Citroen GRAND C4 PICASSO 2017 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2017, Model line: GRAND C4 PICASSO, Model: Citroen GRAND C4 PICASSO 2017 2.GPages: 527, PDF Size: 12.91 MB

Page 291 of 527

289

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

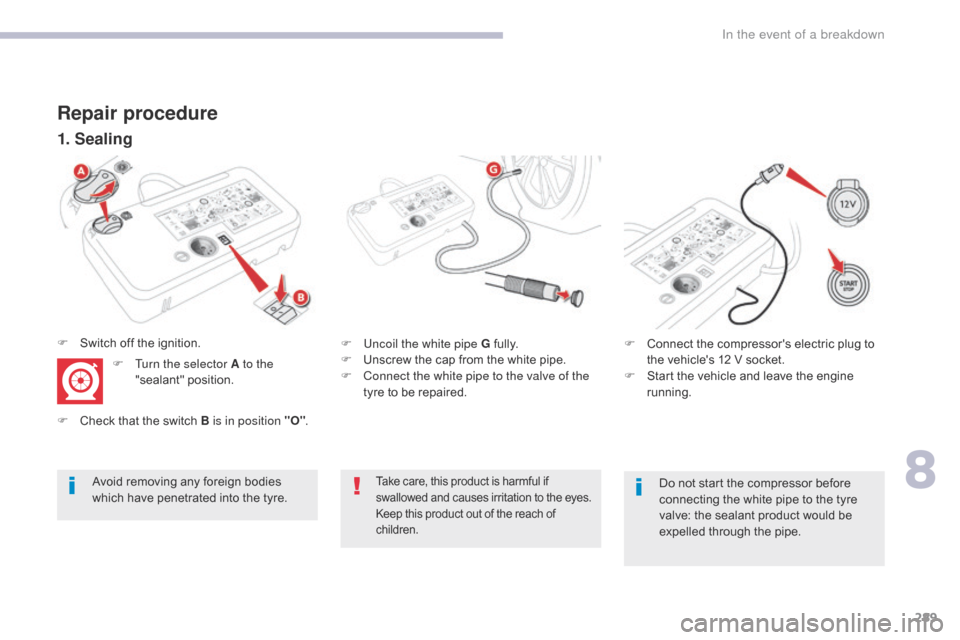

1. Sealing

Repair procedure

Avoid removing any foreign bodies

which have penetrated into the tyre.F

U

ncoil the white pipe G fully.

F

U

nscrew the cap from the white pipe.

F

C

onnect the white pipe to the valve of the

tyre to be repaired.

F

S

witch off the ignition.

F

T

urn the selector A to the

"sealant" position. F

C

onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle and leave the engine

running.Take care, this product is harmful if

swallowed and causes irritation to the eyes.

Keep this product out of the reach of

children.Do not start the compressor before

connecting the white pipe to the tyre

valve: the sealant product would be

expelled through the pipe.

F

C

heck that the switch B is in position "O"

.

8

In the event of a breakdown

Page 292 of 527

290

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

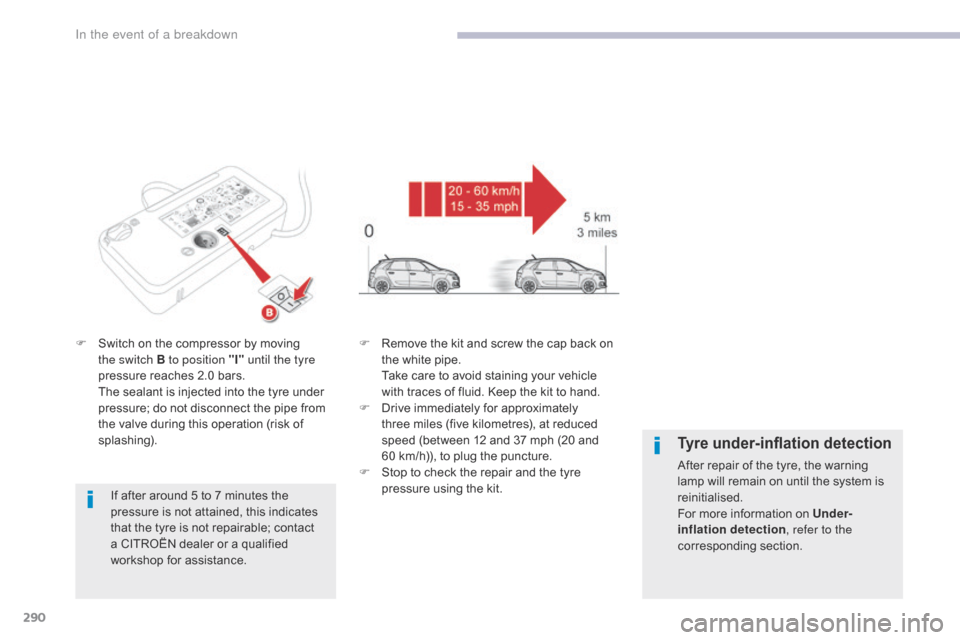

F Switch on the compressor by moving the switch B to position "I" until the tyre

pressure reaches 2.0 bars.

T

he sealant is injected into the tyre under

pressure; do not disconnect the pipe from

the valve during this operation (risk of

splashing).

If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a CITROËN dealer or a qualified

workshop for assistance. F

R emove the kit and screw the cap back on

the white pipe.

T

ake care to avoid staining your vehicle

with traces of fluid. Keep the kit to hand.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 12 and 37 mph (20 and

60

km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.

Tyre under-inflation detection

After repair of the tyre, the warning

lamp will remain on until the system is

reinitialised.

For more information on Under-

inflation detection , refer to the

corresponding section.

In the event of a breakdown

Page 293 of 527

291

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

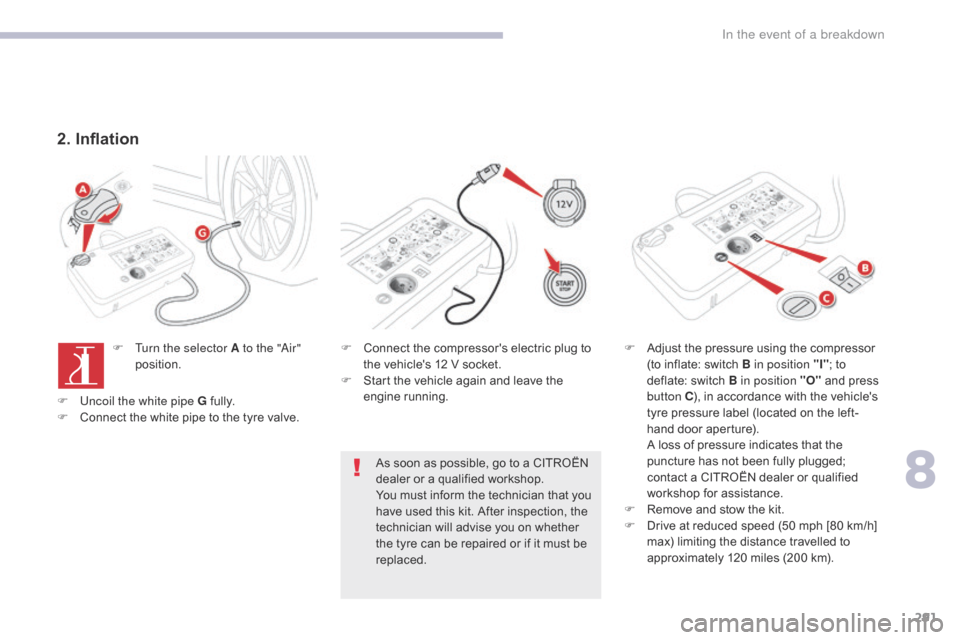

2. Inflation

F Turn the selector A to the "Air" position. F

C onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

engine running.

As soon as possible, go to a CITROËN

dealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced. F

A djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B

in position "O" and press

button C ), in accordance with the vehicle's

tyre pressure label (located on the left-

hand door aperture).

A l

oss of pressure indicates that the

puncture has not been fully plugged;

contact a CITROËN dealer or qualified

workshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph [80 km/h]

max) limiting the distance travelled to

approximately 120 miles (200 km).

F

U

ncoil the white pipe G fully.

F

C

onnect the white pipe to the tyre valve.

8

In the event of a breakdown

Page 294 of 527

292

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

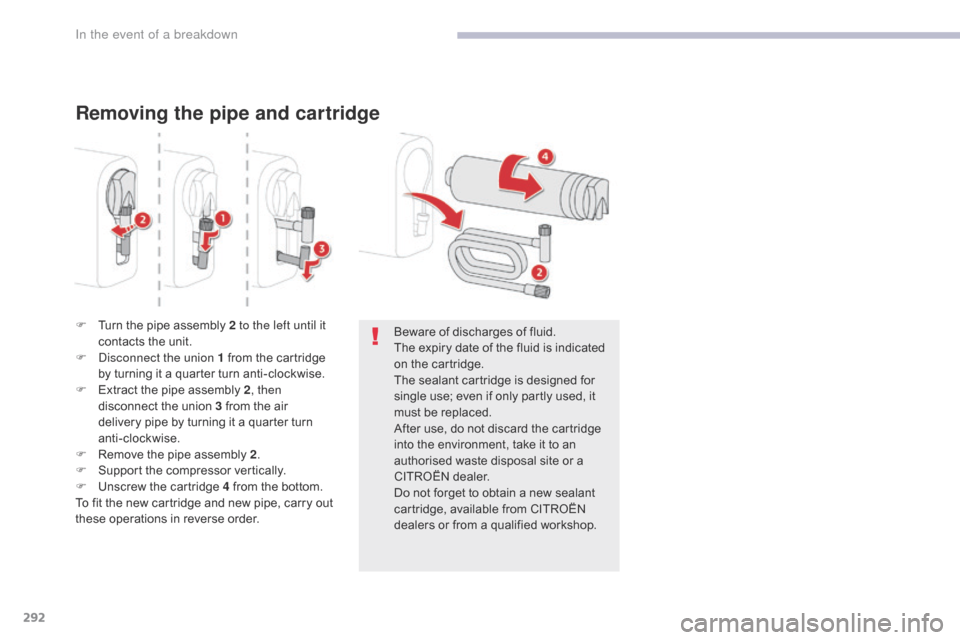

Removing the pipe and cartridge

F Turn the pipe assembly 2 to the left until it contacts the unit.

F

D

isconnect the union 1 from the cartridge

by turning it a quarter turn anti-clockwise.

F

E

xtract the pipe assembly 2 , then

disconnect the union 3 from the air

delivery

pipe by turning it a quarter turn

anti-clockwise.

F

R

emove the pipe assembly 2 .

F

S

upport the compressor vertically.

F

U

nscrew the cartridge 4 from the bottom.

To fit the new cartridge and new pipe, carry out

these operations in reverse order. Beware of discharges of fluid.

The expiry date of the fluid is indicated

on the cartridge.

The sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

CITROËN dealer.

Do not forget to obtain a new sealant

cartridge, available from CITROËN

dealers or from a qualified workshop.

In the event of a breakdown

Page 295 of 527

293

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

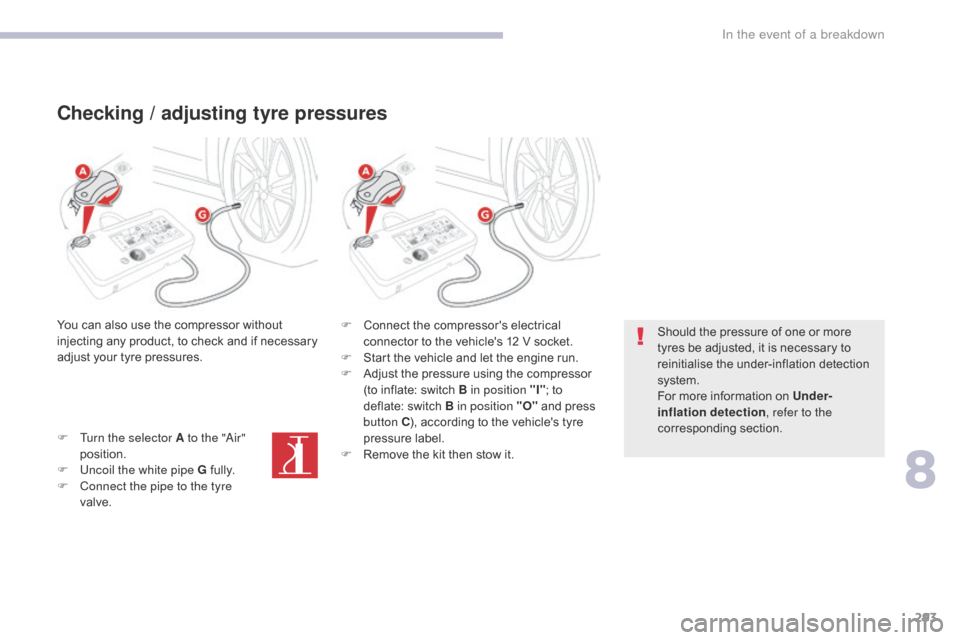

Checking / adjusting tyre pressures

You can also use the compressor without

injecting any product, to check and if necessary

adjust your tyre pressures.

F

T

urn the selector A to the "Air"

position.

F

U

ncoil the white pipe G fully.

F

C

onnect the pipe to the tyre

valve. F

C onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label.

F

R

emove the kit then stow it.Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on Under-

inflation detection

, refer to the

corresponding section.

8

In the event of a breakdown

Page 296 of 527

294

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

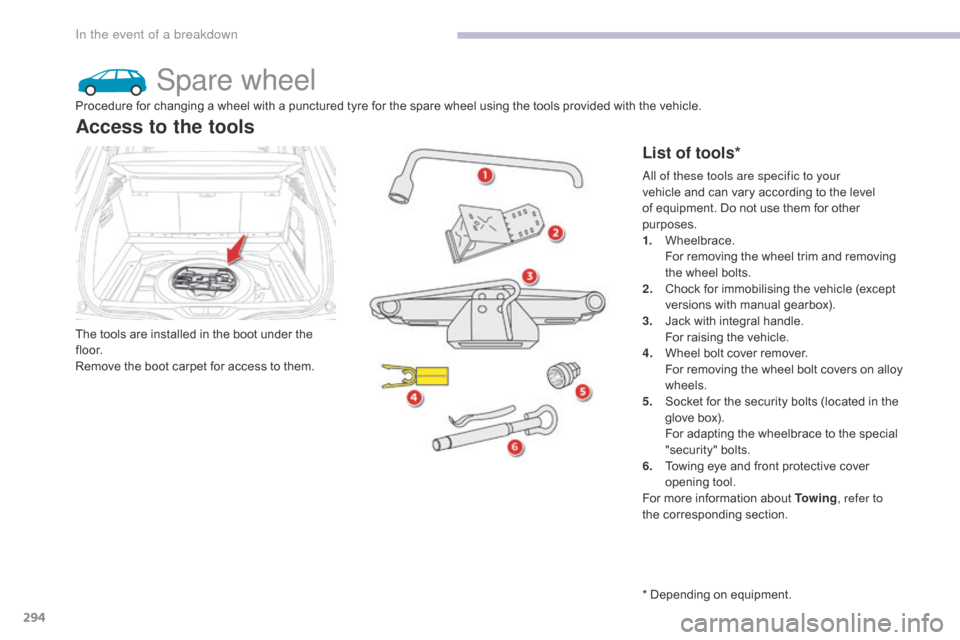

Spare wheel

The tools are installed in the boot under the

f l o o r.

Remove the boot carpet for access to them.

Access to the tools

List of tools*

Procedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.All of these tools are specific to your

vehicle and can vary according to the level

of equipment. Do not use them for other

purposes.

1.

W

heelbrace.

F

or removing the wheel trim and removing

the wheel bolts.

2.

C

hock for immobilising the vehicle (except

versions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

wheels.

5.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts.

6.

T

owing eye and front protective cover

opening tool.

For more information about To w i n g , refer to

the corresponding section.

* Depending on equipment.

In the event of a breakdown

Page 297 of 527

295

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

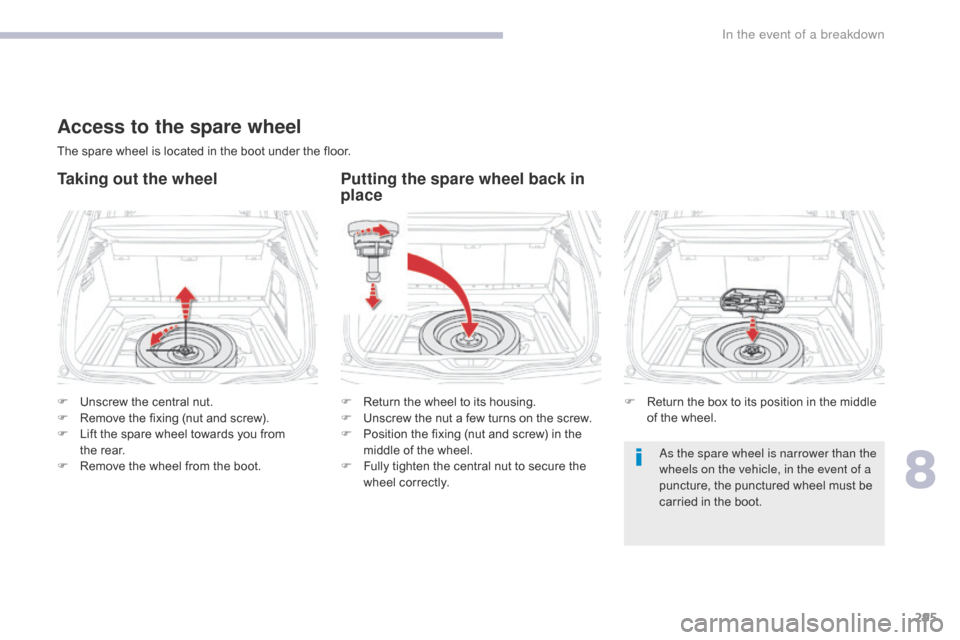

F Unscrew the central nut.

F R emove the fixing (nut and screw).

F

L

ift the spare wheel towards you from

the

rear.

F

R

emove the wheel from the boot. As the spare wheel is narrower than the

wheels on the vehicle, in the event of a

puncture, the punctured wheel must be

carried in the boot.

The spare wheel is located in the boot under the floor.

Access to the spare wheel

F Return the wheel to its housing.

F

U nscrew the nut a few turns on the screw.

F

P

osition the fixing (nut and screw) in the

middle of the wheel.

F

F

ully tighten the central nut to secure the

wheel correctly. F

R eturn the box to its position in the middle

of the wheel.

Taking out the wheel Putting the spare wheel back in

place

8

In the event of a breakdown

Page 298 of 527

296

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

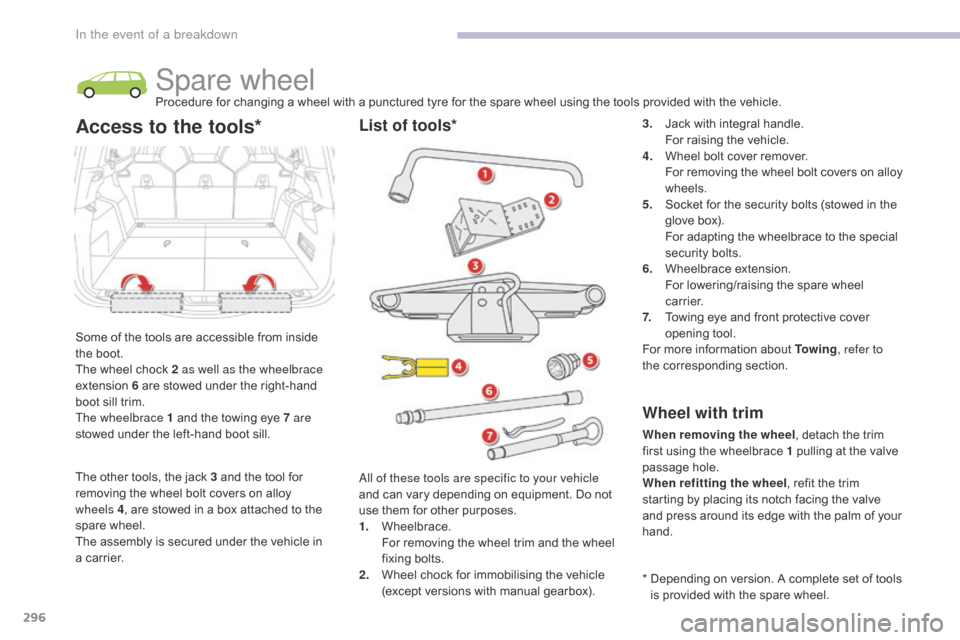

Spare wheelProcedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

Some of the tools are accessible from inside

the boot.

The wheel chock 2 as well as the wheelbrace

extension 6 are stowed under the right-hand

boot sill trim.

The wheelbrace 1 and the towing eye 7 are

stowed under the left-hand boot sill.

Access to the tools*3. Jack with integral handle. F or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

wheels.

5.

S

ocket for the security bolts (stowed in the

glove box).

F

or adapting the wheelbrace to the special

security bolts.

6.

W

heelbrace extension.

F

or lowering/raising the spare wheel

c a r r i e r.

7.

T

owing eye and front protective cover

opening tool.

For more information about To w i n g , refer to

the corresponding section.

Wheel with trim

When removing the wheel , detach the trim

first using the wheelbrace 1 pulling at the valve

passage hole.

When refitting the wheel , refit the trim

starting by placing its notch facing the valve

and press around its edge with the palm of your

hand.

All of these tools are specific to your vehicle

and can vary depending on equipment. Do not

use them for other purposes.

1.

W

heelbrace.

F

or removing the wheel trim and the wheel

fixing bolts.

2.

W

heel chock for immobilising the vehicle

(except versions with manual gearbox). *

D

epending on version. A complete set of tools

is provided with the spare wheel.

The other tools, the jack 3 and the tool for

removing the wheel bolt covers on alloy

wheels

4 , are stowed in a box attached to the

spare wheel.

The assembly is secured under the vehicle in

a carrier.

List of tools*

In the event of a breakdown

Page 299 of 527

297

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

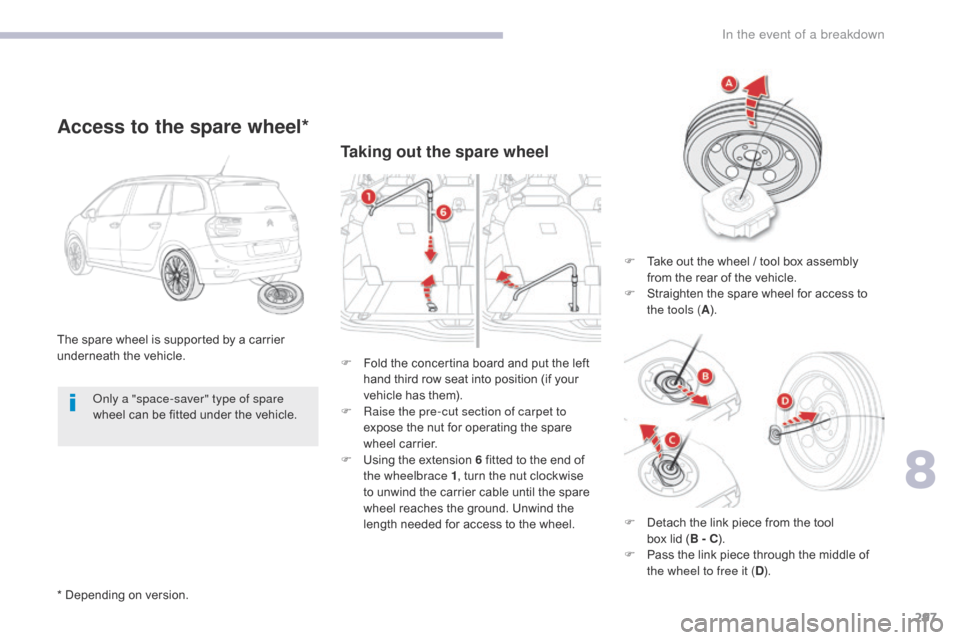

Taking out the spare wheel

The spare wheel is supported by a carrier

underneath the vehicle.

Access to the spare wheel*

F Take out the wheel / tool box assembly from the rear of the vehicle.

F

S

traighten the spare wheel for access to

the tools ( A).

F

F

old the concertina board and put the left

hand third row seat into position (if your

vehicle has them).

F

R

aise the pre-cut section of carpet to

expose the nut for operating the spare

wheel carrier.

F

U

sing the extension 6 fitted to the end of

the wheelbrace 1 , turn the nut clockwise

to unwind the carrier cable until the spare

wheel reaches the ground. Unwind the

length needed for access to the wheel.

Only a "space-saver" type of spare

wheel can be fitted under the vehicle.

* Depending on version. F

D

etach the link piece from the tool

box

lid (B - C ).

F

P

ass the link piece through the middle of

the wheel to free it ( D).

8

In the event of a breakdown

Page 300 of 527

298

C4-Picasso-II_en_Chap08_en-cas-panne_ed02-2016

A punctured wheel from the vehicle

cannot be fitted under the vehicle. It

must be carried in the boot. Use a cover

to protect the boot.

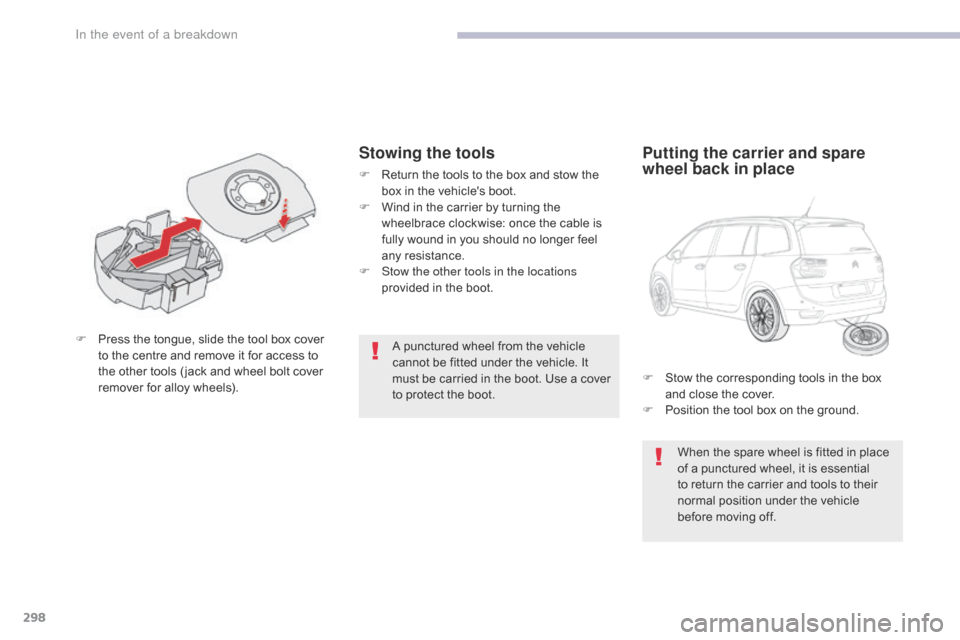

F

P

ress the tongue, slide the tool box cover

to the centre and remove it for access to

the other tools ( jack and wheel bolt cover

remover for alloy wheels).

Putting the carrier and spare

wheel back in place

F Stow the corresponding tools in the box and close the cover.

F

P

osition the tool box on the ground.

Stowing the tools

F Return the tools to the box and stow the box in the vehicle's boot.

F

W

ind in the carrier by turning the

wheelbrace clockwise: once the cable is

fully wound in you should no longer feel

any resistance.

F

S

tow the other tools in the locations

provided in the boot.

When the spare wheel is fitted in place

of a punctured wheel, it is essential

to return the carrier and tools to their

normal position under the vehicle

before moving off.

In the event of a breakdown