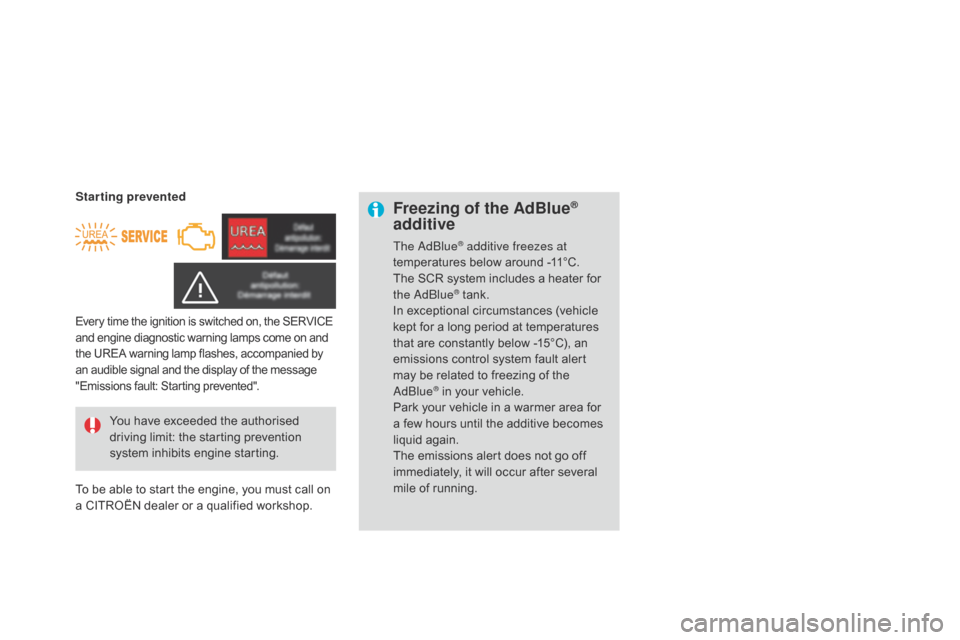

Every time the ignition is switched on, the SERVICE a nd engine diagnostic warning lamps come on and t

he UREA warning lamp flashes, accompanied by

a

n audible signal and the display of the message

"

Emissions fault: Starting prevented".

Starting prevented

To

be able to start the engine, you must call on

a

CITROËN dealer or a qualified workshop.

Page 202 of 376

DS3_en_Chap10_info-pratiques_ed01-2014

Never store bottles of adblue® in

your vehicle.

a

d

blu

e

® freezes at about -11°C and d

eteriorates above 25°C. It is recommended

t

hat bottles be stored in a cool area and

protected

from direct sunlight.

Under these conditions, the additive can be

kept

for

at least a year.

If the additive has frozen, can be used once it

has

completely thawed out.

Recommendations on storage

Before topping-up, ensure that the vehicle is parked on a flat and level sur face.

In wintry conditions, ensure that the

temperature

of the vehicle is above -11°C.

O

ther wise, by freezing, the AdBlue

® cannot

be

poured

into

its

tank.

Park

your

vehicle in a

w

armer

area

for

a

few

hours

to

allow the top-up

t

o

be

carried

out.

Procedure

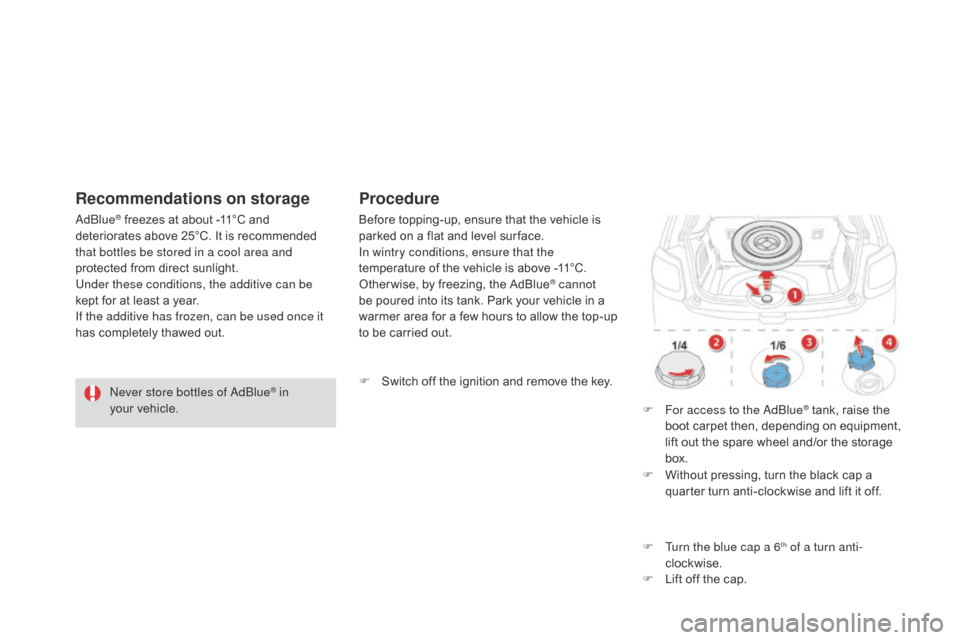

F Switch off the ignition and remove the key.

F

F

or access to the a

dbl

ue

® tank, raise the b

oot

carpet

then,

depending on equipment,

l

ift

out

the

spare

wheel

and/or the storage

b

ox.

F

W

ithout

pressing,

turn

the

black cap a

q

uarter

turn

anti-clockwise and lift it off.

F

T

urn the blue cap a 6

th of a turn anti-

clockwise.

F

L

ift

off

the

cap.

Page 203 of 376

201

DS3_en_Chap10_info-pratiques_ed01-2014

Important: if your vehicle's a

dblu e® tank is completely empty - w

hich

is

confirmed by the alert

m

essages and the impossibility of

s

tarting

the engine, you must add at

l

east

3.8 litres (so two 1.89 litre bottles).If any additive is split or splashed, wash

immediately

with cold water or wipe

w

ith a damp cloth.

If the additive has crystallised, clean it

off using a sponge and hot water.Important:

i

n the event of a top-up after

a breakdown because of a lack of

additive , signalled by the message "Top

u

p emissions additive: Starting prevented",

y

ou must wait around 5 minutes before

s

witching

o

n

t

he

i

gnition,

w

ithout opening

the driver's door, locking the vehicle

or introducing the key into the ignition

switch .

Switch on the ignition, then, after

1

0 seconds, start the engine.

F

o

b

tain a bottle of a

dbl

ue

®. After first c

hecking

the

use-by

date,

read carefully

t

he instructions on use on the label before

pouring

the

contents

of

the bottle into your

v

ehicle's

a

d

blu

e

® tank. N ever dispose of a

dbl

ue

® additive

bottles

in

the

household

waste. Place

t

hem

in

a

special

container provided

t

his

purpose

or

take

them

to your

d

ealer.

F

A

fter

emptying

the

bottle,

wipe

away

any

s

pillage

around

the

tank

filler

using

a

damp

c

loth.

F

R

efit

the

blue

cap

to

the

tank

and

turn

it

a

6

th of a turn clockwise, to its stop.

F

R

efit the black cap and turn it a quarter of

a

turn clockwise without pressing. Ensure

t

hat the indicator on the cap lines up with

the

indicator on the support.

F

D

epending on equipment, return the spare

w

heel and/or the storage box to the bottom

o

f

the boot.

F

R

efit the boot carpet and close the tailgate.

Practical information

Page 205 of 376

203

DS3_en_Chap10_info-pratiques_ed01-2014

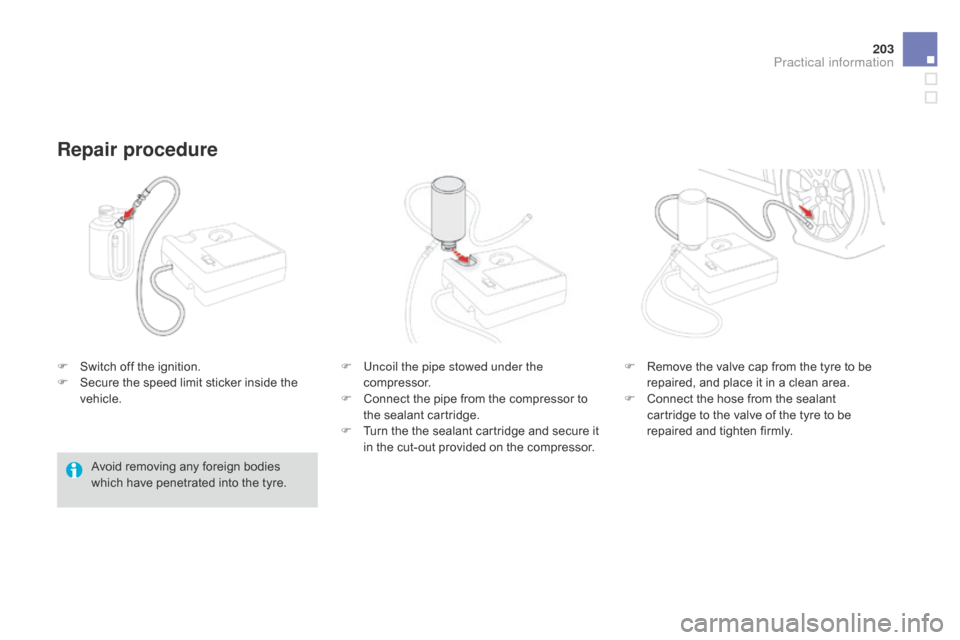

F Switch off the ignition.

F S ecure the speed limit sticker inside the

v

ehicle.

Repair procedure

Avoid removing any foreign bodies which have penetrated into the tyre.F

U

ncoil the pipe stowed under the

compressor.

F

C

onnect the pipe from the compressor to

t

he sealant cartridge.

F

T

urn the the sealant cartridge and secure it

i

n the cut-out provided on the compressor.F

R

emove the valve cap from the tyre to be

r

epaired, and place it in a clean area.

F

C

onnect the hose from the sealant

c

artridge to the valve of the tyre to be

r

epaired and tighten firmly.

Practical information

Page 206 of 376

DS3_en_Chap10_info-pratiques_ed01-2014

If after around 5 to 7 minutes the pressure is not attained, this indicates

that

the tyre is not repairable; contact

a C

ITR

oË

N dealer or a qualified

workshop

for assistance.

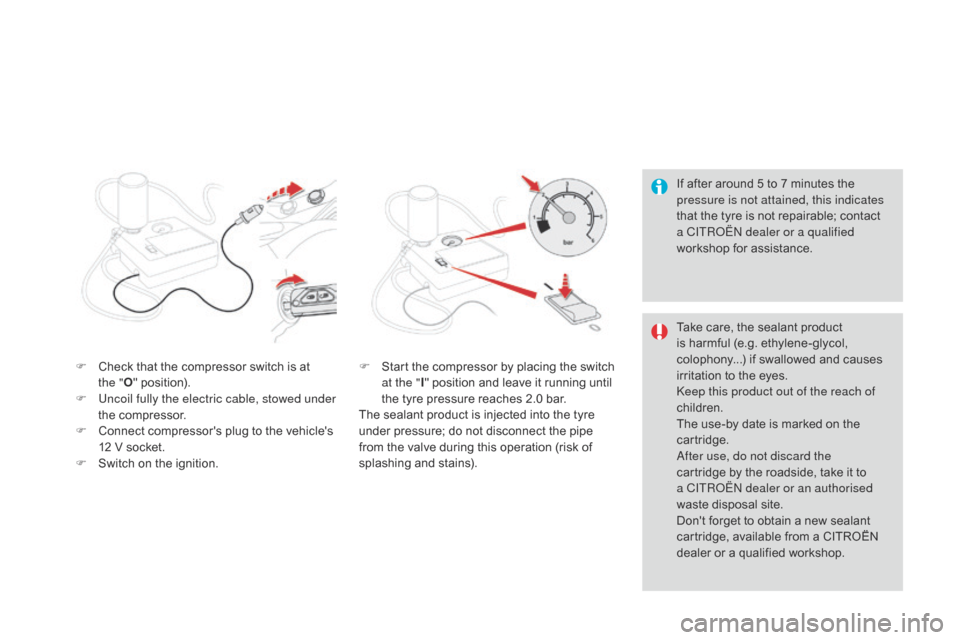

F

C

heck

that

the

compressor

switch

is

at

t

he

" O "

position).

F

U

ncoil fully the electric cable, stowed under

the

compressor.

F

C

onnect

compressor's

plug

to

the

vehicle's

1

2

V

socket.

F

S

witch

on

the

ignition. F

S

tart

the

compressor

by

placing

the

switch

a

t the " I"

position

and

leave

it

running

until

t

he

tyre

pressure

reaches

2.0

bar.

The

sealant

product

is

injected

into

the

tyre

u

nder

pressure;

do

not

disconnect

the

pipe

f

rom

the

valve

during

this

operation

(risk

of

sp

lashing

an

d

s

tains). Take

care, the sealant product

i

s harmful (e.g. ethylene-glycol,

c

olophony...) if swallowed and causes

i

rritation to the eyes.

ke

ep this product out of the reach of

children.

The

use-by date is marked on the

c

artridge.

af

ter use, do not discard the

cartridge

by the roadside, take it to

a C

ITR

oË

N dealer or an authorised

waste

disposal site.

Don't

forget to obtain a new sealant

c

artridge, available from a CITROËN

d

ealer or a qualified workshop.

Page 207 of 376

205

DS3_en_Chap10_info-pratiques_ed01-2014

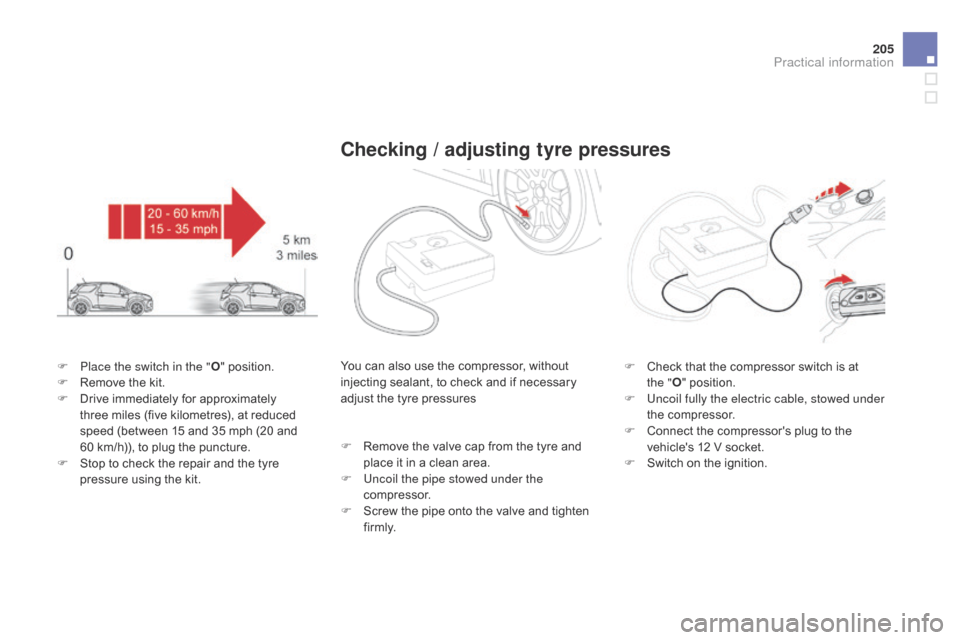

F Place the switch in the "O" position.

F R emove the kit.

F

D

rive immediately for approximately

t

hree miles (five kilometres), at reduced

s

peed (between 15 and 35 mph (20 and

6

0 km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

p

ressure using the kit.

checking / adjusting tyre pressures

You can also use the compressor, without injecting sealant, to check and if necessary

a

djust the tyre pressures

F

R

emove the valve cap from the tyre and

p

lace it in a clean area.

F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f

i r m l y. F

C heck that the compressor switch is at

t

he "O "

position.

F

U

ncoil fully the electric cable, stowed under

the

compressor.

F

C

onnect the compressor's plug to the

v

ehicle's 12 V socket.

F

S

witch on the ignition.

Practical information

Page 228 of 376

DS3_en_Chap10_info-pratiques_ed01-2014

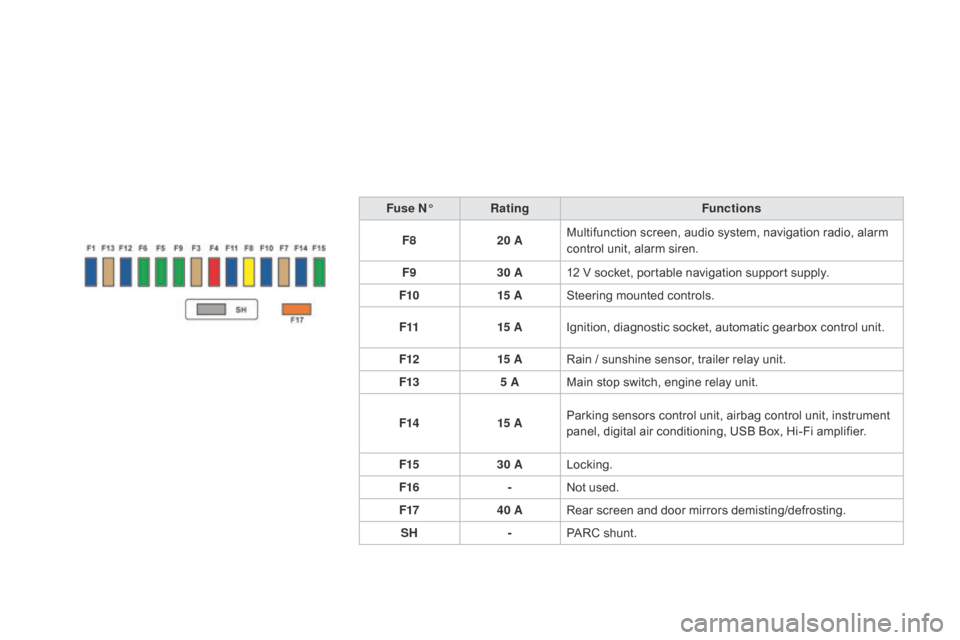

Fuse N°Rating Functions

F8 20 AMultifunction

screen, audio system, navigation radio, alarm

c

ontrol unit, alarm siren.

F9 30 A12

V socket, portable navigation support supply.

F10 15 ASteering

mounted controls.

F11 15 AIgnition,

diagnostic socket, automatic gearbox control unit.

F12 15 ARain

/ sunshine sensor, trailer relay unit.

F13 5 AMain

stop switch, engine relay unit.

F14 15 AParking

sensors control unit, airbag control unit, instrument

p

anel, digital air conditioning, USB Box, Hi-Fi amplifier.

F15 30 ALocking.

F16 -Not

used.

F17 40 ARear

screen and door mirrors demisting/defrosting.

SH -PARC

shunt.

Page 230 of 376

DS3_en_Chap10_info-pratiques_ed01-2014

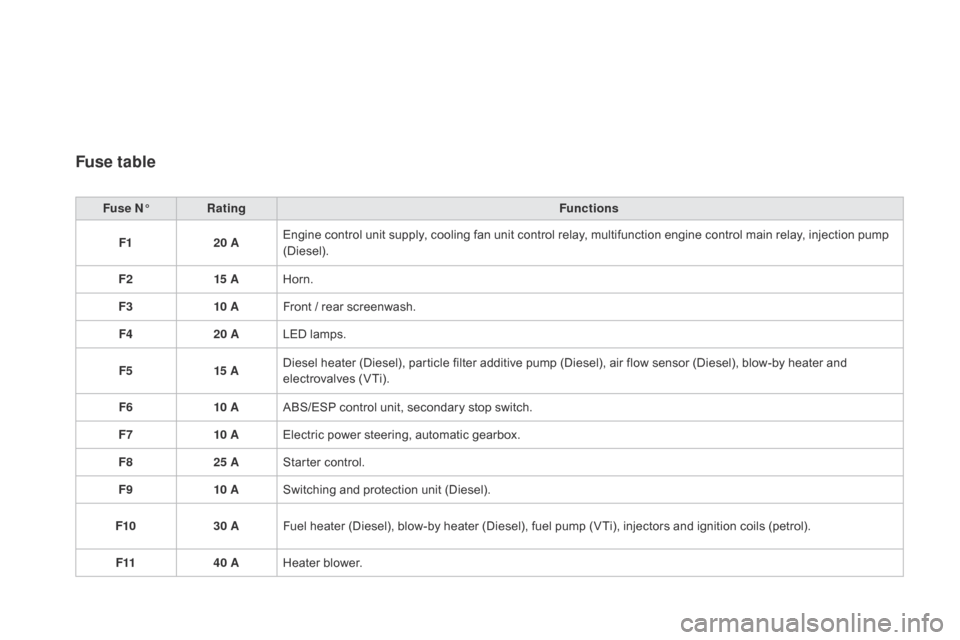

Fuse table

Fuse N°Rating Functions

F1 20 AEngine

control unit supply, cooling fan unit control relay, multifunction engine control main relay, injection pump

(

Diesel).

F2 15 AHorn.

F3 10 AFront

/ rear screenwash.

F4 20 ALED

lamps.

F5 15 ADiesel

heater (Diesel), particle filter additive pump (Diesel), air flow sensor (Diesel), blow-by heater and

e

lectrovalves (VTi).

F6 10 AABS/ESP

control unit, secondary stop switch.

F7 10 AElectric

power steering, automatic gearbox.

F8 25 AStarter

control.

F9 10 ASwitching

and protection unit (Diesel).

F10 30 AFuel

heater (Diesel), blow-by heater (Diesel), fuel pump (VTi), injectors and ignition coils (petrol).

F11 40 AHeater

b

lower.

Page 231 of 376

229

DS3_en_Chap10_info-pratiques_ed01-2014

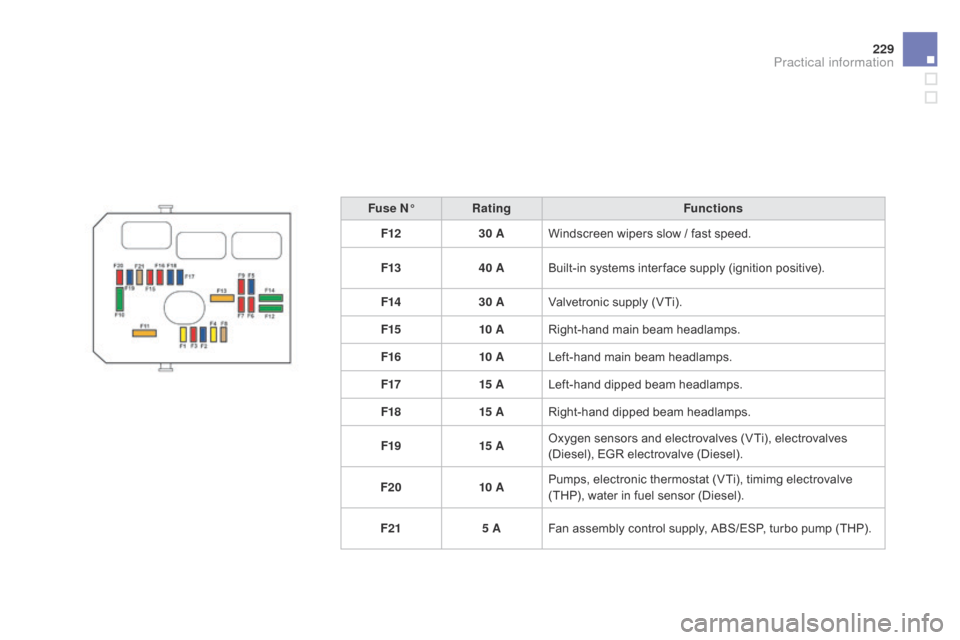

Fuse N°Rating Functions

F12 30 AWindscreen

wipers slow / fast speed.

F13 40 ABuilt-in

systems inter face supply (ignition positive).

F14 30 AValvetronic

supply (VTi).

F15 10 ARight-hand

main beam headlamps.

F16 10 ALeft-hand

main beam headlamps.

F17 15 ALeft-hand

dipped beam headlamps.

F18 15 ARight-hand

dipped beam headlamps.

F19 15 AOxygen

sensors and electrovalves (VTi), electrovalves

(

Diesel), EGR electrovalve (Diesel).

F20 10 APumps,

electronic thermostat (VTi), timimg electrovalve

(

THP), water in fuel sensor (Diesel).

F21 5 AFan

assembly control supply, ABS/ESP, turbo pump (THP).

Practical information

Page 234 of 376

DS3_en_Chap10_info-pratiques_ed01-2014

When the battery on your vehicle is discharged, the engine can be started using a slave battery

(

external or on another vehicle) and jump leads.

Starting using another

battery

First check that the slave battery has a nominal voltage of 12 V and a capacity at least equal to

t

hat of the discharged battery.

Do

not try to start the engine by connecting a

b

attery charger.

Do

not disconnect the (+) terminal when the

e

ngine is running.

F

C

onnect the red cable to the positive

terminal

(+) of the flat battery A, then to the

positive

terminal (+) of the slave battery B.

F

C

onnect one end of the green or black

c

able to the negative terminal (-) of the

s

lave battery B (or earth point on the other

vehicle).

F

C

onnect

t

he

o

ther

e

nd

o

f

t

he

g

reen

o

r

b

lack

c

able to the negative terminal c

(or

the engine mounting) of the broken-

down

vehicle. F

S

tart the engine of the other vehicle and

a

llow it to run for a few minutes.

F

O

perate the starter of the broken-down

v

ehicle and let the engine run.

I

f the engine does not start immediately,

s

witch off the ignition and wait a few

m

oments before trying again.

F

W

ait until the engine returns to idle, then

d

isconnect the jump leads in reverse order.Some

functions are not available if the

b

attery is not sufficiently charged.