DAEWOO LACETTI 2004 Service Repair Manual

LACETTI 2004

DAEWOO

DAEWOO

https://www.carmanualsonline.info/img/54/56877/w960_56877-0.png

DAEWOO LACETTI 2004 Service Repair Manual

Trending: four wheel drive, fuel consumption, air filter, lacett 2004, Panel cluster light symbol, Pressure valve, Panel cluster symbol

Page 1871 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 47

DAEWOO V–121 BL4

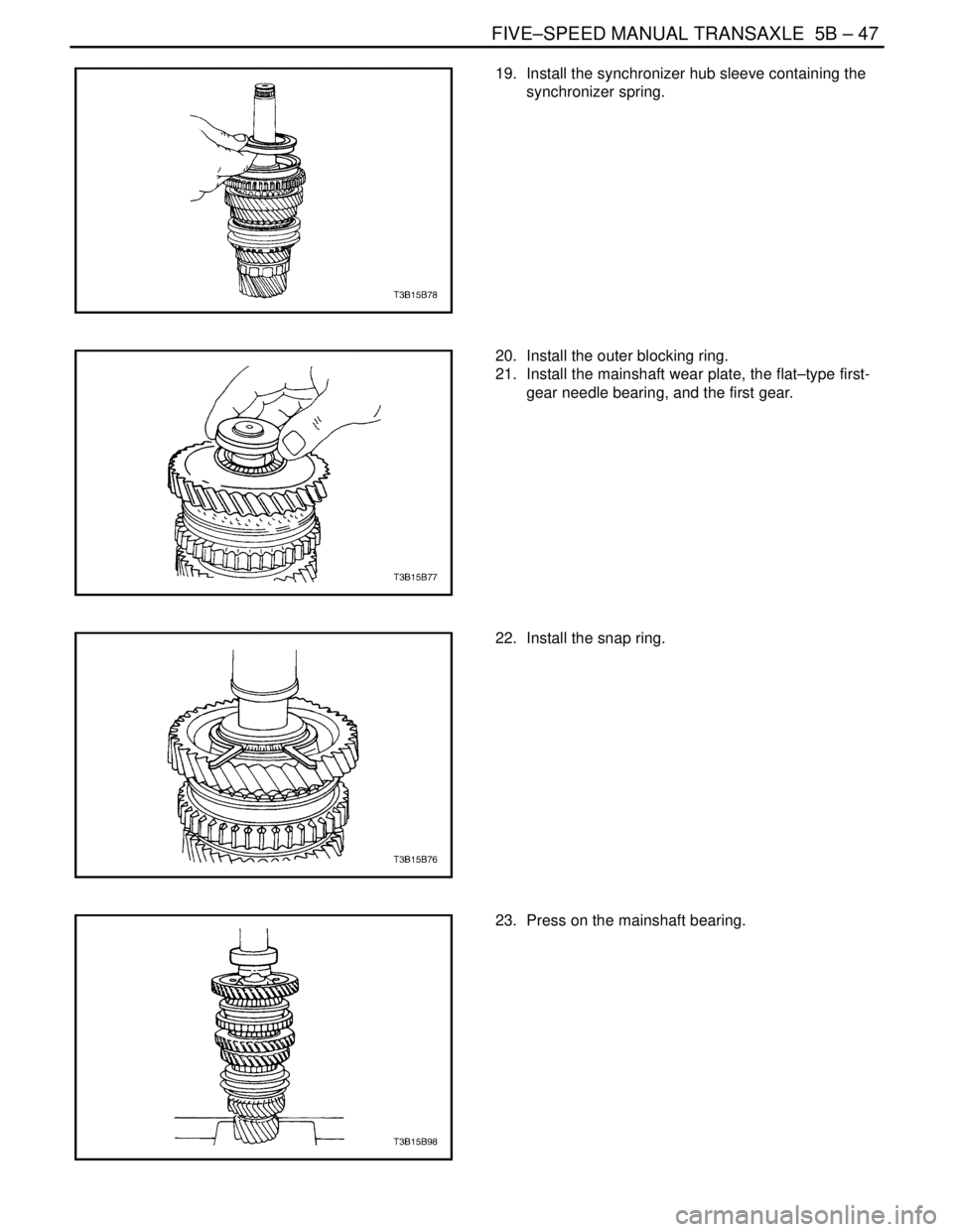

19. Install the synchronizer hub sleeve containing the

synchronizer spring.

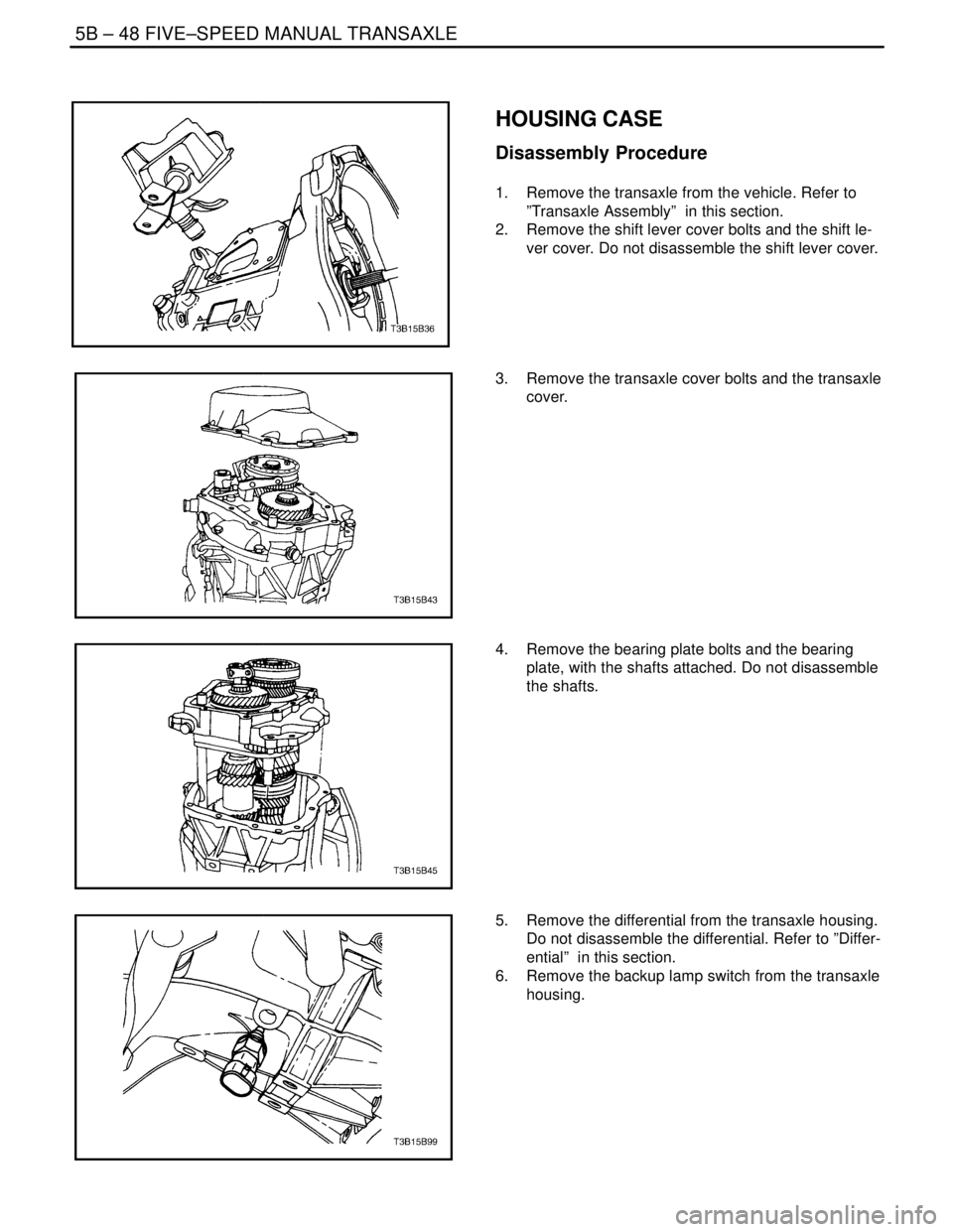

20. Install the outer blocking ring.

21. Install the mainshaft wear plate, the flat–type first-

gear needle bearing, and the first gear.

22. Install the snap ring.

23. Press on the mainshaft bearing.

Page 1872 of 2643

5B – 48IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

HOUSING CASE

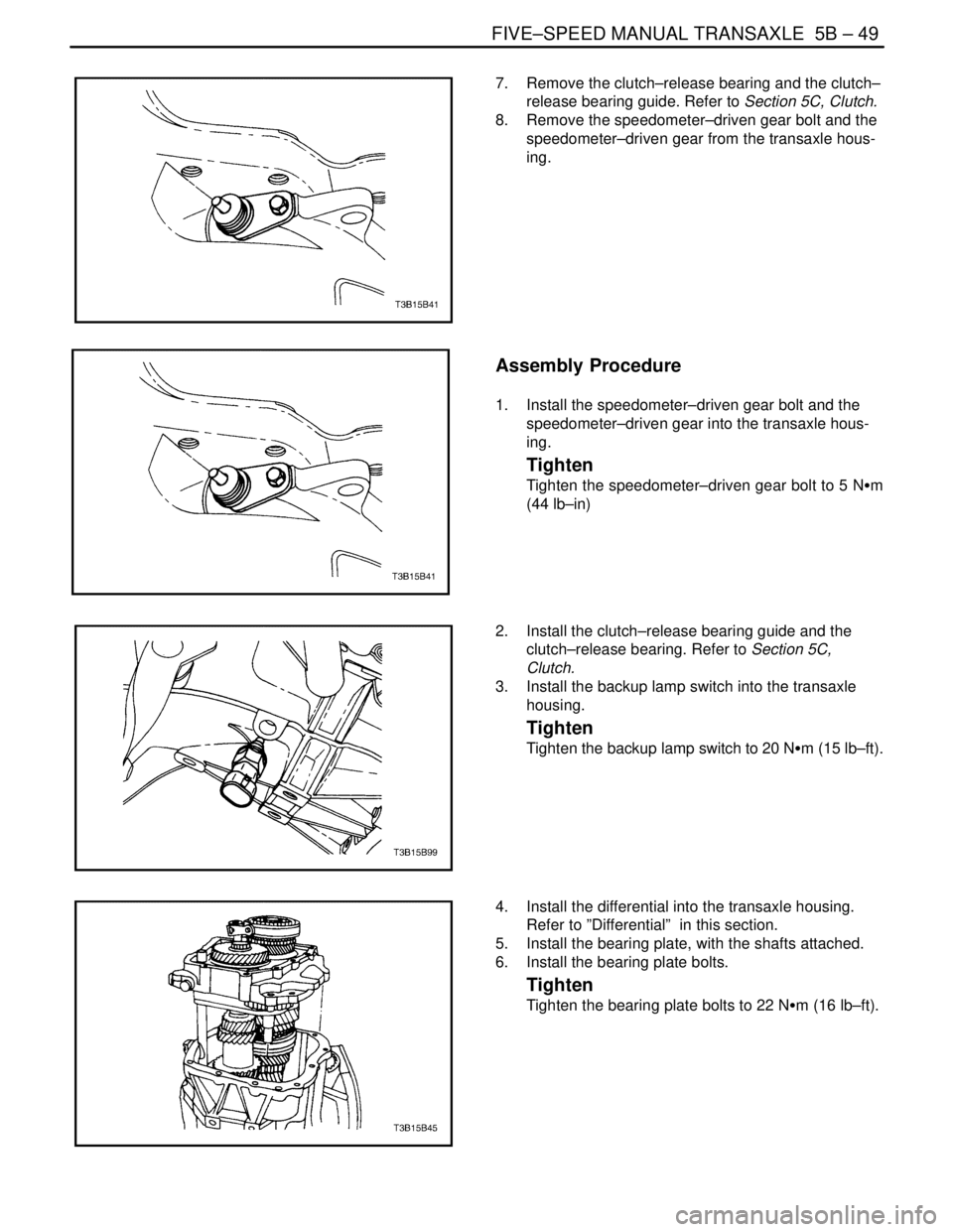

Disassembly Procedure

1. Remove the transaxle from the vehicle. Refer to

”Transaxle Assembly” in this section.

2. Remove the shift lever cover bolts and the shift le-

ver cover. Do not disassemble the shift lever cover.

3. Remove the transaxle cover bolts and the transaxle

cover.

4. Remove the bearing plate bolts and the bearing

plate, with the shafts attached. Do not disassemble

the shafts.

5. Remove the differential from the transaxle housing.

Do not disassemble the differential. Refer to ”Differ-

ential” in this section.

6. Remove the backup lamp switch from the transaxle

housing.

Page 1873 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 49

DAEWOO V–121 BL4

7. Remove the clutch–release bearing and the clutch–

release bearing guide. Refer to Section 5C, Clutch.

8. Remove the speedometer–driven gear bolt and the

speedometer–driven gear from the transaxle hous-

ing.

Assembly Procedure

1. Install the speedometer–driven gear bolt and the

speedometer–driven gear into the transaxle hous-

ing.

Tighten

Tighten the speedometer–driven gear bolt to 5 NSm

(44 lb–in)

2. Install the clutch–release bearing guide and the

clutch–release bearing. Refer to Section 5C,

Clutch.

3. Install the backup lamp switch into the transaxle

housing.

Tighten

Tighten the backup lamp switch to 20 NSm (15 lb–ft).

4. Install the differential into the transaxle housing.

Refer to ”Differential” in this section.

5. Install the bearing plate, with the shafts attached.

6. Install the bearing plate bolts.

Tighten

Tighten the bearing plate bolts to 22 NSm (16 lb–ft).

Page 1874 of 2643

5B – 50IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

7. Install the transaxle cover and the transaxle cover

bolts.

Tighten

Tighten the transaxle cover bolts to 18 NSm (13 lb–ft).

8. Install the gearshift lever cover and the gearshift

lever cover bolts.

Tighten

Tighten the gearshift lever cover bolts to 22 NSm (16

lb–ft).

9. Install the transaxle into the vehicle. Refer to

”Transaxle Assembly” in this section.

DIFFERENTIAL

Tools Required

KM–520 Remover/Installer

KM–525 Installer

J–22888–20–A Bearing Puller with J–22888–35 Puller

Legs

KM–522 Installer

Disassembly Procedure

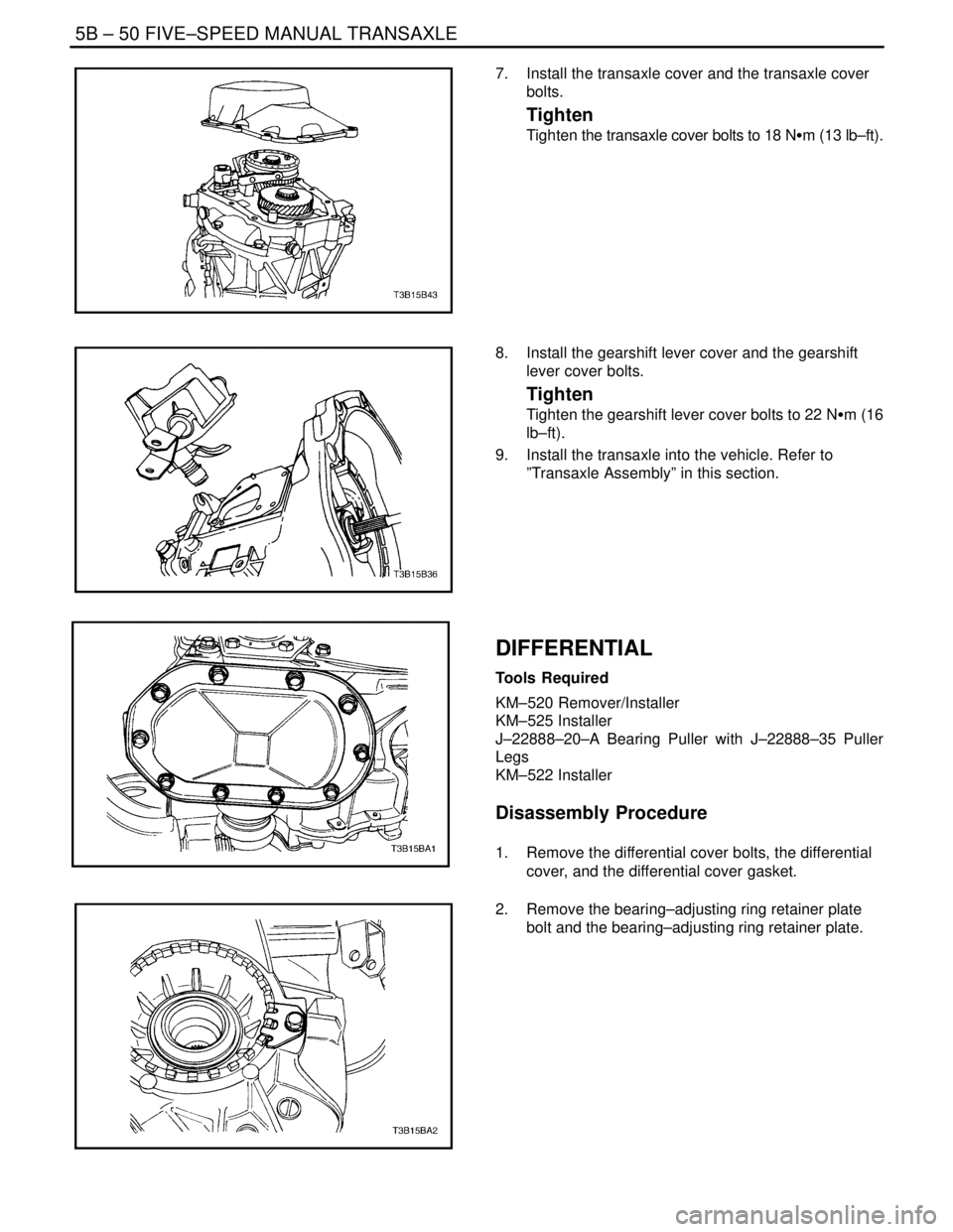

1. Remove the differential cover bolts, the differential

cover, and the differential cover gasket.

2. Remove the bearing–adjusting ring retainer plate

bolt and the bearing–adjusting ring retainer plate.

Page 1875 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 51

DAEWOO V–121 BL4

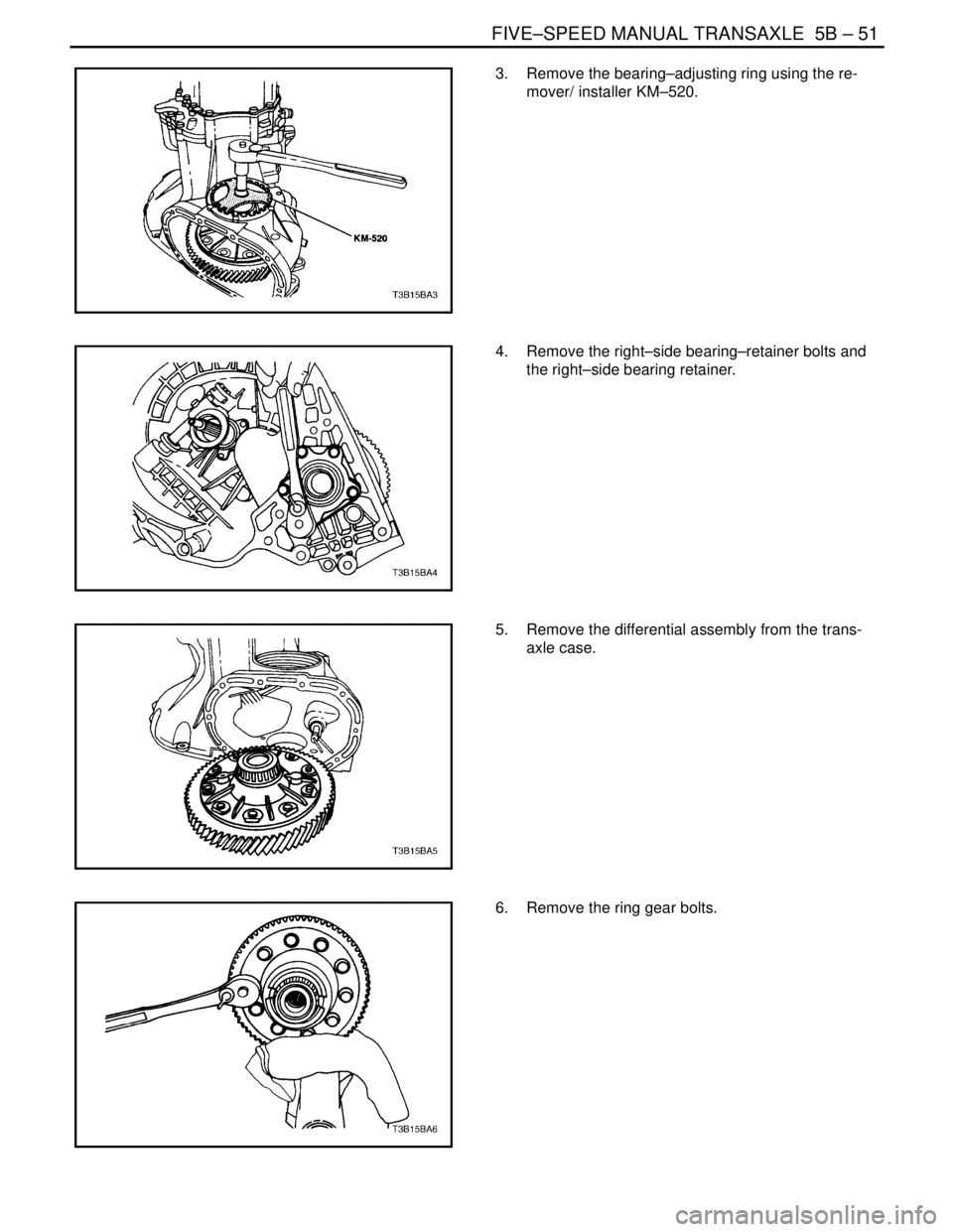

3. Remove the bearing–adjusting ring using the re-

mover/ installer KM–520.

4. Remove the right–side bearing–retainer bolts and

the right–side bearing retainer.

5. Remove the differential assembly from the trans-

axle case.

6. Remove the ring gear bolts.

Page 1876 of 2643

5B – 52IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

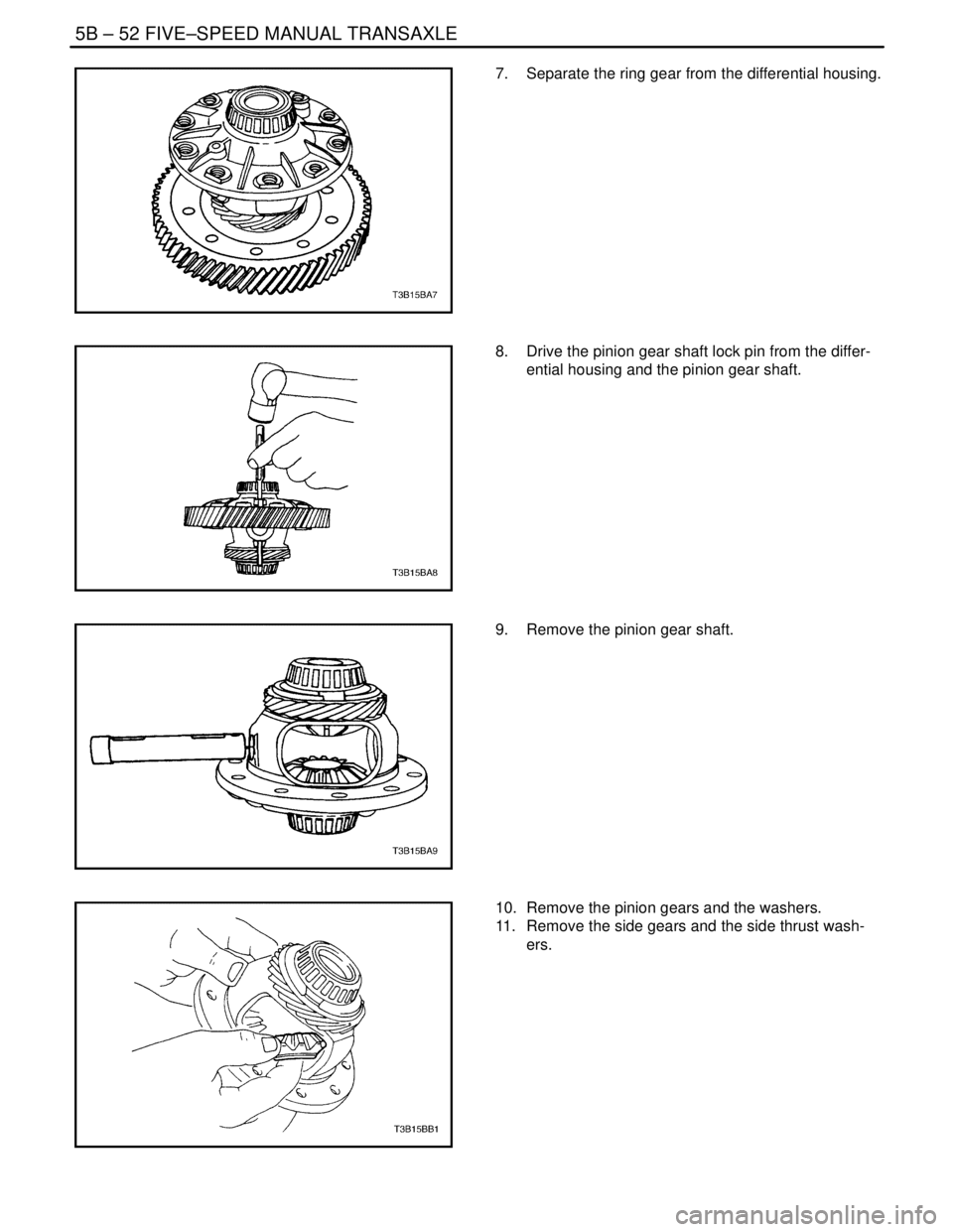

7. Separate the ring gear from the differential housing.

8. Drive the pinion gear shaft lock pin from the differ-

ential housing and the pinion gear shaft.

9. Remove the pinion gear shaft.

10. Remove the pinion gears and the washers.

11. Remove the side gears and the side thrust wash-

ers.

Page 1877 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 53

DAEWOO V–121 BL4

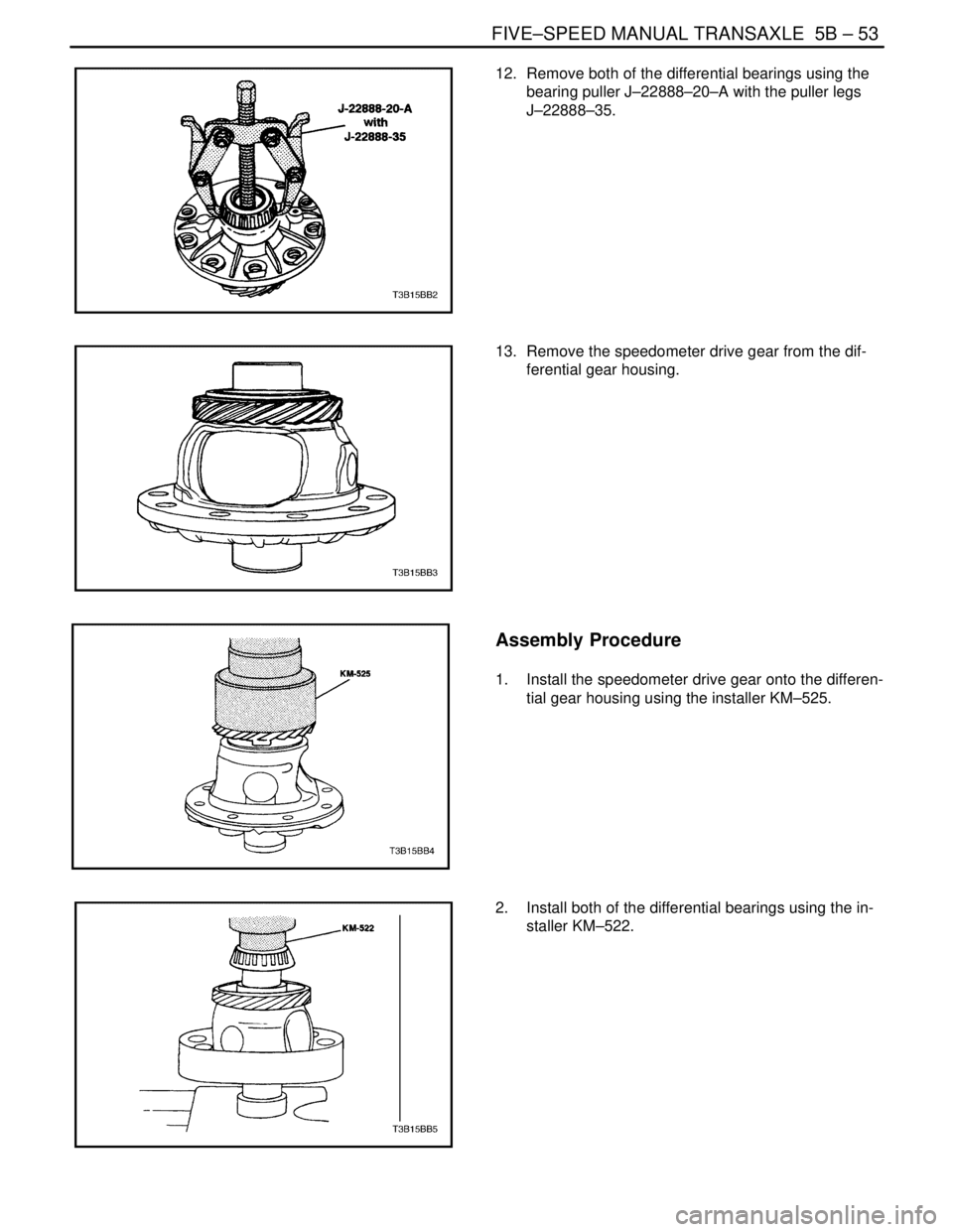

12. Remove both of the differential bearings using the

bearing puller J–22888–20–A with the puller legs

J–22888–35.

13. Remove the speedometer drive gear from the dif-

ferential gear housing.

Assembly Procedure

1. Install the speedometer drive gear onto the differen-

tial gear housing using the installer KM–525.

2. Install both of the differential bearings using the in-

staller KM–522.

Page 1878 of 2643

5B – 54IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

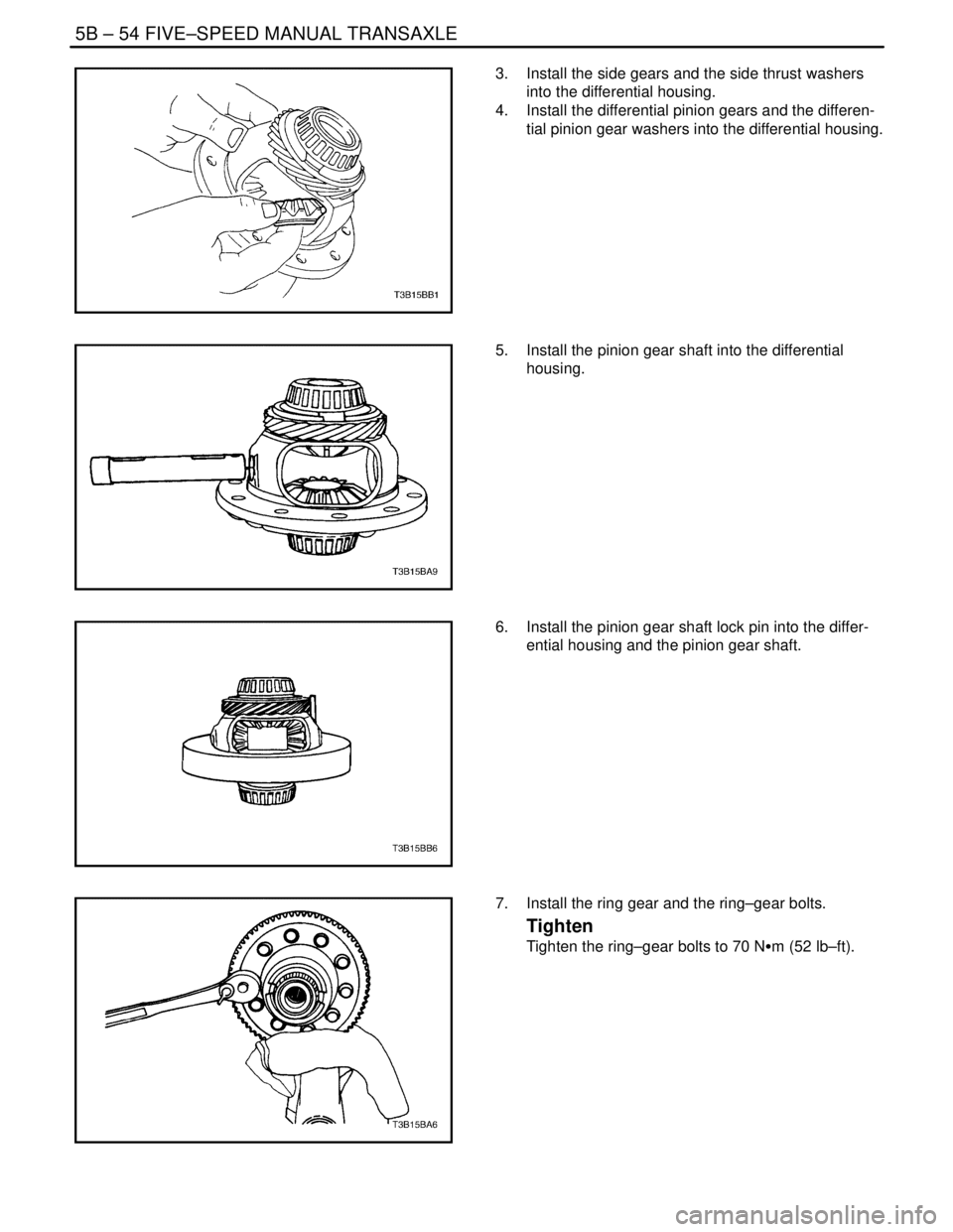

3. Install the side gears and the side thrust washers

into the differential housing.

4. Install the differential pinion gears and the differen-

tial pinion gear washers into the differential housing.

5. Install the pinion gear shaft into the differential

housing.

6. Install the pinion gear shaft lock pin into the differ-

ential housing and the pinion gear shaft.

7. Install the ring gear and the ring–gear bolts.

Tighten

Tighten the ring–gear bolts to 70 NSm (52 lb–ft).

Page 1879 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 55

DAEWOO V–121 BL4

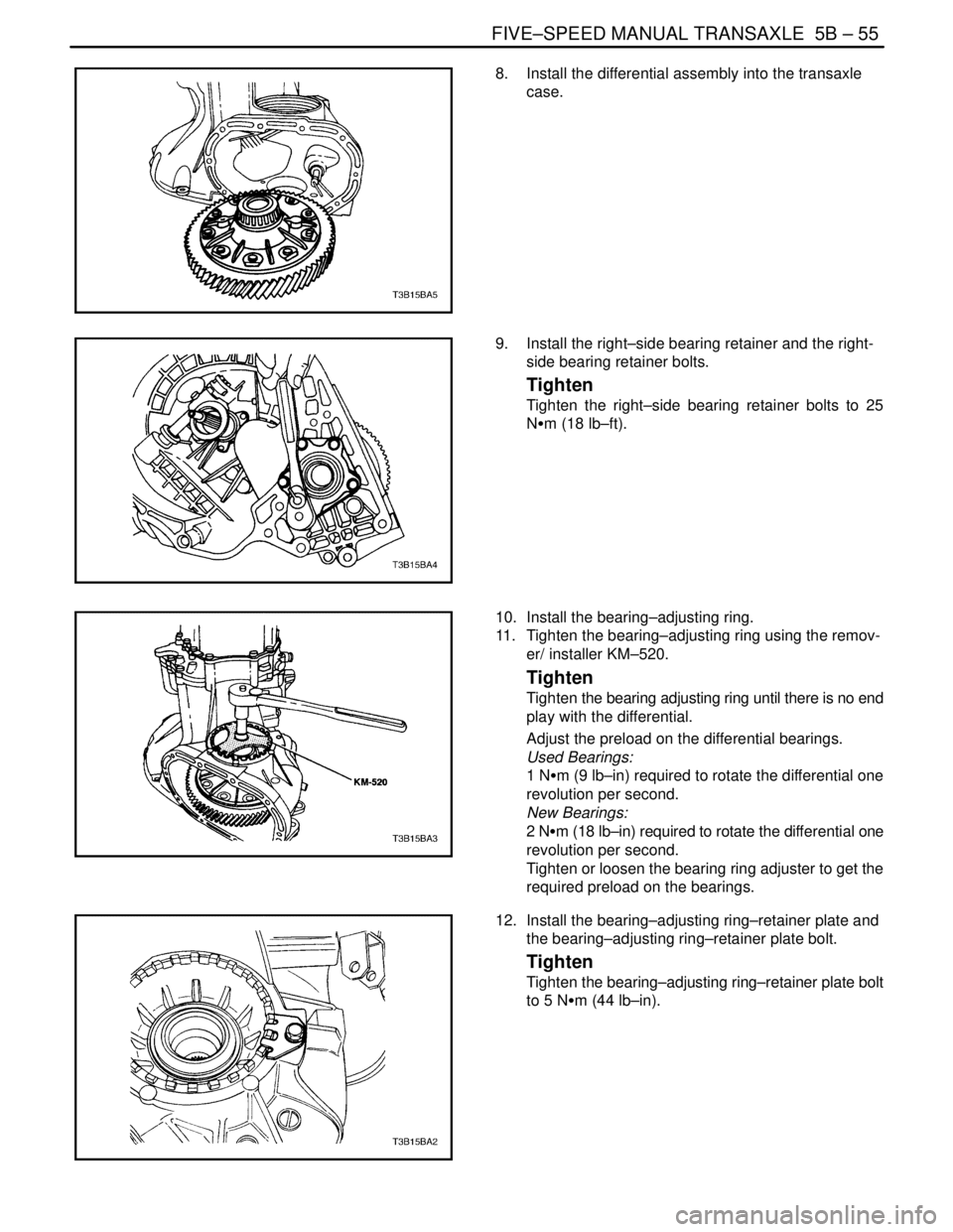

8. Install the differential assembly into the transaxle

case.

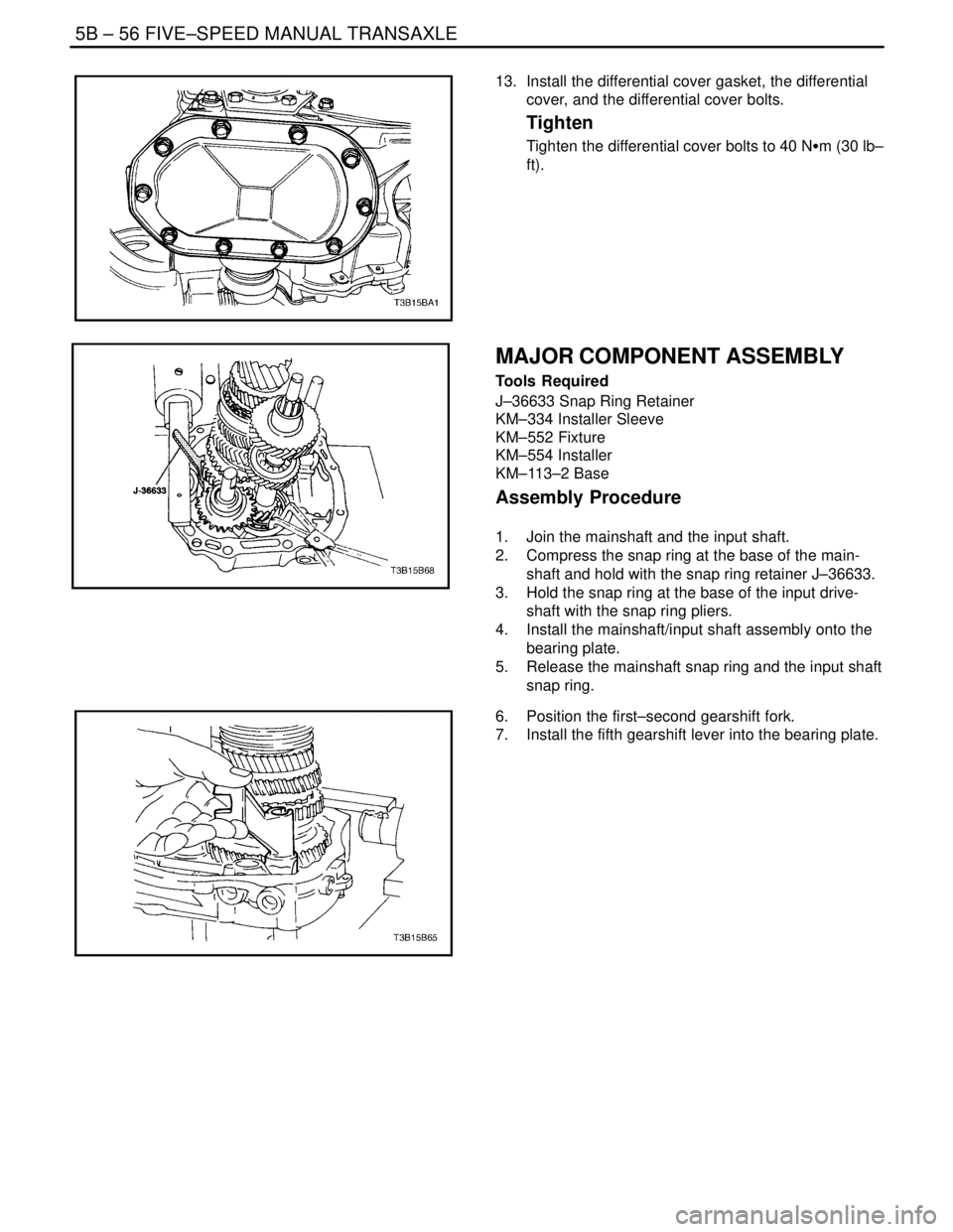

9. Install the right–side bearing retainer and the right-

side bearing retainer bolts.

Tighten

Tighten the right–side bearing retainer bolts to 25

NSm (18 lb–ft).

10. Install the bearing–adjusting ring.

11. Tighten the bearing–adjusting ring using the remov-

er/ installer KM–520.

Tighten

Tighten the bearing adjusting ring until there is no end

play with the differential.

Adjust the preload on the differential bearings.

Used Bearings:

1 NSm (9 lb–in) required to rotate the differential one

revolution per second.

New Bearings:

2 NSm (18 lb–in) required to rotate the differential one

revolution per second.

Tighten or loosen the bearing ring adjuster to get the

required preload on the bearings.

12. Install the bearing–adjusting ring–retainer plate and

the bearing–adjusting ring–retainer plate bolt.

Tighten

Tighten the bearing–adjusting ring–retainer plate bolt

to 5 NSm (44 lb–in).

Page 1880 of 2643

5B – 56IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

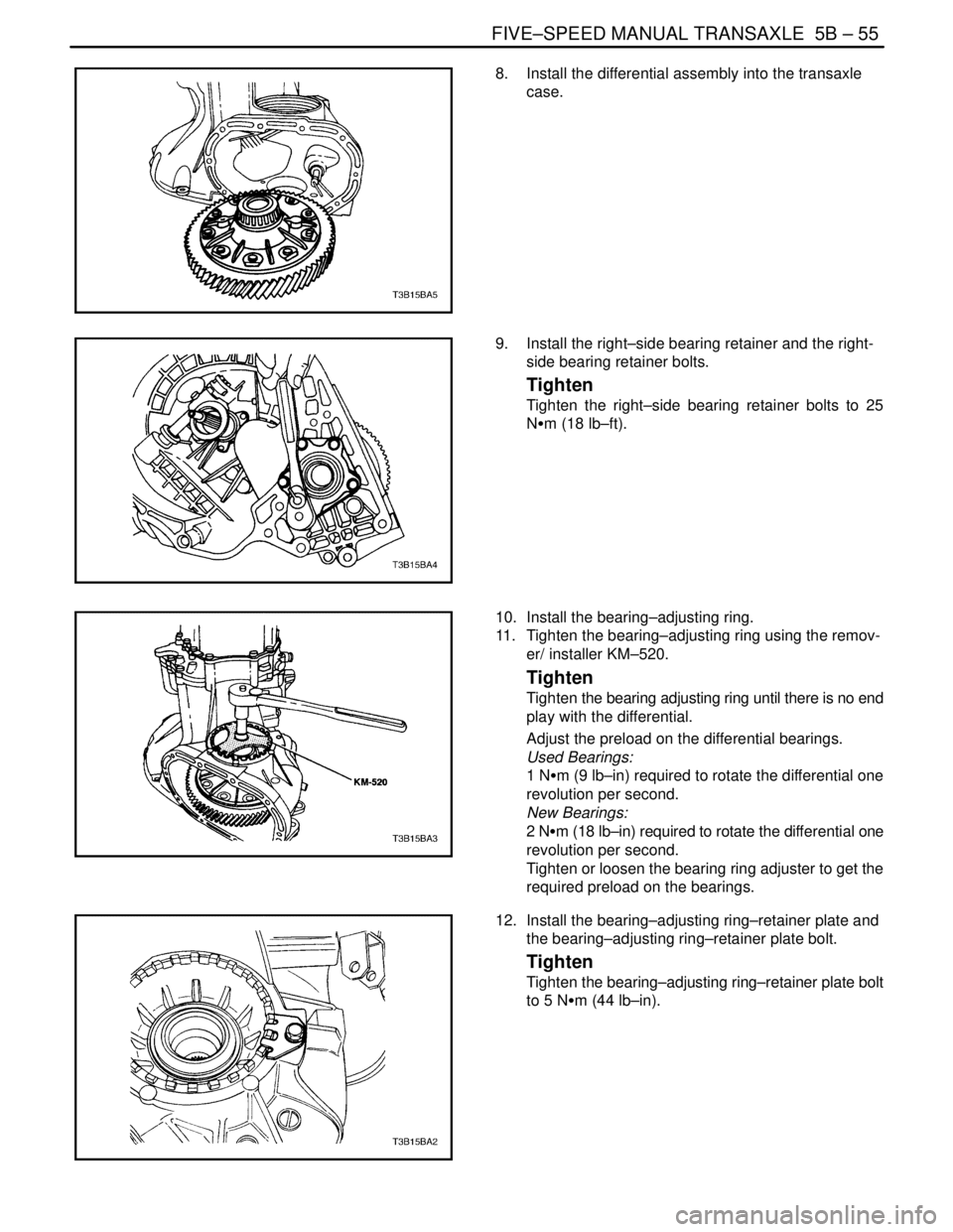

13. Install the differential cover gasket, the differential

cover, and the differential cover bolts.

Tighten

Tighten the differential cover bolts to 40 NSm (30 lb–

ft).

MAJOR COMPONENT ASSEMBLY

Tools Required

J–36633 Snap Ring Retainer

KM–334 Installer Sleeve

KM–552 Fixture

KM–554 Installer

KM–113–2 Base

Assembly Procedure

1. Join the mainshaft and the input shaft.

2. Compress the snap ring at the base of the main-

shaft and hold with the snap ring retainer J–36633.

3. Hold the snap ring at the base of the input drive-

shaft with the snap ring pliers.

4. Install the mainshaft/input shaft assembly onto the

bearing plate.

5. Release the mainshaft snap ring and the input shaft

snap ring.

6. Position the first–second gearshift fork.

7. Install the fifth gearshift lever into the bearing plate.

Trending: hood, oil temperature, Gear, fuel consumption, P1661, child lock, Pressure valve