ignition CITROEN DS3 CABRIO 2018 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2018, Model line: DS3 CABRIO, Model: CITROEN DS3 CABRIO 2018Pages: 248, PDF Size: 8.79 MB

Page 167 of 248

165

Running out of fuel

(Diesel)

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel.For more information on Misfuel

prevention (Diesel) , refer to the

corresponding section.

If the engine does not start first time, do

not keep trying, but start the procedure

again from the beginning.

BlueHDi engines

F Fill the fuel tank with at least five litres of Diesel fuel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10

times.

F

O

perate the starter to run the engine.

Other HDi engines

(except BlueHDi version)

F

F

ill the fuel tank with at least five litres of

Diesel.

F

O

pen the bonnet.

F

I

f necessary, unclip the cover to access the

priming pump.

F

O

perate the priming pump repeatedly until

resistance is felt (there may be resistance at

the first press).

F

O

perate the starter to start the engine (if the

engine does not start at the first attempt,

wait around 15

seconds before trying

again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

P

ut the cover in place and clip it in.

F

C

lose the bonnet again.

Temporary puncture

repair kit

Scan the QR code on page 3 to view

e xplanatory videos.

Comprising a

compressor and a sealant

cartridge, it allows the temporary repair of

a

tyre so that you can drive to the nearest

garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

The vehicle's electrical system allows the

connection of the compressor for long

enough to inflate a

tyre after a puncture

repair.

Under-inflation detection

After repair of the tyre, the warning

lamp will remain on until the system is

reinitialised.

For more information on Under-inflation

detection , refer to the corresponding

section.

08

In the event of a breakdown

Page 168 of 248

166

Access to the kit

This kit is installed in the under floor storage,

under the boot floor.

Composition of the kit

1.12 V compressor, with built-in pressure

gauge.

2. Bottle of sealant, with built-in hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition.

F

U

ncoil the pipe stowed under the

compressor.

Avoid removing any foreign bodies which

have penetrated the tyre. F

R

emove the valve cap from the tyre to be

repaired and keep it in a

clean place.

F

C

onnect the pipe from the compressor to

the bottle of sealant. F

T

urn over the sealant bottle and secure it in

the cut-out provided on the compressor.

F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly.

08

In the event of a breakdown

Page 169 of 248

167

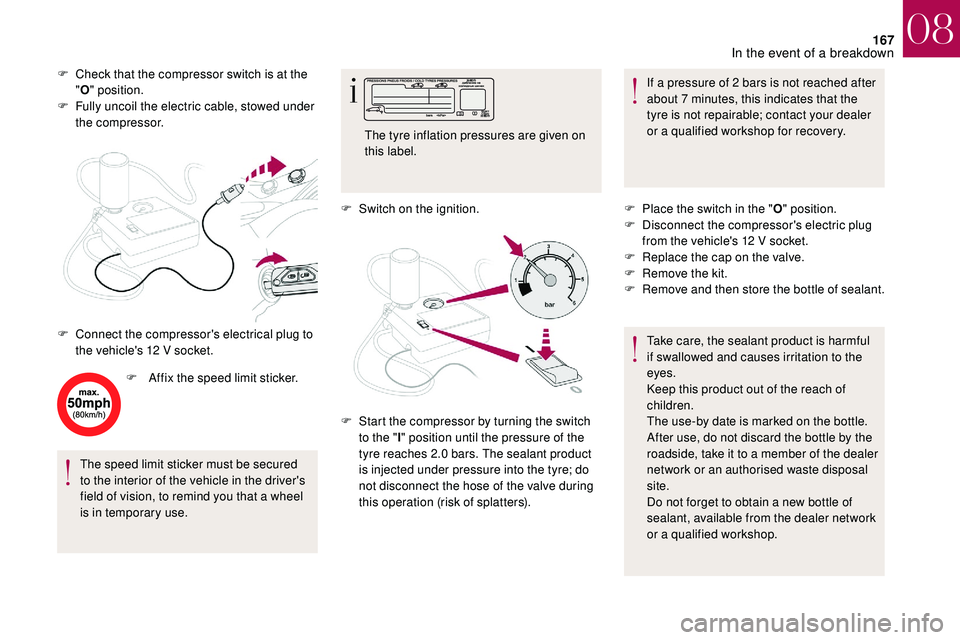

F Check that the compressor switch is at the "O " position.

F

F

ully uncoil the electric cable, stowed under

the compressor.

F

A

ffix the speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a

wheel

is in temporary use. F

S

witch on the ignition.If a

pressure of 2 bars is not reached after

about 7

minutes, this indicates that the

tyre is not repairable; contact your dealer

or a

qualified workshop for recovery.

F

C

onnect the compressor's electrical plug to

the vehicle's 12

V socket. The tyre inflation pressures are given on

this label.

F

S

tart the compressor by turning the switch

to the " l" position until the pressure of the

tyre reaches 2.0

bars. The sealant product

is injected under pressure into the tyre; do

not disconnect the hose of the valve during

this operation (risk of splatters). F

P

lace the switch in the "O" position.

F

D

isconnect the compressor's electric plug

from the vehicle's 12

V socket.

F

R

eplace the cap on the valve.

F

R

emove the kit.

F

R

emove and then store the bottle of sealant.

Take care, the sealant product is harmful

if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

The use-by date is marked on the bottle.

After use, do not discard the bottle by the

roadside, take it to a

member of the dealer

network or an authorised waste disposal

site.

Do not forget to obtain a

new bottle of

sealant, available from the dealer network

or a

qualified workshop.

08

In the event of a breakdown

Page 170 of 248

168

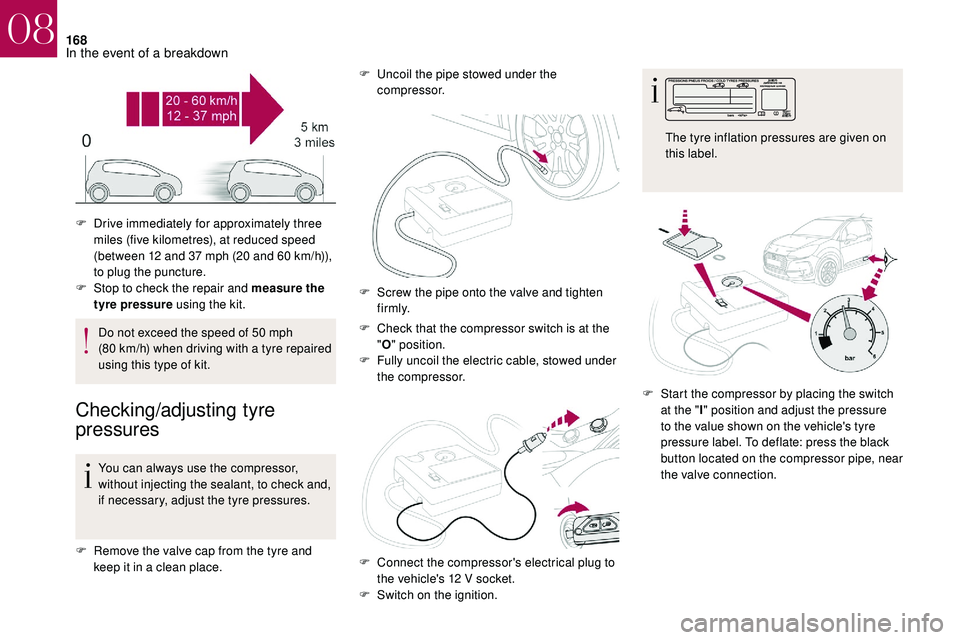

Do not exceed the speed of 50 mph

( 80 km/h) when driving with a tyre repaired

using this type of kit.

Checking/adjusting tyre

pressures

You can always use the compressor,

without injecting the sealant, to check and,

if necessary, adjust the tyre pressures.

F

R

emove the valve cap from the tyre and

keep it in a

clean place. F

C

heck that the compressor switch is at the

" O " position.

F

F

ully uncoil the electric cable, stowed under

the compressor.

F

D

rive immediately for approximately three

miles (five kilometres), at reduced speed

(between 12 and 37 mph (20 and 60 km/h)),

to plug the puncture.

F

S

top to check the repair and measure the

tyre pressure using the kit. F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f i r m l y.

F

C

onnect the compressor's electrical plug to

the vehicle's 12

V socket.

F

S

witch on the ignition.F

S

tart the compressor by placing the switch

at the " I" position and adjust the pressure

to the value shown on the vehicle's tyre

pressure label. To deflate: press the black

button located on the compressor pipe, near

the valve connection. The tyre inflation pressures are given on

this label.

08

In the event of a breakdown

Page 173 of 248

171

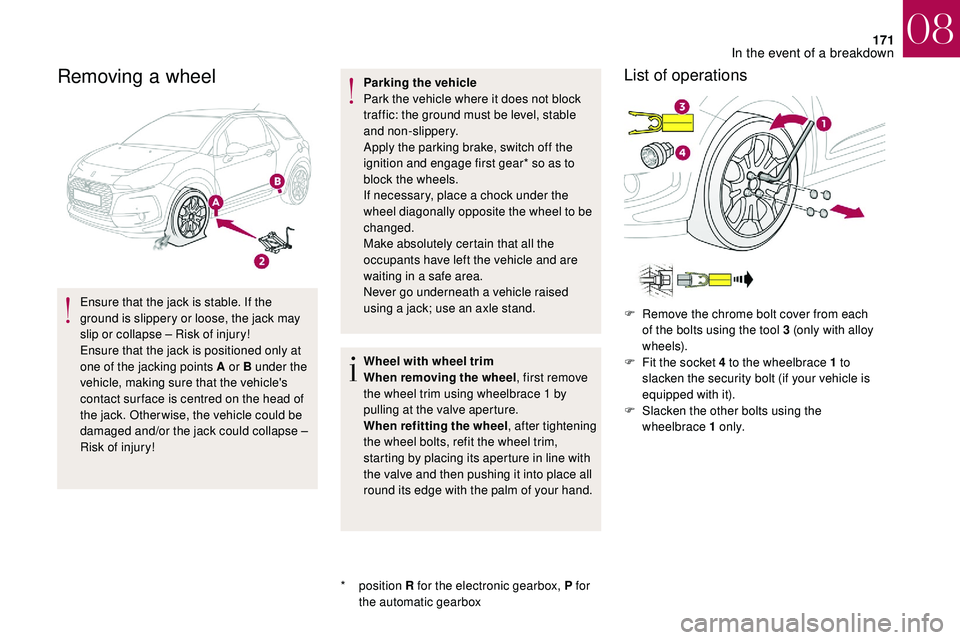

Removing a wheel

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse – Risk of injury!

Ensure that the jack is positioned only at

one of the jacking points A or B under the

vehicle, making sure that the vehicle's

contact sur face is centred on the head of

the jack. Otherwise, the vehicle could be

damaged and/or the jack could collapse –

Risk of injury!

*

position R for the electronic gearbox, P for

the automatic gearbox Parking the vehicle

Park the vehicle where it does not block

traffic: the ground must be level, stable

and non-slippery.

Apply the parking brake, switch off the

ignition and engage first gear* so as to

block the wheels.

If necessary, place a

chock under the

wheel diagonally opposite the wheel to be

changed.

Make absolutely certain that all the

occupants have left the vehicle and are

waiting in a safe area.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim using wheelbrace 1

by

pulling at the valve aperture.

When refitting the wheel , after tightening

the wheel bolts, refit the wheel trim,

starting by placing its aperture in line with

the valve and then pushing it into place all

round its edge with the palm of your hand.

List of operations

F Remove the chrome bolt cover from each of the bolts using the tool 3 (only with alloy

w h e e l s).

F

F

it the socket 4 to the wheelbrace 1 to

slacken the security bolt (if your vehicle is

equipped with it).

F

S

lacken the other bolts using the

wheelbrace 1

o n l y.

08

In the event of a breakdown

Page 176 of 248

174

Changing a bulb

The headlamps have polycarbonate

lenses with a

protective coating:

F

d

o not clean them using a dr y or

abrasive cloth, nor with a

detergent

or solvent product,

F

u

se a sponge and soapy water or a pH

neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep the

lance directed towards the lamps or

their edges for too long, so as not to

damage their protective coating and

seals.

Changing a

bulb must only be done with

the ignition off and after the headlamp has

been switched off for several minutes –

Risk of serious burns!

F

D

o not touch the bulb directly with your

fingers, use a

lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a

failed bulb with a new

bulb with the same type and specification.

Front lamps

Halogen headlamps

1. Direction indicators (PY21W amber).

2. Sidelamps (W5W).

3. Main beam headlamps (H1-55W).

4. Dipped beam headlamps (H7-55W).

5. LED foglamps.

6. LED daytime running lamps.

Direction indicators

Rapid flashing of the direction indicator

lamp (left or right) indicates that one of

the bulbs on the corresponding side has

failed.

F

T

urn the bulb holder a quarter turn and

remove it.

F

P

ull the bulb out and change it.

To refit, carry out these operations in reverse

o r d e r.

Amber colour bulbs, such as the direction

indicators, must be replaced by bulbs with

identical colour and specifications.

To refit, close the protective cover very

carefully to guarantee the leak-tightness

of the lamp.

08

In the event of a breakdown

Page 183 of 248

181

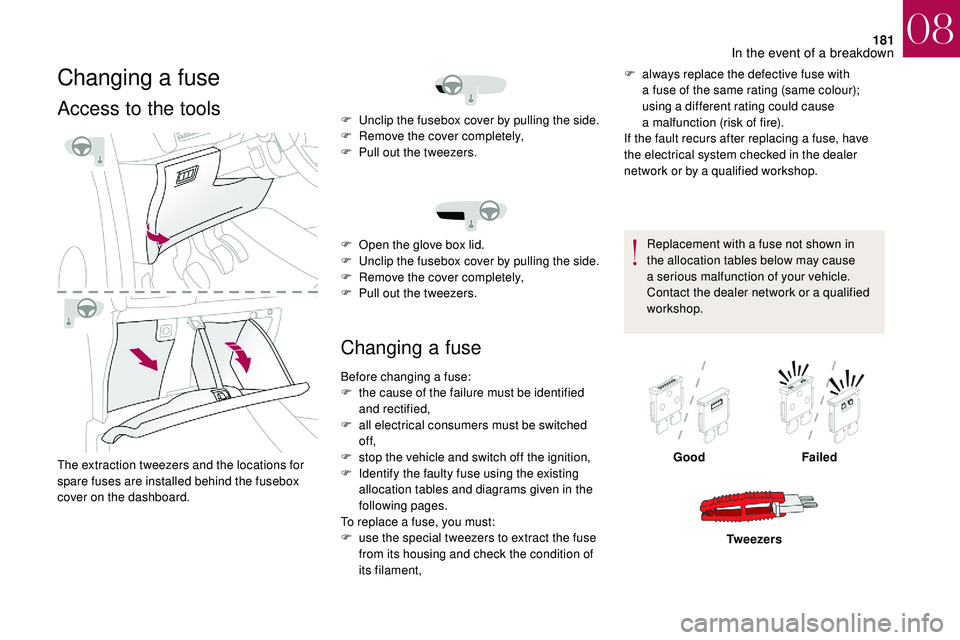

Changing a fuse

Access to the tools

The extraction tweezers and the locations for

spare fuses are installed behind the fusebox

cover on the dashboard.

Changing a fuse

F always replace the defective fuse with

a fuse of the same rating (same colour);

using a

different rating could cause

a

malfunction (risk of fire).

If the fault recurs after replacing a

fuse, have

the electrical system checked in the dealer

network or by a

qualified workshop.

Replacement with a

fuse not shown in

the allocation tables below may cause

a

serious malfunction of your vehicle.

Contact the dealer network or a

qualified

workshop.

F

U

nclip the fusebox cover by pulling the side.

F

R

emove the cover completely,

F

P

ull out the tweezers.

F

O

pen the glove box lid.

F

U

nclip the fusebox cover by pulling the side.

F

R

emove the cover completely,

F

P

ull out the tweezers.

Before changing a

fuse:

F

t

he cause of the failure must be identified

and rectified,

F

a

ll electrical consumers must be switched

of f,

F

s

top the vehicle and switch off the ignition,

F

I

dentify the faulty fuse using the existing

allocation tables and diagrams given in the

following pages.

To replace a

fuse, you must:

F

u

se the special tweezers to extract the fuse

from its housing and check the condition of

its filament, Good

Failed

Tw e e z e r s

08

In the event of a breakdown

Page 186 of 248

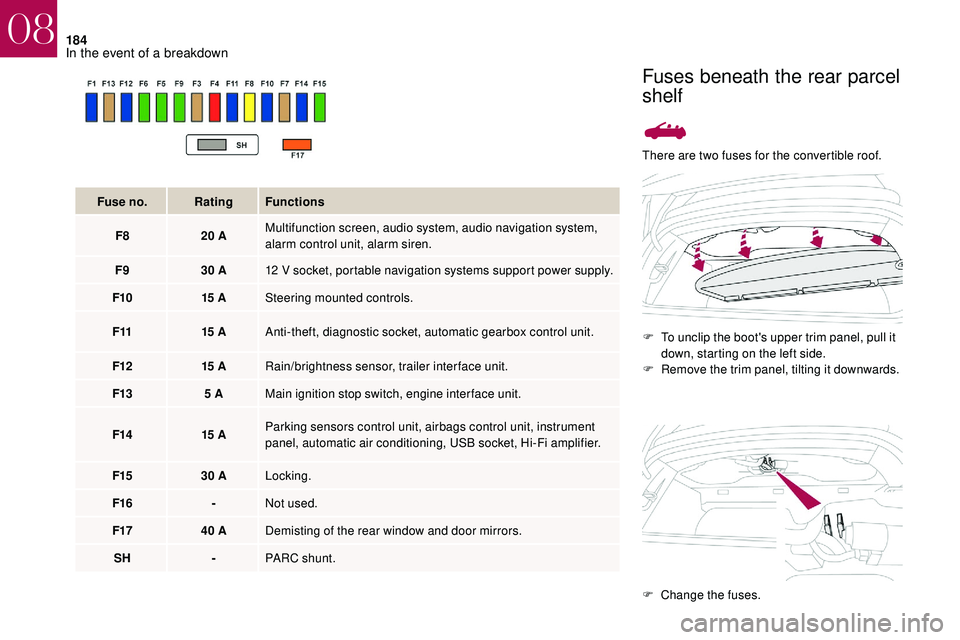

184

There are two fuses for the convertible roof.F

T

o unclip the boot's upper trim panel, pull it

down, starting on the left side.

F

R

emove the trim panel, tilting it downwards.

Fuse no.

Rating Functions

F8 20

A Multifunction screen, audio system, audio navigation system,

alarm control unit, alarm siren.

F9 30

A 12

V socket, portable navigation systems support power supply.

F10 15

A Steering mounted controls.

F11 15

A Anti-theft, diagnostic socket, automatic gearbox control unit.

F12 15

A Rain/brightness sensor, trailer interface unit.

F13 5

A Main ignition stop switch, engine interface unit.

F14 15

A Parking sensors control unit, airbags control unit, instrument

panel, automatic air conditioning, USB socket, Hi-Fi amplifier.

F15 30

A Locking.

F16 -Not used.

F17 40

A Demisting of the rear window and door mirrors.

SH -PARC shunt.

Fuses beneath the rear parcel

shelf

F Change the fuses.

08

In the event of a breakdown

Page 189 of 248

187

Fuse No.Rating Functions

F10 30

ADiesel heater, blow-by heater (Diesel), fuel pump (petrol), injectors and lighting coils (petrol).

F11 40

AAir conditioning blower.

F12 30

AWindscreen wipers slow/fast speed.

F13 40

ABuilt-in systems inter face power supply (+ after ignition).

F14 30

AValvetronic power supply (petrol).

F15 10

ARight-hand main beam headlamp.

F16 10

ALeft-hand main beam headlamp.

F17 15

ALeft-hand dipped beam headlamp.

F18 15

ARight-hand dipped beam headlamp.

F19 15

AOxygen sensors and electrovalves (petrol), electrovalves (Diesel), EGR electrovalve (Diesel).

F20 10

APumps, controlled thermostat (petrol), timing electrovalve (THP), water in Diesel sensor (Diesel).

F21 5

AEngine fan control power supply, ABS/DSC, turbo pump (THP).

08

In the event of a breakdown

Page 191 of 248

189

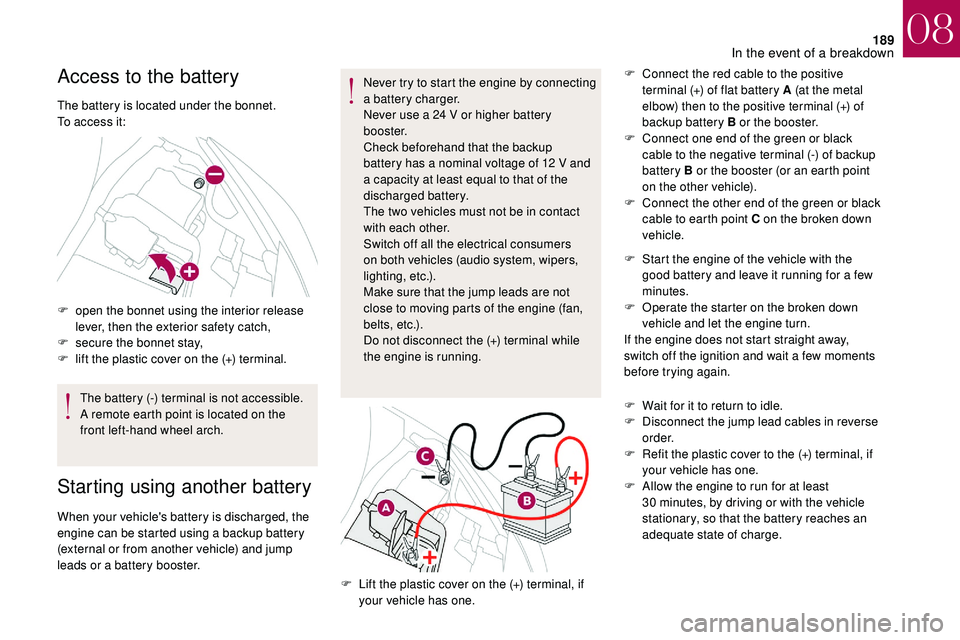

Access to the battery

The battery is located under the bonnet.

To access it:

F

o

pen the bonnet using the interior release

lever, then the exterior safety catch,

F

s

ecure the bonnet stay,

F

l

ift the plastic cover on the (+) terminal.The battery (-) terminal is not accessible.

A remote earth point is located on the

front left-hand wheel arch.

Starting using another battery

When your vehicle's battery is discharged, the

engine can be started using a backup battery

(external or from another vehicle) and jump

leads or a

battery booster. Never try to start the engine by connecting

a

battery charger.

Never use a 24 V or higher battery

b o o s t e r.

Check beforehand that the backup

battery has a nominal voltage of 12 V and

a capacity at least equal to that of the

discharged battery.

The two vehicles must not be in contact

with each other.

Switch off all the electrical consumers

on both vehicles (audio system, wipers,

lighting, etc.).

Make sure that the jump leads are not

close to moving parts of the engine (fan,

belts, etc.).

Do not disconnect the (+) terminal while

the engine is running. F

C

onnect the red cable to the positive

terminal (+) of flat battery A (at the metal

elbow) then to the positive terminal (+) of

backup battery B or the booster.

F

C

onnect one end of the green or black

cable to the negative terminal (-) of backup

battery B or the booster (or an earth point

on the other vehicle).

F

C

onnect the other end of the green or black

cable to earth point C on the broken down

vehicle.

F

L

ift the plastic cover on the (+) terminal, if

your vehicle has one. F

S

tart the engine of the vehicle with the

good battery and leave it running for a few

minutes.

F

O

perate the starter on the broken down

vehicle and let the engine turn.

If the engine does not start straight away,

switch off the ignition and wait a few moments

before trying again.

F

W

ait for it to return to idle.

F

D

isconnect the jump lead cables in reverse

o r d e r.

F

R

efit the plastic cover to the (+) terminal, if

your vehicle has one.

F

A

llow the engine to run for at least

30 minutes, by driving or with the vehicle

stationary, so that the battery reaches an

adequate state of charge.

08

In the event of a breakdown