tran DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1004 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 5

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

DRIVE AXLE ASSEMBLY

Tools Required

KM–507–B Ball Joint Separator

KM–460–A Axle Shaft Remover

Removal Procedure

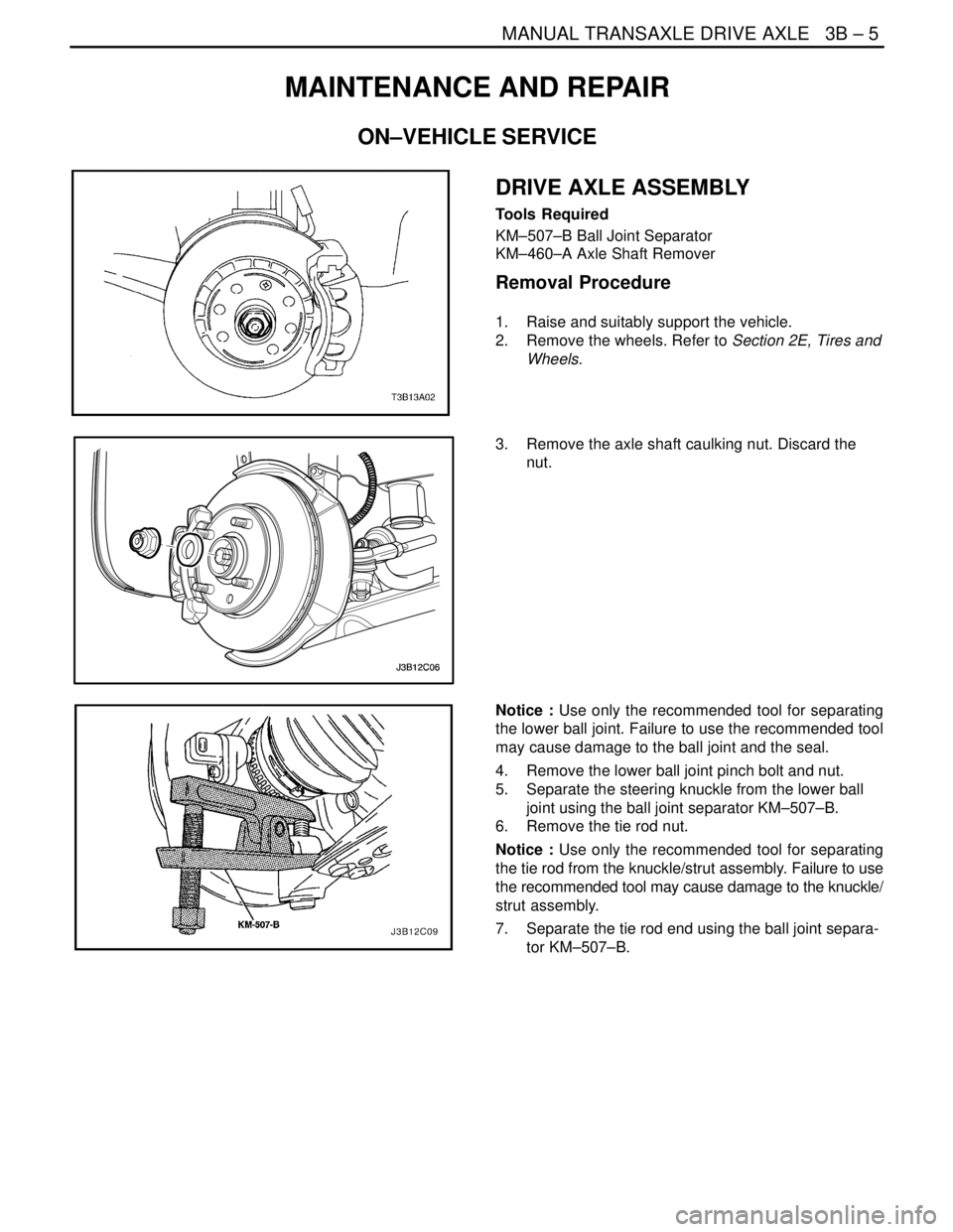

1. Raise and suitably support the vehicle.

2. Remove the wheels. Refer to Section 2E, Tires and

Wheels.

3. Remove the axle shaft caulking nut. Discard the

nut.

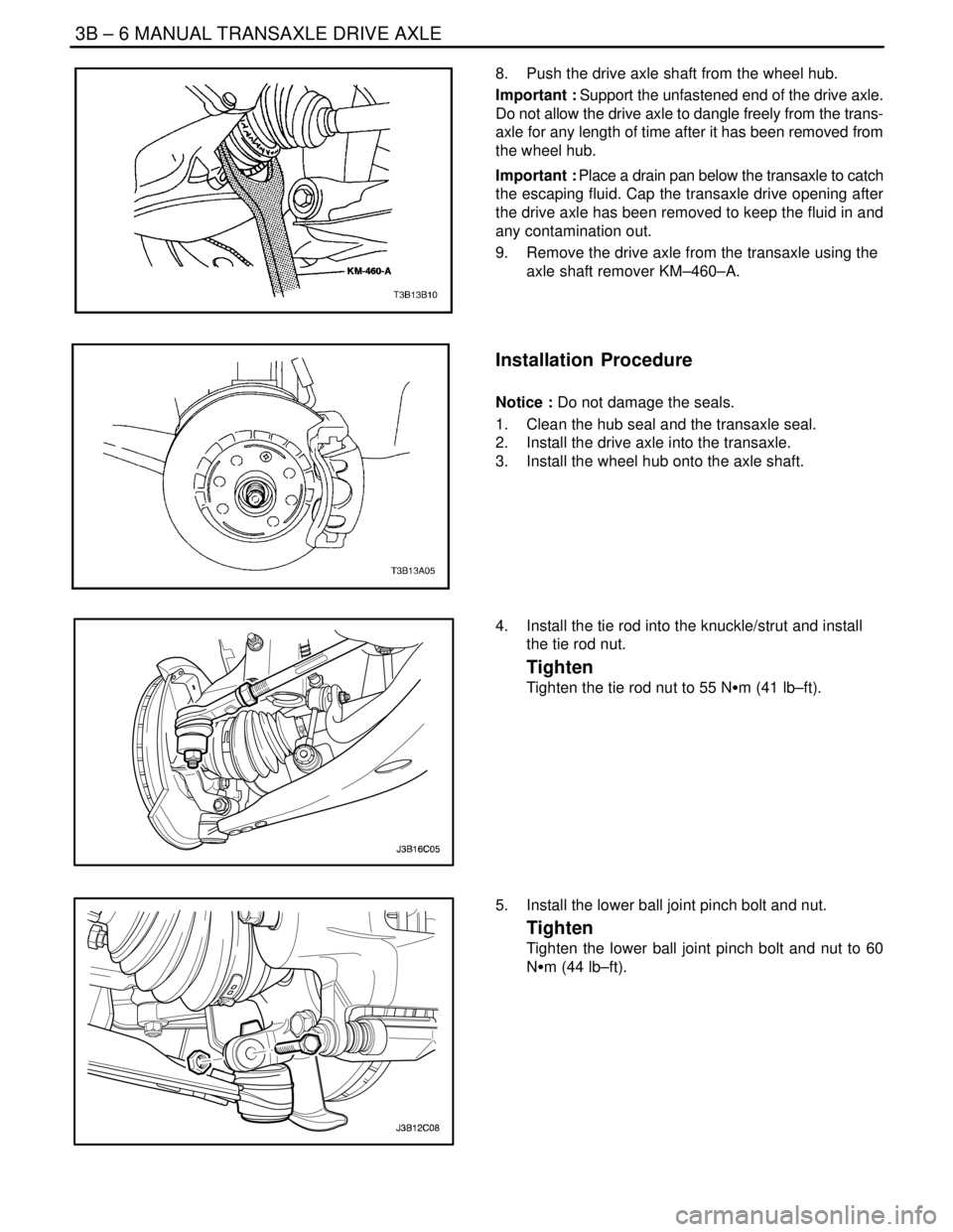

Notice : Use only the recommended tool for separating

the lower ball joint. Failure to use the recommended tool

may cause damage to the ball joint and the seal.

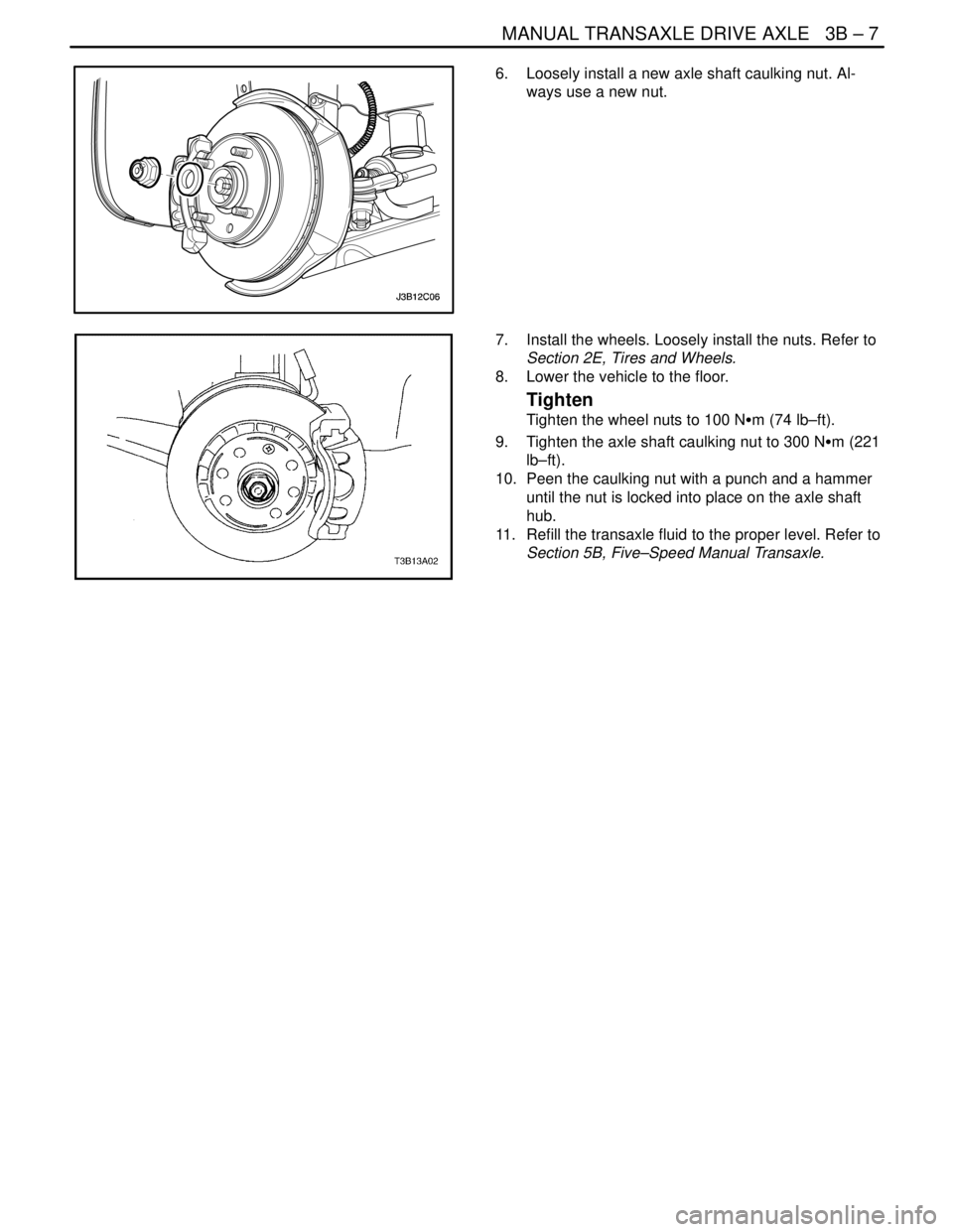

4. Remove the lower ball joint pinch bolt and nut.

5. Separate the steering knuckle from the lower ball

joint using the ball joint separator KM–507–B.

6. Remove the tie rod nut.

Notice : Use only the recommended tool for separating

the tie rod from the knuckle/strut assembly. Failure to use

the recommended tool may cause damage to the knuckle/

strut assembly.

7. Separate the tie rod end using the ball joint separa-

tor KM–507–B.

Page 1005 of 2643

3B – 6IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

8. Push the drive axle shaft from the wheel hub.

Important : Support the unfastened end of the drive axle.

Do not allow the drive axle to dangle freely from the trans-

axle for any length of time after it has been removed from

the wheel hub.

Important : Place a drain pan below the transaxle to catch

the escaping fluid. Cap the transaxle drive opening after

the drive axle has been removed to keep the fluid in and

any contamination out.

9. Remove the drive axle from the transaxle using the

axle shaft remover KM–460–A.

Installation Procedure

Notice : Do not damage the seals.

1. Clean the hub seal and the transaxle seal.

2. Install the drive axle into the transaxle.

3. Install the wheel hub onto the axle shaft.

4. Install the tie rod into the knuckle/strut and install

the tie rod nut.

Tighten

Tighten the tie rod nut to 55 NSm (41 lb–ft).

5. Install the lower ball joint pinch bolt and nut.

Tighten

Tighten the lower ball joint pinch bolt and nut to 60

NSm (44 lb–ft).

Page 1006 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 7

DAEWOO V–121 BL4

6. Loosely install a new axle shaft caulking nut. Al-

ways use a new nut.

7. Install the wheels. Loosely install the nuts. Refer to

Section 2E, Tires and Wheels.

8. Lower the vehicle to the floor.

Tighten

Tighten the wheel nuts to 100 NSm (74 lb–ft).

9. Tighten the axle shaft caulking nut to 300 NSm (221

lb–ft).

10. Peen the caulking nut with a punch and a hammer

until the nut is locked into place on the axle shaft

hub.

11. Refill the transaxle fluid to the proper level. Refer to

Section 5B, Five–Speed Manual Transaxle.

Page 1007 of 2643

3B – 8IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

UNIT REPAIR

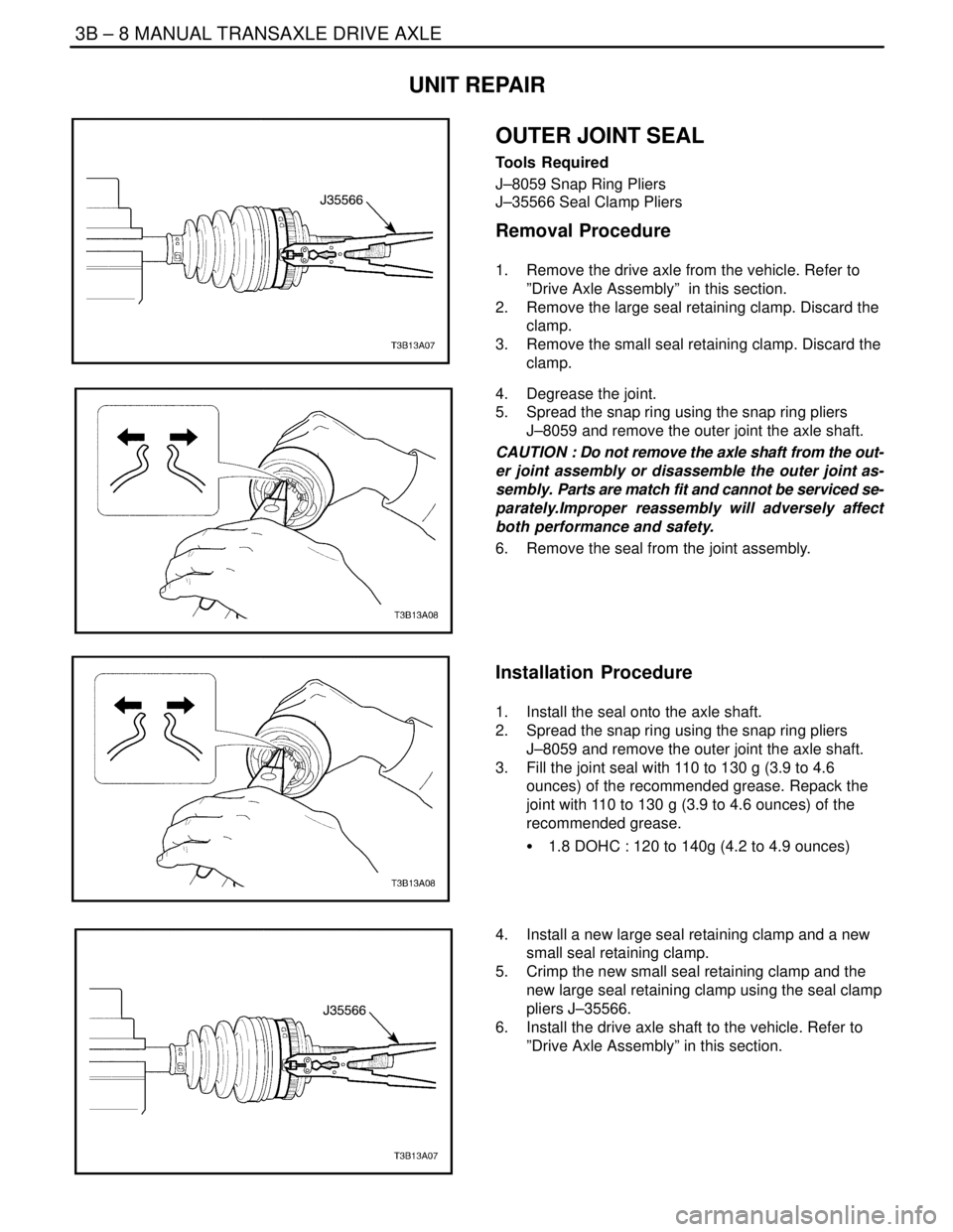

OUTER JOINT SEAL

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle Assembly” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Degrease the joint.

5. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

CAUTION : Do not remove the axle shaft from the out-

er joint assembly or disassemble the outer joint as-

sembly. Parts are match fit and cannot be serviced se-

parately.Improper reassembly will adversely affect

both performance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install the seal onto the axle shaft.

2. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

3. Fill the joint seal with 110 to 130 g (3.9 to 4.6

ounces) of the recommended grease. Repack the

joint with 110 to 130 g (3.9 to 4.6 ounces) of the

recommended grease.

S 1.8 DOHC : 120 to 140g (4.2 to 4.9 ounces)

4. Install a new large seal retaining clamp and a new

small seal retaining clamp.

5. Crimp the new small seal retaining clamp and the

new large seal retaining clamp using the seal clamp

pliers J–35566.

6. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.

Page 1008 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 9

DAEWOO V–121 BL4

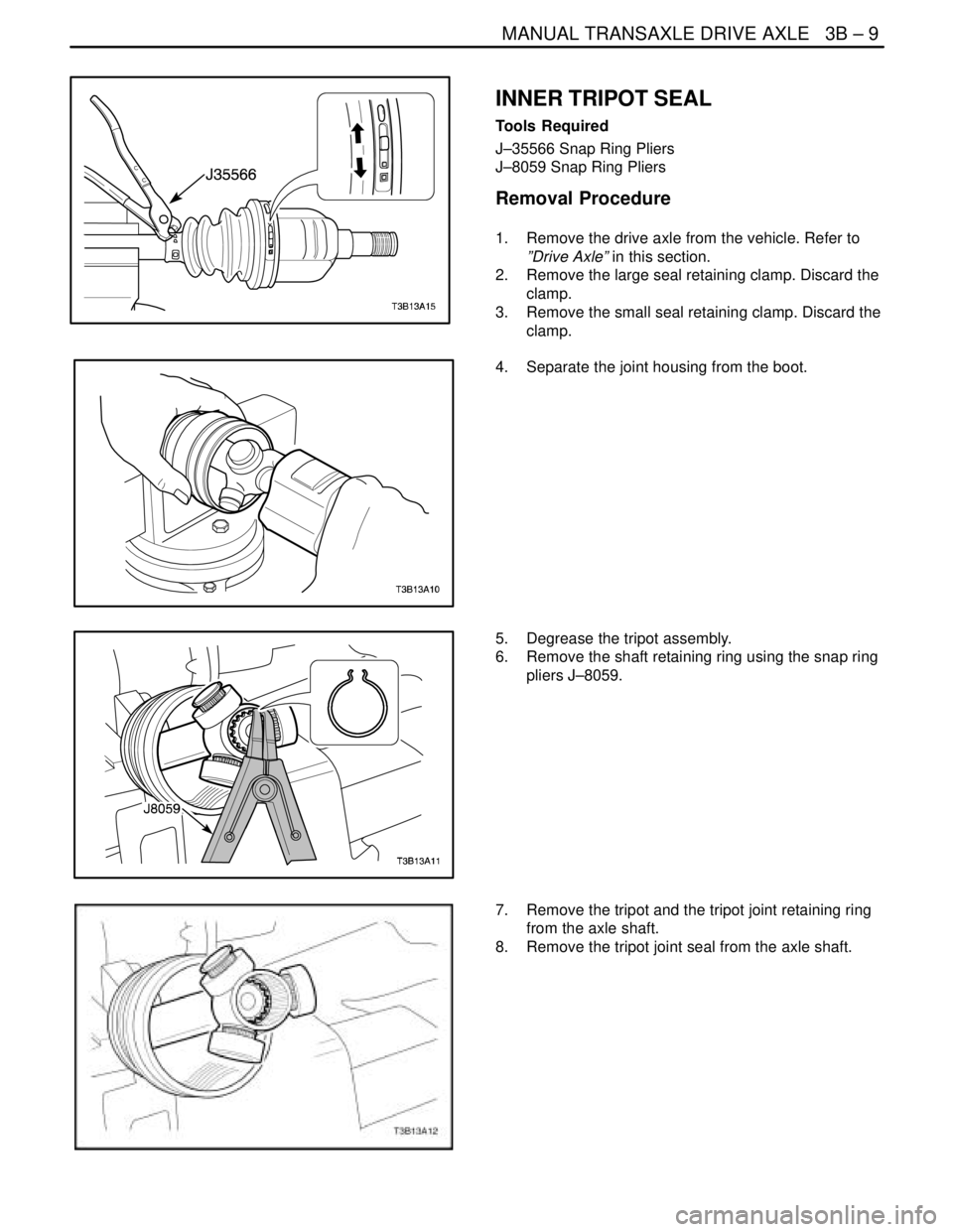

INNER TRIPOT SEAL

Tools Required

J–35566 Snap Ring Pliers

J–8059 Snap Ring Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Separate the joint housing from the boot.

5. Degrease the tripot assembly.

6. Remove the shaft retaining ring using the snap ring

pliers J–8059.

7. Remove the tripot and the tripot joint retaining ring

from the axle shaft.

8. Remove the tripot joint seal from the axle shaft.

Page 1009 of 2643

3B – 10IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

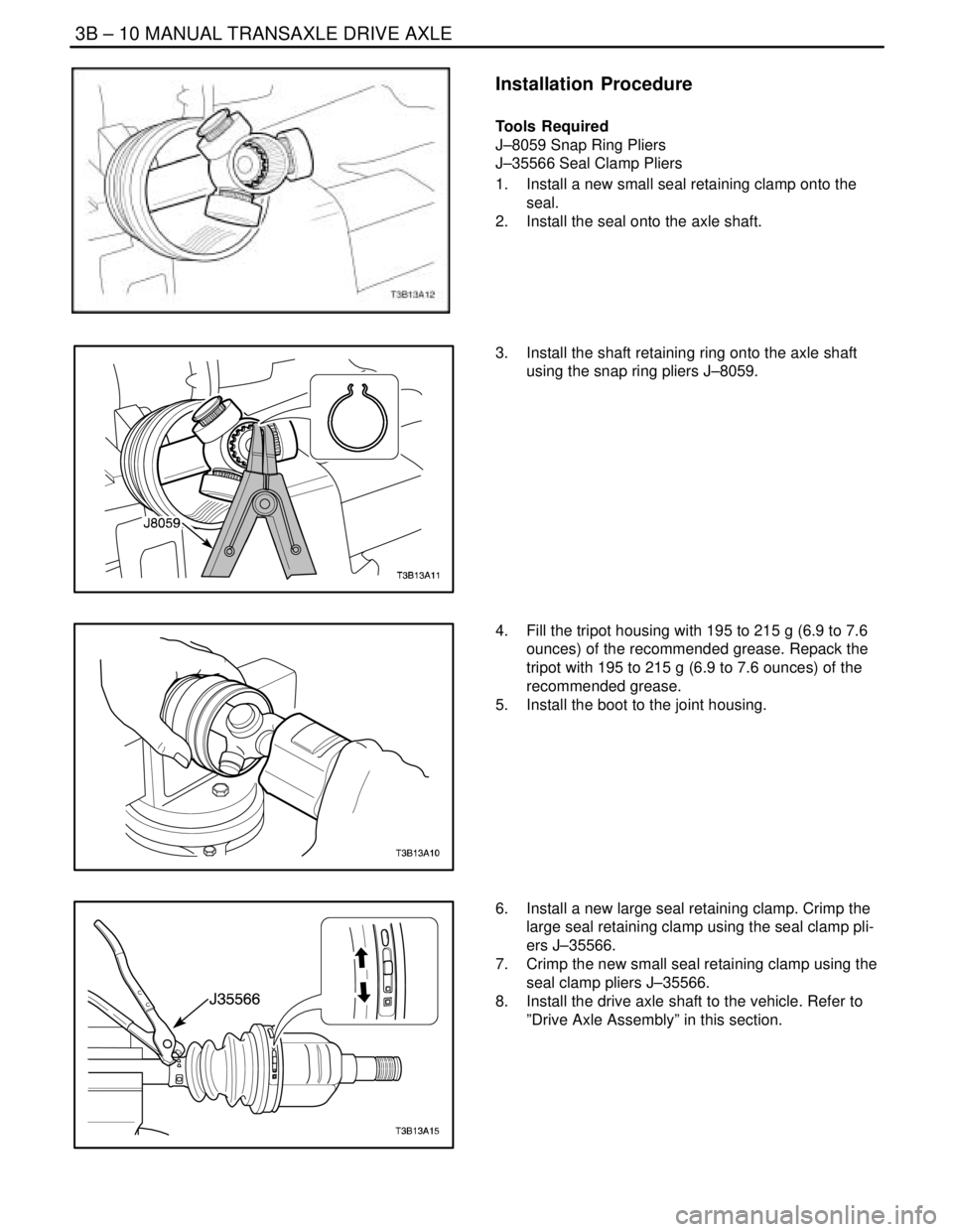

Installation Procedure

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

1. Install a new small seal retaining clamp onto the

seal.

2. Install the seal onto the axle shaft.

3. Install the shaft retaining ring onto the axle shaft

using the snap ring pliers J–8059.

4. Fill the tripot housing with 195 to 215 g (6.9 to 7.6

ounces) of the recommended grease. Repack the

tripot with 195 to 215 g (6.9 to 7.6 ounces) of the

recommended grease.

5. Install the boot to the joint housing.

6. Install a new large seal retaining clamp. Crimp the

large seal retaining clamp using the seal clamp pli-

ers J–35566.

7. Crimp the new small seal retaining clamp using the

seal clamp pliers J–35566.

8. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.

Page 1010 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 11

DAEWOO V–121 BL4

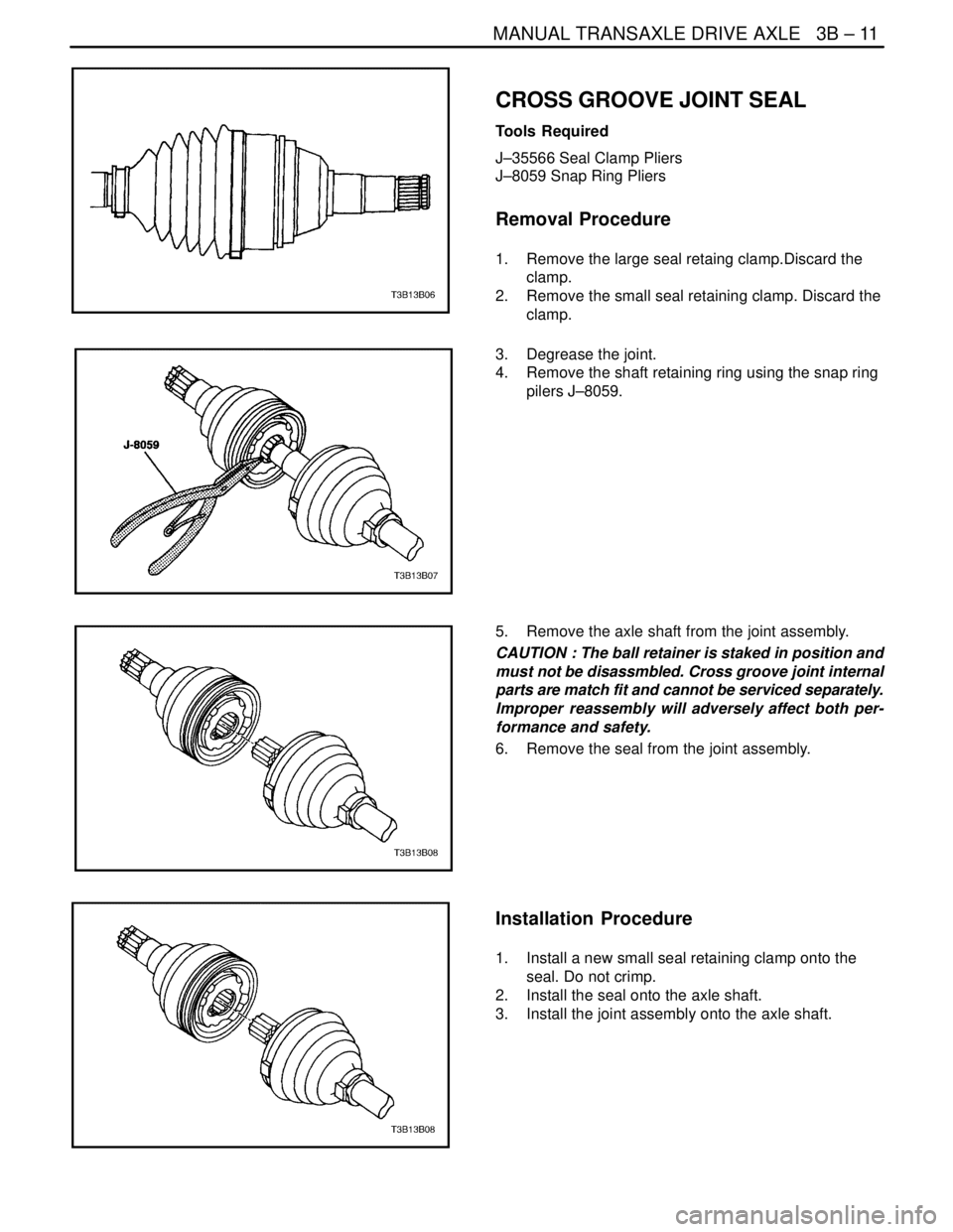

CROSS GROOVE JOINT SEAL

Tools Required

J–35566 Seal Clamp Pliers

J–8059 Snap Ring Pliers

Removal Procedure

1. Remove the large seal retaing clamp.Discard the

clamp.

2. Remove the small seal retaining clamp. Discard the

clamp.

3. Degrease the joint.

4. Remove the shaft retaining ring using the snap ring

pilers J–8059.

5. Remove the axle shaft from the joint assembly.

CAUTION : The ball retainer is staked in position and

must not be disassmbled. Cross groove joint internal

parts are match fit and cannot be serviced separately.

Improper reassembly will adversely affect both per-

formance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install a new small seal retaining clamp onto the

seal. Do not crimp.

2. Install the seal onto the axle shaft.

3. Install the joint assembly onto the axle shaft.

Page 1011 of 2643

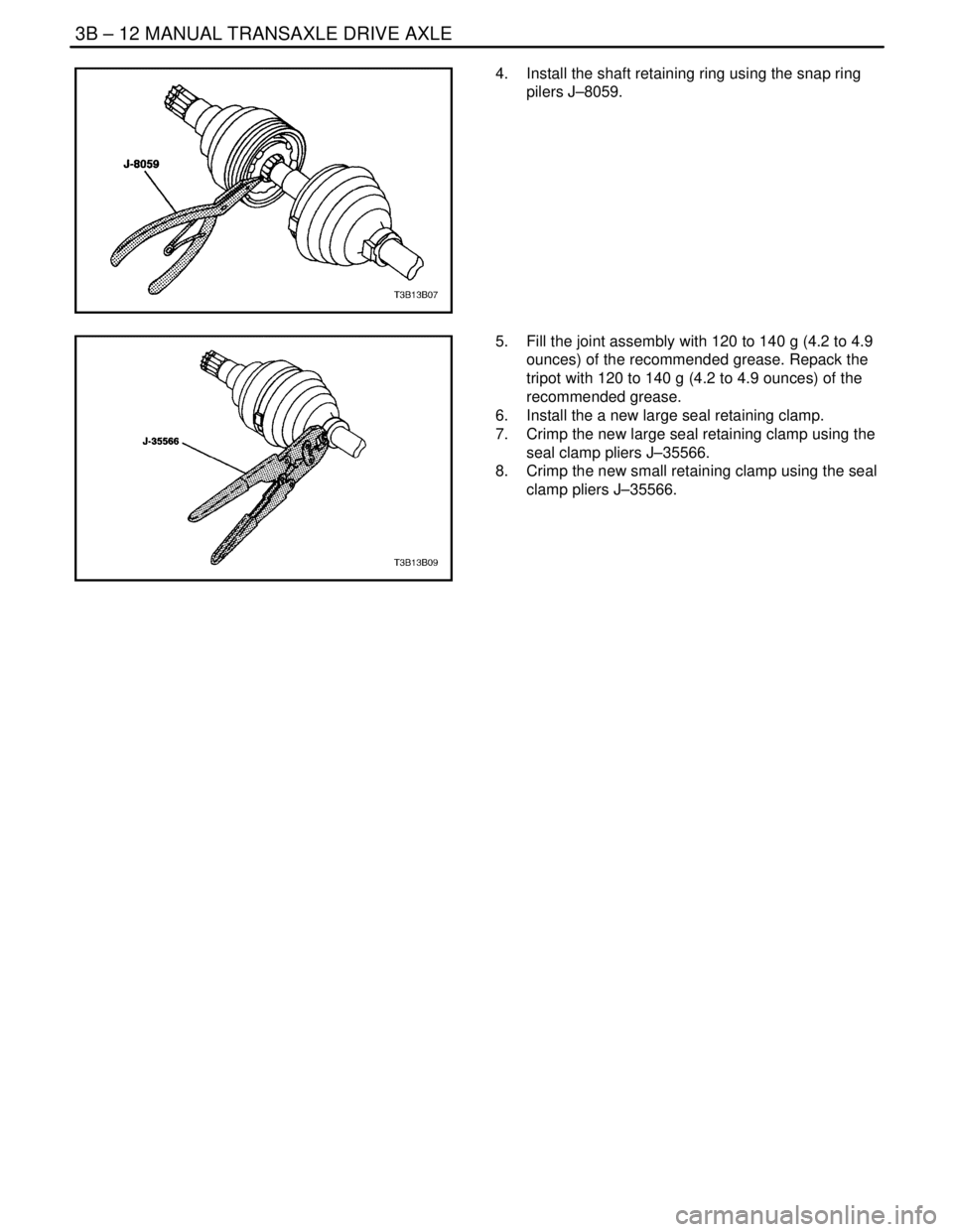

3B – 12IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

4. Install the shaft retaining ring using the snap ring

pilers J–8059.

5. Fill the joint assembly with 120 to 140 g (4.2 to 4.9

ounces) of the recommended grease. Repack the

tripot with 120 to 140 g (4.2 to 4.9 ounces) of the

recommended grease.

6. Install the a new large seal retaining clamp.

7. Crimp the new large seal retaining clamp using the

seal clamp pliers J–35566.

8. Crimp the new small retaining clamp using the seal

clamp pliers J–35566.

Page 1012 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 13

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FRONT DRIVE AXLE

General Description

Drive axles are flexible shaft assemblies that transmit a

rotational force from the transaxle to the front–wheel as-

semblies. Each axle assembly consists of an innerconstant–velocity joint and an outer constant–velocity

joint connected to an axle shaft. The inner joint is com-

pletely flexible and has the ability to move in and out. The

outer joint is also flexible, but it cannot move in and out.

The drive axles use one type of outboard joint and two

types of inboard joints.

Page 1027 of 2643

HYDRAULIC BRAKES 4A – 11

DAEWOO V–121 BL4

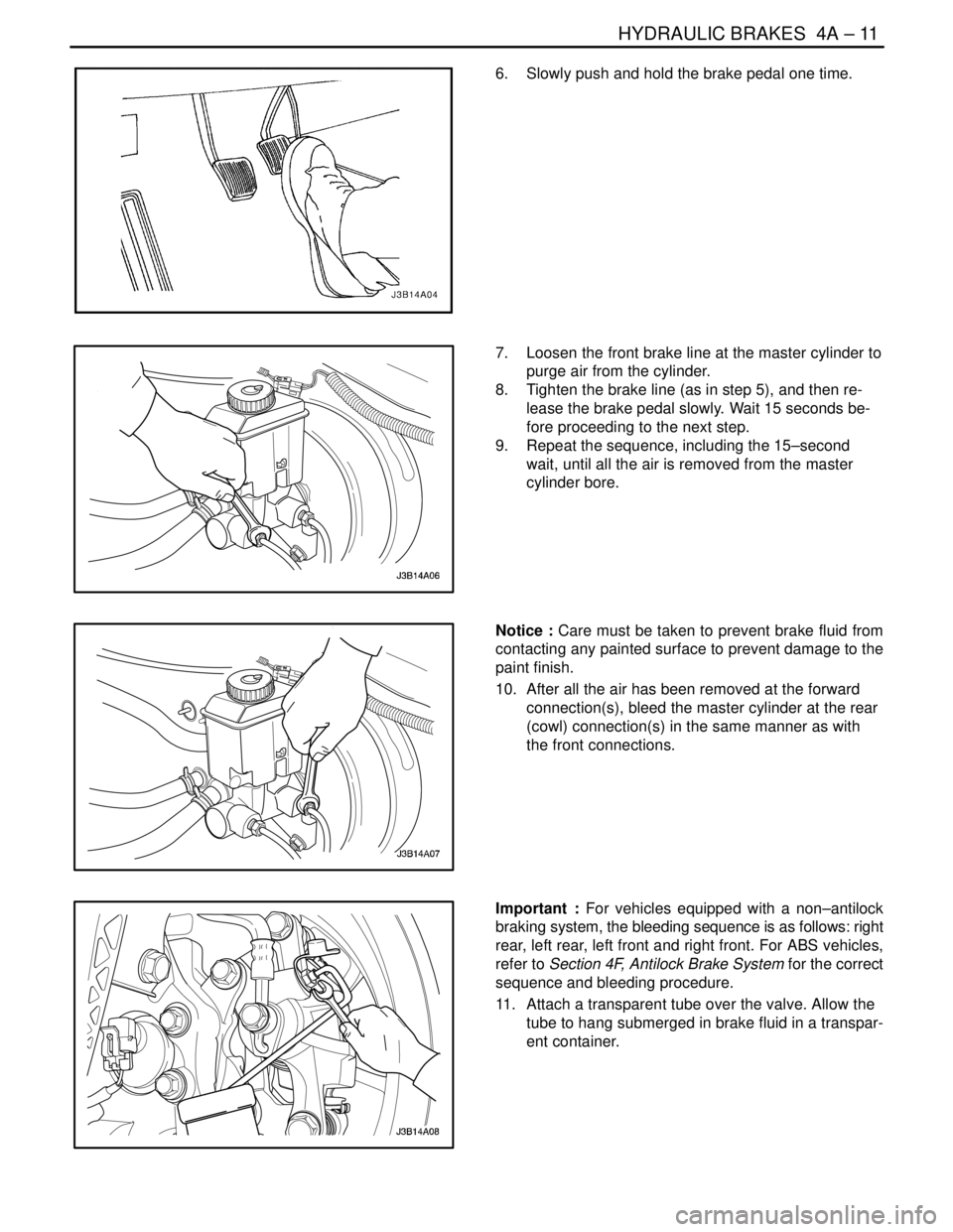

6. Slowly push and hold the brake pedal one time.

7. Loosen the front brake line at the master cylinder to

purge air from the cylinder.

8. Tighten the brake line (as in step 5), and then re-

lease the brake pedal slowly. Wait 15 seconds be-

fore proceeding to the next step.

9. Repeat the sequence, including the 15–second

wait, until all the air is removed from the master

cylinder bore.

Notice : Care must be taken to prevent brake fluid from

contacting any painted surface to prevent damage to the

paint finish.

10. After all the air has been removed at the forward

connection(s), bleed the master cylinder at the rear

(cowl) connection(s) in the same manner as with

the front connections.

Important : For vehicles equipped with a non–antilock

braking system, the bleeding sequence is as follows: right

rear, left rear, left front and right front. For ABS vehicles,

refer to Section 4F, Antilock Brake System for the correct

sequence and bleeding procedure.

11. Attach a transparent tube over the valve. Allow the

tube to hang submerged in brake fluid in a transpar-

ent container.