Reverse DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1369 of 2643

5A1 – 20IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

Reverse

In Reverse, transaxle drive is via the input shaft and clutch

B. The elements of this transaxle function are as follows:

S Clutch B is engaged and drives the reverse sun

gear in a clock––wise direction.

S The D band is engaged and holds the planetary

gear carrier (front & rear) stationary causing the

differential pinion to rotate clockwise.

S The differential rotates in a counterclockwise direc-

tion.

S The output shaft is driven in a counterclockwise or

reverse direction.

Control

Clutch B Engaged

The line pressure, which is supplied by the oil pump, is di-

rected to clutch B via the manual valve. The position of the

check ball will change allowing direct pressure to clutch B.

Brake D Engaged

The line pressure, which engaged clutch B, is also sup-

plied to clutch valve D.In Reverse, solenoid 1 is switched ON and EDS 4 is

switched OFF. This will cause the fluid supplied to the re-

duction valve to flow to clutch valve D via the EDS 4.

The spool of clutch valve D will be depressed allowing fluid

to pass to holding valve D.

Lock–up Clutch (TCC)

Solenoid 2 is turned ON and the line pressure control valve

spool will be depressed. Fluid will now flow through the

torque converter pressure valve.

As a result, the oil pressure behind the converter lock–up

clutch piston and in the turbine zone is equal. The direction

of flow is through the turbine shaft and through the space

behind the piston, to the turbine chamber.

Lubrication/Cooling

The lubricating valve ensures that the converter is sup-

plied with cooling oil first if the pump rate is low. The lubri-

cating pressure valve in addition guarantees that the nec-

essary amount of cooling and lubricating oil is available via

the bypass duct.

The fluid, which is supplied from the torque converter,

flows to the cooler via the lubrication valve.

Page 1392 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 43

DAEWOO V–121 BL4

DIAGNOSTIC INFORMATION AND

PROCEDURES DIAGNOSIS

BASIC KNOWLEDGE REQUIRED

You must be familiar with some basic electronics to use

this section of the Service Manual. They will help you to

follow diagnostic procedures.

Notice : Lack of the basic knowledge of this transaxle

when performing diagnostic procedures could result in in-

correct diagnostic performance or damage to transaxle

components.

Do not, under any circumstances, attempt to diagnose a

transaxle problem without this basic knowledge.

Notice : If a wire is probed with a sharp instrument and not

properly sealed afterward, the wire will corrode and an

open circuit will result.

Diagnostic test probes are now available that allow you to

probe individual wires without leaving the wire open to the

environment. These probe devices are inexpensive and

easy to install, and they permanently seal the wire from

corrosion.

Special Tools

You should be able to use a Digital Volt Meter (DVM), a cir-

cuit tester, jumper wires or leads and a line pressure gauge

set.

The functional check procedure is designed to verify the

correct operation of electronic components in the trans-

axle.

This will eliminate the unnecessary removal of transaxle

components.

FUNCTIONAL CHECK PROCEDURE

Begin with the Functional Check Procedure which pro-

vides a general outline of how to diagnose automatic

transaxle. The following functional check procedure will in-

dicate the proper path of diagnosing the transaxle by de-

scribing the basic checks and then referencing the loca-

tions of the specific checks.

S Check the fluid level according to the Fluid Level

Service Procedure.

S Check the transaxle for fluid leaks.

S Check if the transaxle fluid is not burnt by color and

smell.

S Ensure that the transaxle is not in Limp Home

Mode(LHM).

S Check the battery terminals and the ground con-

nections for corrosion or looseness.

S Check that the cooler flow is not restricted.S Check all electrical connections for tightness.

S Use on–board diagnostic tool or a scan tool to see

if any transaxle trouble codes have been set. Refer

to the appropriate ”Diagnostic Trouble Code (DTC)”

information and repair the vehicle as directed. After

repairing the vehicle, perform the road test and

verify that the code has not set again.

S Perform the Electrical/Garage Shift Tests.

S Perform the Road Test Procedure in this section.

S Inspect the oil and check for metal or other contam-

inants in the oil pan.

LINE PRESSURE CHECK

PROCEDURE

The 4HP 16 A/T uses a trochoid type oil pump to produce

hydraulic pressure, and a pressure control solenoid (sole-

noid 1) to control that pressure at the pressure regulator

valve, after it leaves the pump. The transaxle pressure

control solenoid is controlled by an electrical signal that

ranges from 0 to 12 volts corresponds to minimum line

pressure (approx. 89.9 to 124.7 psi (6.2 to 8.6 bar)) and

0 volt corresponds to a maximum line pressure (approx.

221.9 to 252.4 psi (15.3 to 17.4 bar)) in all range.

Line pressures are calculated for two sets of gear ranges

– Drive–Park–Neutral and Reverse. This allow the trans-

axle line pressure to be appropriate for different pressure

needs in different gear ranges:

Gear

Range

Solenoid

1RPMPressure

Drive,

ReverseOff2,500221.9~252.4psi

(15.3~17.4 bar)

On2,50017.4~269.8psi

(1.2~18.6 bar)

Neutral,

ParkOff2,500221.9~252.4psi

(15.3~17.4 bar)

On2,50089.9~269.8 psi

(6.2~18.6 bar)

Before performing a line pressure check, verify that the

pressure control solenoid is receiving the correct electrical

signal from the TCM:

1. Install a scan tool.

2. Start the engine and set parking brake.

3. Check for a stored pressure control solenoid diag-

nostic trouble code, and other diagnostic trouble

codes.

Page 1393 of 2643

5A1 – 44IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

4. Repair vehicle, if necessary.

Inspect:

S Fluid level.

S Manual linkage.

Install or Connect:

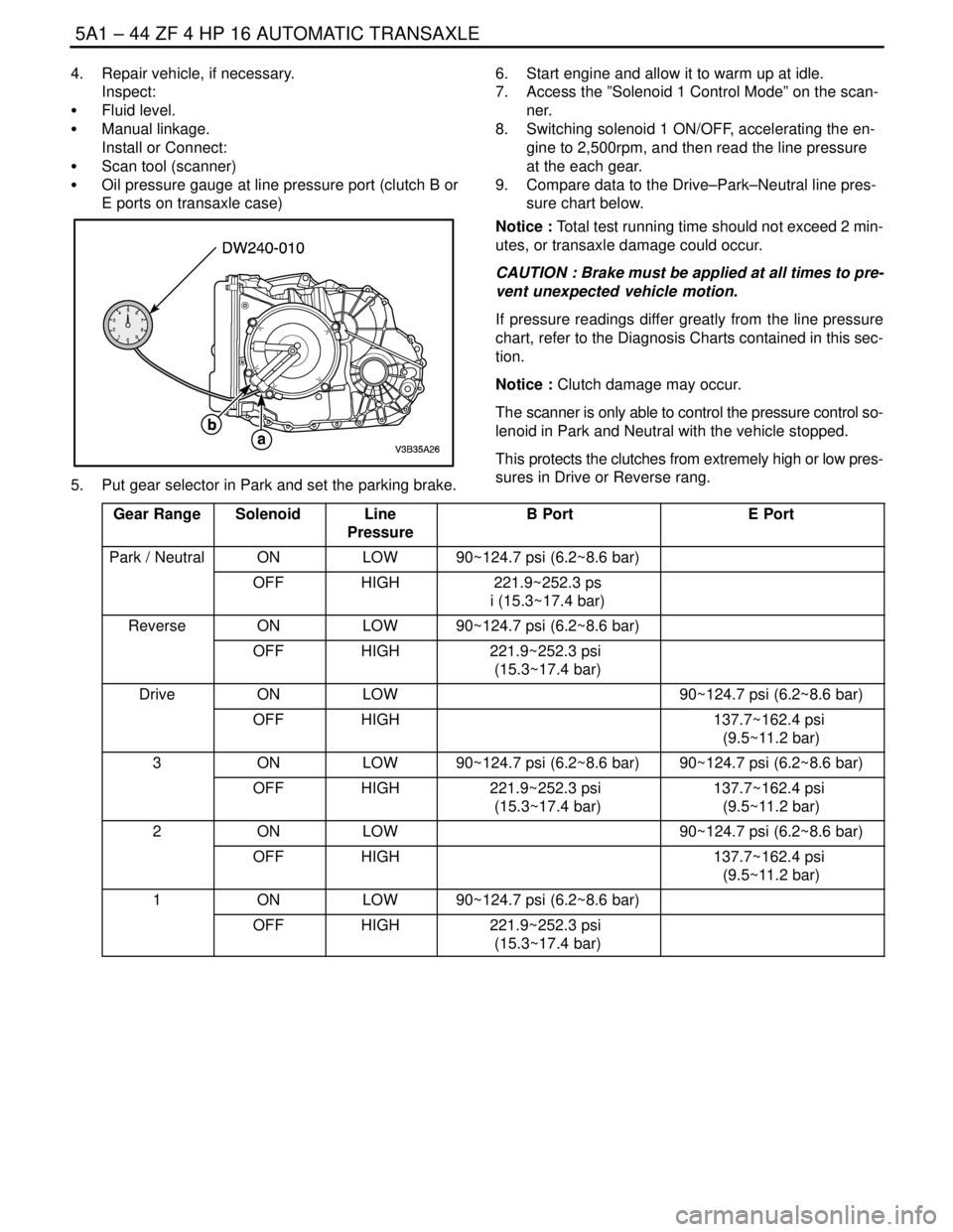

S Scan tool (scanner)

S Oil pressure gauge at line pressure port (clutch B or

E ports on transaxle case)

5. Put gear selector in Park and set the parking brake.6. Start engine and allow it to warm up at idle.

7. Access the ”Solenoid 1 Control Mode” on the scan-

ner.

8. Switching solenoid 1 ON/OFF, accelerating the en-

gine to 2,500rpm, and then read the line pressure

at the each gear.

9. Compare data to the Drive–Park–Neutral line pres-

sure chart below.

Notice : Total test running time should not exceed 2 min-

utes, or transaxle damage could occur.

CAUTION : Brake must be applied at all times to pre-

vent unexpected vehicle motion.

If pressure readings differ greatly from the line pressure

chart, refer to the Diagnosis Charts contained in this sec-

tion.

Notice : Clutch damage may occur.

The scanner is only able to control the pressure control so-

lenoid in Park and Neutral with the vehicle stopped.

This protects the clutches from extremely high or low pres-

sures in Drive or Reverse rang.

Gear Range

SolenoidLine

Pressure B PortE Port

Park / NeutralONLOW90~124.7 psi (6.2~8.6 bar)

OFFHIGH221.9~252.3 ps

i (15.3~17.4 bar)

ReverseONLOW90~124.7 psi (6.2~8.6 bar)

OFFHIGH221.9~252.3 psi

(15.3~17.4 bar)

DriveONLOW90~124.7 psi (6.2~8.6 bar)

OFFHIGH137.7~162.4 psi

(9.5~11.2 bar)

3ONLOW90~124.7 psi (6.2~8.6 bar)90~124.7 psi (6.2~8.6 bar)

OFFHIGH221.9~252.3 psi

(15.3~17.4 bar)137.7~162.4 psi

(9.5~11.2 bar)

2ONLOW90~124.7 psi (6.2~8.6 bar)

OFFHIGH137.7~162.4 psi

(9.5~11.2 bar)

1ONLOW90~124.7 psi (6.2~8.6 bar)

OFFHIGH221.9~252.3 psi

(15.3~17.4 bar)

Page 1394 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 45

DAEWOO V–121 BL4

CLUTCH PLATE DIAGNOSIS

Composition Plates

Dry the plate and inspect the plates for the following condi-

tions :

S Pitting

S Flaking

S Wear

S Glazing

S Cracking

S Charring

Chips or metal particles embedded in the lining

Replace a composition plate which shows any of these

conditions.

Steel Plates

Wipe the plates dry and check the plates for heat discolor-

ation. If the surfaces are smooth, even if colorsmear is in-

dicated, you can reuse the plate. If the plate is discolored

with hot spots or if the surface is scuffed, replace the plate.

Important : If the clutch shows evidence or extreme heat

or burning, replace the springs.

Causes of Burned Clutch Plates

The following conditions can result in a burned clutch

plate:

S Incorrect usage of clutch plates.

S Engine coolant in the transaxle fluid.

S A cracked clutch piston.

S Damaged or missing seals.

S Low line pressure.

S Valve problems.

– The valve body face is not flat

– Porosity between channels

– The valve bushing clips are improperly installed.

– The check balls are misplaced.

S The seal rings are worn or damaged

Engine Coolant in Transaxle

Notice : Antifreeze will deteriorate the O–ring seals and

the glue used to bond the clutch material to the pressure

plate. Both conditions may cause transaxle damage.

Perform the following steps if the transaxle oil cooler has

developed a leak, allowing engine coolant to enter the

transaxle:

1. Because the coolant will attach to the seal material

causing leakage, disassemble the transaxle and

replace all rubber type seals.

2. Because the facing material may become sepa-

rated from the steel center portion, replace the

composition faced clutch plate assemblies.

3. Replace all nylon parts including washers.

4. Replace the torque converter.

5. Thoroughly clean and rebuild the transaxle, using

new gaskets and oil filter.6. Flush the cooler lines after you have properly re-

paired or replaced the transaxle.

COOLER FLUSHING AND FLOW

TEST

Notice : You must flush the cooler whenever you receive

a transaxle for service. Cooler flushing is essential for

SRTA installation, major overhaul, whenever you replace

a pump or torque converter, or whenever you suspect that

the fluid has been contaminated.

After filling the transaxle with fluid, start the engine and run

for 30 seconds. This will remove any residual moisture

from the oil cooler. Disconnect the return line at the trans-

axle and observe the flow with the engine running. If the

fluid flow is insufficient, check the fluid flow by disconnect-

ing the feed line at the cooler. Observe the flow with the

engine running.

S If the flow from the cooler return line at the trans-

axle is insufficient, check the flow rate from the feed

line to the cooler. BLockage exists in the transaxle

or the cooler.

S If the flow from the transaxle feed line to the cooler

is insufficient, the transaxle is the cause of the fluid

flow problem.

S If the flow the transaxle feed line to the cooler is

insufficient, but flow from the cooler return line to

the transaxle is insufficient, inspect the cooler pipes

and fittings. Then repeat the cooler flushing proce-

dure. If the flow is still insufficient, replace the cool-

er.

TRANSAXLE FLUID LEVEL SERVICE

PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will result

in slipping and loss of drive/ reverse or delay on engage-

ment of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transaxle diagnostic mes-

sages on the scan tool. If the oil level is low, it is possible

to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is an

abnormal delay when selecting drive or reverse, or loss of

drive. One symptom of low fluid level is a momentary loss

of drive when driving the vehicle around a corner. Also

when the transaxle fluid level is low, a loss of drive may oc-

cur when the transaxle fluid temperature is low.

When adding or changing transaxle fluid use only ESSO

LT 71141 automatic transaxle fluid or other approved

fluids. The use of incorrect fluid will cause the performance

and durability of the transaxle to be severely degraded.

Fluid Level Diagnosis Procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes (825~875 rpm), if pos-

Page 1397 of 2643

5A1 – 48IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

The Lock up clutch should not apply unless the transaxle

has reached a minimum operating temperature of 8°C

(46°F) TRANS TEMP AND engine coolant temp of 50°C

(122°F).

5. Repeat steps 1–4 using several different throttle

angles.

Part Throttle Detent Downshift

At vehicle steeds of 55 to 65km/h (34 to 40mph) in Fourth

gear, quickly increase throttle angle to greater than 50%.

Verify that :

S TCC apply.

S Transaxle downshift to 3rd gear.

S Solenoid 1 turns ON to OFF.

S Solenoid 2 turns OFF.

Full Throttle Detent Downshift

At vehicle speeds of 55 to 65km/h (34 to 40mph)in Fourth

gear, quickly increase throttle angle to its maximum posi-

tion (100%)

Verify that :

S TCC release.

S Transaxle downshift to Second gear immediately.

S Solenoid 1 turns ON to OFF

S Solenoid 2 turns OFF.

Manual Downshifts

1. At vehicle speeds of 60km/h (40mph)in Fourth

gear, release accelerator pedal while moving gear

selector to Manual Third (3). Observe that :

S Transaxle downshift to Third gear immediately.

S Engine slows vehicle down.

2. Move gear selector back to overdrive(D) and accel-

erate to 31mph (50km/h). Release the accelerator

pedal and move the gear selector to Manual

First(1) and observe that :

S Transaxle downshift to second gear immediate-

ly.

S Engine slows vehicle down

Notice : A Manual First––Third Gear Ratio will occur at

high speeds as an upshift safety feature. Do not attempt

to perform this shift.

Coasting Downshifts

1. With the gear selector in Overdrive(D), accelerate

to Fourth gear with TCC applied.

2. Release the accelerator pedal and lightly apply the

brakes, and observe that :

S TCC release.

S Down shifts occur at speeds shown ON the shift

speed chart.

Manual Gear Range Selection

Upshifts in the manual gear ranges are controlled by the

shift solenoids. Perform the following tests by accelerating

at 25 percent TP sensor increments.

Manual Third (3)

S With vehicle stopped, move the gear selector to

Manual third(3) and accelerate to observe :

– 1–2 shift.

– 2–3 shift.

Manual Second (2)

S With vehicle stopped, move the gear selector to

Manual second(2) and accelerate to observe :

– 1–2 shift.

S Accelerate to 40km/h(25mph) and observe :

– 2–3 shift does not occur

– TCC does not apply

Manual First (1)

S With vehicle stopped, move gear selector to Manu-

al First(1). Accelerate to 30km/h(19mph) and ob-

serve :

– No upshifts occur

Reverse (R)

S With vehicle stopped, move gear selector to R(Re-

verse) and observe :

– Solenoid 1 is OFF

– Solenoid 2 is OFF

Use a scan tool to see if any transaxle trouble codes have

been set. Refer to ”Diagnostic Trouble Codes”in this sec-

tion and repair the vehicle as directed. After repairing the

vehicle, perform the hoist test and verify that the code has

not set again.

If the transaxle is not performing well and no trouble codes

have been set, there may be an intermittent condition.

Check all electrical connections for damage or a loose fit.

You also have to perform a snapshot test which can help

catch an intermittent condition that dose not occur long

enough to set a code.

You may want to read ”Electronic Component Diagnosis”

in this section to become familiar with transaxle conditions

caused by transaxle electrical malfunction.

If no trouble codes have been set and the condition is sus-

pected to be hydraulic, take the vehicle on a road test.

TORQUE CONVERTER LOCK–UP

CLUTCH(TCC) DIAGNOSIS

To properly diagnosis the lock–up clutch(TCC) system,

perform all electrical testing first and then the hydraulic

testing.

The TCC is applied by fluid pressure which is controlled by

a solenoid Located inside the valve body. The solenoid is

energized by completing an electrical circuit through a

combination of switches and sensors.

Page 1407 of 2643

5A1 – 58IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

Symptom ActionPossible Cause

NoiseThe Engine’s Torsional Vibrations are

Being Transmitted to the Drive ShaftsS At low speeds in fourth gear, vibration can

arise (driving at too low an engine speed)

S Noise is functionally unavoidable; due to toler-

ances. Convince the customer.

NoiseTorque Reaction Strut LooseS Check mounting and repair if necessary.

Shift quality

Notice :

– The assessment of shaft quality is, to a large ex-

tent, an individual, subjective matter. Take careful

note of how the customer describes the complaint

and of the manner in which he or she handles the

vehicle and the controls.

– A sudden deterioration of shift quality may also

be caused by the transaxle selecting an emergency

or substitute program

Test Steps :– Carry out the general checks described in the

automatic transaxle diagnostic information.

– Perform a test drive to answer the following ques-

tions.

In which driving situations does the shift quality

complaint arise?

To which shifts does the complaint apply?

Is the complaint reproducible within a short period,

or has it only occurred sporadically or on a single

occasion?

– Check the oil level and oil quality

– Interrogate the fault memory and read out mea-

surement block data.

Symptom

Possible CauseAction

Shift QualityRapid Pressure Build–up in the ClutchS Operating error (position selected several times

in quick succession).

Jerk When Parking Lock Is ReleasedS Refer to ”Noise” in this section.

Incorrect Electronic Transaxle Control

moduleS Check the data status for transaxle control

module ; refer to ”TCM” in this section.

Emergency/Substitute Program Has

Been ActivatedS For checking and remedial action, refer to

”Emergency/Substitute program” in this sec-

tion.

Accelerator Pedal in Indefinite Position

Between Full Throttle and Kick DownS Persuade customer to choose clearly between

kick down and full throttle

S Check setting according go engine repair in-

struction ; adjust if necessary.

Control Overlap Between to Clutches

During ShiftS Production status

S Convince the customer

Temperature Sensor

(Not Fault Memory)S Check function according to ”Emergency/Sub-

stitute program” in this section.

Kick Down Setting IncorrectS Check

A) Floor mat is obstructing accelerator pedal

B) The kick down setting as described in the

Engine Section.

Malfunction

Notice :

The faults dealt with here concern transaxle functions

such as ”traction” (forwards and reverse) and all type of

shifts. Entries will not always be made in the fault memory.Test Steps :

Perform the general checks according to the automatic

transaxle diagnostic procedure.

– Test drive

– Check oil level and quality

– Interrogate fault memory

Page 1435 of 2643

5A1 – 86IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

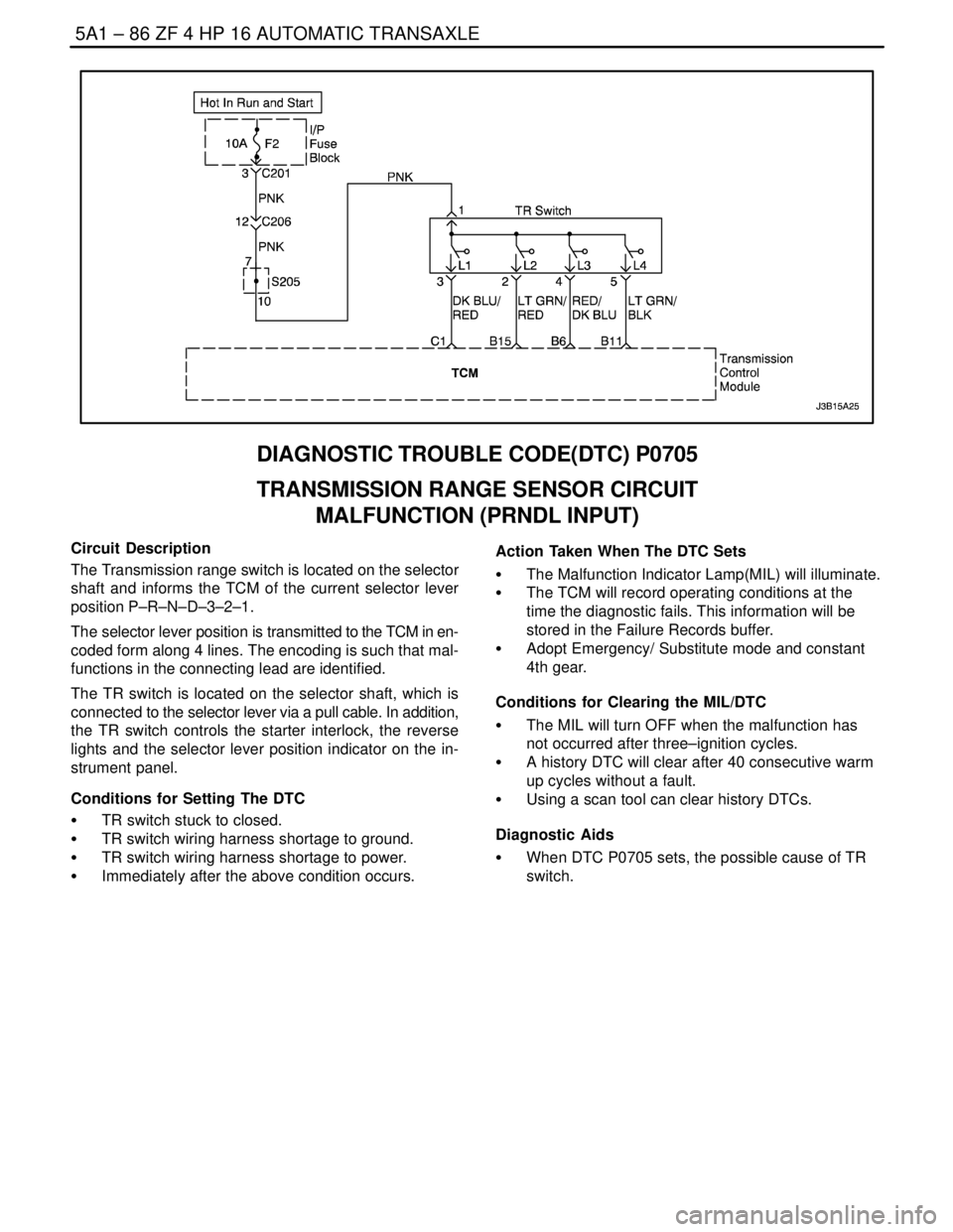

DIAGNOSTIC TROUBLE CODE(DTC) P0705

TRANSMISSION RANGE SENSOR CIRCUIT

MALFUNCTION (PRNDL INPUT)

Circuit Description

The Transmission range switch is located on the selector

shaft and informs the TCM of the current selector lever

position P–R–N–D–3–2–1.

The selector lever position is transmitted to the TCM in en-

coded form along 4 lines. The encoding is such that mal-

functions in the connecting lead are identified.

The TR switch is located on the selector shaft, which is

connected to the selector lever via a pull cable. In addition,

the TR switch controls the starter interlock, the reverse

lights and the selector lever position indicator on the in-

strument panel.

Conditions for Setting The DTC

S TR switch stuck to closed.

S TR switch wiring harness shortage to ground.

S TR switch wiring harness shortage to power.

S Immediately after the above condition occurs.Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

4th gear.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycles.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P0705 sets, the possible cause of TR

switch.

Page 1561 of 2643

5A1 – 212IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

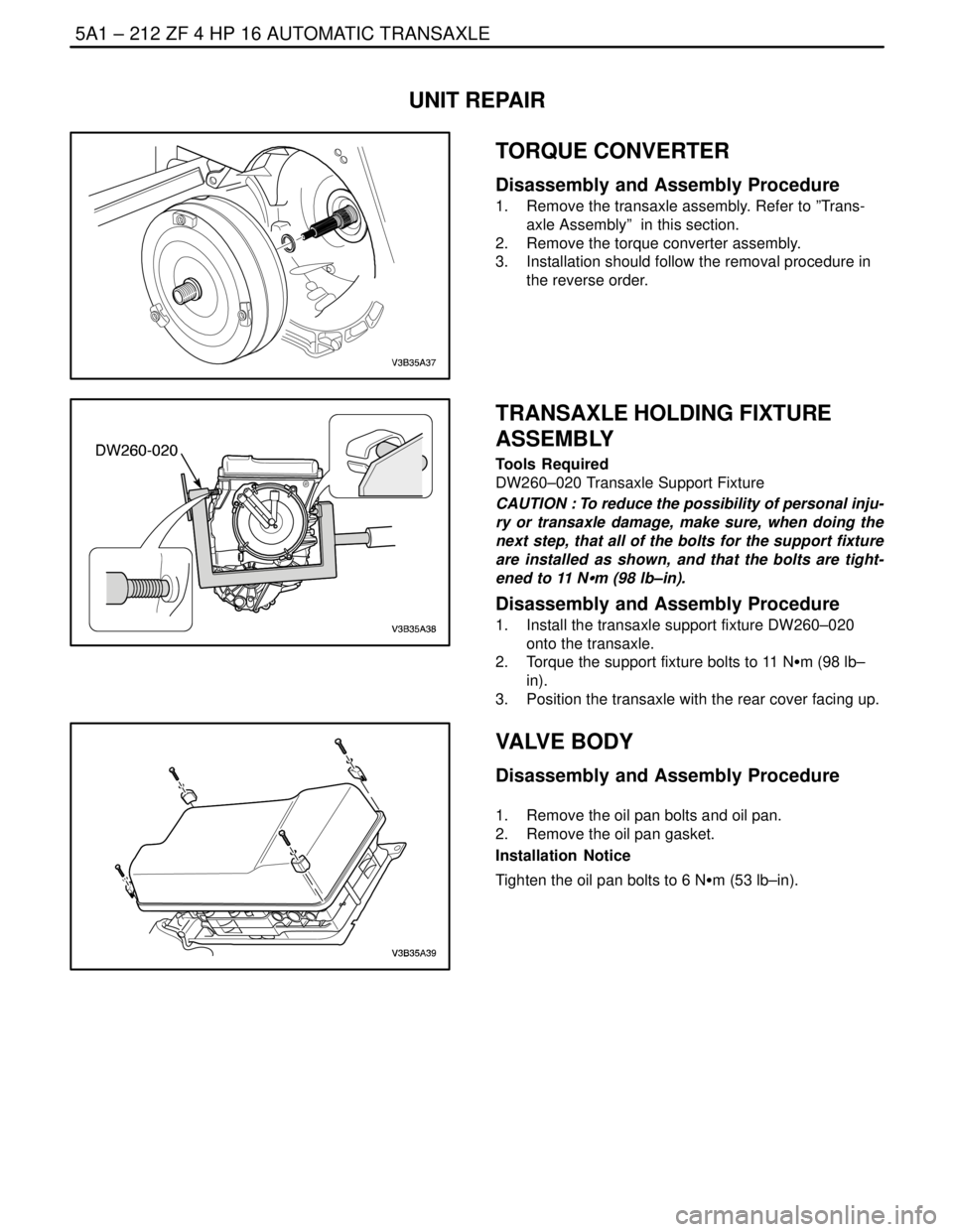

UNIT REPAIR

TORQUE CONVERTER

Disassembly and Assembly Procedure

1. Remove the transaxle assembly. Refer to ”Trans-

axle Assembly” in this section.

2. Remove the torque converter assembly.

3. Installation should follow the removal procedure in

the reverse order.

TRANSAXLE HOLDING FIXTURE

ASSEMBLY

Tools Required

DW260–020 Transaxle Support Fixture

CAUTION : To reduce the possibility of personal inju-

ry or transaxle damage, make sure, when doing the

next step, that all of the bolts for the support fixture

are installed as shown, and that the bolts are tight-

ened to 11 NSm (98 lb–in).

Disassembly and Assembly Procedure

1. Install the transaxle support fixture DW260–020

onto the transaxle.

2. Torque the support fixture bolts to 11 NSm (98 lb–

in).

3. Position the transaxle with the rear cover facing up.

VALVE BODY

Disassembly and Assembly Procedure

1. Remove the oil pan bolts and oil pan.

2. Remove the oil pan gasket.

Installation Notice

Tighten the oil pan bolts to 6 NSm (53 lb–in).

Page 1562 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 213

DAEWOO V–121 BL4

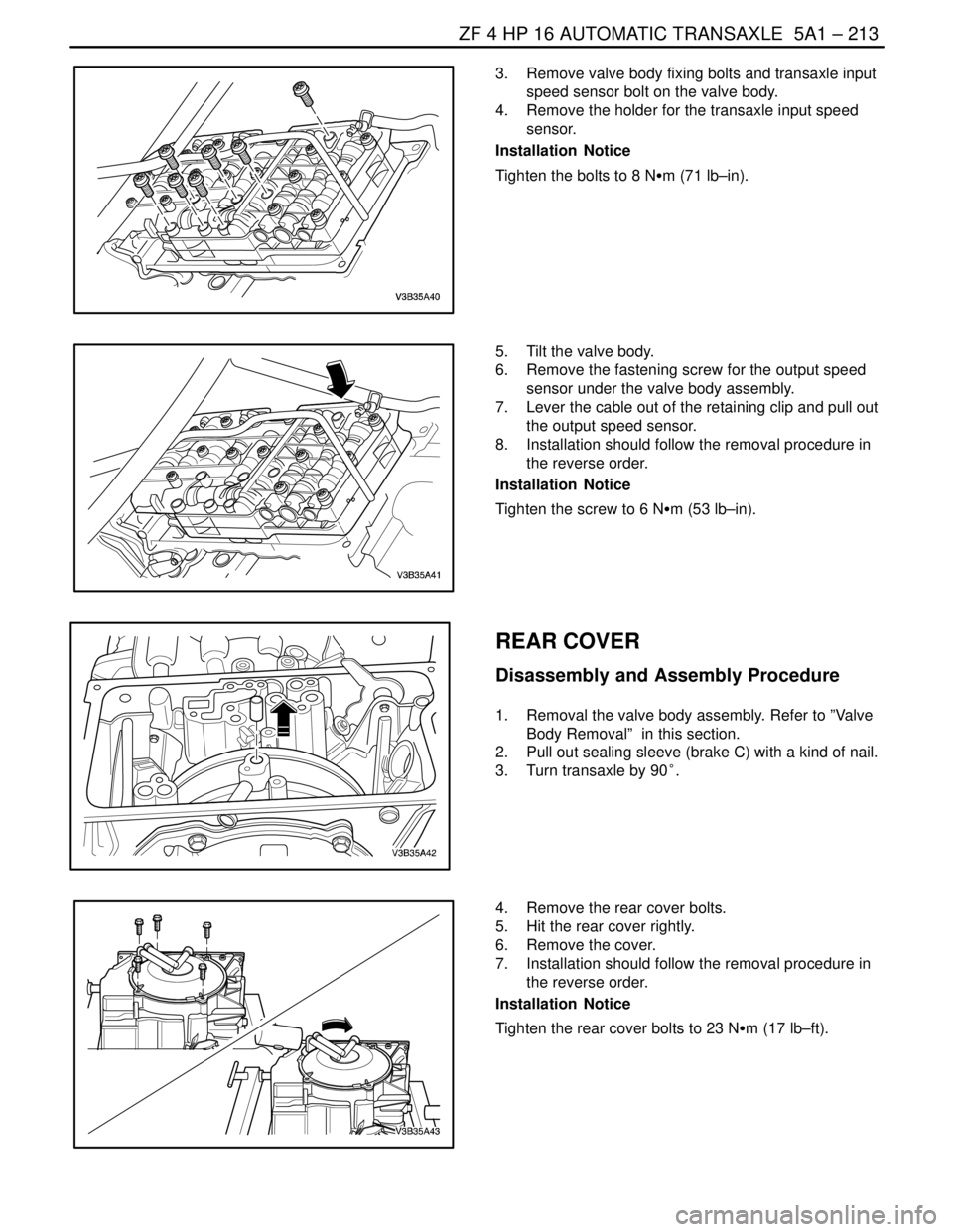

3. Remove valve body fixing bolts and transaxle input

speed sensor bolt on the valve body.

4. Remove the holder for the transaxle input speed

sensor.

Installation Notice

Tighten the bolts to 8 NSm (71 lb–in).

5. Tilt the valve body.

6. Remove the fastening screw for the output speed

sensor under the valve body assembly.

7. Lever the cable out of the retaining clip and pull out

the output speed sensor.

8. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tighten the screw to 6 NSm (53 lb–in).

REAR COVER

Disassembly and Assembly Procedure

1. Removal the valve body assembly. Refer to ”Valve

Body Removal” in this section.

2. Pull out sealing sleeve (brake C) with a kind of nail.

3. Turn transaxle by 90°.

4. Remove the rear cover bolts.

5. Hit the rear cover rightly.

6. Remove the cover.

7. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tighten the rear cover bolts to 23 NSm (17 lb–ft).

Page 1566 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 217

DAEWOO V–121 BL4

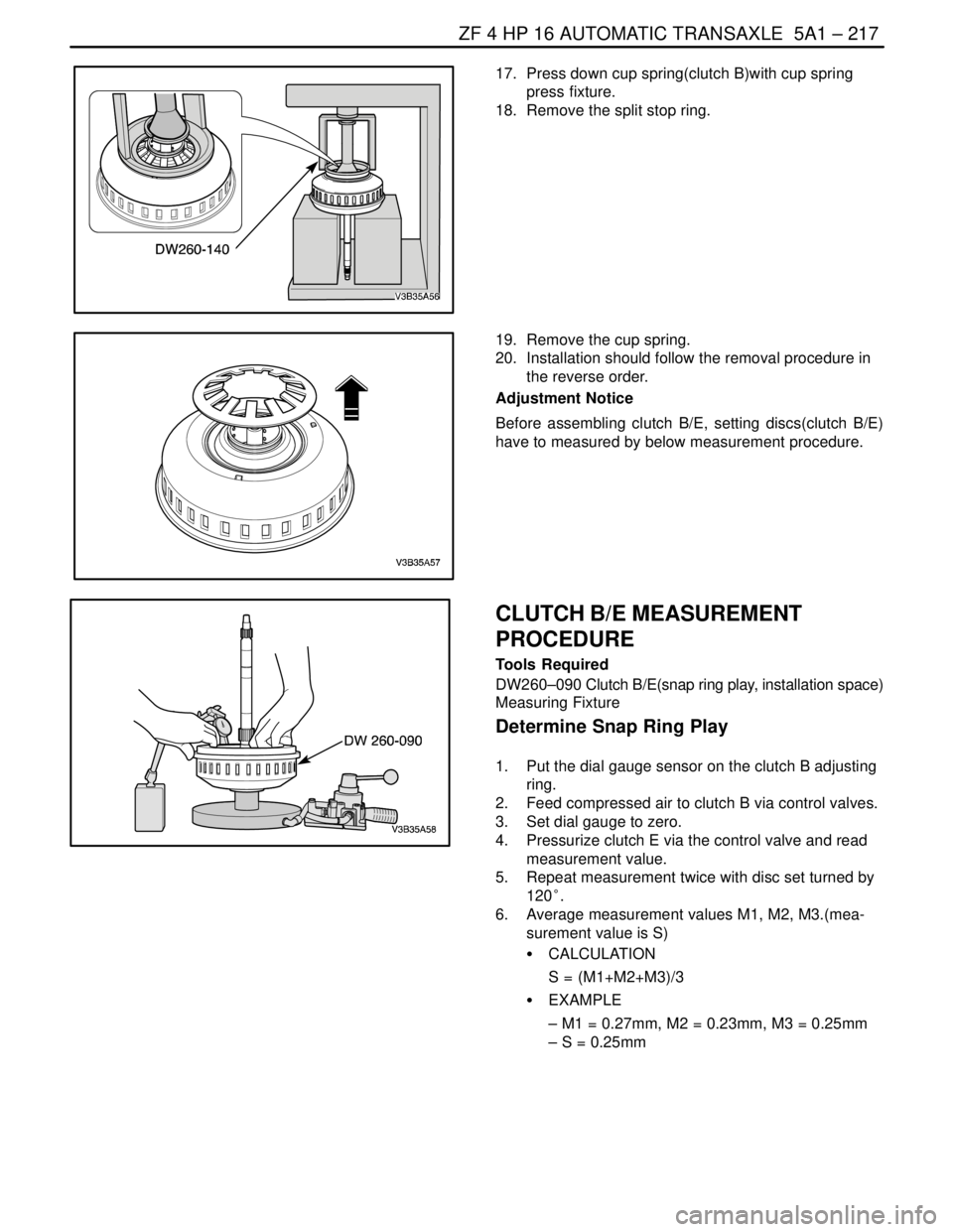

17. Press down cup spring(clutch B)with cup spring

press fixture.

18. Remove the split stop ring.

19. Remove the cup spring.

20. Installation should follow the removal procedure in

the reverse order.

Adjustment Notice

Before assembling clutch B/E, setting discs(clutch B/E)

have to measured by below measurement procedure.

CLUTCH B/E MEASUREMENT

PROCEDURE

Tools Required

DW260–090 Clutch B/E(snap ring play, installation space)

Measuring Fixture

Determine Snap Ring Play

1. Put the dial gauge sensor on the clutch B adjusting

ring.

2. Feed compressed air to clutch B via control valves.

3. Set dial gauge to zero.

4. Pressurize clutch E via the control valve and read

measurement value.

5. Repeat measurement twice with disc set turned by

120°.

6. Average measurement values M1, M2, M3.(mea-

surement value is S)

S CALCULATION

S = (M1+M2+M3)/3

S EXAMPLE

– M1 = 0.27mm, M2 = 0.23mm, M3 = 0.25mm

– S = 0.25mm