tran DAEWOO LACETTI 2004 Service Manual Online

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 814 of 2643

1F – 568IENGINE CONTROLS

DAEWOO V–121 BL4

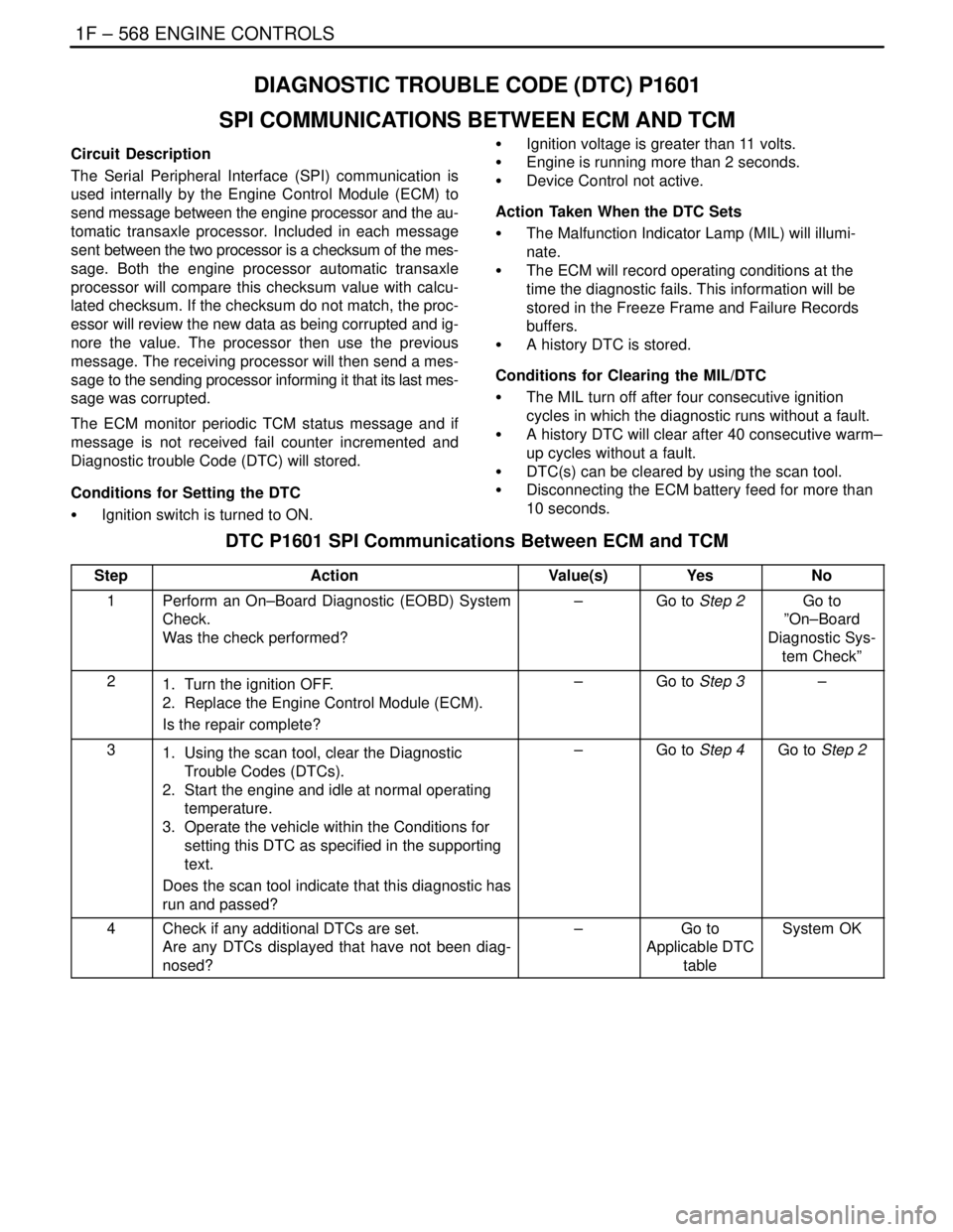

DIAGNOSTIC TROUBLE CODE (DTC) P1601

SPI COMMUNICATIONS BETWEEN ECM AND TCM

Circuit Description

The Serial Peripheral Interface (SPI) communication is

used internally by the Engine Control Module (ECM) to

send message between the engine processor and the au-

tomatic transaxle processor. Included in each message

sent between the two processor is a checksum of the mes-

sage. Both the engine processor automatic transaxle

processor will compare this checksum value with calcu-

lated checksum. If the checksum do not match, the proc-

essor will review the new data as being corrupted and ig-

nore the value. The processor then use the previous

message. The receiving processor will then send a mes-

sage to the sending processor informing it that its last mes-

sage was corrupted.

The ECM monitor periodic TCM status message and if

message is not received fail counter incremented and

Diagnostic trouble Code (DTC) will stored.

Conditions for Setting the DTC

S Ignition switch is turned to ON.S Ignition voltage is greater than 11 volts.

S Engine is running more than 2 seconds.

S Device Control not active.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1601 SPI Communications Between ECM and TCM

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 815 of 2643

ENGINE CONTROLS 1F – 569

DAEWOO V–121 BL4

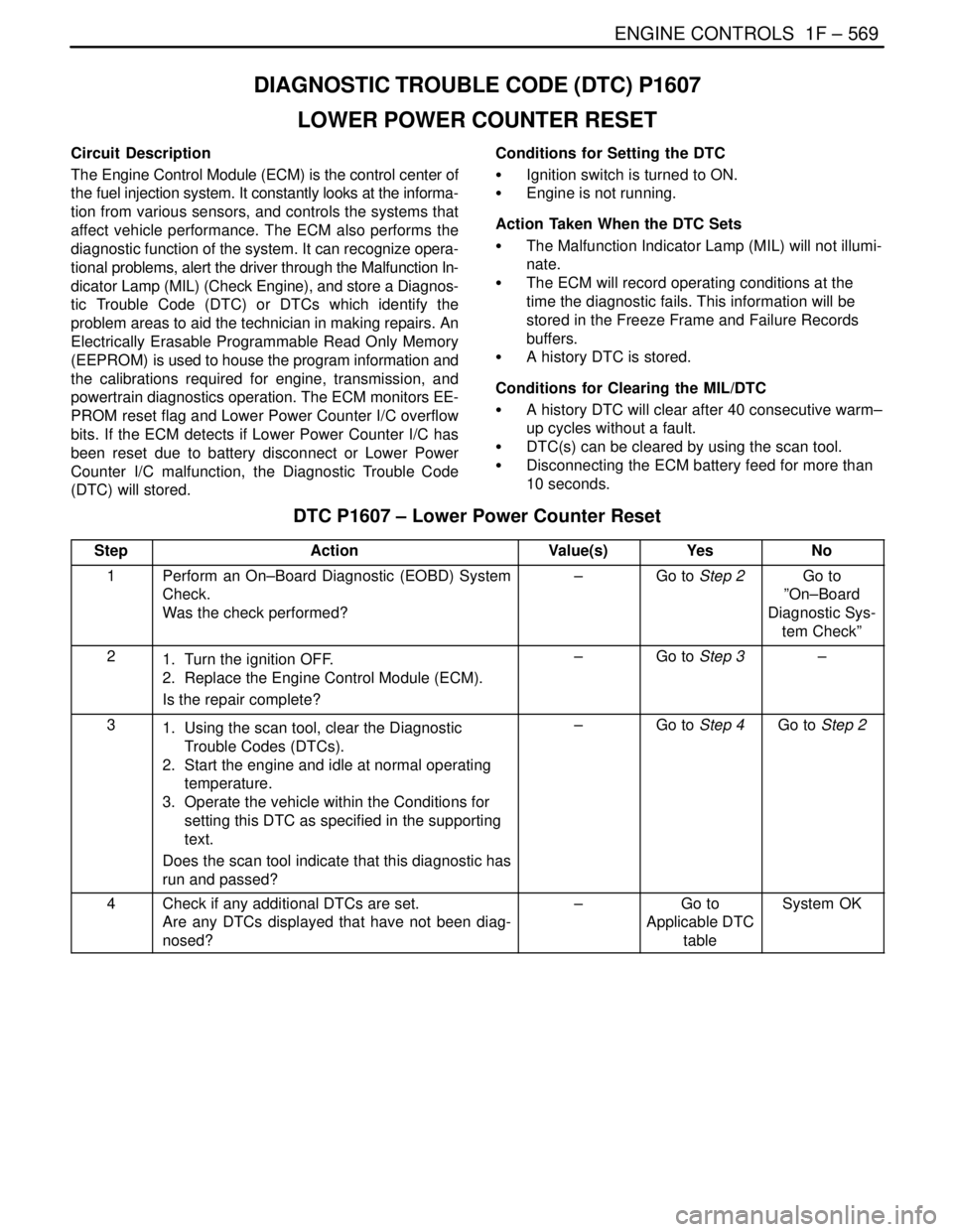

DIAGNOSTIC TROUBLE CODE (DTC) P1607

LOWER POWER COUNTER RESET

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The ECM monitors EE-

PROM reset flag and Lower Power Counter I/C overflow

bits. If the ECM detects if Lower Power Counter I/C has

been reset due to battery disconnect or Lower Power

Counter I/C malfunction, the Diagnostic Trouble Code

(DTC) will stored.Conditions for Setting the DTC

S Ignition switch is turned to ON.

S Engine is not running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1607 – Lower Power Counter Reset

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 818 of 2643

1F – 572IENGINE CONTROLS

DAEWOO V–121 BL4

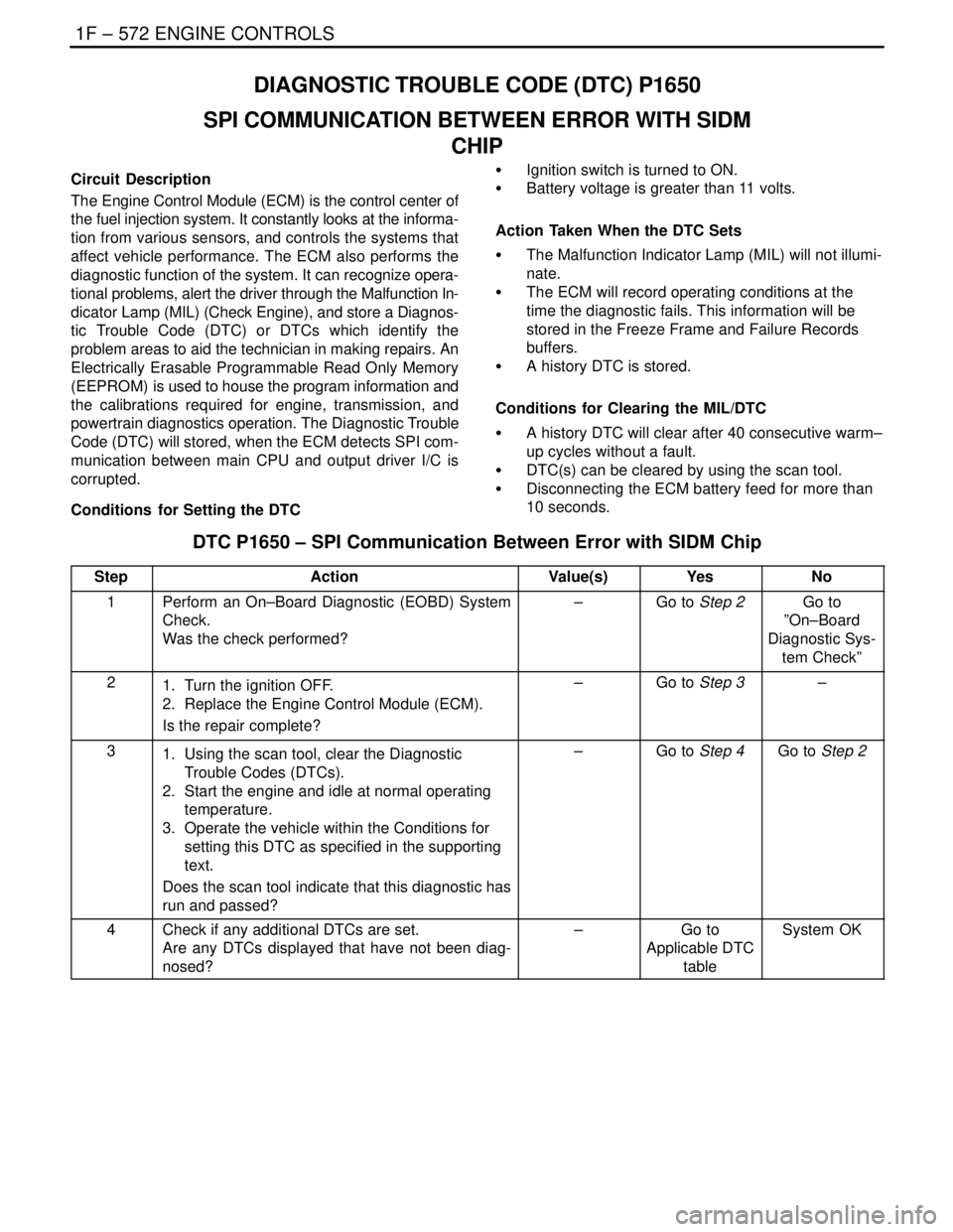

DIAGNOSTIC TROUBLE CODE (DTC) P1650

SPI COMMUNICATION BETWEEN ERROR WITH SIDM

CHIP

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The Diagnostic Trouble

Code (DTC) will stored, when the ECM detects SPI com-

munication between main CPU and output driver I/C is

corrupted.

Conditions for Setting the DTCS Ignition switch is turned to ON.

S Battery voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1650 – SPI Communication Between Error with SIDM Chip

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 819 of 2643

ENGINE CONTROLS 1F – 573

DAEWOO V–121 BL4

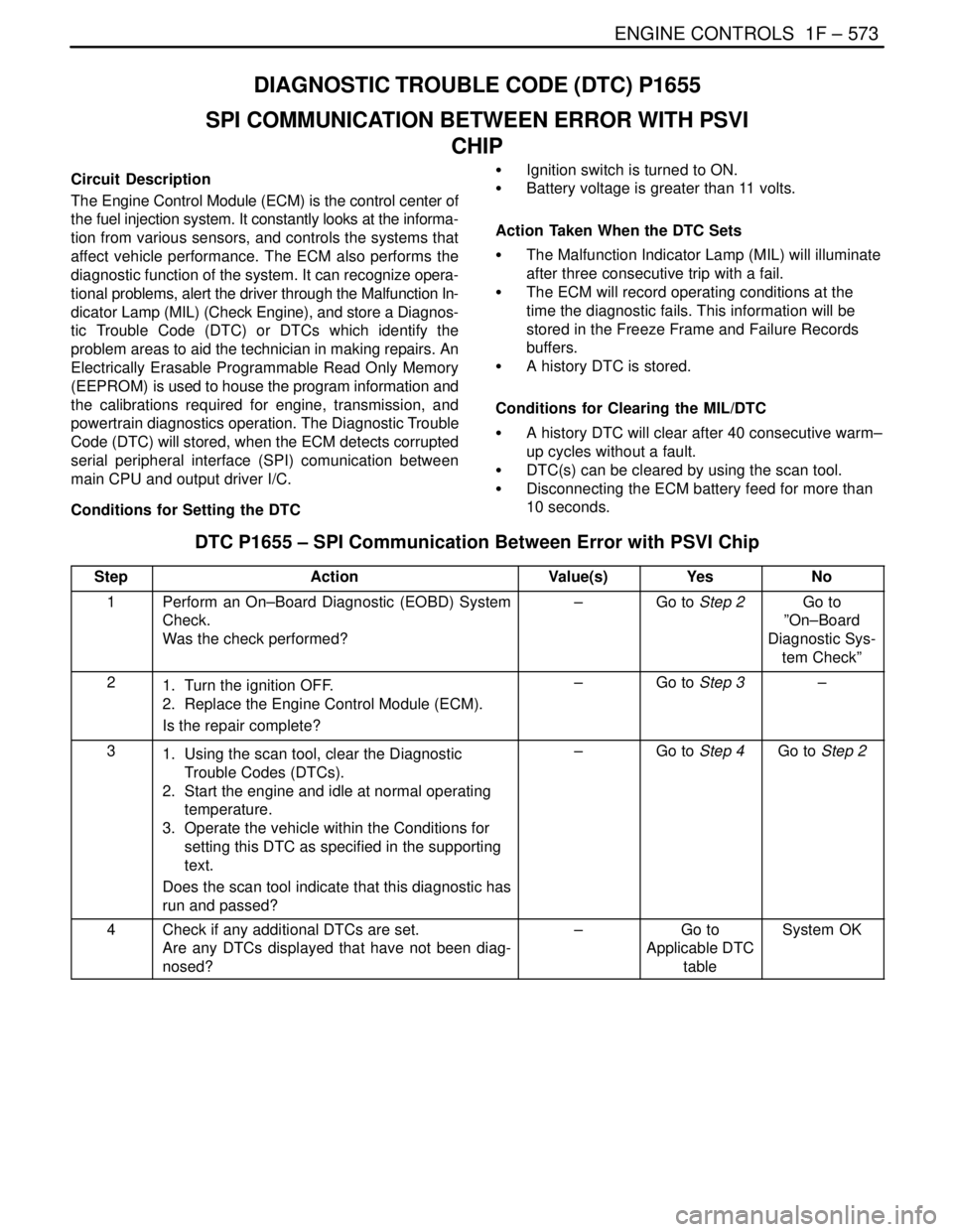

DIAGNOSTIC TROUBLE CODE (DTC) P1655

SPI COMMUNICATION BETWEEN ERROR WITH PSVI

CHIP

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The Diagnostic Trouble

Code (DTC) will stored, when the ECM detects corrupted

serial peripheral interface (SPI) comunication between

main CPU and output driver I/C.

Conditions for Setting the DTCS Ignition switch is turned to ON.

S Battery voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1655 – SPI Communication Between Error with PSVI Chip

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 827 of 2643

ENGINE CONTROLS 1F – 581

DAEWOO V–121 BL4

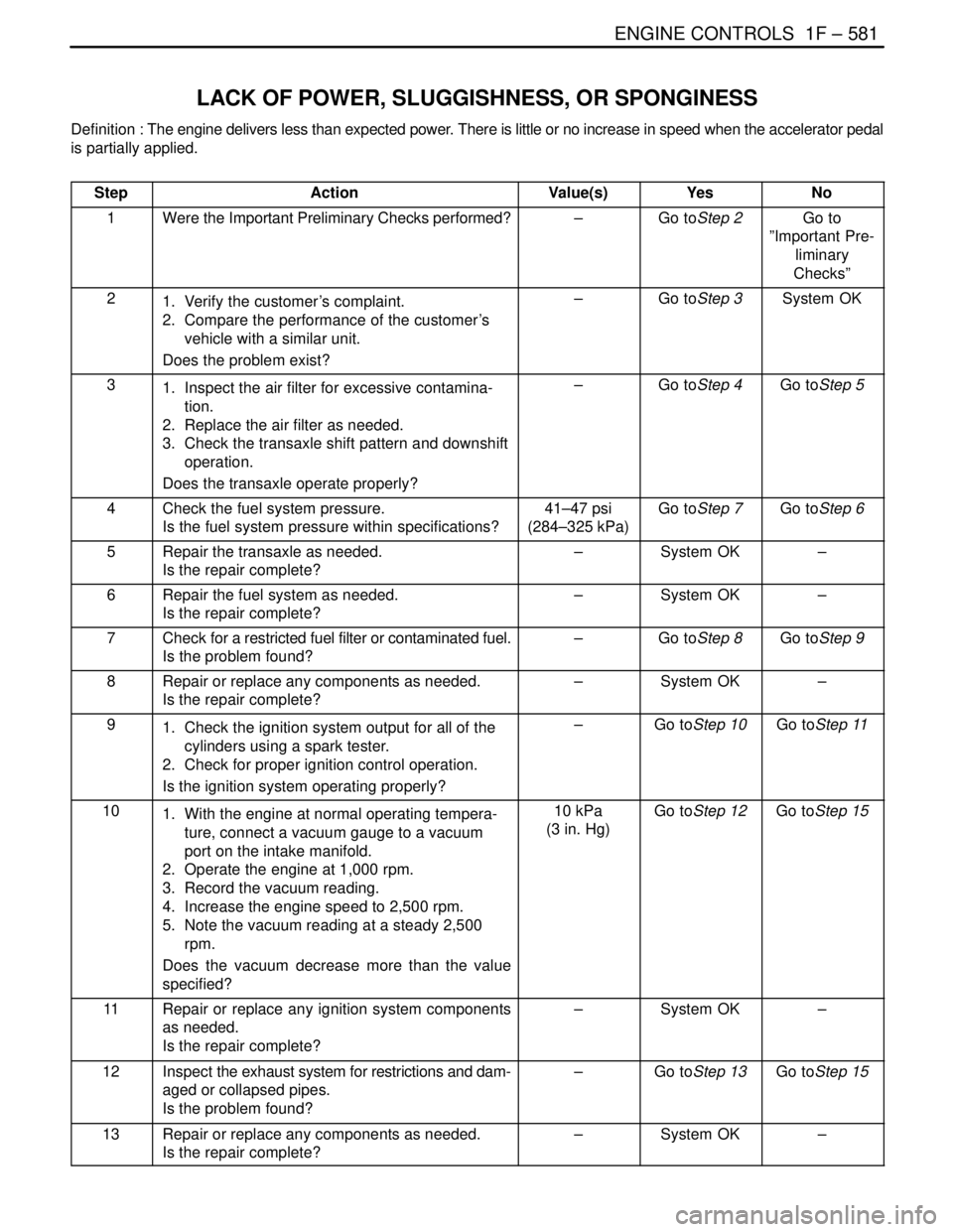

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Definition : The engine delivers less than expected power. There is little or no increase in speed when the accelerator pedal

is partially applied.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Verify the customer’s complaint.

2. Compare the performance of the customer’s

vehicle with a similar unit.

Does the problem exist?–Go toStep 3System OK

31. Inspect the air filter for excessive contamina-

tion.

2. Replace the air filter as needed.

3. Check the transaxle shift pattern and downshift

operation.

Does the transaxle operate properly?–Go toStep 4Go toStep 5

4Check the fuel system pressure.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 7Go toStep 6

5Repair the transaxle as needed.

Is the repair complete?–System OK–

6Repair the fuel system as needed.

Is the repair complete?–System OK–

7Check for a restricted fuel filter or contaminated fuel.

Is the problem found?–Go toStep 8Go toStep 9

8Repair or replace any components as needed.

Is the repair complete?–System OK–

91. Check the ignition system output for all of the

cylinders using a spark tester.

2. Check for proper ignition control operation.

Is the ignition system operating properly?–Go toStep 10Go toStep 11

101. With the engine at normal operating tempera-

ture, connect a vacuum gauge to a vacuum

port on the intake manifold.

2. Operate the engine at 1,000 rpm.

3. Record the vacuum reading.

4. Increase the engine speed to 2,500 rpm.

5. Note the vacuum reading at a steady 2,500

rpm.

Does the vacuum decrease more than the value

specified?10 kPa

(3 in. Hg)Go toStep 12Go toStep 15

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

12Inspect the exhaust system for restrictions and dam-

aged or collapsed pipes.

Is the problem found?–Go toStep 13Go toStep 15

13Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 833 of 2643

ENGINE CONTROLS 1F – 587

DAEWOO V–121 BL4

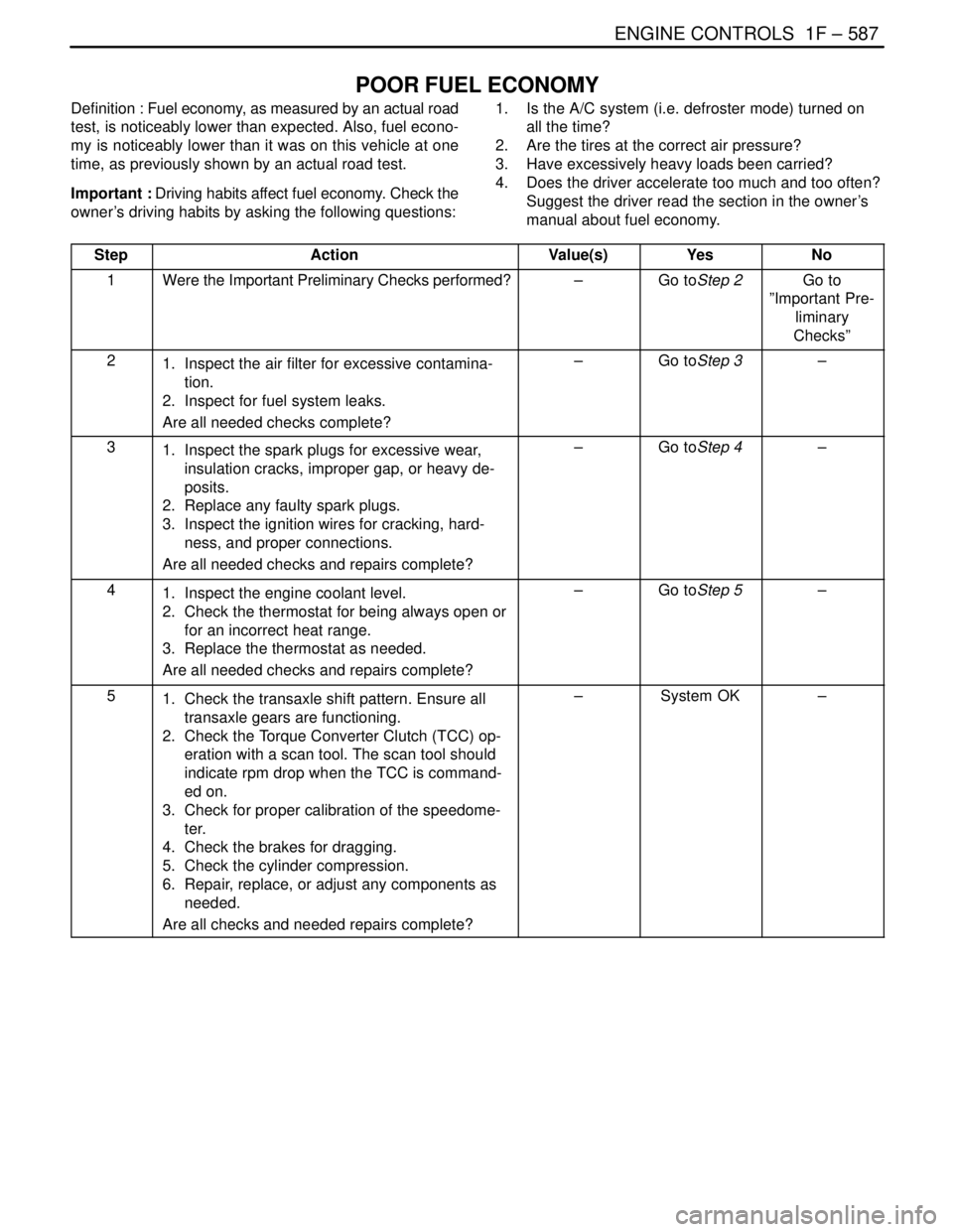

POOR FUEL ECONOMY

Definition : Fuel economy, as measured by an actual road

test, is noticeably lower than expected. Also, fuel econo-

my is noticeably lower than it was on this vehicle at one

time, as previously shown by an actual road test.

Important : Driving habits affect fuel economy. Check the

owner’s driving habits by asking the following questions:1. Is the A/C system (i.e. defroster mode) turned on

all the time?

2. Are the tires at the correct air pressure?

3. Have excessively heavy loads been carried?

4. Does the driver accelerate too much and too often?

Suggest the driver read the section in the owner’s

manual about fuel economy.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Inspect the air filter for excessive contamina-

tion.

2. Inspect for fuel system leaks.

Are all needed checks complete?–Go toStep 3–

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Replace any faulty spark plugs.

3. Inspect the ignition wires for cracking, hard-

ness, and proper connections.

Are all needed checks and repairs complete?–Go toStep 4–

41. Inspect the engine coolant level.

2. Check the thermostat for being always open or

for an incorrect heat range.

3. Replace the thermostat as needed.

Are all needed checks and repairs complete?–Go toStep 5–

51. Check the transaxle shift pattern. Ensure all

transaxle gears are functioning.

2. Check the Torque Converter Clutch (TCC) op-

eration with a scan tool. The scan tool should

indicate rpm drop when the TCC is command-

ed on.

3. Check for proper calibration of the speedome-

ter.

4. Check the brakes for dragging.

5. Check the cylinder compression.

6. Repair, replace, or adjust any components as

needed.

Are all checks and needed repairs complete?–System OK–

Page 841 of 2643

ENGINE CONTROLS 1F – 595

DAEWOO V–121 BL4

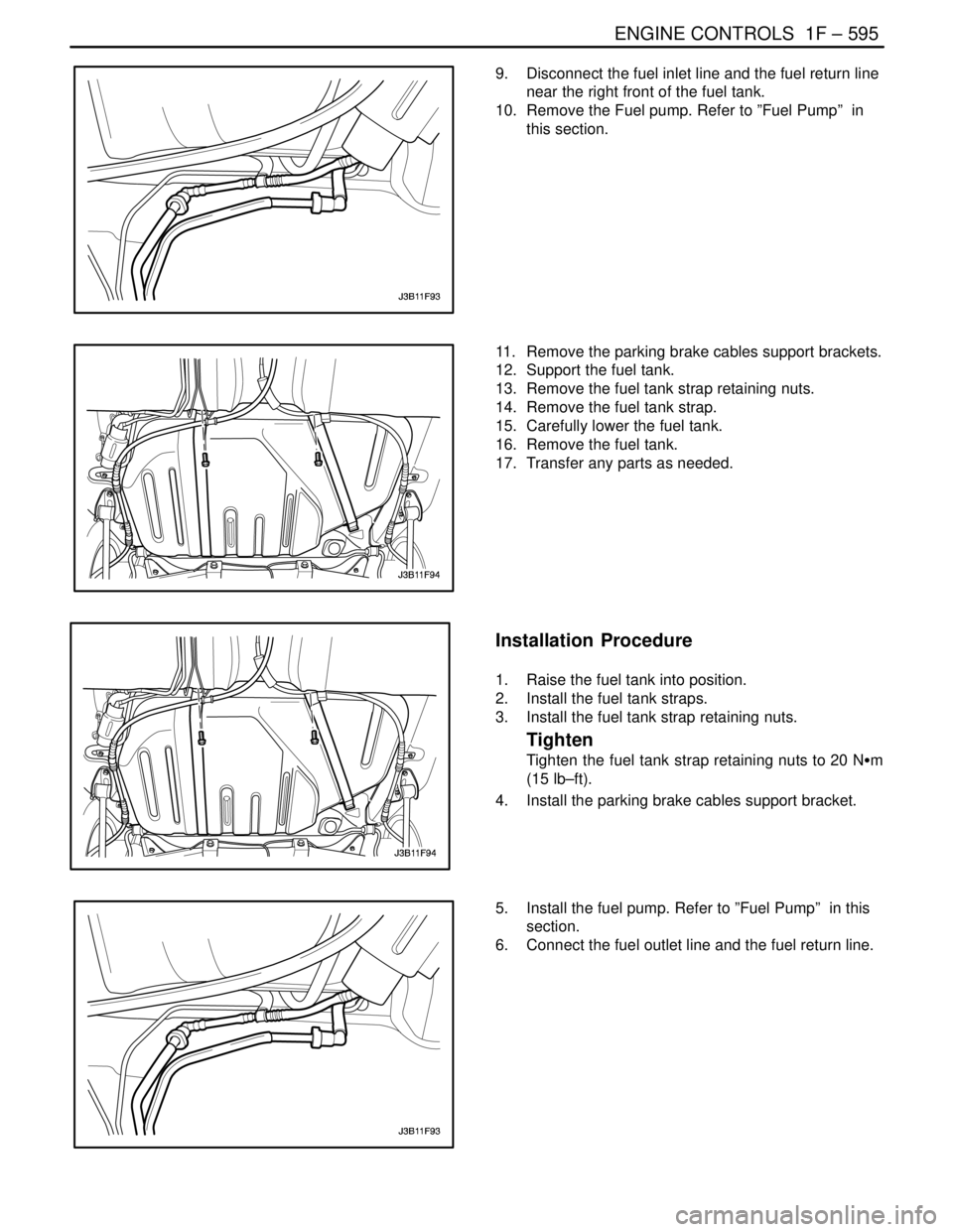

9. Disconnect the fuel inlet line and the fuel return line

near the right front of the fuel tank.

10. Remove the Fuel pump. Refer to ”Fuel Pump” in

this section.

11. Remove the parking brake cables support brackets.

12. Support the fuel tank.

13. Remove the fuel tank strap retaining nuts.

14. Remove the fuel tank strap.

15. Carefully lower the fuel tank.

16. Remove the fuel tank.

17. Transfer any parts as needed.

Installation Procedure

1. Raise the fuel tank into position.

2. Install the fuel tank straps.

3. Install the fuel tank strap retaining nuts.

Tighten

Tighten the fuel tank strap retaining nuts to 20 NSm

(15 lb–ft).

4. Install the parking brake cables support bracket.

5. Install the fuel pump. Refer to ”Fuel Pump” in this

section.

6. Connect the fuel outlet line and the fuel return line.

Page 870 of 2643

1F – 624IENGINE CONTROLS

DAEWOO V–121 BL4

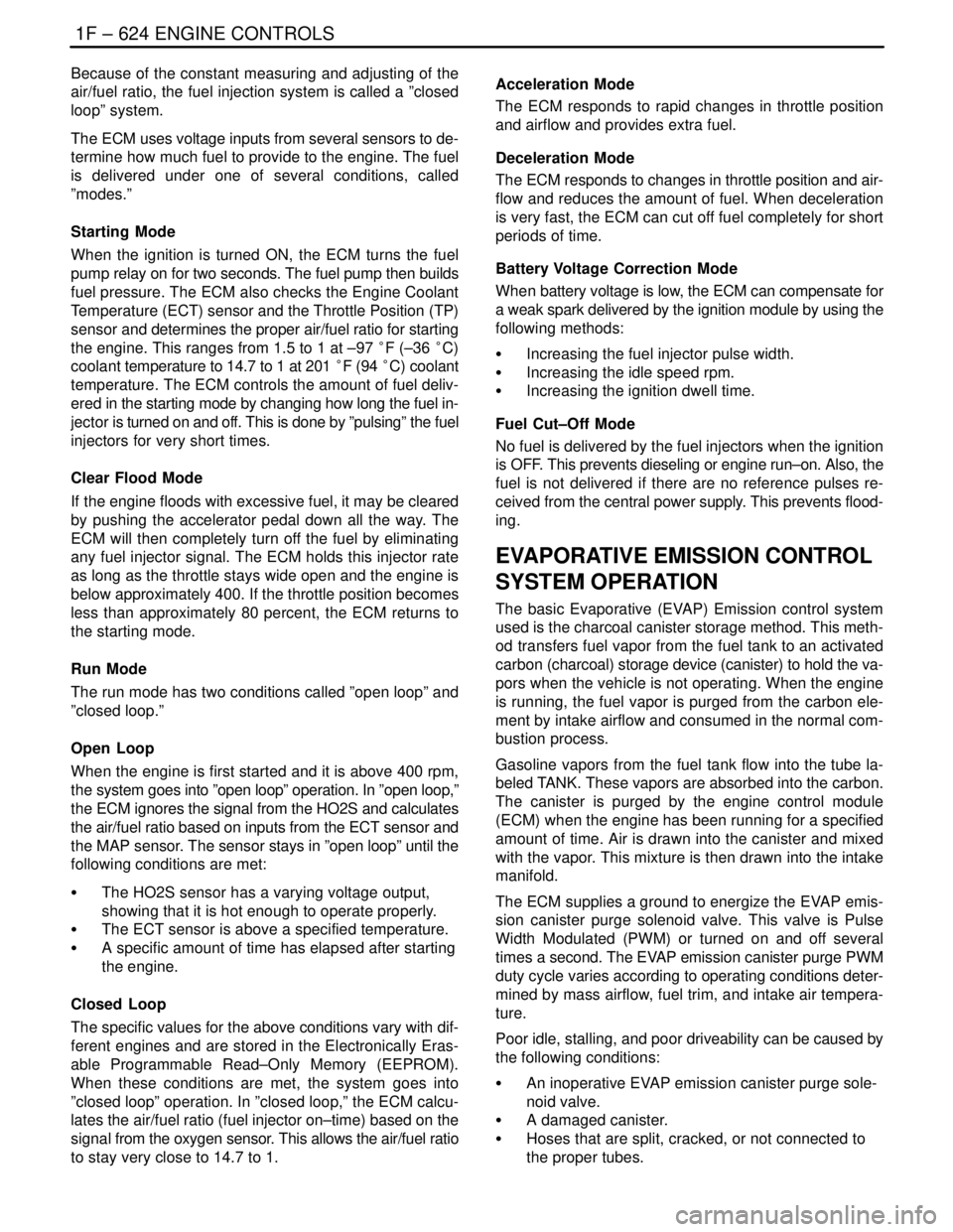

Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a ”closed

loop” system.

The ECM uses voltage inputs from several sensors to de-

termine how much fuel to provide to the engine. The fuel

is delivered under one of several conditions, called

”modes.”

Starting Mode

When the ignition is turned ON, the ECM turns the fuel

pump relay on for two seconds. The fuel pump then builds

fuel pressure. The ECM also checks the Engine Coolant

Temperature (ECT) sensor and the Throttle Position (TP)

sensor and determines the proper air/fuel ratio for starting

the engine. This ranges from 1.5 to 1 at –97 °F (–36 °C)

coolant temperature to 14.7 to 1 at 201 °F (94 °C) coolant

temperature. The ECM controls the amount of fuel deliv-

ered in the starting mode by changing how long the fuel in-

jector is turned on and off. This is done by ”pulsing” the fuel

injectors for very short times.

Clear Flood Mode

If the engine floods with excessive fuel, it may be cleared

by pushing the accelerator pedal down all the way. The

ECM will then completely turn off the fuel by eliminating

any fuel injector signal. The ECM holds this injector rate

as long as the throttle stays wide open and the engine is

below approximately 400. If the throttle position becomes

less than approximately 80 percent, the ECM returns to

the starting mode.

Run Mode

The run mode has two conditions called ”open loop” and

”closed loop.”

Open Loop

When the engine is first started and it is above 400 rpm,

the system goes into ”open loop” operation. In ”open loop,”

the ECM ignores the signal from the HO2S and calculates

the air/fuel ratio based on inputs from the ECT sensor and

the MAP sensor. The sensor stays in ”open loop” until the

following conditions are met:

S The HO2S sensor has a varying voltage output,

showing that it is hot enough to operate properly.

S The ECT sensor is above a specified temperature.

S A specific amount of time has elapsed after starting

the engine.

Closed Loop

The specific values for the above conditions vary with dif-

ferent engines and are stored in the Electronically Eras-

able Programmable Read–Only Memory (EEPROM).

When these conditions are met, the system goes into

”closed loop” operation. In ”closed loop,” the ECM calcu-

lates the air/fuel ratio (fuel injector on–time) based on the

signal from the oxygen sensor. This allows the air/fuel ratio

to stay very close to 14.7 to 1.Acceleration Mode

The ECM responds to rapid changes in throttle position

and airflow and provides extra fuel.

Deceleration Mode

The ECM responds to changes in throttle position and air-

flow and reduces the amount of fuel. When deceleration

is very fast, the ECM can cut off fuel completely for short

periods of time.

Battery Voltage Correction Mode

When battery voltage is low, the ECM can compensate for

a weak spark delivered by the ignition module by using the

following methods:

S Increasing the fuel injector pulse width.

S Increasing the idle speed rpm.

S Increasing the ignition dwell time.

Fuel Cut–Off Mode

No fuel is delivered by the fuel injectors when the ignition

is OFF. This prevents dieseling or engine run–on. Also, the

fuel is not delivered if there are no reference pulses re-

ceived from the central power supply. This prevents flood-

ing.

EVAPORATIVE EMISSION CONTROL

SYSTEM OPERATION

The basic Evaporative (EVAP) Emission control system

used is the charcoal canister storage method. This meth-

od transfers fuel vapor from the fuel tank to an activated

carbon (charcoal) storage device (canister) to hold the va-

pors when the vehicle is not operating. When the engine

is running, the fuel vapor is purged from the carbon ele-

ment by intake airflow and consumed in the normal com-

bustion process.

Gasoline vapors from the fuel tank flow into the tube la-

beled TANK. These vapors are absorbed into the carbon.

The canister is purged by the engine control module

(ECM) when the engine has been running for a specified

amount of time. Air is drawn into the canister and mixed

with the vapor. This mixture is then drawn into the intake

manifold.

The ECM supplies a ground to energize the EVAP emis-

sion canister purge solenoid valve. This valve is Pulse

Width Modulated (PWM) or turned on and off several

times a second. The EVAP emission canister purge PWM

duty cycle varies according to operating conditions deter-

mined by mass airflow, fuel trim, and intake air tempera-

ture.

Poor idle, stalling, and poor driveability can be caused by

the following conditions:

S An inoperative EVAP emission canister purge sole-

noid valve.

S A damaged canister.

S Hoses that are split, cracked, or not connected to

the proper tubes.

Page 872 of 2643

1F – 626IENGINE CONTROLS

DAEWOO V–121 BL4

EXHAUST GAS RECIRCULATION

VA LV E

The Exhaust Gas Recirculation (EGR) system is used on

engines equipped with an automatic transaxle to lower

NOx (oxides of nitrogen) emission levels caused by high

combustion temperature. The EGR valve is controlled by

the engine control module (ECM). The EGR valve feeds

small amounts of exhaust gas into the intake manifold to

decrease combustion temperature. The amount of ex-

haust gas recirculated is controlled by variations in vacu-

um and exhaust back pressure. If too much exhaust gas

enters, combustion will not take place. For this reason,

very little exhaust gas is allowed to pass through the valve,

especially at idle.

The EGR valve is usually open under the following condi-

tions:

S Warm engine operation.

S Above idle speed.

Results of Incorrect Operation

Too much EGR flow tends to weaken combustion, causing

the engine to run roughly or to stop. With too much EGR

flow at idle, cruise, or cold operation, any of the following

conditions may occur:

S The engine stops after a cold start.

S The engine stops at idle after deceleration.

S The vehicle surges during cruise.

S Rough idle.

If the EGR valve stays open all the time, the engine may

not idle. Too little or no EGR flow allows combustion tem-

peratures to get too high during acceleration and load con-

ditions. This could cause the following conditions:

S Spark knock (detonation)

S Engine overheating

S Emission test failure

INTAKE AIR TEMPERATURE

SENSOR

The Intake Air Temperature (IAT) sensor is a thermistor,

a resistor which changes value based on the temperature

of the air entering the engine. Low temperature produces

a high resistance (4,500 ohms at –40°F [–40°C]), while

high temperature causes a low resistance (70 ohms at

266°F [130°C]).

The engine control module (ECM) provides 5 volts to the

IAT sensor through a resistor in the ECM and measures

the change in voltage to determine the IAT. The voltage will

be high when the manifold air is cold and low when the air

is hot. The ECM knows the intake IAT by measuring the

voltage.

The IAT sensor is also used to control spark timing when

the manifold air is cold.

A failure in the IAT sensor circuit sets a diagnostic trouble

code P0112 or P0113.

IDLE AIR CONTROL VALVE

Notice : Do not attempt to remove the protective cap to

readjust the stop screw. Misadjustment may result in dam-

age to the Idle Air Control (IAC) valve or to the throttle

body.

The IAC valve is mounted on the throttle body where it

controls the engine idle speed under the command of the

engine control module (ECM). The ECM sends voltage

pulses to the IAC valve motor windings, causing the IAC

valve pintle to move in or out a given distance (a step or

count) for each pulse. The pintle movement controls the

airflow around the throttle valves which, in turn, control the

engine idle speed.

The desired idle speeds for all engine operating conditions

are programmed into the calibration of the ECM. These

programmed engine speeds are based on the coolant

temperature, the park/neutral position switch status, the

vehicle speed, the battery voltage, and the A/C system

pressure (if equipped).

The ECM ”learns” the proper IAC valve positions to

achieve warm, stabilized idle speeds (rpm) desired for the

various conditions (park/neutral or drive, A/C on or off, if

equipped). This information is stored in ECM ”keep alive”

memories. Information is retained after the ignition is

turned OFF. All other IAC valve positioning is calculated

based on these memory values. As a result, engine varia-

tions due to wear and variations in the minimum throttle

valve position (within limits) do not affect engine idle

speeds. This system provides correct idle control under all

conditions. This also means that disconnecting power to

the ECM can result in incorrect idle control or the necessity

to partially press the accelerator when starting until the

ECM relearns idle control.

Engine idle speed is a function of total airflow into the en-

gine based on the IAC valve pintle position, the throttle

valve opening, and the calibrated vacuum loss through ac-

cessories. The minimum throttle valve position is set at the

factory with a stop screw. This setting allows enough air-

flow by the throttle valve to cause the IAC valve pintle to

be positioned a calibrated number of steps (counts) from

the seat during ”controlled” idle operation. The minimum

throttle valve position setting on this engine should not be

considered the ”minimum idle speed,” as on other fuel in-

jected engines. The throttle stop screw is covered with a

plug at the factory following adjustment.

If the IAC valve is suspected as the cause of improper idle

speed, refer to ”Idle Air Control System Check” in this sec-

tion.

MANIFOLD ABSOLUTE PRESSURE

SENSOR

The Manifold Absolute Pressure (MAP) sensor measures

the changes in the intake manifold pressure which result

from engine load and speed changes. It converts these to

a voltage output.

Page 873 of 2643

ENGINE CONTROLS 1F – 627

DAEWOO V–121 BL4

A closed throttle on engine coast down produces a rela-

tively low MAP output. MAP is the opposite of vacuum.

When manifold pressure is high, vacuum is low. The MAP

sensor is also used to measure barometric pressure. This

is performed as part of MAP sensor calculations. With the

ignition ON and the engine not running, the engine control

module (ECM) will read the manifold pressure as baromet-

ric pressure and adjust the air/fuel ratio accordingly. This

compensation for altitude allows the system to maintaindriving performance while holding emissions low. The

barometric function will update periodically during steady

driving or under a wide open throttle condition. In the case

of a fault in the barometric portion of the MAP sensor, the

ECM will set to the default value.

A failure in the MAP sensor circuit sets a diagnostic trouble

code P0107 or P0108.

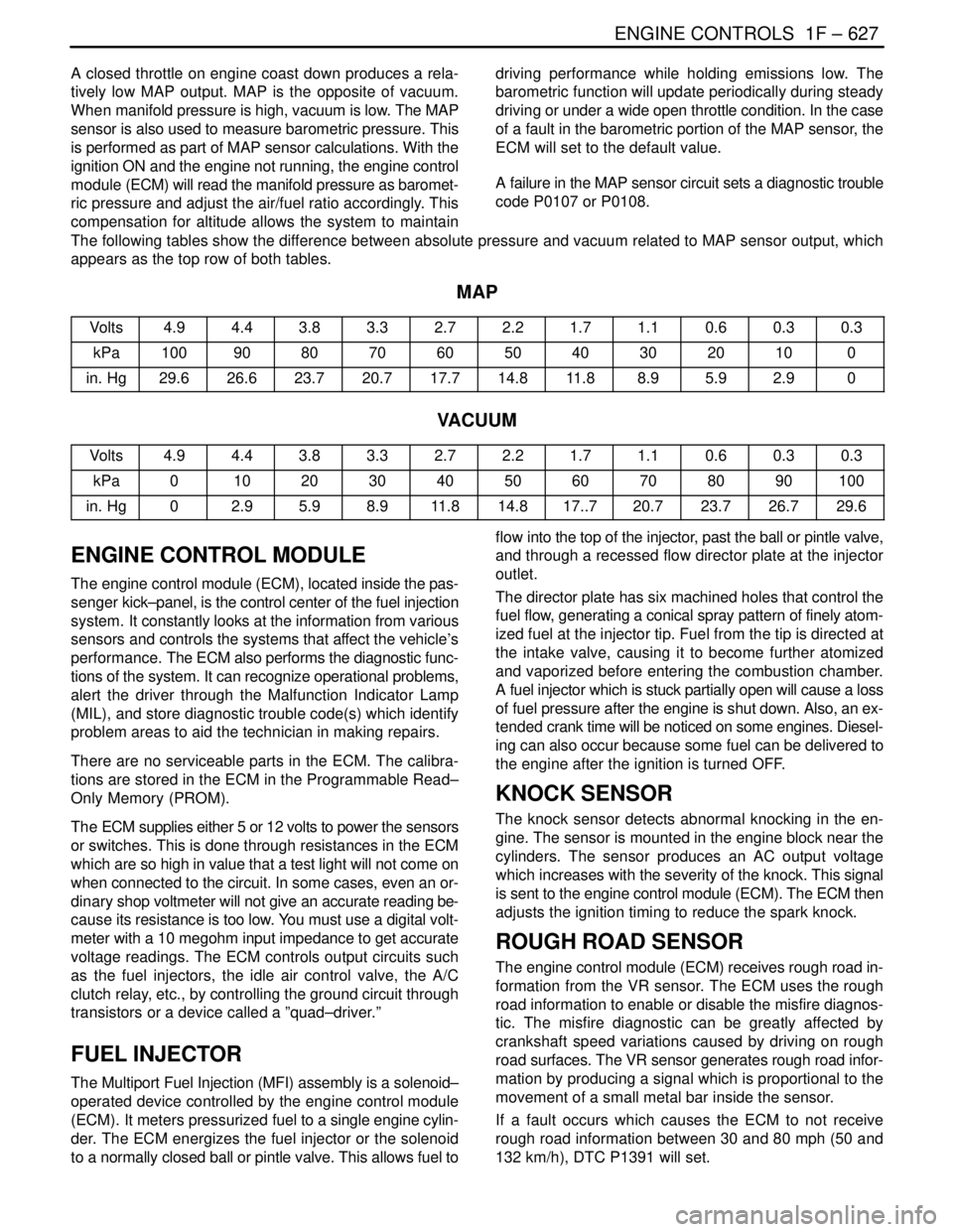

The following tables show the difference between absolute pressure and vacuum related to MAP sensor output, which

appears as the top row of both tables.

MAP

Volts4.94.43.83.32.72.21.71.10.60.30.3

kPa1009080706050403020100

in. Hg29.626.623.720.717.714.811.88.95.92.90

VACUUM

Volts4.94.43.83.32.72.21.71.10.60.30.3

kPa0102030405060708090100

in. Hg02.95.98.911.814.817..720.723.726.729.6

ENGINE CONTROL MODULE

The engine control module (ECM), located inside the pas-

senger kick–panel, is the control center of the fuel injection

system. It constantly looks at the information from various

sensors and controls the systems that affect the vehicle’s

performance. The ECM also performs the diagnostic func-

tions of the system. It can recognize operational problems,

alert the driver through the Malfunction Indicator Lamp

(MIL), and store diagnostic trouble code(s) which identify

problem areas to aid the technician in making repairs.

There are no serviceable parts in the ECM. The calibra-

tions are stored in the ECM in the Programmable Read–

Only Memory (PROM).

The ECM supplies either 5 or 12 volts to power the sensors

or switches. This is done through resistances in the ECM

which are so high in value that a test light will not come on

when connected to the circuit. In some cases, even an or-

dinary shop voltmeter will not give an accurate reading be-

cause its resistance is too low. You must use a digital volt-

meter with a 10 megohm input impedance to get accurate

voltage readings. The ECM controls output circuits such

as the fuel injectors, the idle air control valve, the A/C

clutch relay, etc., by controlling the ground circuit through

transistors or a device called a ”quad–driver.”

FUEL INJECTOR

The Multiport Fuel Injection (MFI) assembly is a solenoid–

operated device controlled by the engine control module

(ECM). It meters pressurized fuel to a single engine cylin-

der. The ECM energizes the fuel injector or the solenoid

to a normally closed ball or pintle valve. This allows fuel toflow into the top of the injector, past the ball or pintle valve,

and through a recessed flow director plate at the injector

outlet.

The director plate has six machined holes that control the

fuel flow, generating a conical spray pattern of finely atom-

ized fuel at the injector tip. Fuel from the tip is directed at

the intake valve, causing it to become further atomized

and vaporized before entering the combustion chamber.

A fuel injector which is stuck partially open will cause a loss

of fuel pressure after the engine is shut down. Also, an ex-

tended crank time will be noticed on some engines. Diesel-

ing can also occur because some fuel can be delivered to

the engine after the ignition is turned OFF.

KNOCK SENSOR

The knock sensor detects abnormal knocking in the en-

gine. The sensor is mounted in the engine block near the

cylinders. The sensor produces an AC output voltage

which increases with the severity of the knock. This signal

is sent to the engine control module (ECM). The ECM then

adjusts the ignition timing to reduce the spark knock.

ROUGH ROAD SENSOR

The engine control module (ECM) receives rough road in-

formation from the VR sensor. The ECM uses the rough

road information to enable or disable the misfire diagnos-

tic. The misfire diagnostic can be greatly affected by

crankshaft speed variations caused by driving on rough

road surfaces. The VR sensor generates rough road infor-

mation by producing a signal which is proportional to the

movement of a small metal bar inside the sensor.

If a fault occurs which causes the ECM to not receive

rough road information between 30 and 80 mph (50 and

132 km/h), DTC P1391 will set.