Automatic DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 27 of 2643

0B – 20IGENERAL INFORMATION

DAEWOO V–121 BL4

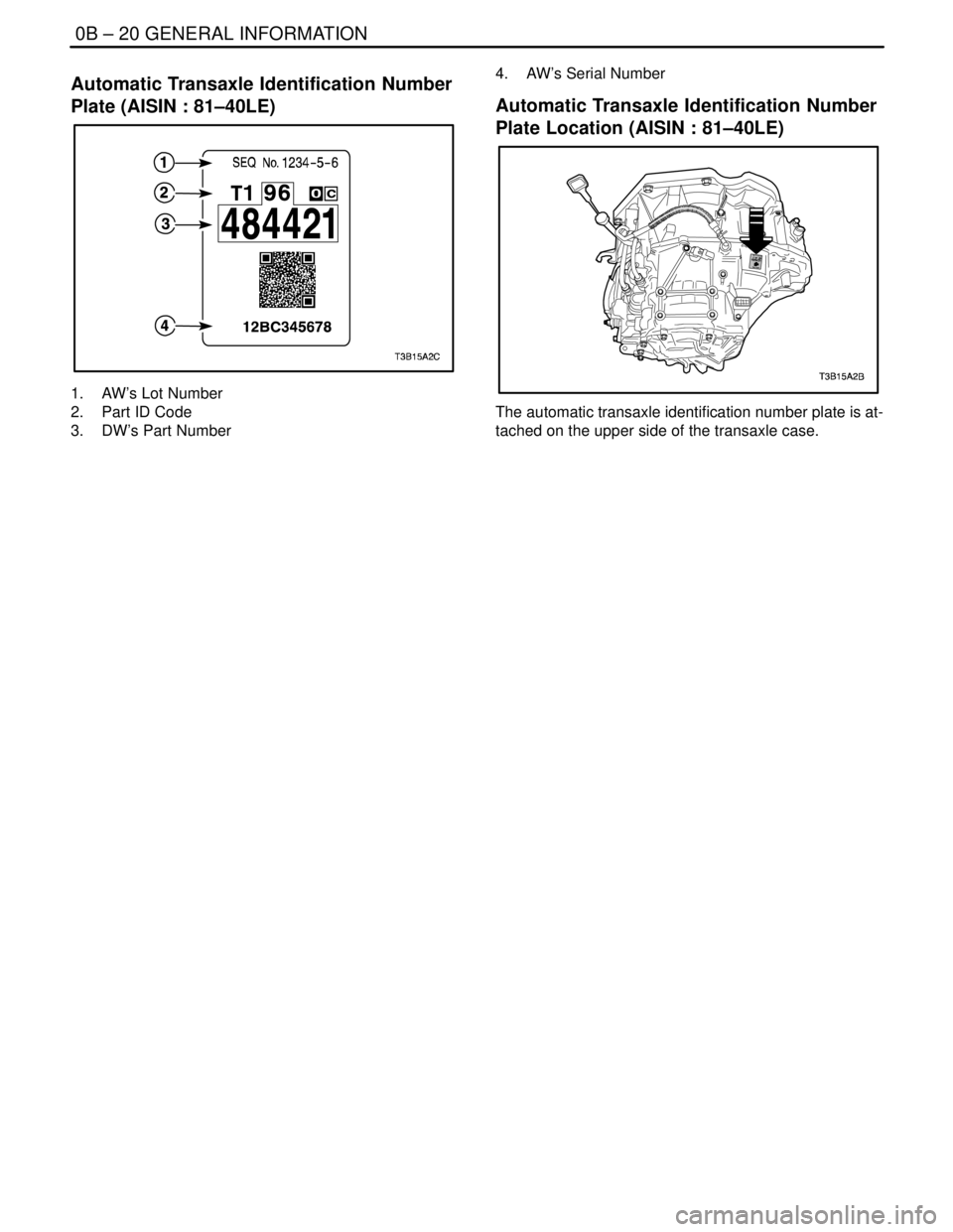

Automatic Transaxle Identification Number

Plate (AISIN : 81–40LE)

1. AW’s Lot Number

2. Part ID Code

3. DW’s Part Number4. AW’s Serial Number

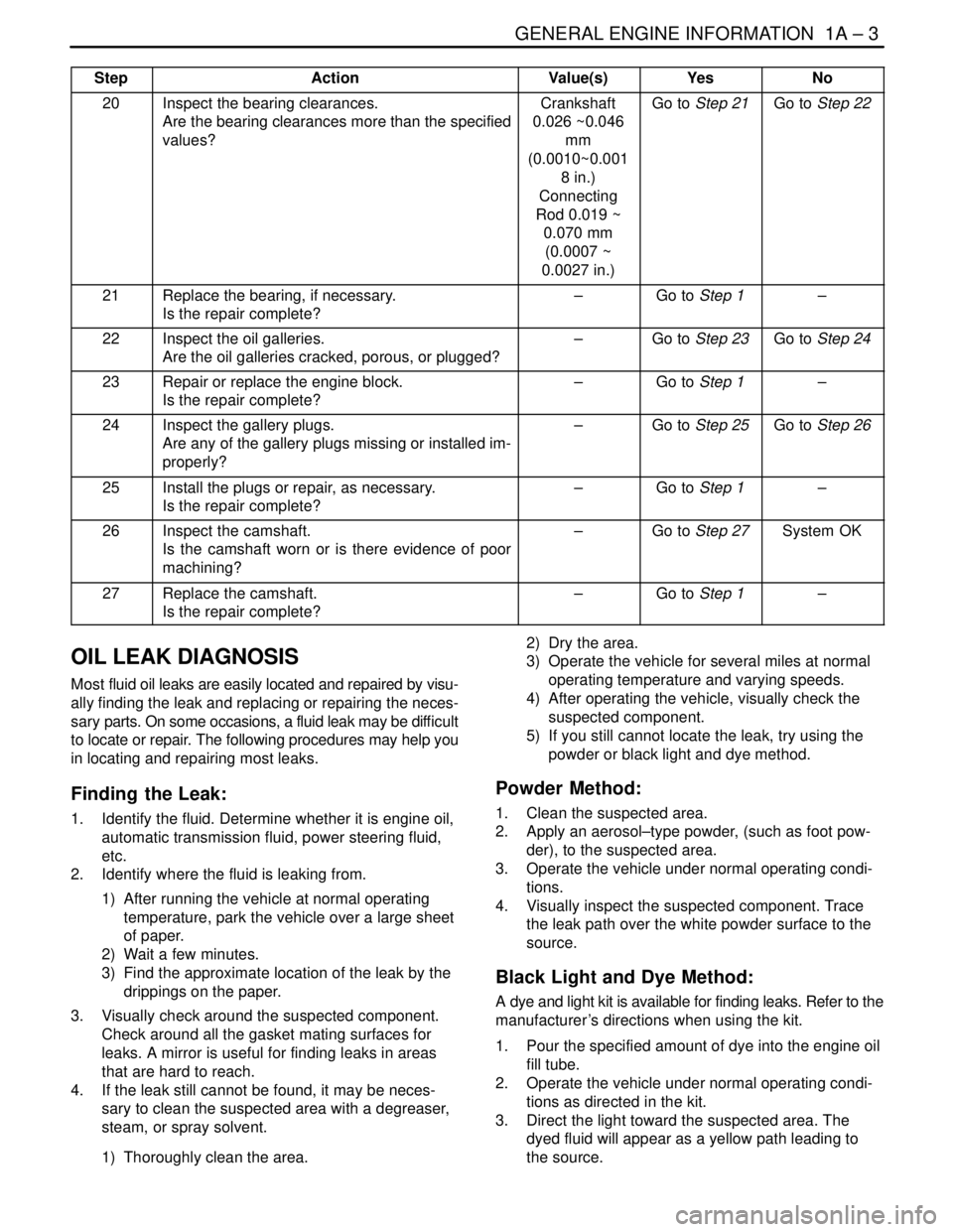

Automatic Transaxle Identification Number

Plate Location (AISIN : 81–40LE)

The automatic transaxle identification number plate is at-

tached on the upper side of the transaxle case.

Page 35 of 2643

GENERAL ENGINE INFORMATION 1A – 3

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

20Inspect the bearing clearances.

Are the bearing clearances more than the specified

values?Crankshaft

0.026 ~0.046

mm

(0.0010~0.001

8 in.)

Connecting

Rod 0.019 ~

0.070 mm

(0.0007 ~

0.0027 in.)Go to Step 21Go to Step 22

21Replace the bearing, if necessary.

Is the repair complete?–Go to Step 1–

22Inspect the oil galleries.

Are the oil galleries cracked, porous, or plugged?–Go to Step 23Go to Step 24

23Repair or replace the engine block.

Is the repair complete?–Go to Step 1–

24Inspect the gallery plugs.

Are any of the gallery plugs missing or installed im-

properly?–Go to Step 25Go to Step 26

25Install the plugs or repair, as necessary.

Is the repair complete?–Go to Step 1–

26Inspect the camshaft.

Is the camshaft worn or is there evidence of poor

machining?–Go to Step 27System OK

27Replace the camshaft.

Is the repair complete?–Go to Step 1–

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by visu-

ally finding the leak and replacing or repairing the neces-

sary parts. On some occasions, a fluid leak may be difficult

to locate or repair. The following procedures may help you

in locating and repairing most leaks.

Finding the Leak:

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid,

etc.

2. Identify where the fluid is leaking from.

1) After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2) Wait a few minutes.

3) Find the approximate location of the leak by the

drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas

that are hard to reach.

4. If the leak still cannot be found, it may be neces-

sary to clean the suspected area with a degreaser,

steam, or spray solvent.

1) Thoroughly clean the area.2) Dry the area.

3) Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4) After operating the vehicle, visually check the

suspected component.

5) If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method:

1. Clean the suspected area.

2. Apply an aerosol–type powder, (such as foot pow-

der), to the suspected area.

3. Operate the vehicle under normal operating condi-

tions.

4. Visually inspect the suspected component. Trace

the leak path over the white powder surface to the

source.

Black Light and Dye Method:

A dye and light kit is available for finding leaks. Refer to the

manufacturer ’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.

2. Operate the vehicle under normal operating condi-

tions as directed in the kit.

3. Direct the light toward the suspected area. The

dyed fluid will appear as a yellow path leading to

the source.

Page 45 of 2643

1C1 – 2I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

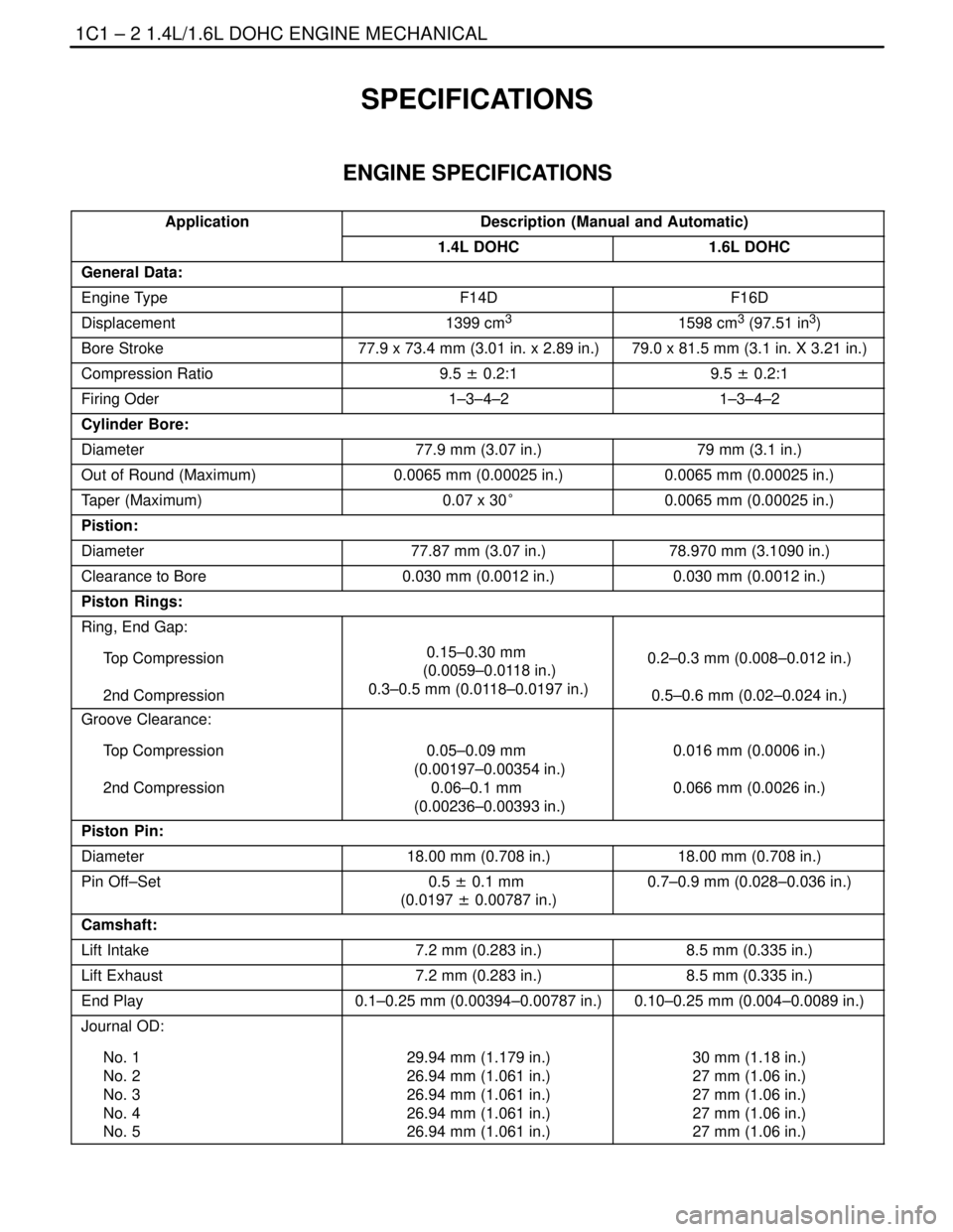

SPECIFICATIONS

ENGINE SPECIFICATIONS

ApplicationDescription (Manual and Automatic)

1.4L DOHC1.6L DOHC

General Data:

Engine TypeF14DF16D

Displacement1399 cm31598 cm3 (97.51 in3)

Bore Stroke77.9 x 73.4 mm (3.01 in. x 2.89 in.)79.0 x 81.5 mm (3.1 in. X 3.21 in.)

Compression Ratio9.5 ± 0.2:19.5 ± 0.2:1

Firing Oder1–3–4–21–3–4–2

Cylinder Bore:

Diameter77.9 mm (3.07 in.)79 mm (3.1 in.)

Out of Round (Maximum)0.0065 mm (0.00025 in.)0.0065 mm (0.00025 in.)

Taper (Maximum)0.07 x 30°0.0065 mm (0.00025 in.)

Pistion:

Diameter77.87 mm (3.07 in.)78.970 mm (3.1090 in.)

Clearance to Bore0.030 mm (0.0012 in.)0.030 mm (0.0012 in.)

Piston Rings:

Ring, End Gap:

Top Compression

2nd Compression0.15–0.30 mm

(0.0059–0.0118 in.)

0.3–0.5 mm (0.0118–0.0197 in.)0.2–0.3 mm (0.008–0.012 in.)

0.5–0.6 mm (0.02–0.024 in.)

Groove Clearance:

Top Compression

2nd Compression0.05–0.09 mm

(0.00197–0.00354 in.)

0.06–0.1 mm

(0.00236–0.00393 in.)0.016 mm (0.0006 in.)

0.066 mm (0.0026 in.)

Piston Pin:

Diameter18.00 mm (0.708 in.)18.00 mm (0.708 in.)

Pin Off–Set0.5 ± 0.1 mm

(0.0197 ± 0.00787 in.)0.7–0.9 mm (0.028–0.036 in.)

Camshaft:

Lift Intake7.2 mm (0.283 in.)8.5 mm (0.335 in.)

Lift Exhaust7.2 mm (0.283 in.)8.5 mm (0.335 in.)

End Play0.1–0.25 mm (0.00394–0.00787 in.)0.10–0.25 mm (0.004–0.0089 in.)

Journal OD:

No. 1

No. 2

No. 3

No. 4

No. 529.94 mm (1.179 in.)

26.94 mm (1.061 in.)

26.94 mm (1.061 in.)

26.94 mm (1.061 in.)

26.94 mm (1.061 in.)30 mm (1.18 in.)

27 mm (1.06 in.)

27 mm (1.06 in.)

27 mm (1.06 in.)

27 mm (1.06 in.)

Page 46 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 3

DAEWOO V–121 BL4

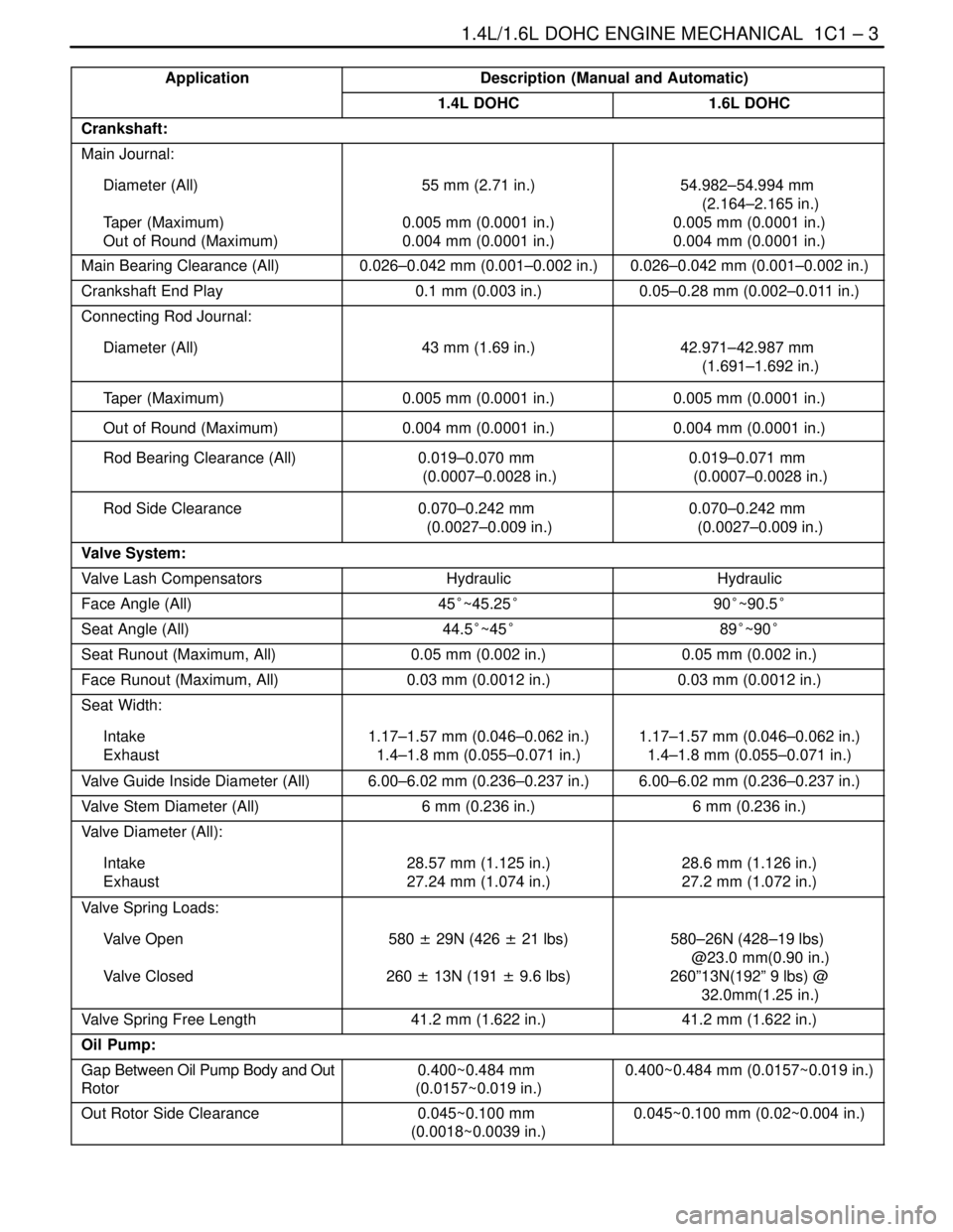

ApplicationDescription (Manual and Automatic)

1.4L DOHC1.6L DOHC

Crankshaft:

Main Journal:

Diameter (All)

Taper (Maximum)

Out of Round (Maximum)55 mm (2.71 in.)

0.005 mm (0.0001 in.)

0.004 mm (0.0001 in.)54.982–54.994 mm

(2.164–2.165 in.)

0.005 mm (0.0001 in.)

0.004 mm (0.0001 in.)

Main Bearing Clearance (All)0.026–0.042 mm (0.001–0.002 in.)0.026–0.042 mm (0.001–0.002 in.)

Crankshaft End Play0.1 mm (0.003 in.)0.05–0.28 mm (0.002–0.011 in.)

Connecting Rod Journal:

Diameter (All)43 mm (1.69 in.)

42.971–42.987 mm

(1.691–1.692 in.)

Taper (Maximum)0.005 mm (0.0001 in.)0.005 mm (0.0001 in.)

Out of Round (Maximum)0.004 mm (0.0001 in.)0.004 mm (0.0001 in.)

Rod Bearing Clearance (All)0.019–0.070 mm

(0.0007–0.0028 in.)0.019–0.071 mm

(0.0007–0.0028 in.)

Rod Side Clearance0.070–0.242 mm

(0.0027–0.009 in.)0.070–0.242 mm

(0.0027–0.009 in.)

Valve System:

Valve Lash CompensatorsHydraulicHydraulic

Face Angle (All)45°~45.25°90°~90.5°

Seat Angle (All)44.5°~45°89°~90°

Seat Runout (Maximum, All)0.05 mm (0.002 in.)0.05 mm (0.002 in.)

Face Runout (Maximum, All)0.03 mm (0.0012 in.)0.03 mm (0.0012 in.)

Seat Width:

Intake

Exhaust1.17–1.57 mm (0.046–0.062 in.)

1.4–1.8 mm (0.055–0.071 in.)1.17–1.57 mm (0.046–0.062 in.)

1.4–1.8 mm (0.055–0.071 in.)

Valve Guide Inside Diameter (All)6.00–6.02 mm (0.236–0.237 in.)6.00–6.02 mm (0.236–0.237 in.)

Valve Stem Diameter (All)6 mm (0.236 in.)6 mm (0.236 in.)

Valve Diameter (All):

Intake

Exhaust28.57 mm (1.125 in.)

27.24 mm (1.074 in.)28.6 mm (1.126 in.)

27.2 mm (1.072 in.)

Valve Spring Loads:

Valve Open

Valve Closed580 ± 29N (426 ± 21 lbs)

260 ± 13N (191 ± 9.6 lbs)580–26N (428–19 lbs)

@23.0 mm(0.90 in.)

260”13N(192” 9 lbs) @

32.0mm(1.25 in.)

Valve Spring Free Length41.2 mm (1.622 in.)41.2 mm (1.622 in.)

Oil Pump:

Gap Between Oil Pump Body and Out

Rotor0.400~0.484 mm

(0.0157~0.019 in.)0.400~0.484 mm (0.0157~0.019 in.)

Out Rotor Side Clearance0.045~0.100 mm

(0.0018~0.0039 in.)0.045~0.100 mm (0.02~0.004 in.)

Page 47 of 2643

1C1 – 4I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

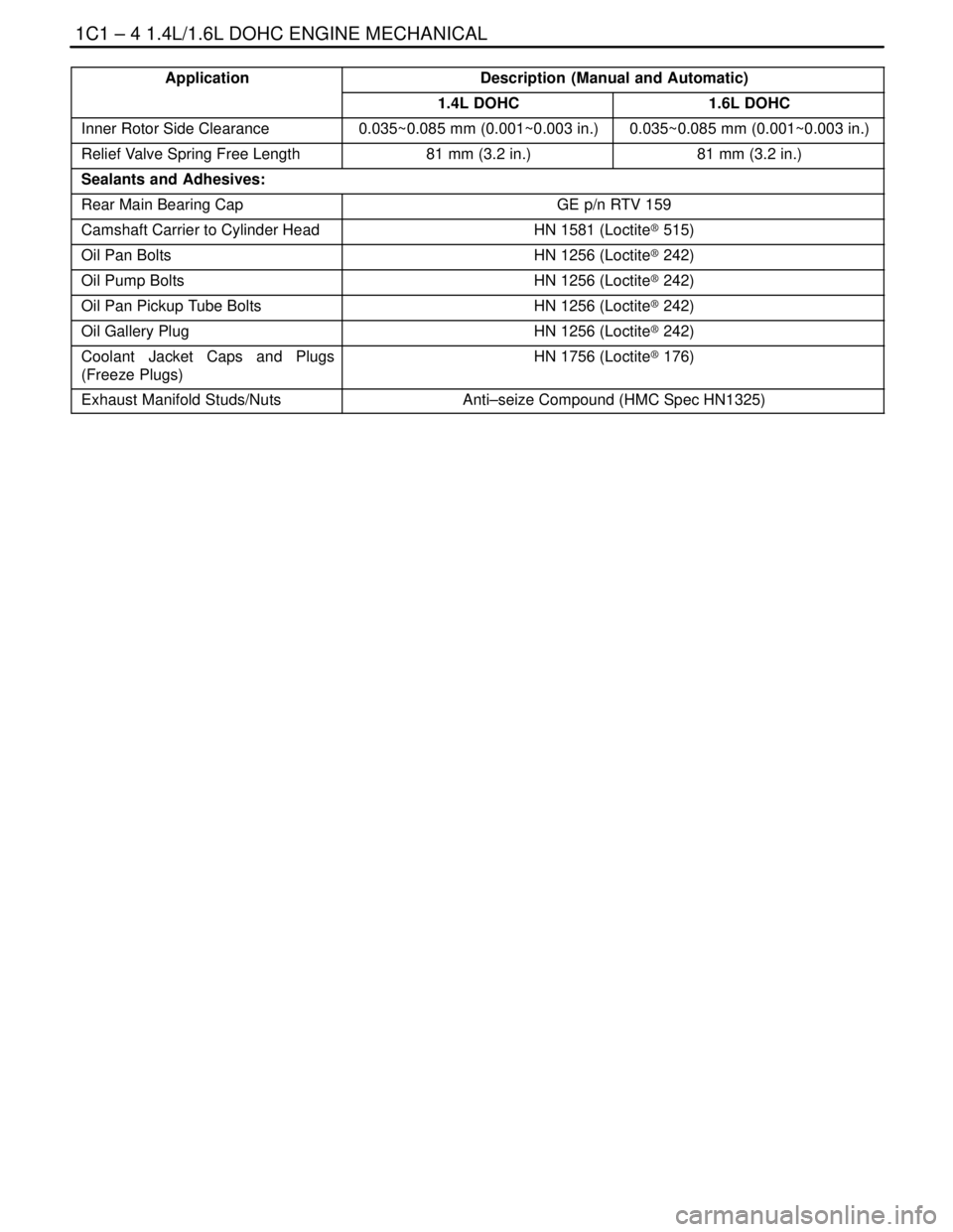

ApplicationDescription (Manual and Automatic)

1.4L DOHC1.6L DOHC

Inner Rotor Side Clearance0.035~0.085 mm (0.001~0.003 in.)0.035~0.085 mm (0.001~0.003 in.)

Relief Valve Spring Free Length81 mm (3.2 in.)81 mm (3.2 in.)

Sealants and Adhesives:

Rear Main Bearing CapGE p/n RTV 159

Camshaft Carrier to Cylinder HeadHN 1581 (Loctite® 515)

Oil Pan BoltsHN 1256 (Loctite® 242)

Oil Pump BoltsHN 1256 (Loctite® 242)

Oil Pan Pickup Tube BoltsHN 1256 (Loctite® 242)

Oil Gallery PlugHN 1256 (Loctite® 242)

Coolant Jacket Caps and Plugs

(Freeze Plugs)HN 1756 (Loctite® 176)

Exhaust Manifold Studs/NutsAnti–seize Compound (HMC Spec HN1325)

Page 49 of 2643

1C1 – 6I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

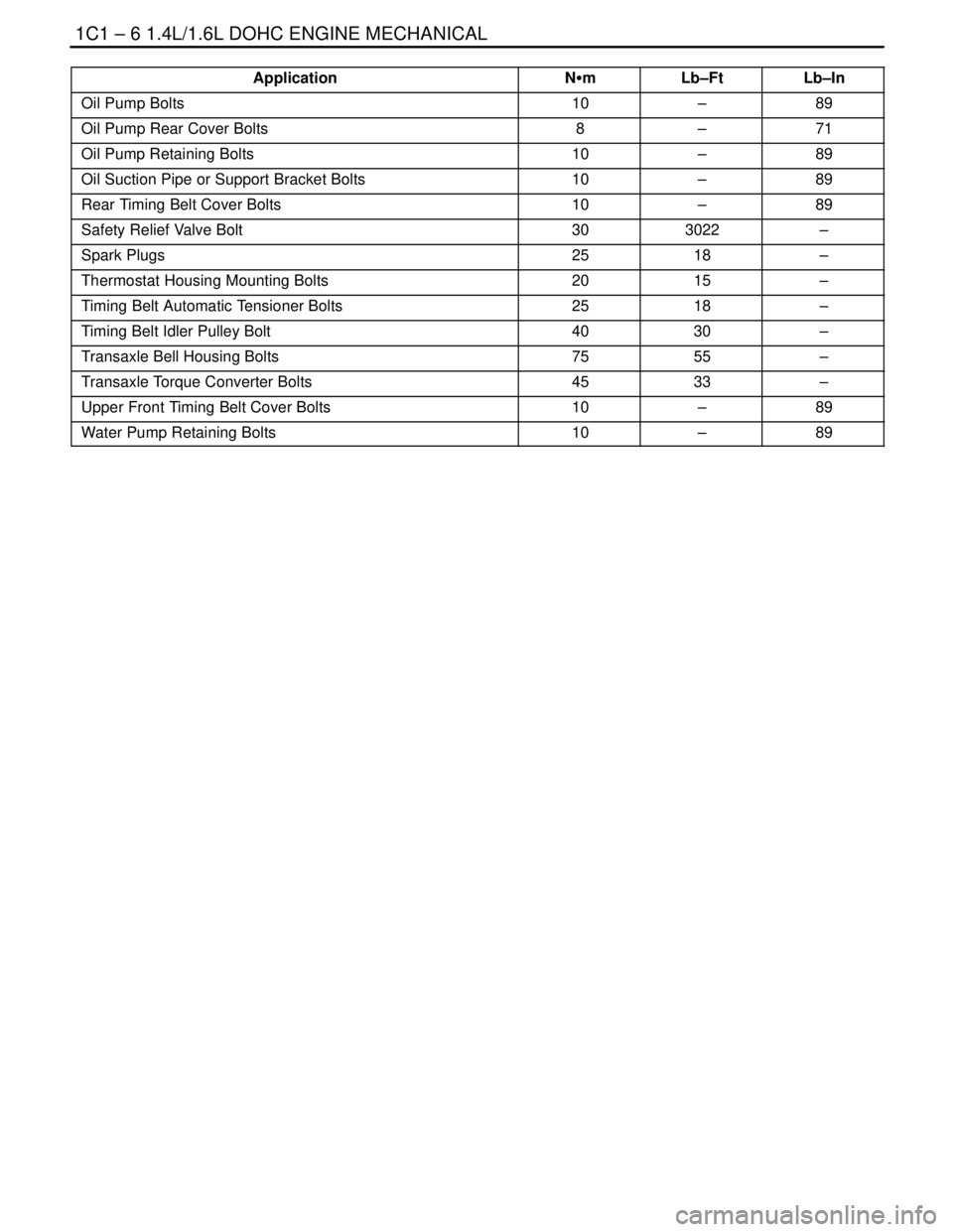

Application Lb–InLb–Ft NSm

Oil Pump Bolts10–89

Oil Pump Rear Cover Bolts8–71

Oil Pump Retaining Bolts10–89

Oil Suction Pipe or Support Bracket Bolts10–89

Rear Timing Belt Cover Bolts10–89

Safety Relief Valve Bolt303022–

Spark Plugs2518–

Thermostat Housing Mounting Bolts2015–

Timing Belt Automatic Tensioner Bolts2518–

Timing Belt Idler Pulley Bolt4030–

Transaxle Bell Housing Bolts7555–

Transaxle Torque Converter Bolts4533–

Upper Front Timing Belt Cover Bolts10–89

Water Pump Retaining Bolts10–89

Page 67 of 2643

1C1 – 24I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

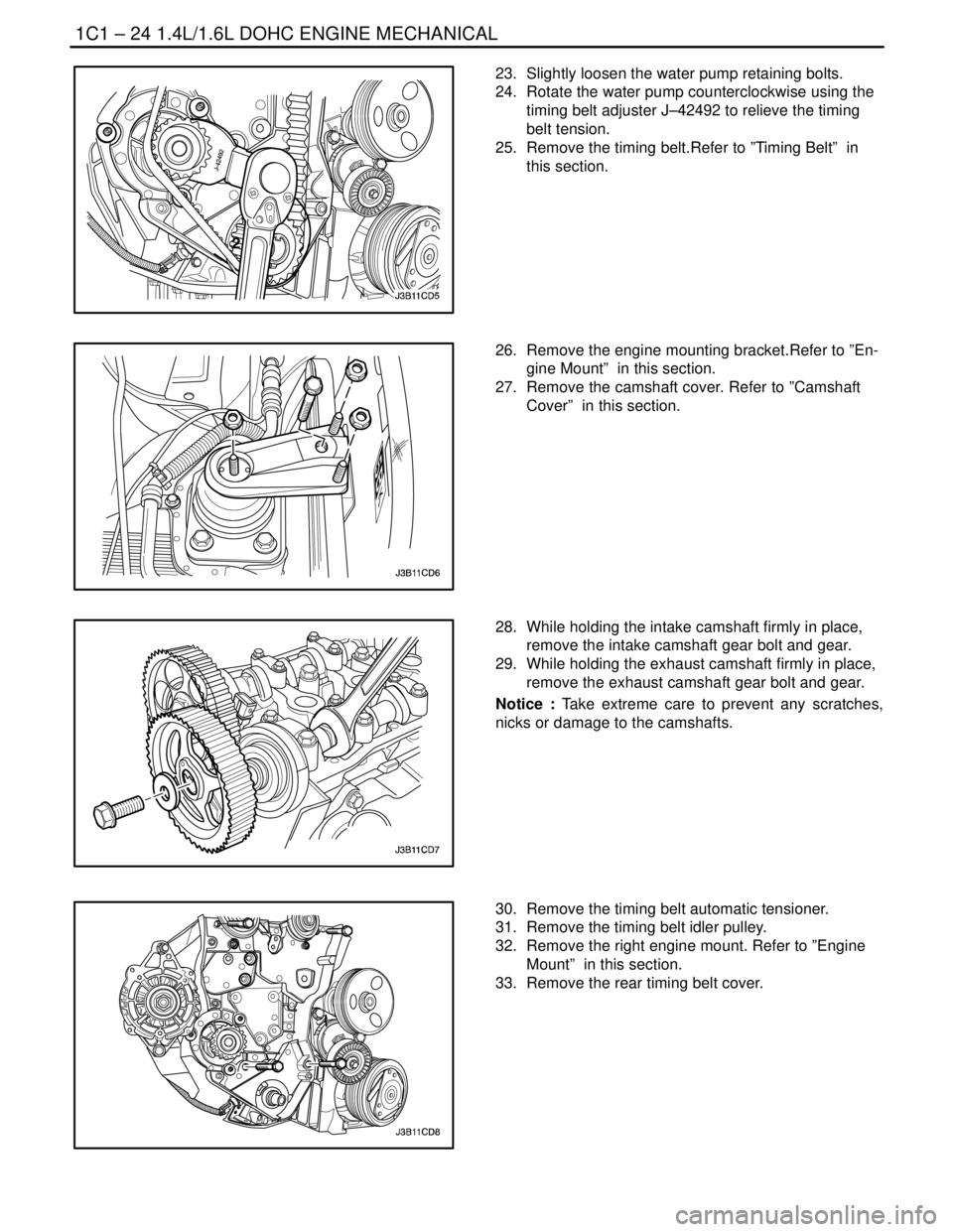

23. Slightly loosen the water pump retaining bolts.

24. Rotate the water pump counterclockwise using the

timing belt adjuster J–42492 to relieve the timing

belt tension.

25. Remove the timing belt.Refer to ”Timing Belt” in

this section.

26. Remove the engine mounting bracket.Refer to ”En-

gine Mount” in this section.

27. Remove the camshaft cover. Refer to ”Camshaft

Cover” in this section.

28. While holding the intake camshaft firmly in place,

remove the intake camshaft gear bolt and gear.

29. While holding the exhaust camshaft firmly in place,

remove the exhaust camshaft gear bolt and gear.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

30. Remove the timing belt automatic tensioner.

31. Remove the timing belt idler pulley.

32. Remove the right engine mount. Refer to ”Engine

Mount” in this section.

33. Remove the rear timing belt cover.

Page 70 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 27

DAEWOO V–121 BL4

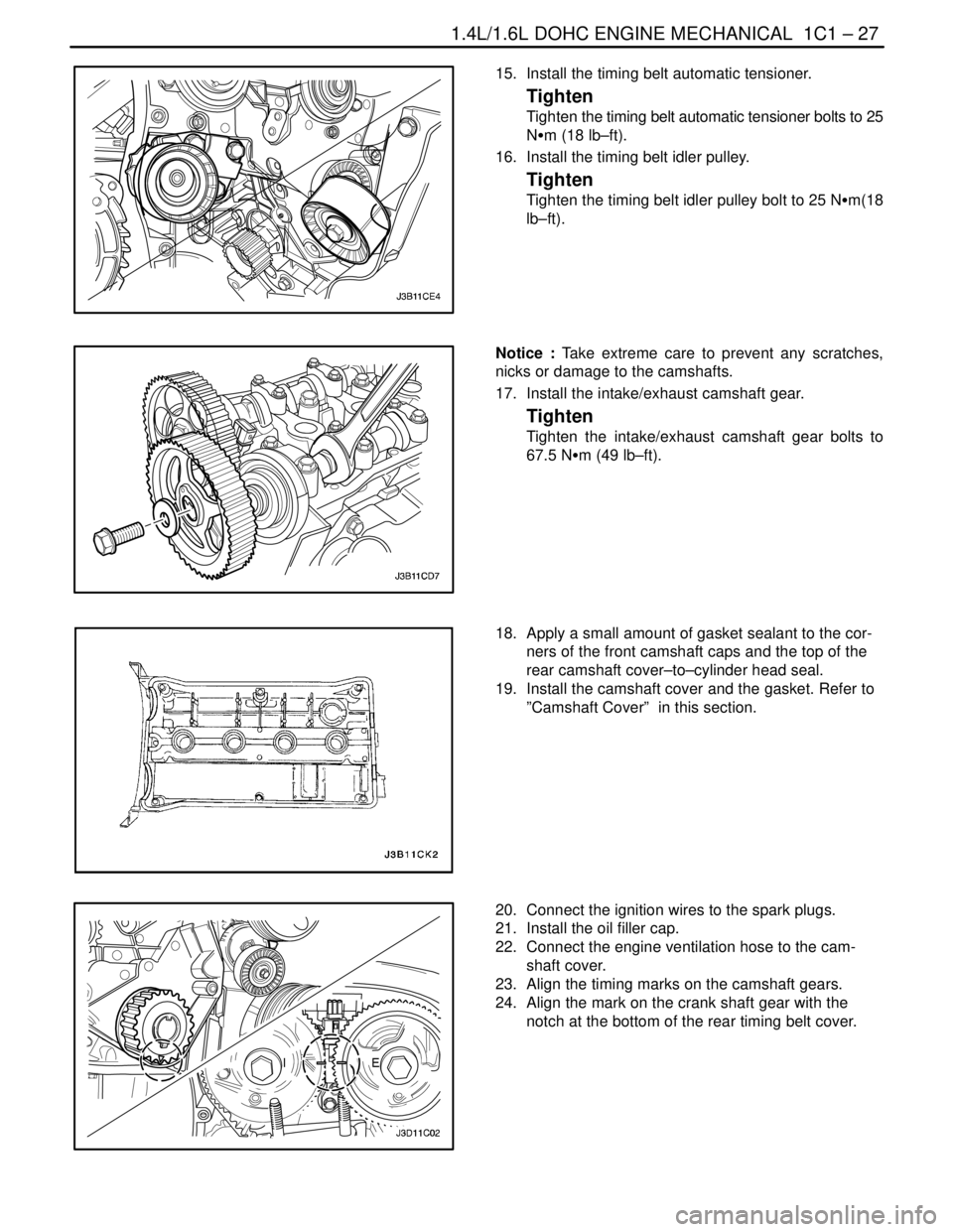

15. Install the timing belt automatic tensioner.

Tighten

Tighten the timing belt automatic tensioner bolts to 25

NSm (18 lb–ft).

16. Install the timing belt idler pulley.

Tighten

Tighten the timing belt idler pulley bolt to 25 NSm(18

lb–ft).

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

17. Install the intake/exhaust camshaft gear.

Tighten

Tighten the intake/exhaust camshaft gear bolts to

67.5 NSm (49 lb–ft).

18. Apply a small amount of gasket sealant to the cor-

ners of the front camshaft caps and the top of the

rear camshaft cover–to–cylinder head seal.

19. Install the camshaft cover and the gasket. Refer to

”Camshaft Cover” in this section.

20. Connect the ignition wires to the spark plugs.

21. Install the oil filler cap.

22. Connect the engine ventilation hose to the cam-

shaft cover.

23. Align the timing marks on the camshaft gears.

24. Align the mark on the crank shaft gear with the

notch at the bottom of the rear timing belt cover.

Page 75 of 2643

1C1 – 32I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

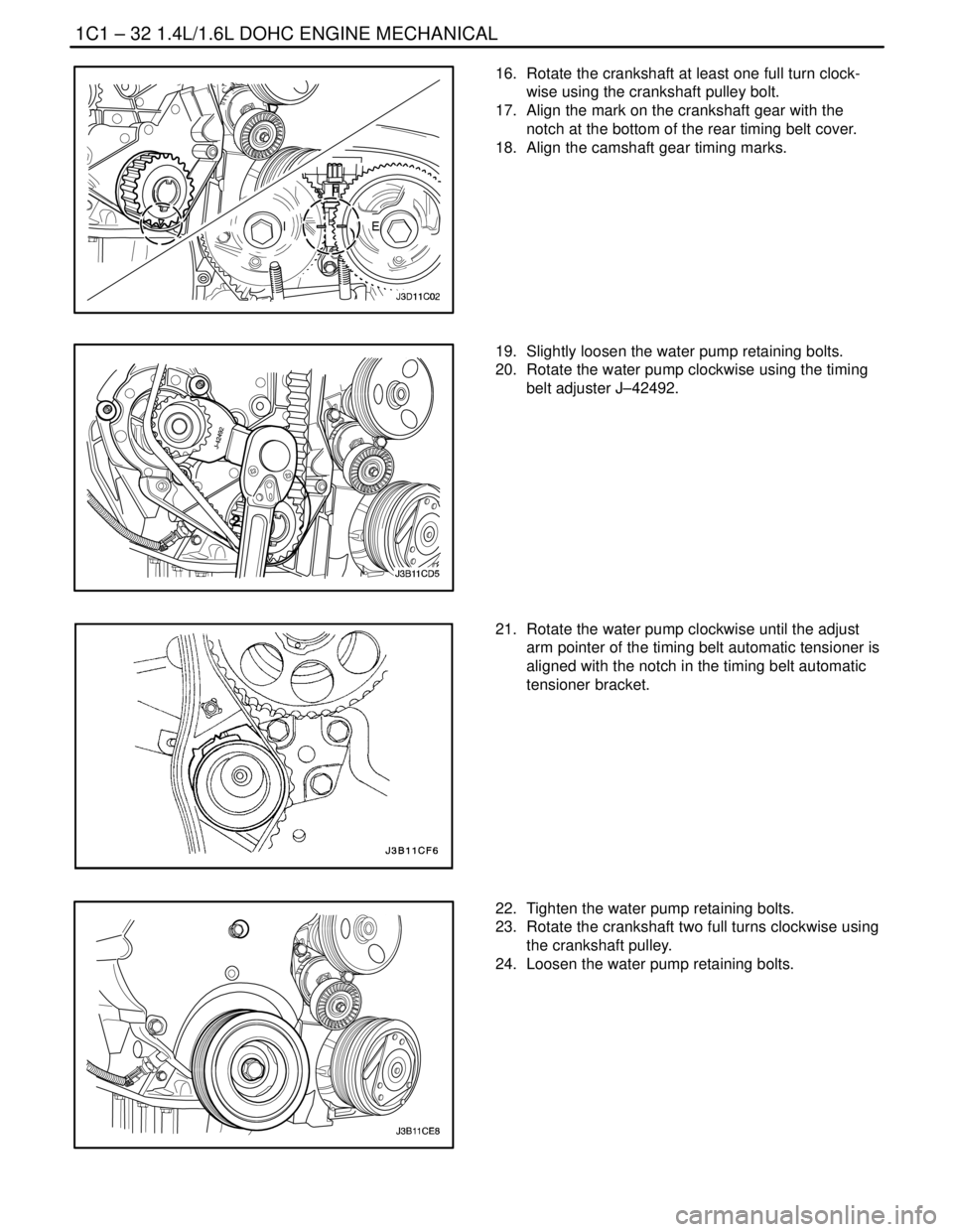

16. Rotate the crankshaft at least one full turn clock-

wise using the crankshaft pulley bolt.

17. Align the mark on the crankshaft gear with the

notch at the bottom of the rear timing belt cover.

18. Align the camshaft gear timing marks.

19. Slightly loosen the water pump retaining bolts.

20. Rotate the water pump clockwise using the timing

belt adjuster J–42492.

21. Rotate the water pump clockwise until the adjust

arm pointer of the timing belt automatic tensioner is

aligned with the notch in the timing belt automatic

tensioner bracket.

22. Tighten the water pump retaining bolts.

23. Rotate the crankshaft two full turns clockwise using

the crankshaft pulley.

24. Loosen the water pump retaining bolts.

Page 76 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 33

DAEWOO V–121 BL4

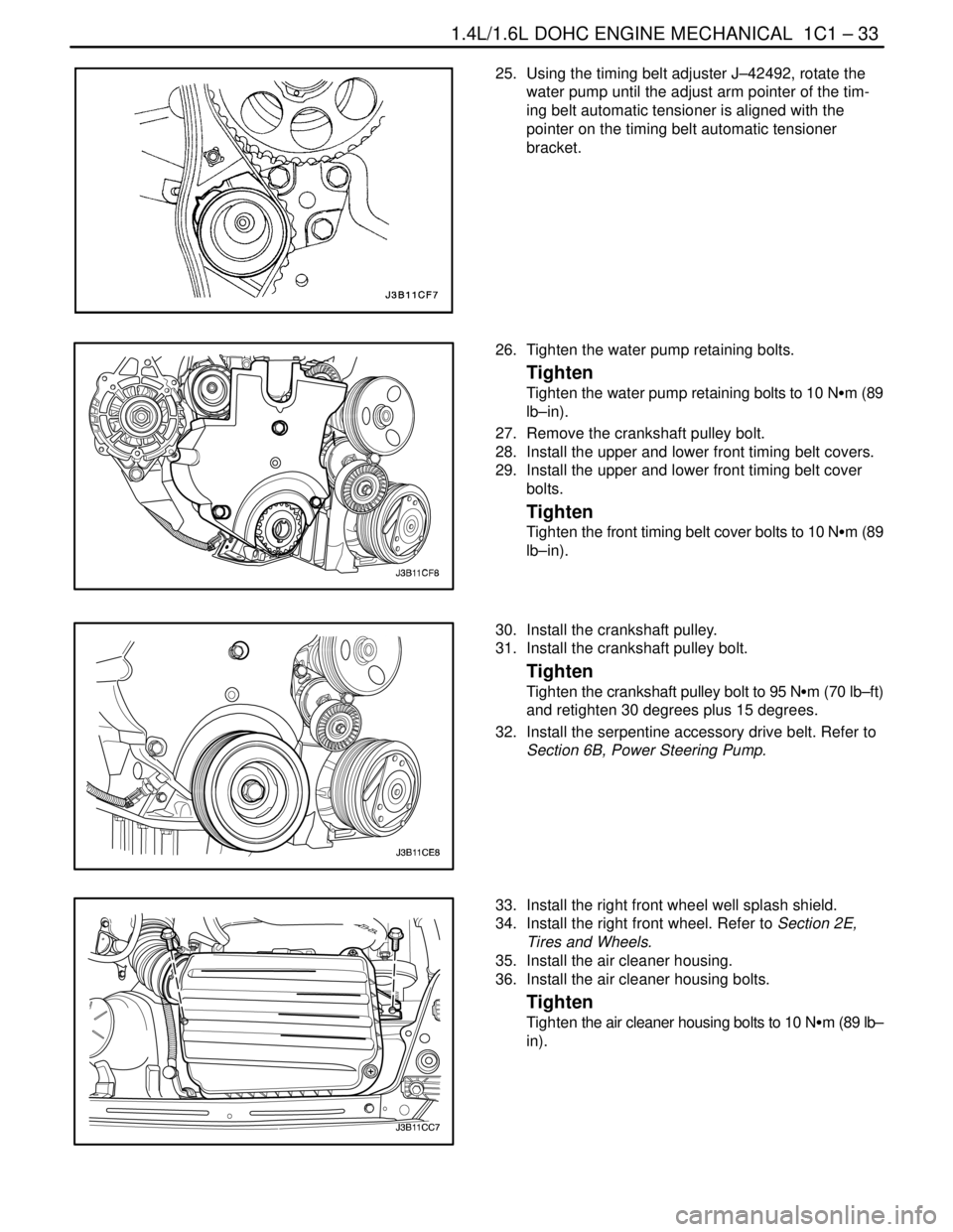

25. Using the timing belt adjuster J–42492, rotate the

water pump until the adjust arm pointer of the tim-

ing belt automatic tensioner is aligned with the

pointer on the timing belt automatic tensioner

bracket.

26. Tighten the water pump retaining bolts.

Tighten

Tighten the water pump retaining bolts to 10 NSm (89

lb–in).

27. Remove the crankshaft pulley bolt.

28. Install the upper and lower front timing belt covers.

29. Install the upper and lower front timing belt cover

bolts.

Tighten

Tighten the front timing belt cover bolts to 10 NSm (89

lb–in).

30. Install the crankshaft pulley.

31. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 NSm (70 lb–ft)

and retighten 30 degrees plus 15 degrees.

32. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

33. Install the right front wheel well splash shield.

34. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

35. Install the air cleaner housing.

36. Install the air cleaner housing bolts.

Tighten

Tighten the air cleaner housing bolts to 10 NSm (89 lb–

in).