engine electrical DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 652 of 2643

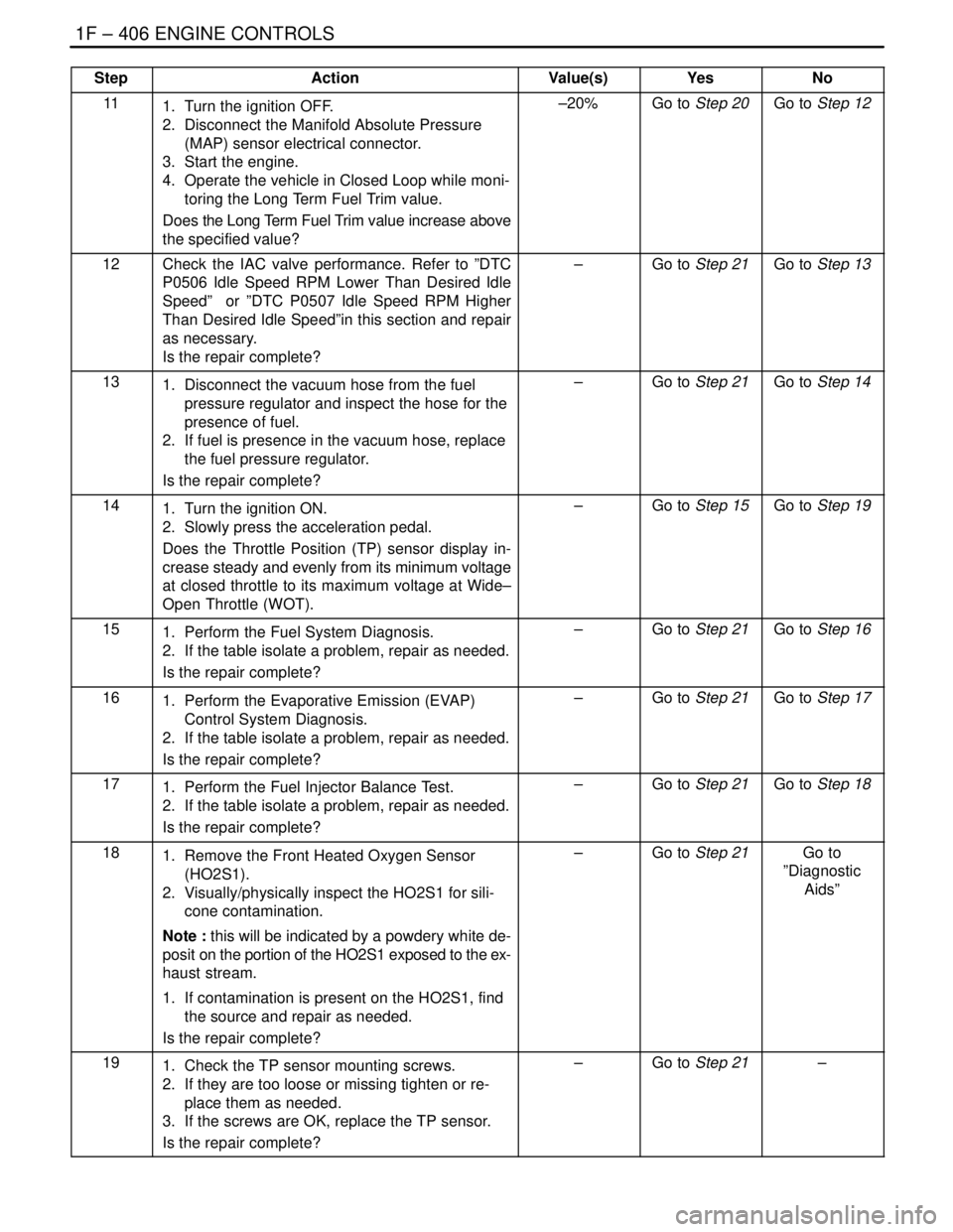

1F – 406IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

111. Turn the ignition OFF.

2. Disconnect the Manifold Absolute Pressure

(MAP) sensor electrical connector.

3. Start the engine.

4. Operate the vehicle in Closed Loop while moni-

toring the Long Term Fuel Trim value.

Does the Long Term Fuel Trim value increase above

the specified value?–20%Go to Step 20Go to Step 12

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed”in this section and repair

as necessary.

Is the repair complete?–Go to Step 21Go to Step 13

131. Disconnect the vacuum hose from the fuel

pressure regulator and inspect the hose for the

presence of fuel.

2. If fuel is presence in the vacuum hose, replace

the fuel pressure regulator.

Is the repair complete?–Go to Step 21Go to Step 14

141. Turn the ignition ON.

2. Slowly press the acceleration pedal.

Does the Throttle Position (TP) sensor display in-

crease steady and evenly from its minimum voltage

at closed throttle to its maximum voltage at Wide–

Open Throttle (WOT).–Go to Step 15Go to Step 19

151. Perform the Fuel System Diagnosis.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 16

161. Perform the Evaporative Emission (EVAP)

Control System Diagnosis.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 17

171. Perform the Fuel Injector Balance Test.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 18

181. Remove the Front Heated Oxygen Sensor

(HO2S1).

2. Visually/physically inspect the HO2S1 for sili-

cone contamination.

Note : this will be indicated by a powdery white de-

posit on the portion of the HO2S1 exposed to the ex-

haust stream.

1. If contamination is present on the HO2S1, find

the source and repair as needed.

Is the repair complete?–Go to Step 21Go to

”Diagnostic

Aids”

191. Check the TP sensor mounting screws.

2. If they are too loose or missing tighten or re-

place them as needed.

3. If the screws are OK, replace the TP sensor.

Is the repair complete?–Go to Step 21–

Page 705 of 2643

ENGINE CONTROLS 1F – 459

DAEWOO V–121 BL4

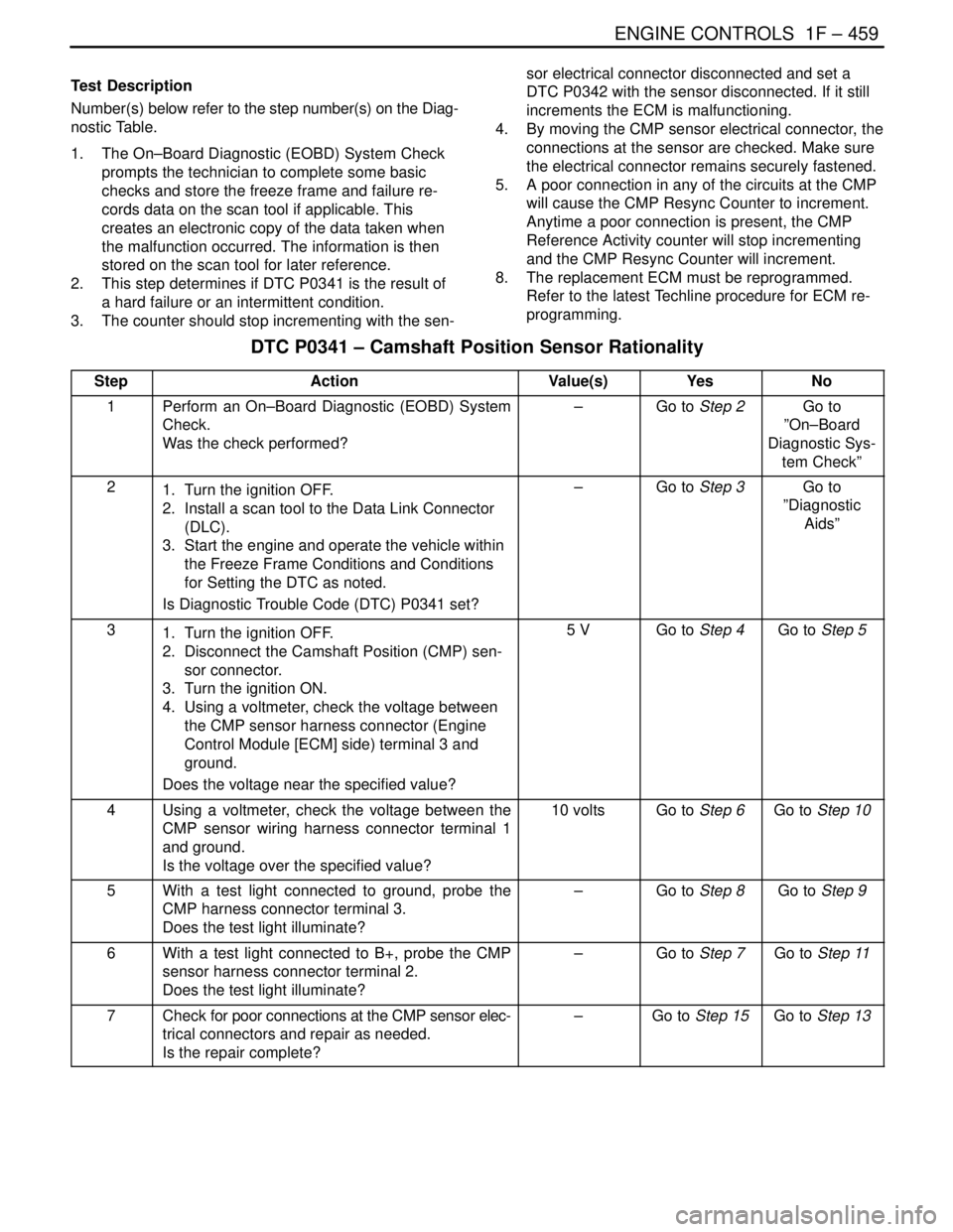

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0341 is the result of

a hard failure or an intermittent condition.

3. The counter should stop incrementing with the sen-sor electrical connector disconnected and set a

DTC P0342 with the sensor disconnected. If it still

increments the ECM is malfunctioning.

4. By moving the CMP sensor electrical connector, the

connections at the sensor are checked. Make sure

the electrical connector remains securely fastened.

5. A poor connection in any of the circuits at the CMP

will cause the CMP Resync Counter to increment.

Anytime a poor connection is present, the CMP

Reference Activity counter will stop incrementing

and the CMP Resync Counter will increment.

8. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0341 – Camshaft Position Sensor Rationality

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Start the engine and operate the vehicle within

the Freeze Frame Conditions and Conditions

for Setting the DTC as noted.

Is Diagnostic Trouble Code (DTC) P0341 set?–Go to Step 3Go to

”Diagnostic

Aids”

31. Turn the ignition OFF.

2. Disconnect the Camshaft Position (CMP) sen-

sor connector.

3. Turn the ignition ON.

4. Using a voltmeter, check the voltage between

the CMP sensor harness connector (Engine

Control Module [ECM] side) terminal 3 and

ground.

Does the voltage near the specified value?5 VGo to Step 4Go to Step 5

4Using a voltmeter, check the voltage between the

CMP sensor wiring harness connector terminal 1

and ground.

Is the voltage over the specified value?10 voltsGo to Step 6Go to Step 10

5With a test light connected to ground, probe the

CMP harness connector terminal 3.

Does the test light illuminate?–Go to Step 8Go to Step 9

6With a test light connected to B+, probe the CMP

sensor harness connector terminal 2.

Does the test light illuminate?–Go to Step 7Go to Step 11

7Check for poor connections at the CMP sensor elec-

trical connectors and repair as needed.

Is the repair complete?–Go to Step 15Go to Step 13

Page 717 of 2643

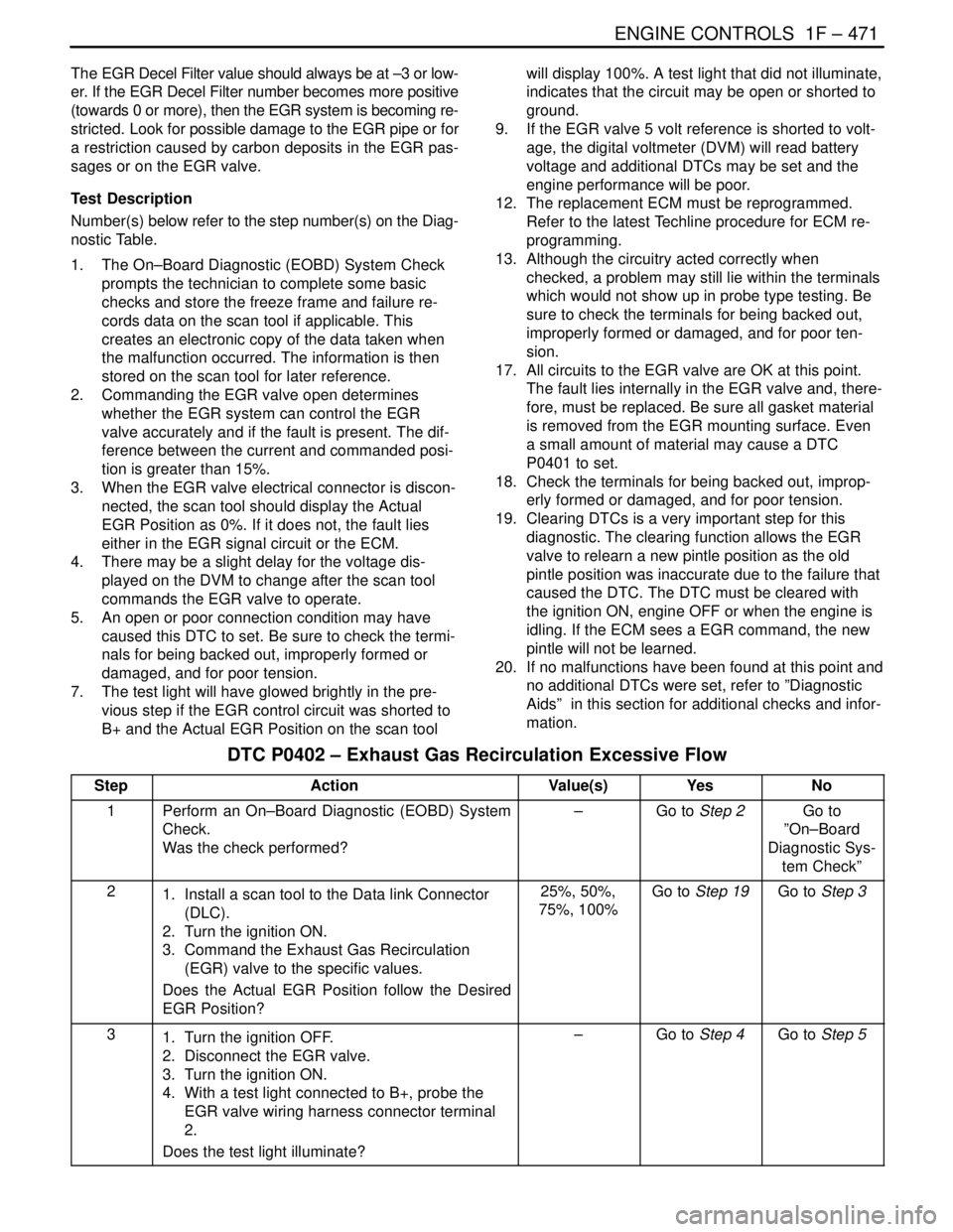

ENGINE CONTROLS 1F – 471

DAEWOO V–121 BL4

The EGR Decel Filter value should always be at –3 or low-

er. If the EGR Decel Filter number becomes more positive

(towards 0 or more), then the EGR system is becoming re-

stricted. Look for possible damage to the EGR pipe or for

a restriction caused by carbon deposits in the EGR pas-

sages or on the EGR valve.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Commanding the EGR valve open determines

whether the EGR system can control the EGR

valve accurately and if the fault is present. The dif-

ference between the current and commanded posi-

tion is greater than 15%.

3. When the EGR valve electrical connector is discon-

nected, the scan tool should display the Actual

EGR Position as 0%. If it does not, the fault lies

either in the EGR signal circuit or the ECM.

4. There may be a slight delay for the voltage dis-

played on the DVM to change after the scan tool

commands the EGR valve to operate.

5. An open or poor connection condition may have

caused this DTC to set. Be sure to check the termi-

nals for being backed out, improperly formed or

damaged, and for poor tension.

7. The test light will have glowed brightly in the pre-

vious step if the EGR control circuit was shorted to

B+ and the Actual EGR Position on the scan toolwill display 100%. A test light that did not illuminate,

indicates that the circuit may be open or shorted to

ground.

9. If the EGR valve 5 volt reference is shorted to volt-

age, the digital voltmeter (DVM) will read battery

voltage and additional DTCs may be set and the

engine performance will be poor.

12. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

13. Although the circuitry acted correctly when

checked, a problem may still lie within the terminals

which would not show up in probe type testing. Be

sure to check the terminals for being backed out,

improperly formed or damaged, and for poor ten-

sion.

17. All circuits to the EGR valve are OK at this point.

The fault lies internally in the EGR valve and, there-

fore, must be replaced. Be sure all gasket material

is removed from the EGR mounting surface. Even

a small amount of material may cause a DTC

P0401 to set.

18. Check the terminals for being backed out, improp-

erly formed or damaged, and for poor tension.

19. Clearing DTCs is a very important step for this

diagnostic. The clearing function allows the EGR

valve to relearn a new pintle position as the old

pintle position was inaccurate due to the failure that

caused the DTC. The DTC must be cleared with

the ignition ON, engine OFF or when the engine is

idling. If the ECM sees a EGR command, the new

pintle will not be learned.

20. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation.

DTC P0402 – Exhaust Gas Recirculation Excessive Flow

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data link Connector

(DLC).

2. Turn the ignition ON.

3. Command the Exhaust Gas Recirculation

(EGR) valve to the specific values.

Does the Actual EGR Position follow the Desired

EGR Position?25%, 50%,

75%, 100%Go to Step 19Go to Step 3

31. Turn the ignition OFF.

2. Disconnect the EGR valve.

3. Turn the ignition ON.

4. With a test light connected to B+, probe the

EGR valve wiring harness connector terminal

2.

Does the test light illuminate?–Go to Step 4Go to Step 5

Page 721 of 2643

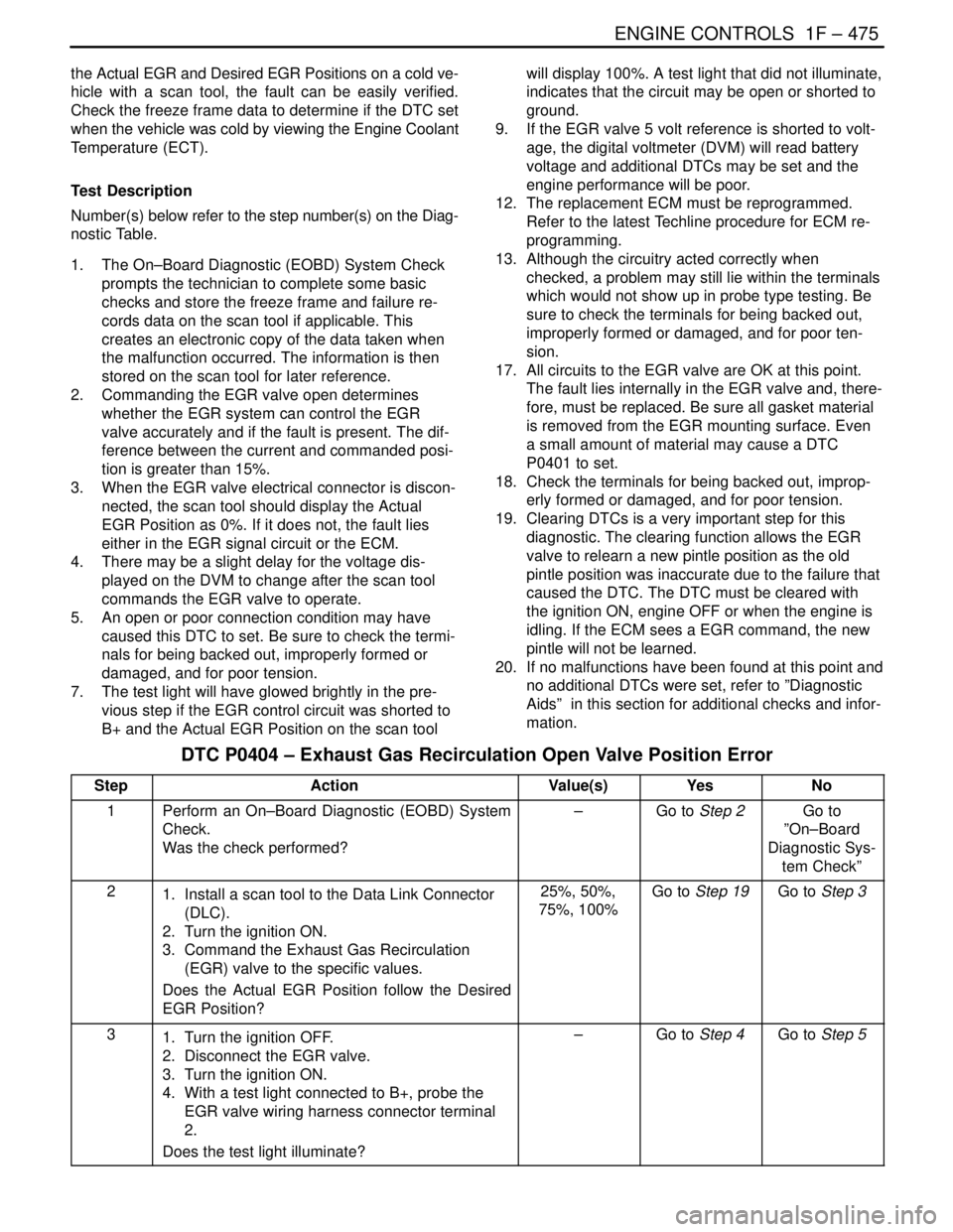

ENGINE CONTROLS 1F – 475

DAEWOO V–121 BL4

the Actual EGR and Desired EGR Positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the freeze frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Commanding the EGR valve open determines

whether the EGR system can control the EGR

valve accurately and if the fault is present. The dif-

ference between the current and commanded posi-

tion is greater than 15%.

3. When the EGR valve electrical connector is discon-

nected, the scan tool should display the Actual

EGR Position as 0%. If it does not, the fault lies

either in the EGR signal circuit or the ECM.

4. There may be a slight delay for the voltage dis-

played on the DVM to change after the scan tool

commands the EGR valve to operate.

5. An open or poor connection condition may have

caused this DTC to set. Be sure to check the termi-

nals for being backed out, improperly formed or

damaged, and for poor tension.

7. The test light will have glowed brightly in the pre-

vious step if the EGR control circuit was shorted to

B+ and the Actual EGR Position on the scan toolwill display 100%. A test light that did not illuminate,

indicates that the circuit may be open or shorted to

ground.

9. If the EGR valve 5 volt reference is shorted to volt-

age, the digital voltmeter (DVM) will read battery

voltage and additional DTCs may be set and the

engine performance will be poor.

12. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

13. Although the circuitry acted correctly when

checked, a problem may still lie within the terminals

which would not show up in probe type testing. Be

sure to check the terminals for being backed out,

improperly formed or damaged, and for poor ten-

sion.

17. All circuits to the EGR valve are OK at this point.

The fault lies internally in the EGR valve and, there-

fore, must be replaced. Be sure all gasket material

is removed from the EGR mounting surface. Even

a small amount of material may cause a DTC

P0401 to set.

18. Check the terminals for being backed out, improp-

erly formed or damaged, and for poor tension.

19. Clearing DTCs is a very important step for this

diagnostic. The clearing function allows the EGR

valve to relearn a new pintle position as the old

pintle position was inaccurate due to the failure that

caused the DTC. The DTC must be cleared with

the ignition ON, engine OFF or when the engine is

idling. If the ECM sees a EGR command, the new

pintle will not be learned.

20. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation.

DTC P0404 – Exhaust Gas Recirculation Open Valve Position Error

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

3. Command the Exhaust Gas Recirculation

(EGR) valve to the specific values.

Does the Actual EGR Position follow the Desired

EGR Position?25%, 50%,

75%, 100%Go to Step 19Go to Step 3

31. Turn the ignition OFF.

2. Disconnect the EGR valve.

3. Turn the ignition ON.

4. With a test light connected to B+, probe the

EGR valve wiring harness connector terminal

2.

Does the test light illuminate?–Go to Step 4Go to Step 5

Page 747 of 2643

ENGINE CONTROLS 1F – 501

DAEWOO V–121 BL4

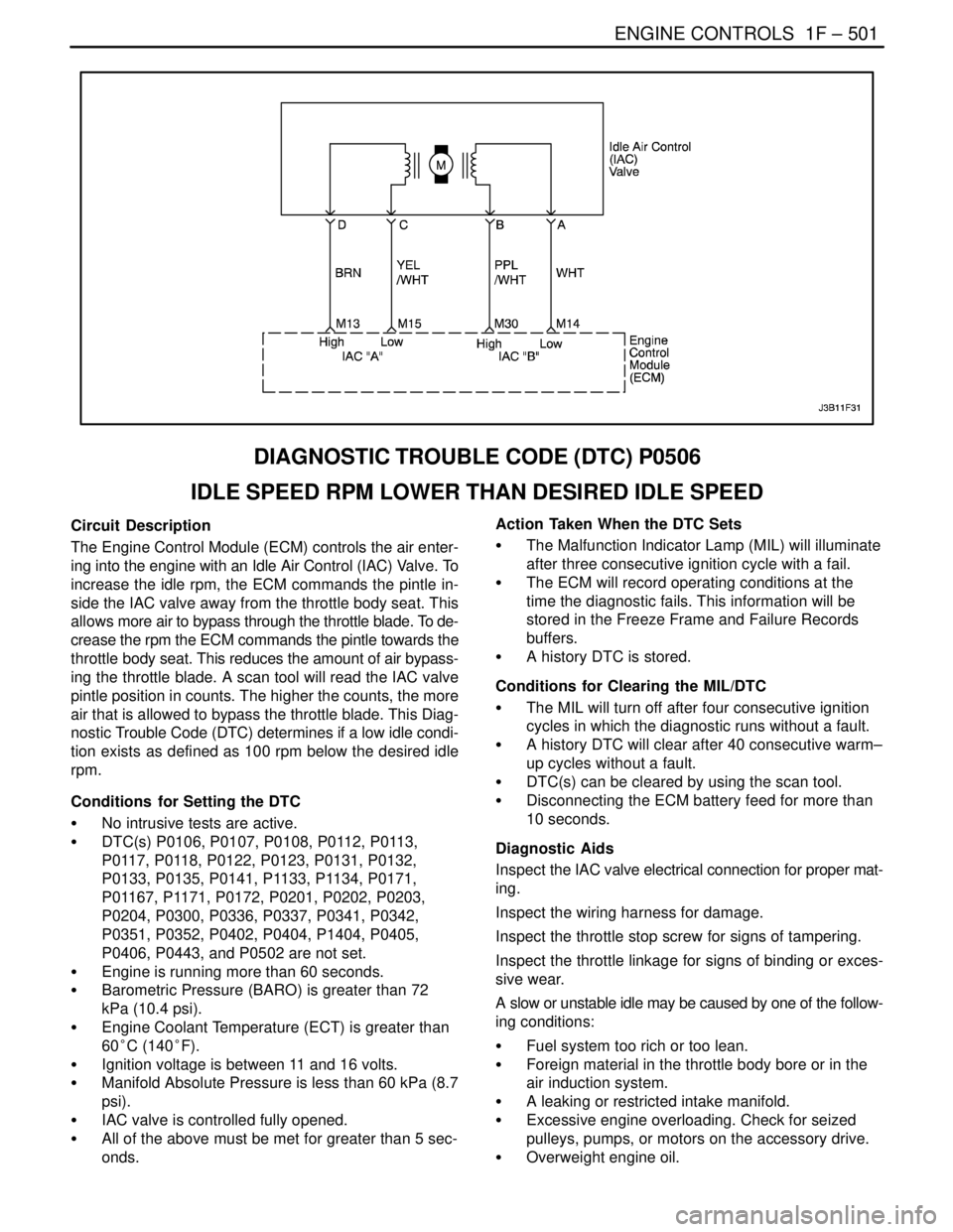

DIAGNOSTIC TROUBLE CODE (DTC) P0506

IDLE SPEED RPM LOWER THAN DESIRED IDLE SPEED

Circuit Description

The Engine Control Module (ECM) controls the air enter-

ing into the engine with an Idle Air Control (IAC) Valve. To

increase the idle rpm, the ECM commands the pintle in-

side the IAC valve away from the throttle body seat. This

allows more air to bypass through the throttle blade. To de-

crease the rpm the ECM commands the pintle towards the

throttle body seat. This reduces the amount of air bypass-

ing the throttle blade. A scan tool will read the IAC valve

pintle position in counts. The higher the counts, the more

air that is allowed to bypass the throttle blade. This Diag-

nostic Trouble Code (DTC) determines if a low idle condi-

tion exists as defined as 100 rpm below the desired idle

rpm.

Conditions for Setting the DTC

S No intrusive tests are active.

S DTC(s) P0106, P0107, P0108, P0112, P0113,

P0117, P0118, P0122, P0123, P0131, P0132,

P0133, P0135, P0141, P1133, P1134, P0171,

P01167, P1171, P0172, P0201, P0202, P0203,

P0204, P0300, P0336, P0337, P0341, P0342,

P0351, P0352, P0402, P0404, P1404, P0405,

P0406, P0443, and P0502 are not set.

S Engine is running more than 60 seconds.

S Barometric Pressure (BARO) is greater than 72

kPa (10.4 psi).

S Engine Coolant Temperature (ECT) is greater than

60°C (140°F).

S Ignition voltage is between 11 and 16 volts.

S Manifold Absolute Pressure is less than 60 kPa (8.7

psi).

S IAC valve is controlled fully opened.

S All of the above must be met for greater than 5 sec-

onds.Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Inspect the IAC valve electrical connection for proper mat-

ing.

Inspect the wiring harness for damage.

Inspect the throttle stop screw for signs of tampering.

Inspect the throttle linkage for signs of binding or exces-

sive wear.

A slow or unstable idle may be caused by one of the follow-

ing conditions:

S Fuel system too rich or too lean.

S Foreign material in the throttle body bore or in the

air induction system.

S A leaking or restricted intake manifold.

S Excessive engine overloading. Check for seized

pulleys, pumps, or motors on the accessory drive.

S Overweight engine oil.

Page 750 of 2643

1F – 504IENGINE CONTROLS

DAEWOO V–121 BL4

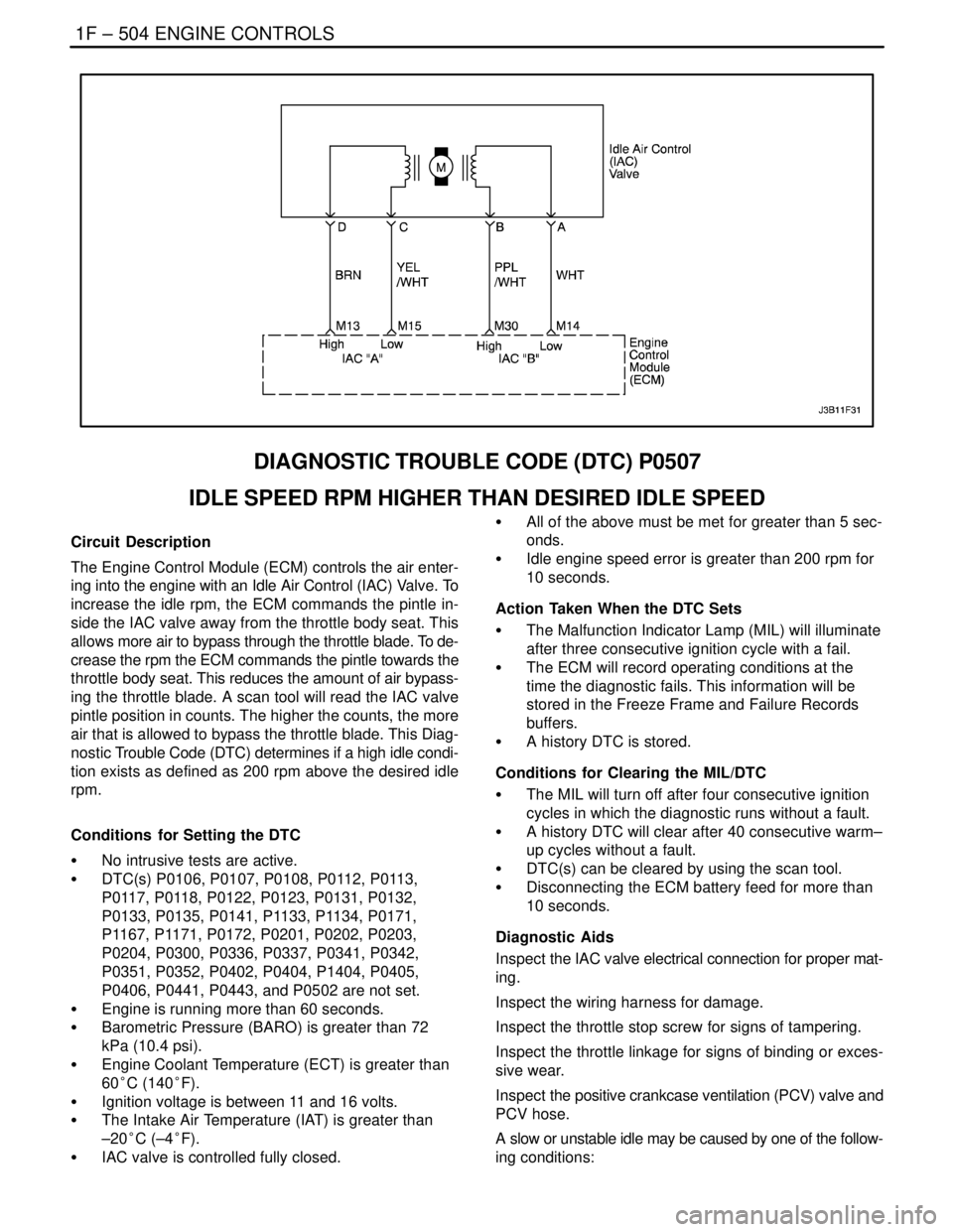

DIAGNOSTIC TROUBLE CODE (DTC) P0507

IDLE SPEED RPM HIGHER THAN DESIRED IDLE SPEED

Circuit Description

The Engine Control Module (ECM) controls the air enter-

ing into the engine with an Idle Air Control (IAC) Valve. To

increase the idle rpm, the ECM commands the pintle in-

side the IAC valve away from the throttle body seat. This

allows more air to bypass through the throttle blade. To de-

crease the rpm the ECM commands the pintle towards the

throttle body seat. This reduces the amount of air bypass-

ing the throttle blade. A scan tool will read the IAC valve

pintle position in counts. The higher the counts, the more

air that is allowed to bypass the throttle blade. This Diag-

nostic Trouble Code (DTC) determines if a high idle condi-

tion exists as defined as 200 rpm above the desired idle

rpm.

Conditions for Setting the DTC

S No intrusive tests are active.

S DTC(s) P0106, P0107, P0108, P0112, P0113,

P0117, P0118, P0122, P0123, P0131, P0132,

P0133, P0135, P0141, P1133, P1134, P0171,

P1167, P1171, P0172, P0201, P0202, P0203,

P0204, P0300, P0336, P0337, P0341, P0342,

P0351, P0352, P0402, P0404, P1404, P0405,

P0406, P0441, P0443, and P0502 are not set.

S Engine is running more than 60 seconds.

S Barometric Pressure (BARO) is greater than 72

kPa (10.4 psi).

S Engine Coolant Temperature (ECT) is greater than

60°C (140°F).

S Ignition voltage is between 11 and 16 volts.

S The Intake Air Temperature (IAT) is greater than

–20°C (–4°F).

S IAC valve is controlled fully closed.S All of the above must be met for greater than 5 sec-

onds.

S Idle engine speed error is greater than 200 rpm for

10 seconds.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Inspect the IAC valve electrical connection for proper mat-

ing.

Inspect the wiring harness for damage.

Inspect the throttle stop screw for signs of tampering.

Inspect the throttle linkage for signs of binding or exces-

sive wear.

Inspect the positive crankcase ventilation (PCV) valve and

PCV hose.

A slow or unstable idle may be caused by one of the follow-

ing conditions:

Page 760 of 2643

1F – 514IENGINE CONTROLS

DAEWOO V–121 BL4

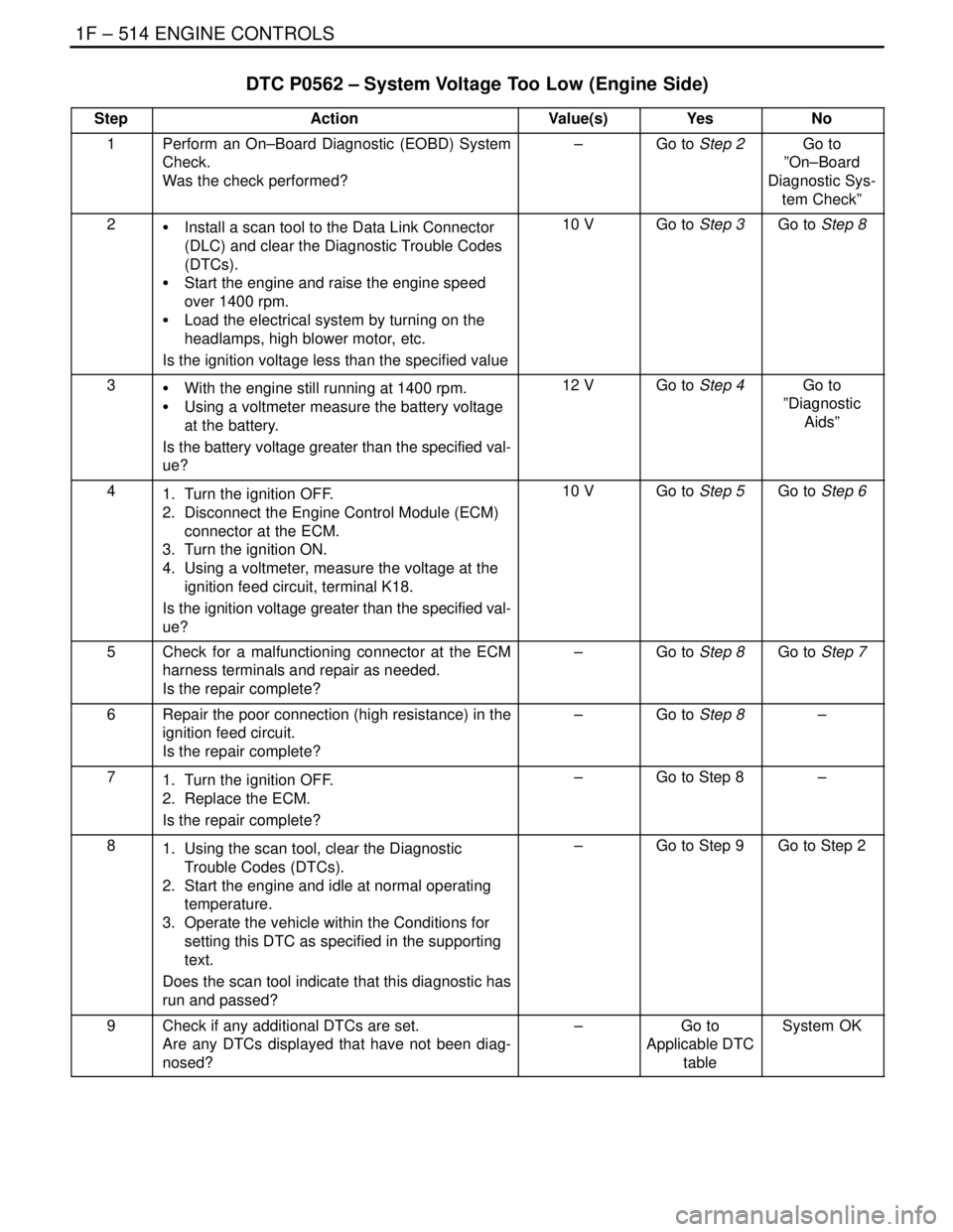

DTC P0562 – System Voltage Too Low (Engine Side)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2S Install a scan tool to the Data Link Connector

(DLC) and clear the Diagnostic Trouble Codes

(DTCs).

S Start the engine and raise the engine speed

over 1400 rpm.

S Load the electrical system by turning on the

headlamps, high blower motor, etc.

Is the ignition voltage less than the specified value10 VGo to Step 3Go to Step 8

3S With the engine still running at 1400 rpm.

S Using a voltmeter measure the battery voltage

at the battery.

Is the battery voltage greater than the specified val-

ue?12 VGo to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

connector at the ECM.

3. Turn the ignition ON.

4. Using a voltmeter, measure the voltage at the

ignition feed circuit, terminal K18.

Is the ignition voltage greater than the specified val-

ue?10 VGo to Step 5Go to Step 6

5Check for a malfunctioning connector at the ECM

harness terminals and repair as needed.

Is the repair complete?–Go to Step 8Go to Step 7

6Repair the poor connection (high resistance) in the

ignition feed circuit.

Is the repair complete?–Go to Step 8–

71. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 8–

81. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 9Go to Step 2

9Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 762 of 2643

1F – 516IENGINE CONTROLS

DAEWOO V–121 BL4

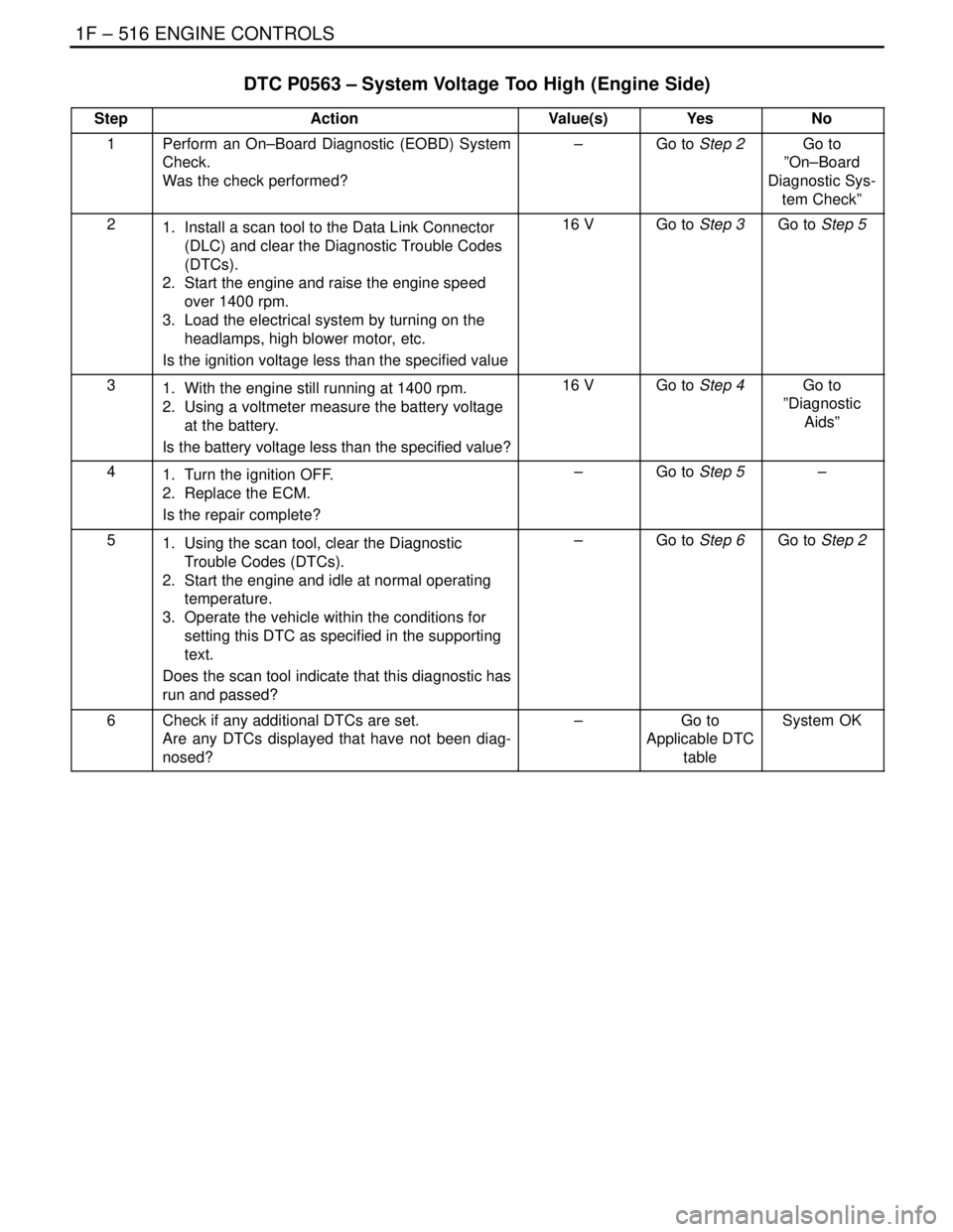

DTC P0563 – System Voltage Too High (Engine Side)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC) and clear the Diagnostic Trouble Codes

(DTCs).

2. Start the engine and raise the engine speed

over 1400 rpm.

3. Load the electrical system by turning on the

headlamps, high blower motor, etc.

Is the ignition voltage less than the specified value16 VGo to Step 3Go to Step 5

31. With the engine still running at 1400 rpm.

2. Using a voltmeter measure the battery voltage

at the battery.

Is the battery voltage less than the specified value?16 VGo to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 5–

51. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 6Go to Step 2

6Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 763 of 2643

ENGINE CONTROLS 1F – 517

DAEWOO V–121 BL4

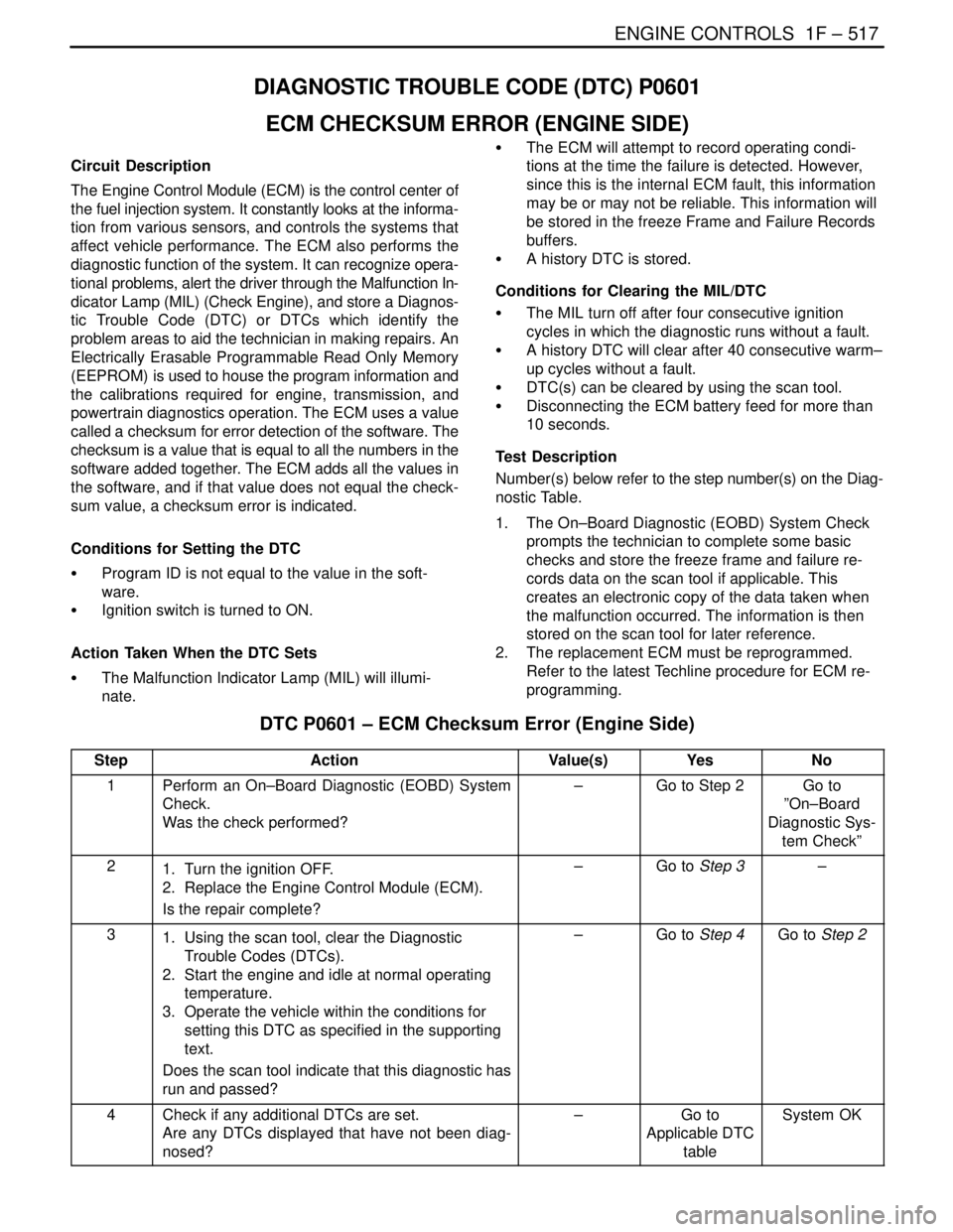

DIAGNOSTIC TROUBLE CODE (DTC) P0601

ECM CHECKSUM ERROR (ENGINE SIDE)

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The ECM uses a value

called a checksum for error detection of the software. The

checksum is a value that is equal to all the numbers in the

software added together. The ECM adds all the values in

the software, and if that value does not equal the check-

sum value, a checksum error is indicated.

Conditions for Setting the DTC

S Program ID is not equal to the value in the soft-

ware.

S Ignition switch is turned to ON.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will attempt to record operating condi-

tions at the time the failure is detected. However,

since this is the internal ECM fault, this information

may be or may not be reliable. This information will

be stored in the freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0601 – ECM Checksum Error (Engine Side)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 764 of 2643

1F – 518IENGINE CONTROLS

DAEWOO V–121 BL4

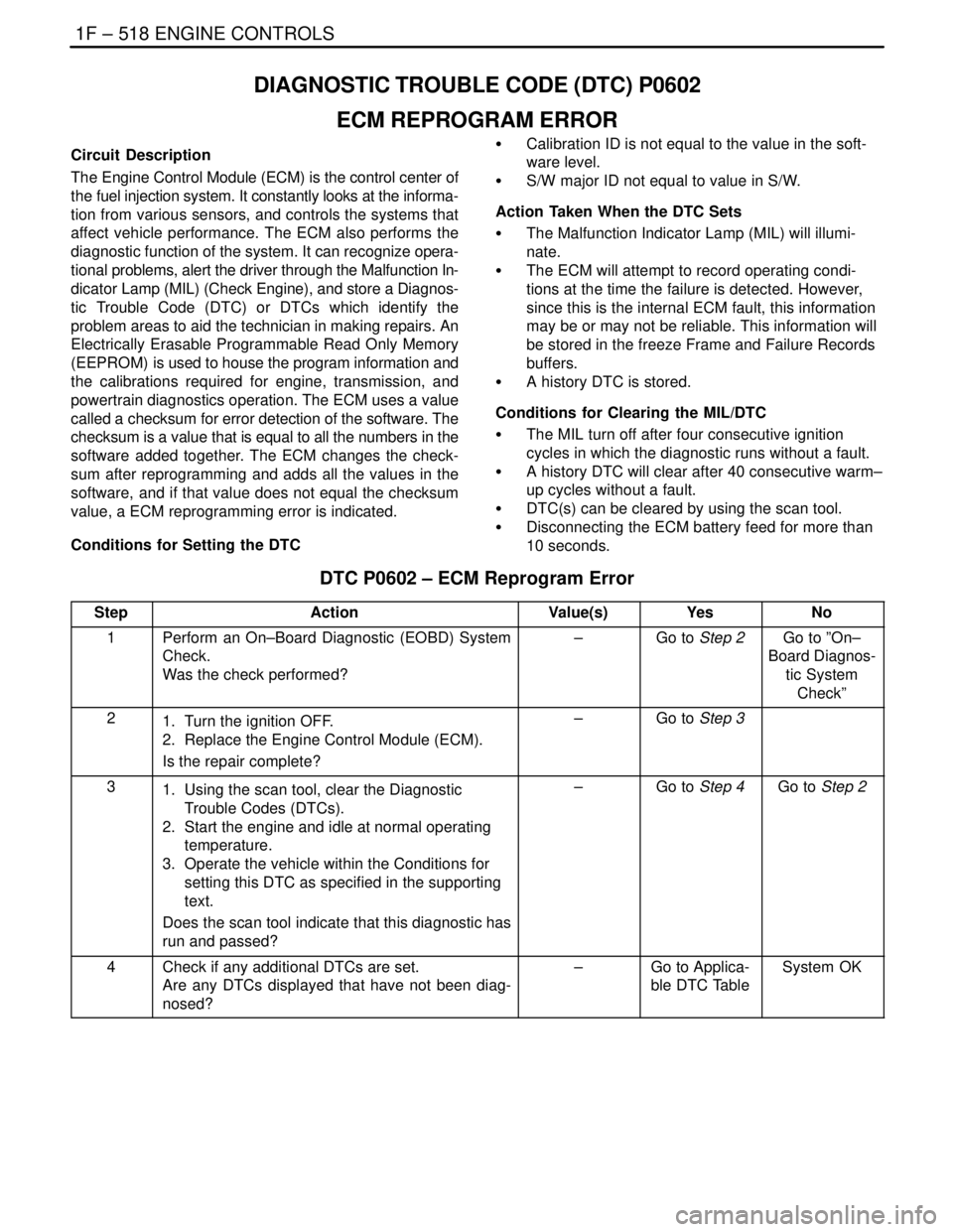

DIAGNOSTIC TROUBLE CODE (DTC) P0602

ECM REPROGRAM ERROR

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The ECM uses a value

called a checksum for error detection of the software. The

checksum is a value that is equal to all the numbers in the

software added together. The ECM changes the check-

sum after reprogramming and adds all the values in the

software, and if that value does not equal the checksum

value, a ECM reprogramming error is indicated.

Conditions for Setting the DTCS Calibration ID is not equal to the value in the soft-

ware level.

S S/W major ID not equal to value in S/W.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will attempt to record operating condi-

tions at the time the failure is detected. However,

since this is the internal ECM fault, this information

may be or may not be reliable. This information will

be stored in the freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P0602 – ECM Reprogram Error

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to Applica-

ble DTC TableSystem OK