boot CITROEN DS3 2018 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2018, Model line: DS3, Model: CITROEN DS3 2018Pages: 248, PDF Size: 8.79 MB

Page 164 of 248

162

F After emptying the bottle or container, wipe away any spillage around the tank filler

using a

damp cloth.

If any AdBlue

® additive is spilt or splashed,

wash immediately with cold water or wipe

with a

damp cloth.

If the AdBlue

® has crystallised, clean it off

using a

sponge and hot water.

F

R

efit the blue cap to the tank filler and turn it

a

6

th of a turn clockwise, to its stop.

F

D

epending on equipment, return the spare

wheel and/or the storage box to the bottom

of the boot.

F

R

efit the boot carpet and close the tailgate.

Important: when topping up after

running out of AdBlue

®, you must wait

for around 5 minutes before switching

on the ignition, without opening the

driver's door , or unlocking the vehicle ,

or placing the key in the ignition

switch .

Switch on the ignition, then after

10

seconds, start the engine.

Advice on care and

maintenance

Recommendations on the care and

maintenance of your vehicle are given in the

Maintenance and Warranty Guide.

Textured paint

Textured paint reacts to light with variations of

appearance and finish that emphasise the car's

lines and form. This paint coating has particles

that remain visible and create a unique satin

relief effect. Its lightly granulated texture gives

it a

surprising feel. Observe the following recommendations

to avoid damaging the paint finish:

-

c

hoose a high pressure wash, or at

least a high water delivery; roller brush

washing is compatible.

-

g

ently wipe the body with a clean

microfibre cloth.

-

c

arefully wipe off any fuel spilt on the

body using a soft cloth, then allow to

d r y.

-

c

lean off minor marks (for example,

finger marks), using the product in the

"TECHNATURE" range intended for

removing insects.

H o w eve r,

-

d

o not select the programme with hot

wax finish.

-

d

o not use waterless cleaning.

-

n

ever polish the vehicle.

-

d

o not use paint restorers, abrasive

or polishing products, or bright paint

preser vers (wax polish, for example).

It is always preferable to have paint

repairs carried out in the dealer network or

by a

qualified workshop.

07

Practical information

Page 168 of 248

166

Access to the kit

This kit is installed in the under floor storage,

under the boot floor.

Composition of the kit

1.12 V compressor, with built-in pressure

gauge.

2. Bottle of sealant, with built-in hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition.

F

U

ncoil the pipe stowed under the

compressor.

Avoid removing any foreign bodies which

have penetrated the tyre. F

R

emove the valve cap from the tyre to be

repaired and keep it in a

clean place.

F

C

onnect the pipe from the compressor to

the bottle of sealant. F

T

urn over the sealant bottle and secure it in

the cut-out provided on the compressor.

F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly.

08

In the event of a breakdown

Page 171 of 248

169

If a pressure of 2 bars is not reached after

7 minutes, this indicates that the tyre is

not repairable; contact your dealer or

a

qualified workshop for recovery.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 120

miles (200 km)

with a

temporarily repaired tyre; see your

dealer or a

qualified workshop to change

the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Under-inflation

detection , refer to the corresponding

section.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

Procedure for changing a

damaged wheel with

the spare wheel using the tools provided with

the vehicle.

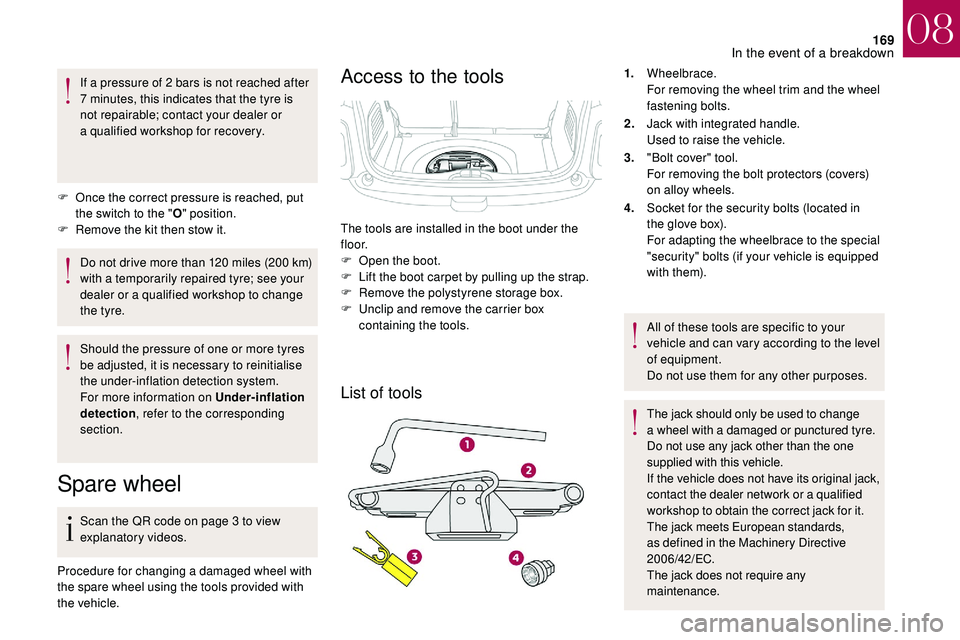

Access to the tools

List of tools

1. Wheelbrace.

For removing the wheel trim and the wheel

fastening bolts.

2. Jack with integrated handle.

Used to raise the vehicle.

3. "Bolt cover" tool.

For removing the bolt protectors (covers)

on alloy wheels.

4. Socket for the security bolts (located in

the glove box).

For adapting the wheelbrace to the special

"security" bolts (if your vehicle is equipped

with them).

All of these tools are specific to your

vehicle and can vary according to the level

of equipment.

Do not use them for any other purposes.

The jack should only be used to change

a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact the dealer network or a

qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

The tools are installed in the boot under the

f l o o r.

F

O

pen the boot.

F

L

ift the boot carpet by pulling up the strap.

F

R

emove the polystyrene storage box.

F

U

nclip and remove the carrier box

containing the tools.

08

In the event of a breakdown

Page 172 of 248

170

Access to the spare wheel

Taking out the wheelPutting the wheel back in place

The spare wheel is located in the boot under

t h e f l o o r.

Depending on the country of sale, you will

have a "space-saver" type spare wheel or

a

temporary puncture repair kit.

F

U

nscrew the central nut.

F

R

emove the fastening device (nut and bolt). F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

On vehicles with a "space-saver" type

spare wheel, the punctured tyre can

replace the "space-saver" wheel; however,

the boot floor will no longer be even.

F

P

ut the wheel back in its housing.

F

S

lacken the nut on the bolt by a few turns.

F

P

osition the fastening device (nut and bolt)

in the middle of the wheel.

F

T

ighten fully until the central nut clicks, to

retain the wheel correctly. F

P

ut the carrier box back in place in the

centre of the wheel and clip it.

F

P

ut the polystyrene storage box back in

place.

F

R

eposition the carpet at the back of the boot

by folding it gently in two.

08

In the event of a breakdown

Page 174 of 248

172

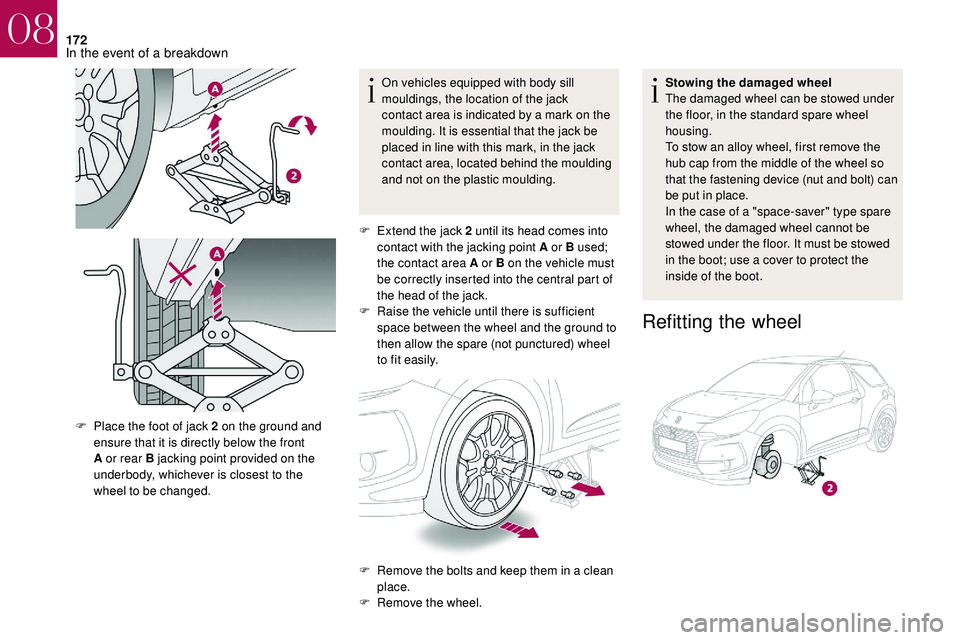

On vehicles equipped with body sill

mouldings, the location of the jack

contact area is indicated by a mark on the

moulding. It is essential that the jack be

placed in line with this mark, in the jack

contact area, located behind the moulding

and not on the plastic moulding.

F

E

xtend the jack 2 until its head comes into

contact with the jacking point A or B used;

the contact area A or B on the vehicle must

be correctly inserted into the central part of

the head of the jack.

F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground to

then allow the spare (not punctured) wheel

to fit easily. Stowing the damaged wheel

The damaged wheel can be stowed under

the floor, in the standard spare wheel

housing.

To stow an alloy wheel, first remove the

hub cap from the middle of the wheel so

that the fastening device (nut and bolt) can

be put in place.

In the case of a "space-saver" type spare

wheel, the damaged wheel cannot be

stowed under the floor. It must be stowed

in the boot; use a

cover to protect the

inside of the boot.

Refitting the wheel

F Place the foot of jack 2 on the ground and

ensure that it is directly below the front

A or rear B jacking point provided on the

underbody, whichever is closest to the

wheel to be changed.

F

R

emove the bolts and keep them in a clean

place.

F

R

emove the wheel.

08

In the event of a breakdown

Page 179 of 248

177

3.LED side marker lamps.

4. Direction indicators (PY21W amber).

5. Foglamp (H21W red) or reversing lamp

(H21W ).

Amber or red colour bulbs, such as the

direction indicators or foglamps, must be

replaced by bulbs with identical colour and

specifications.

Access to bulbs

Removing the access cover

F Open the boot.

Ty p e 1 Ty p e 2Removing the lamp

To reassemble, proceed in reverse order.

Make sure to engage the lamp unit in its guides

while keeping it in line with the vehicle.

Refitting the access cover

Ty p e 1

F

R

emove the access cover by pulling it

downwards.

F

U

nscrew the lamp fixing wing nut.

F

U

nclip the lamp unit connector.

F

E

xtract the lamp unit carefully pulling it

straight towards the outside. F

P

osition the 3 hooks A of the cover in the

lower part.

08

In the event of a breakdown

Page 180 of 248

178

Ty p e 2

Changing bulbs

Model with conventional bulb lampsModel with rear 3D lamps

Direction indicators (4) and foglamp or

reversing lamp (5)

Replacing LED sidelamps and brake

lamps (diodes)

For the replacement of this type of diode

lamp, contact the dealer network or a

qualified

workshop.

F

T

ip the cover upwards and position the

hooks B under the boot trim.

F

Ra

ise the cover.

F

S

lide the cover so as to put it properly back

in place. F

P

osition the cover in the lower part.

F

T

ip the cover upwards.

F

T

urn the bulb a quarter of a turn and change

it.

F

S

pread the four tabs and remove the bulb

h o l d e r.

F

T

urn the bulb a

quarter turn and change it.

08

In the event of a breakdown

Page 181 of 248

179

Number plate lamps (LED)

Third brake lamp (4 x W5W bulbs)F Push centrally on the lamp body, while levering it with two screwdrivers to extract it

to the outside.

F

D

isconnect the connector and, if necessary,

the lamp screenwash tube.

F

T

urn the bulb holder corresponding to the

faulty bulb a

quarter turn.

F

P

ull the bulb out and change it.

To refit, carry out these operations in reverse

o r d e r.Third brake lamp (LED)

For the replacement of this type of LED lamp,

contact the dealer network or a qualified

workshop.

F

O

pen the boot.

F

R

emove the two blanking plugs A located

on the lining. For the replacement of this type of light emitting

diode lamp, contact the dealer network or

a

qualified workshop.

08

In the event of a breakdown

Page 182 of 248

180

Interior lighting

Courtesy lamp (1/W5W)

Unclip the cover of courtesy lamp 1 with a fine

s crewdriver, on the control side, to access the

faulty bulb.

Map reading lamps (2/W5W)

Unclip the cover of courtesy lamp 1 . To

access the faulty bulb, unclip the reading lamp

2

partition concerned.

Boot lamp (W5W) Footwell and central storage lighting

(W5W)

Unclip the unit to access the bulb.

Glove box lighting (W5W)Unclip the unit by pushing the base from

behind.

Unclip the unit to access the bulb.

08

In the event of a breakdown

Page 186 of 248

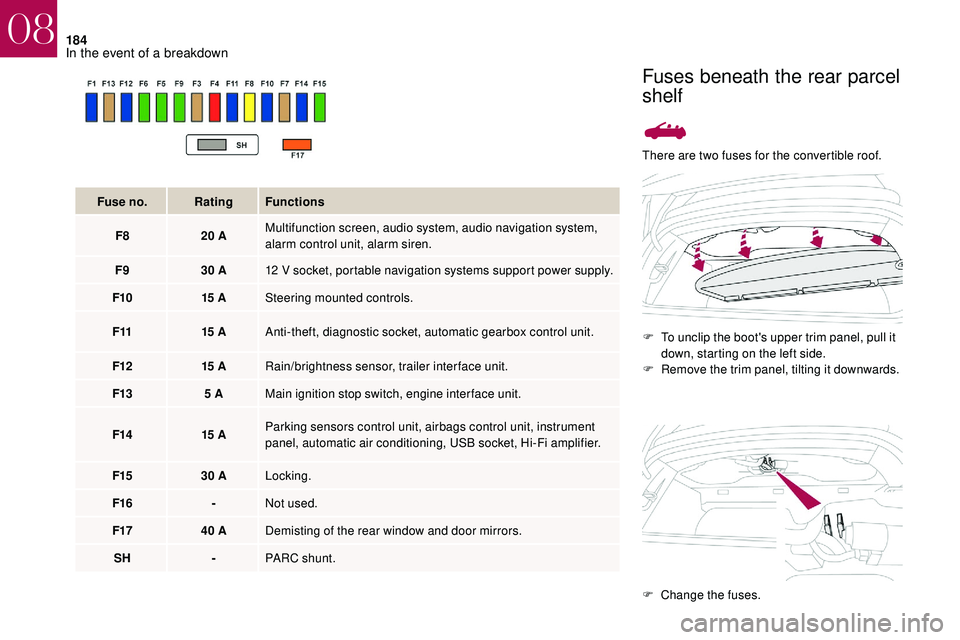

184

There are two fuses for the convertible roof.F

T

o unclip the boot's upper trim panel, pull it

down, starting on the left side.

F

R

emove the trim panel, tilting it downwards.

Fuse no.

Rating Functions

F8 20

A Multifunction screen, audio system, audio navigation system,

alarm control unit, alarm siren.

F9 30

A 12

V socket, portable navigation systems support power supply.

F10 15

A Steering mounted controls.

F11 15

A Anti-theft, diagnostic socket, automatic gearbox control unit.

F12 15

A Rain/brightness sensor, trailer interface unit.

F13 5

A Main ignition stop switch, engine interface unit.

F14 15

A Parking sensors control unit, airbags control unit, instrument

panel, automatic air conditioning, USB socket, Hi-Fi amplifier.

F15 30

A Locking.

F16 -Not used.

F17 40

A Demisting of the rear window and door mirrors.

SH -PARC shunt.

Fuses beneath the rear parcel

shelf

F Change the fuses.

08

In the event of a breakdown