Reverse DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1570 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 221

DAEWOO V–121 BL4

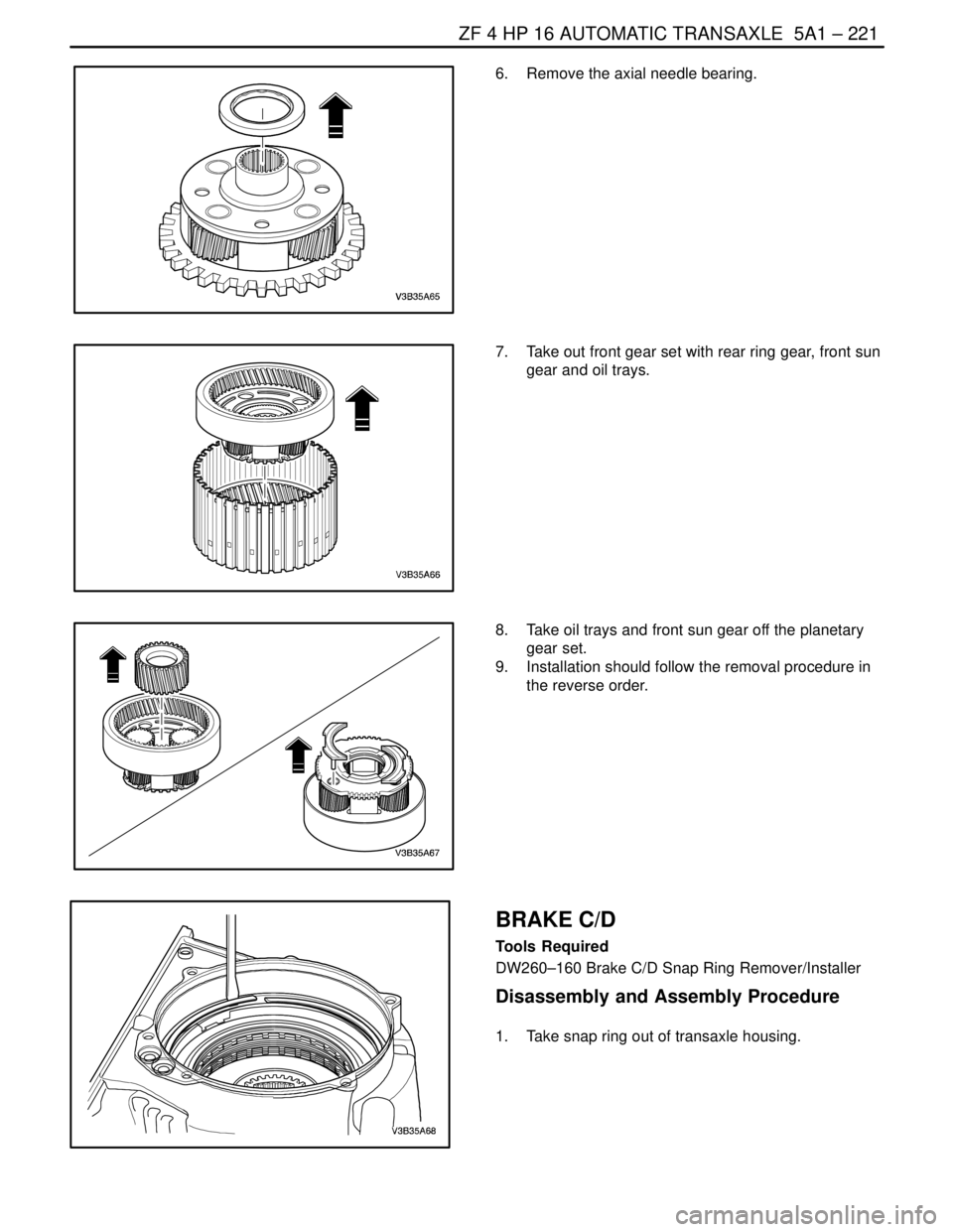

6. Remove the axial needle bearing.

7. Take out front gear set with rear ring gear, front sun

gear and oil trays.

8. Take oil trays and front sun gear off the planetary

gear set.

9. Installation should follow the removal procedure in

the reverse order.

BRAKE C/D

Tools Required

DW260–160 Brake C/D Snap Ring Remover/Installer

Disassembly and Assembly Procedure

1. Take snap ring out of transaxle housing.

Page 1573 of 2643

5A1 – 224IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

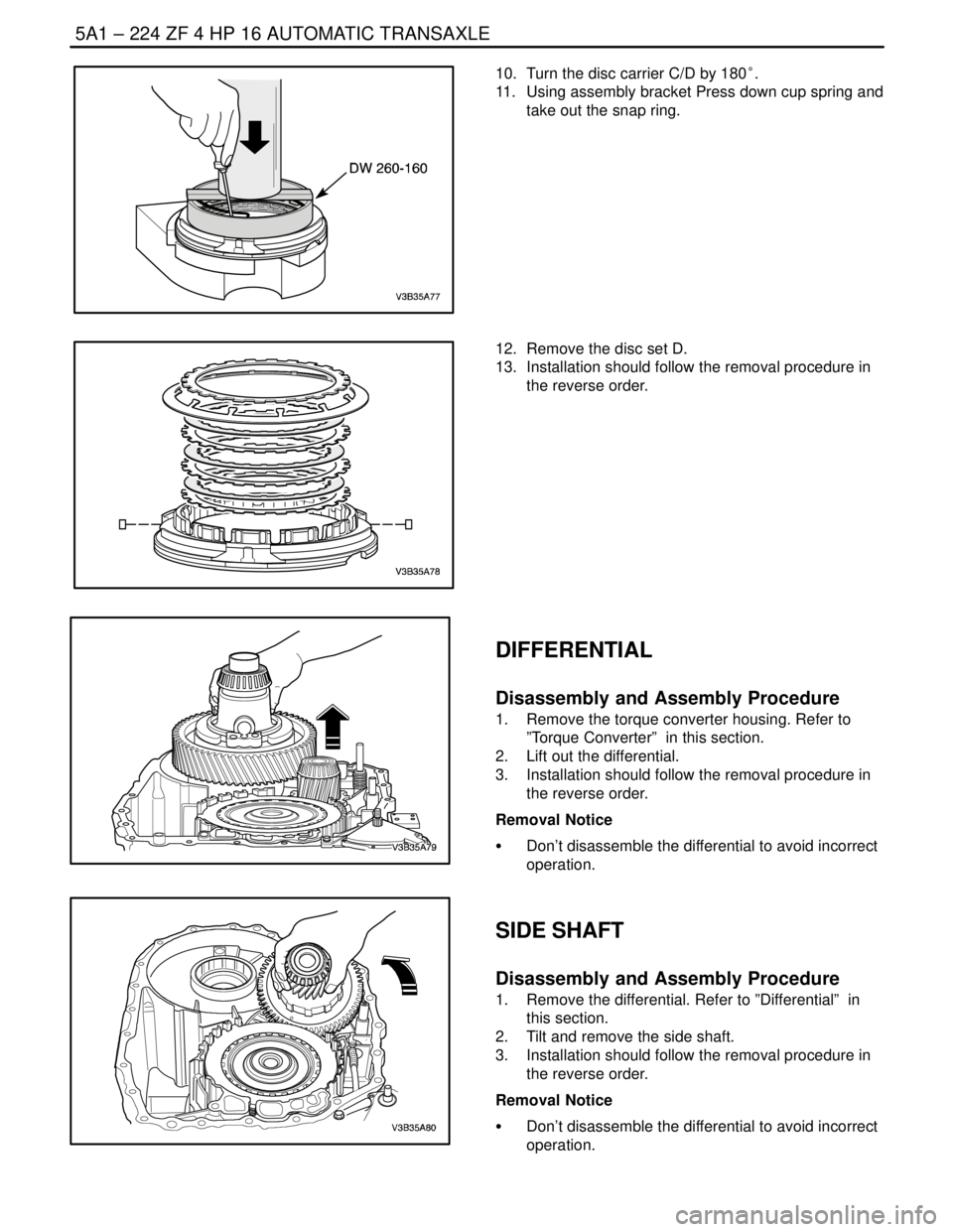

10. Turn the disc carrier C/D by 180°.

11. Using assembly bracket Press down cup spring and

take out the snap ring.

12. Remove the disc set D.

13. Installation should follow the removal procedure in

the reverse order.

DIFFERENTIAL

Disassembly and Assembly Procedure

1. Remove the torque converter housing. Refer to

”Torque Converter” in this section.

2. Lift out the differential.

3. Installation should follow the removal procedure in

the reverse order.

Removal Notice

S Don’t disassemble the differential to avoid incorrect

operation.

SIDE SHAFT

Disassembly and Assembly Procedure

1. Remove the differential. Refer to ”Differential” in

this section.

2. Tilt and remove the side shaft.

3. Installation should follow the removal procedure in

the reverse order.

Removal Notice

S Don’t disassemble the differential to avoid incorrect

operation.

Page 1575 of 2643

5A1 – 226IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

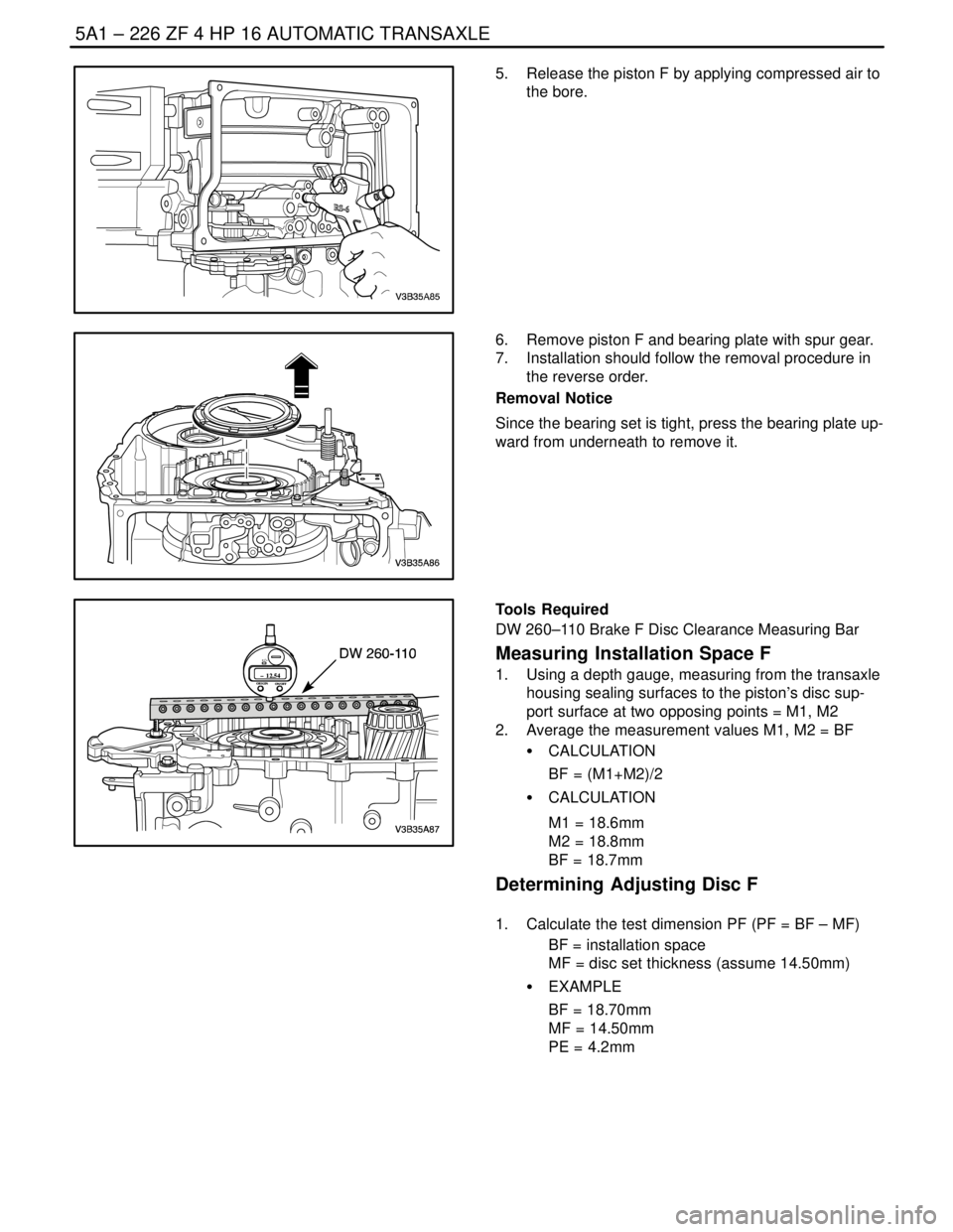

5. Release the piston F by applying compressed air to

the bore.

6. Remove piston F and bearing plate with spur gear.

7. Installation should follow the removal procedure in

the reverse order.

Removal Notice

Since the bearing set is tight, press the bearing plate up-

ward from underneath to remove it.

ORIGIN

ON/OFF– 12.54

+ / –

ORIGIN

ON/OFF– 12.54

+ / –

Tools Required

DW 260–110 Brake F Disc Clearance Measuring Bar

Measuring Installation Space F

1. Using a depth gauge, measuring from the transaxle

housing sealing surfaces to the piston’s disc sup-

port surface at two opposing points = M1, M2

2. Average the measurement values M1, M2 = BF

S CALCULATION

BF = (M1+M2)/2

S CALCULATION

M1 = 18.6mm

M2 = 18.8mm

BF = 18.7mm

Determining Adjusting Disc F

1. Calculate the test dimension PF (PF = BF – MF)

BF = installation space

MF = disc set thickness (assume 14.50mm)

S EXAMPLE

BF = 18.70mm

MF = 14.50mm

PE = 4.2mm

Page 1577 of 2643

5A1 – 228IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

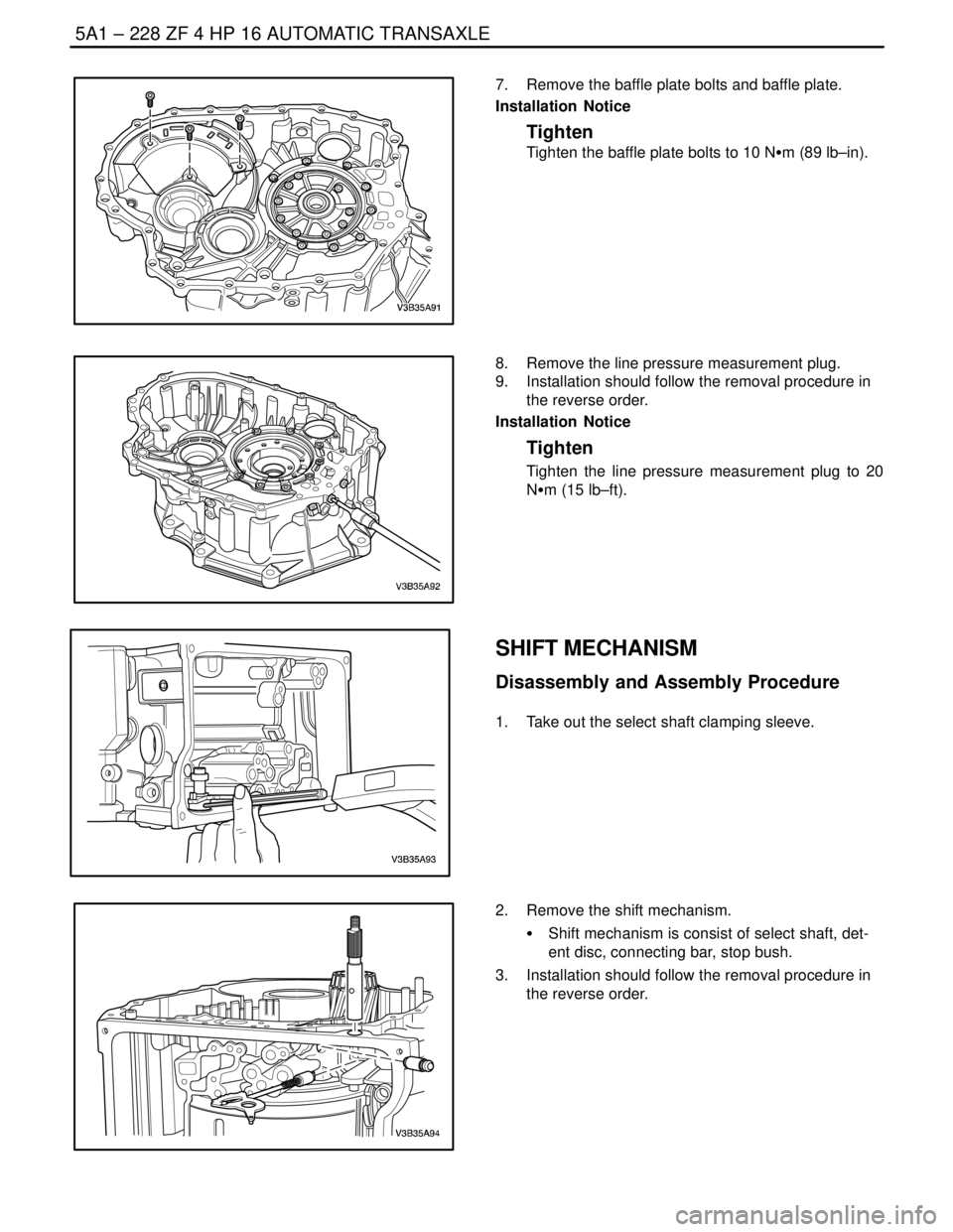

7. Remove the baffle plate bolts and baffle plate.

Installation Notice

Tighten

Tighten the baffle plate bolts to 10 NSm (89 lb–in).

8. Remove the line pressure measurement plug.

9. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tighten

Tighten the line pressure measurement plug to 20

NSm (15 lb–ft).

SHIFT MECHANISM

Disassembly and Assembly Procedure

1. Take out the select shaft clamping sleeve.

2. Remove the shift mechanism.

S Shift mechanism is consist of select shaft, det-

ent disc, connecting bar, stop bush.

3. Installation should follow the removal procedure in

the reverse order.

Page 1578 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 229

DAEWOO V–121 BL4

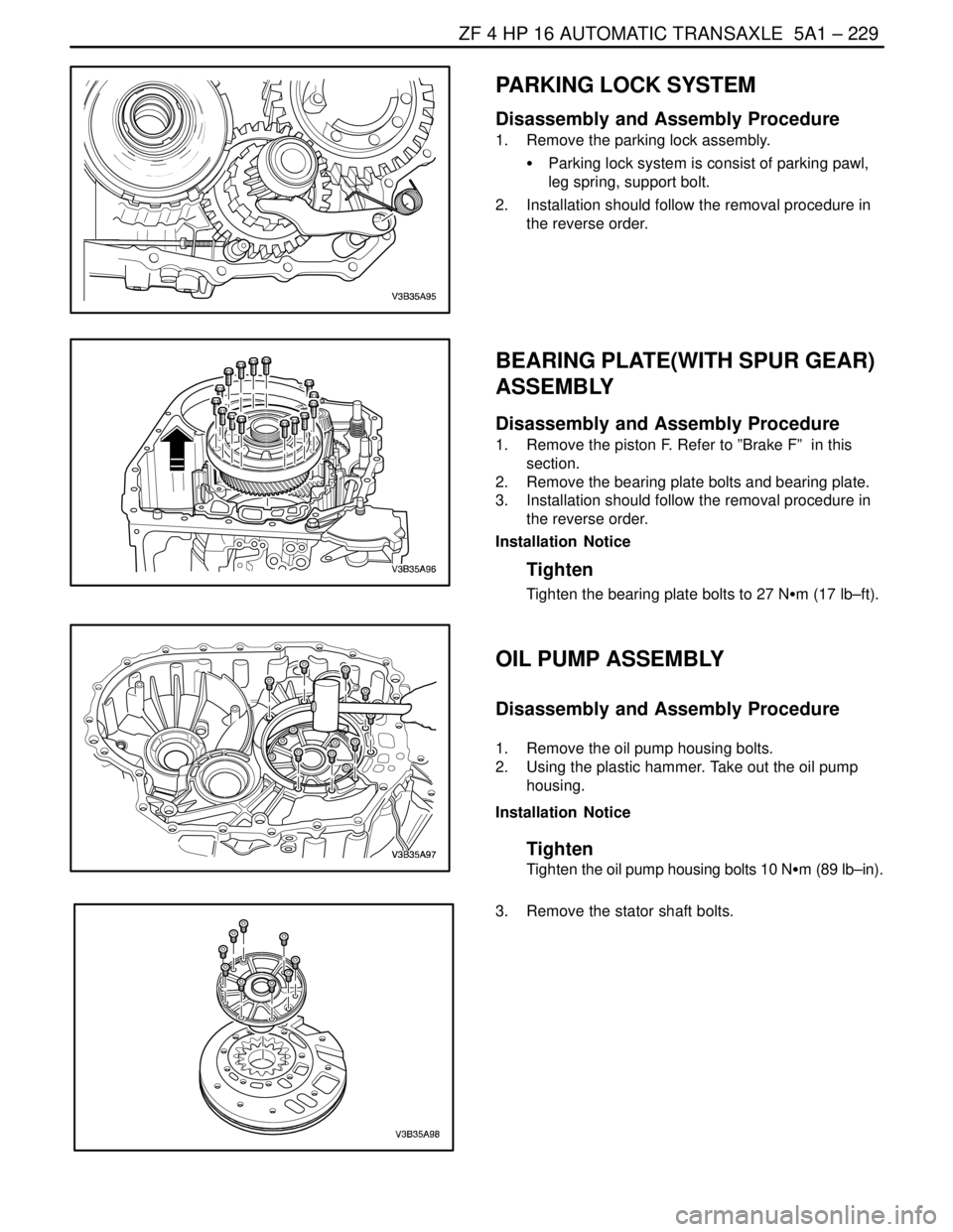

PARKING LOCK SYSTEM

Disassembly and Assembly Procedure

1. Remove the parking lock assembly.

S Parking lock system is consist of parking pawl,

leg spring, support bolt.

2. Installation should follow the removal procedure in

the reverse order.

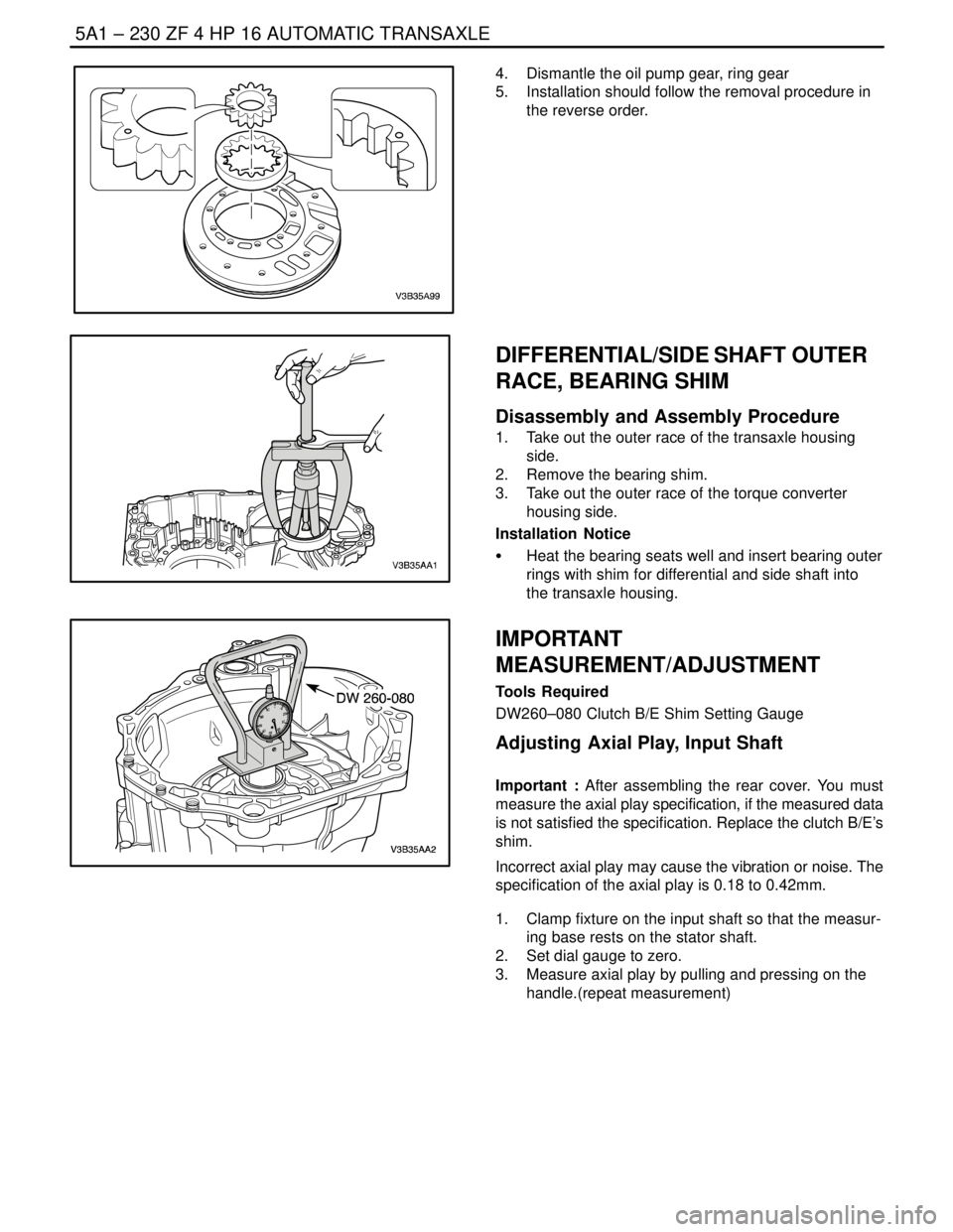

BEARING PLATE(WITH SPUR GEAR)

ASSEMBLY

Disassembly and Assembly Procedure

1. Remove the piston F. Refer to ”Brake F” in this

section.

2. Remove the bearing plate bolts and bearing plate.

3. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tighten

Tighten the bearing plate bolts to 27 NSm (17 lb–ft).

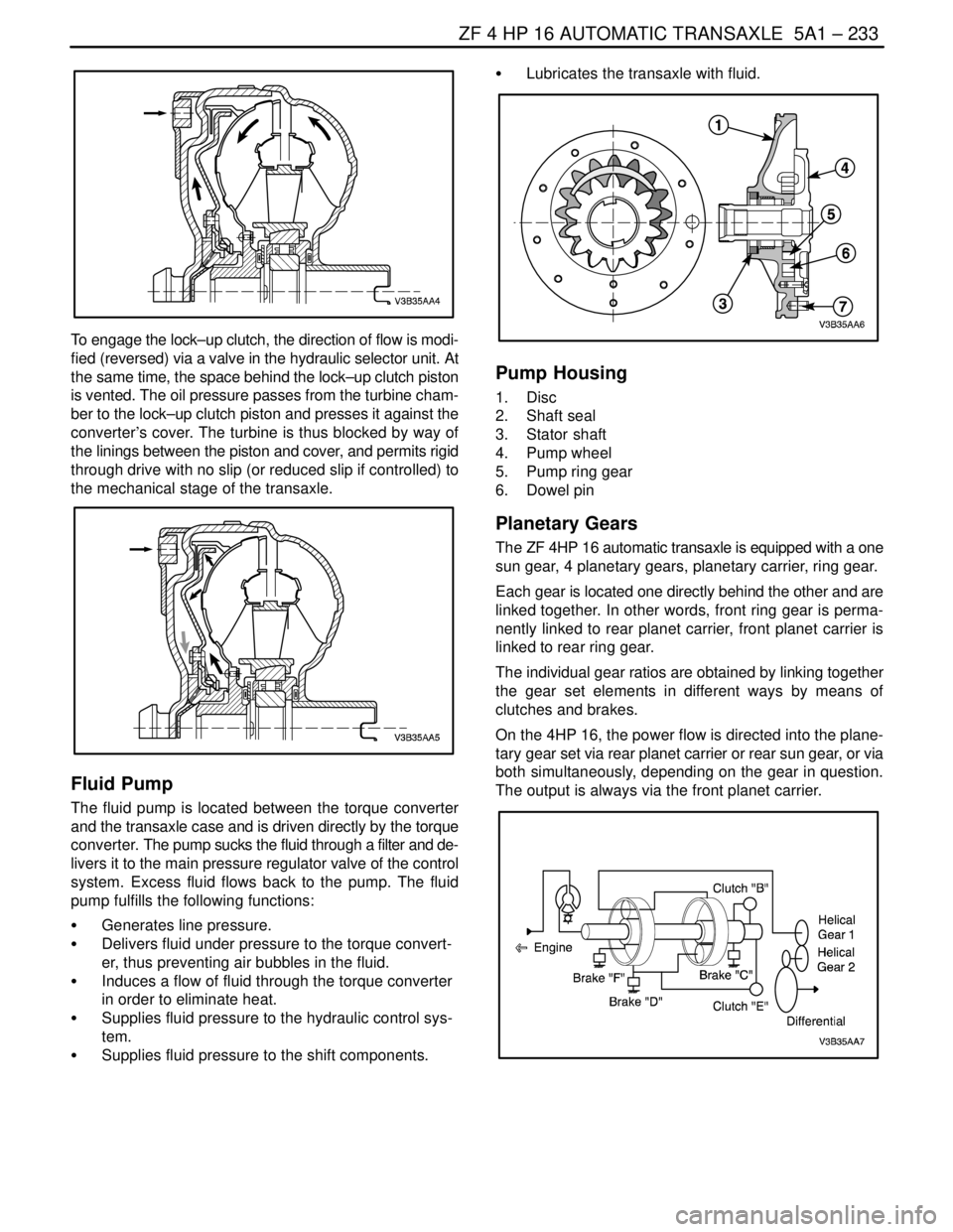

OIL PUMP ASSEMBLY

Disassembly and Assembly Procedure

1. Remove the oil pump housing bolts.

2. Using the plastic hammer. Take out the oil pump

housing.

Installation Notice

Tighten

Tighten the oil pump housing bolts 10 NSm (89 lb–in).

3. Remove the stator shaft bolts.

Page 1579 of 2643

5A1 – 230IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

4. Dismantle the oil pump gear, ring gear

5. Installation should follow the removal procedure in

the reverse order.

DIFFERENTIAL/SIDE SHAFT OUTER

RACE, BEARING SHIM

Disassembly and Assembly Procedure

1. Take out the outer race of the transaxle housing

side.

2. Remove the bearing shim.

3. Take out the outer race of the torque converter

housing side.

Installation Notice

S Heat the bearing seats well and insert bearing outer

rings with shim for differential and side shaft into

the transaxle housing.

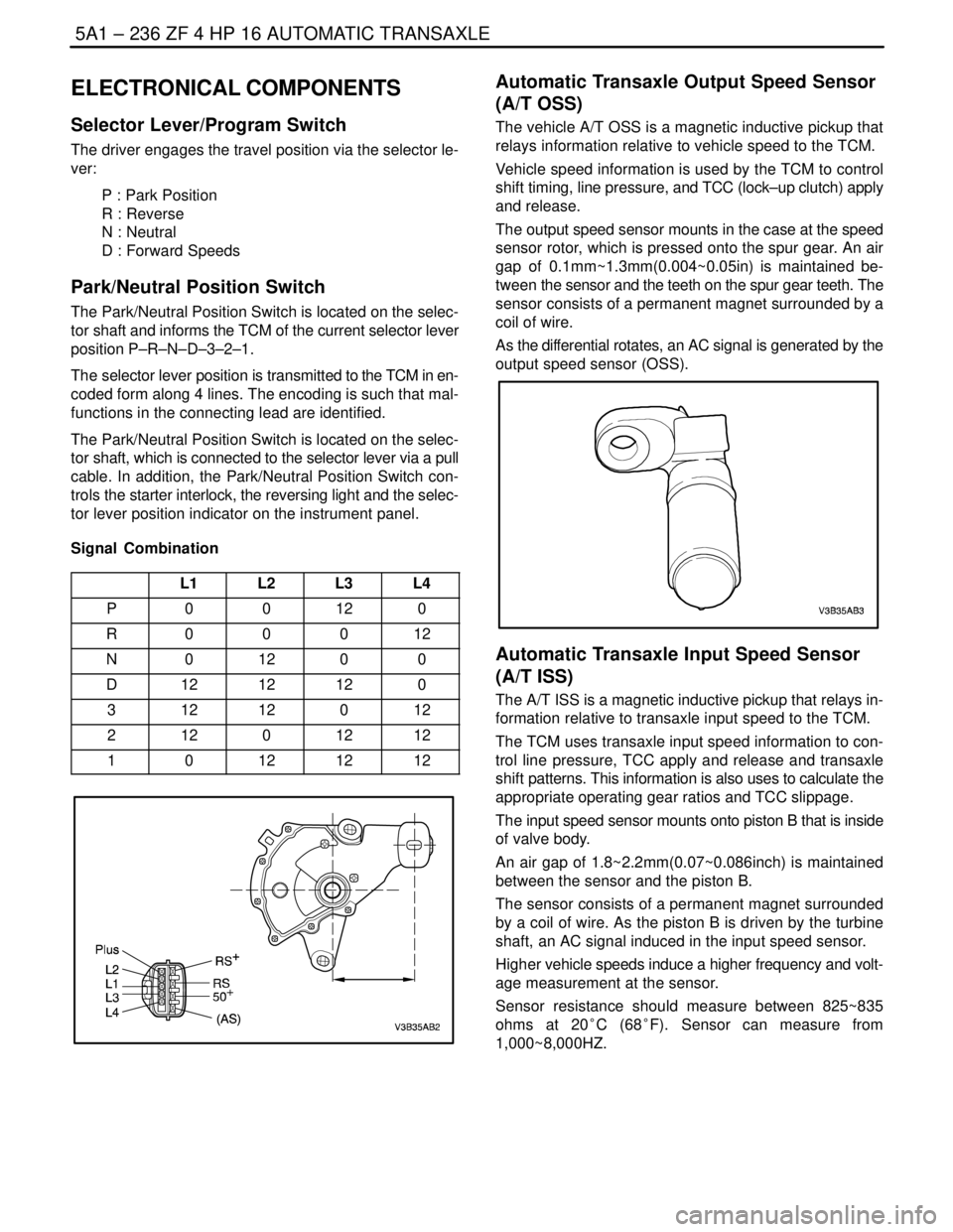

IMPORTANT

MEASUREMENT/ADJUSTMENT

Tools Required

DW260–080 Clutch B/E Shim Setting Gauge

Adjusting Axial Play, Input Shaft

Important : After assembling the rear cover. You must

measure the axial play specification, if the measured data

is not satisfied the specification. Replace the clutch B/E’s

shim.

Incorrect axial play may cause the vibration or noise. The

specification of the axial play is 0.18 to 0.42mm.

1. Clamp fixture on the input shaft so that the measur-

ing base rests on the stator shaft.

2. Set dial gauge to zero.

3. Measure axial play by pulling and pressing on the

handle.(repeat measurement)

Page 1582 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 233

DAEWOO V–121 BL4

To engage the lock–up clutch, the direction of flow is modi-

fied (reversed) via a valve in the hydraulic selector unit. At

the same time, the space behind the lock–up clutch piston

is vented. The oil pressure passes from the turbine cham-

ber to the lock–up clutch piston and presses it against the

converter’s cover. The turbine is thus blocked by way of

the linings between the piston and cover, and permits rigid

through drive with no slip (or reduced slip if controlled) to

the mechanical stage of the transaxle.

Fluid Pump

The fluid pump is located between the torque converter

and the transaxle case and is driven directly by the torque

converter. The pump sucks the fluid through a filter and de-

livers it to the main pressure regulator valve of the control

system. Excess fluid flows back to the pump. The fluid

pump fulfills the following functions:

S Generates line pressure.

S Delivers fluid under pressure to the torque convert-

er, thus preventing air bubbles in the fluid.

S Induces a flow of fluid through the torque converter

in order to eliminate heat.

S Supplies fluid pressure to the hydraulic control sys-

tem.

S Supplies fluid pressure to the shift components.S Lubricates the transaxle with fluid.

Pump Housing

1. Disc

2. Shaft seal

3. Stator shaft

4. Pump wheel

5. Pump ring gear

6. Dowel pin

Planetary Gears

The ZF 4HP 16 automatic transaxle is equipped with a one

sun gear, 4 planetary gears, planetary carrier, ring gear.

Each gear is located one directly behind the other and are

linked together. In other words, front ring gear is perma-

nently linked to rear planet carrier, front planet carrier is

linked to rear ring gear.

The individual gear ratios are obtained by linking together

the gear set elements in different ways by means of

clutches and brakes.

On the 4HP 16, the power flow is directed into the plane-

tary gear set via rear planet carrier or rear sun gear, or via

both simultaneously, depending on the gear in question.

The output is always via the front planet carrier.

Page 1585 of 2643

5A1 – 236IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

ELECTRONICAL COMPONENTS

Selector Lever/Program Switch

The driver engages the travel position via the selector le-

ver:

P : Park Position

R : Reverse

N : Neutral

D : Forward Speeds

Park/Neutral Position Switch

The Park/Neutral Position Switch is located on the selec-

tor shaft and informs the TCM of the current selector lever

position P–R–N–D–3–2–1.

The selector lever position is transmitted to the TCM in en-

coded form along 4 lines. The encoding is such that mal-

functions in the connecting lead are identified.

The Park/Neutral Position Switch is located on the selec-

tor shaft, which is connected to the selector lever via a pull

cable. In addition, the Park/Neutral Position Switch con-

trols the starter interlock, the reversing light and the selec-

tor lever position indicator on the instrument panel.

Signal Combination

L1L2L3L4

P00120

R00012

N01200

D1212120

31212012

21201212

10121212

Automatic Transaxle Output Speed Sensor

(A/T OSS)

The vehicle A/T OSS is a magnetic inductive pickup that

relays information relative to vehicle speed to the TCM.

Vehicle speed information is used by the TCM to control

shift timing, line pressure, and TCC (lock–up clutch) apply

and release.

The output speed sensor mounts in the case at the speed

sensor rotor, which is pressed onto the spur gear. An air

gap of 0.1mm~1.3mm(0.004~0.05in) is maintained be-

tween the sensor and the teeth on the spur gear teeth. The

sensor consists of a permanent magnet surrounded by a

coil of wire.

As the differential rotates, an AC signal is generated by the

output speed sensor (OSS).

Automatic Transaxle Input Speed Sensor

(A/T ISS)

The A/T ISS is a magnetic inductive pickup that relays in-

formation relative to transaxle input speed to the TCM.

The TCM uses transaxle input speed information to con-

trol line pressure, TCC apply and release and transaxle

shift patterns. This information is also uses to calculate the

appropriate operating gear ratios and TCC slippage.

The input speed sensor mounts onto piston B that is inside

of valve body.

An air gap of 1.8~2.2mm(0.07~0.086inch) is maintained

between the sensor and the piston B.

The sensor consists of a permanent magnet surrounded

by a coil of wire. As the piston B is driven by the turbine

shaft, an AC signal induced in the input speed sensor.

Higher vehicle speeds induce a higher frequency and volt-

age measurement at the sensor.

Sensor resistance should measure between 825~835

ohms at 20°C (68°F). Sensor can measure from

1,000~8,000HZ.

Page 1586 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 237

DAEWOO V–121 BL4

Shift Solenoid Valve: Solenoid 1,2

The shift solenoids are two identical, normally open elec-

tronic exhaust work that control upshifts and downshifts in

all forward gear ranges. These shift solenoids valves to-

gether in a combination of ON and OFF sequences to con-

trol the line pressure and shift mechanisms (clutches,

brakes).

Solenoid 1 controls the high or low of the line pressure

(flow to each clutch valve) by the operation type (ON/

OFF), i.e. solenoid 1is ON, line pressure will be low

(87~116 psi (6~8bar)), solenoid 1 is OFF, line pressure will

be high (232~261 psi (16~18bar)).

Solenoid 2 controls the oil flow to clutch valve E or lockup

clutch valve by the ON/OFF signal.

The TCM monitors numerous inputs to determine the ap-

propriate solenoid state combination and transaxle gear

for the vehicle operating conditions.

Gear

Solenoid 1Solenoid 2

Park, NeutralONON

FirstON/OFFON

SecondON/OFFOFF

ThirdON/OFFOFF

FourthON/OFFOFF

ReverseON/OFFON

Line PressureResistance

Solenoid

valve 1/Sole-

noid valve 2ON(low)

89.9~98.6 psi

(6.2~6.8 bar)

OFF(high)

S 221.9~253.24

psi

S (15.3~17.46

bar)26.5 ± 0.5ohm

Pressure Control Solenoid Valve (EDS

VALVE 3,4,5,6)

The pressure control valve (EDS valve 3,4,5,6) is a preci-

sion electronic pressure regulator that controls the opera-

tion of the clutches, brakes and the lock–up clutch.

The valve reduces the system pressure with which the

downstream solenoid valves and electrical pressure regu-

lating valves are supplied. It is possible to use smaller so-

lenoid valves as a result. The EDS require a constant input

pressure.

Page 1592 of 2643

5A2 – 2IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

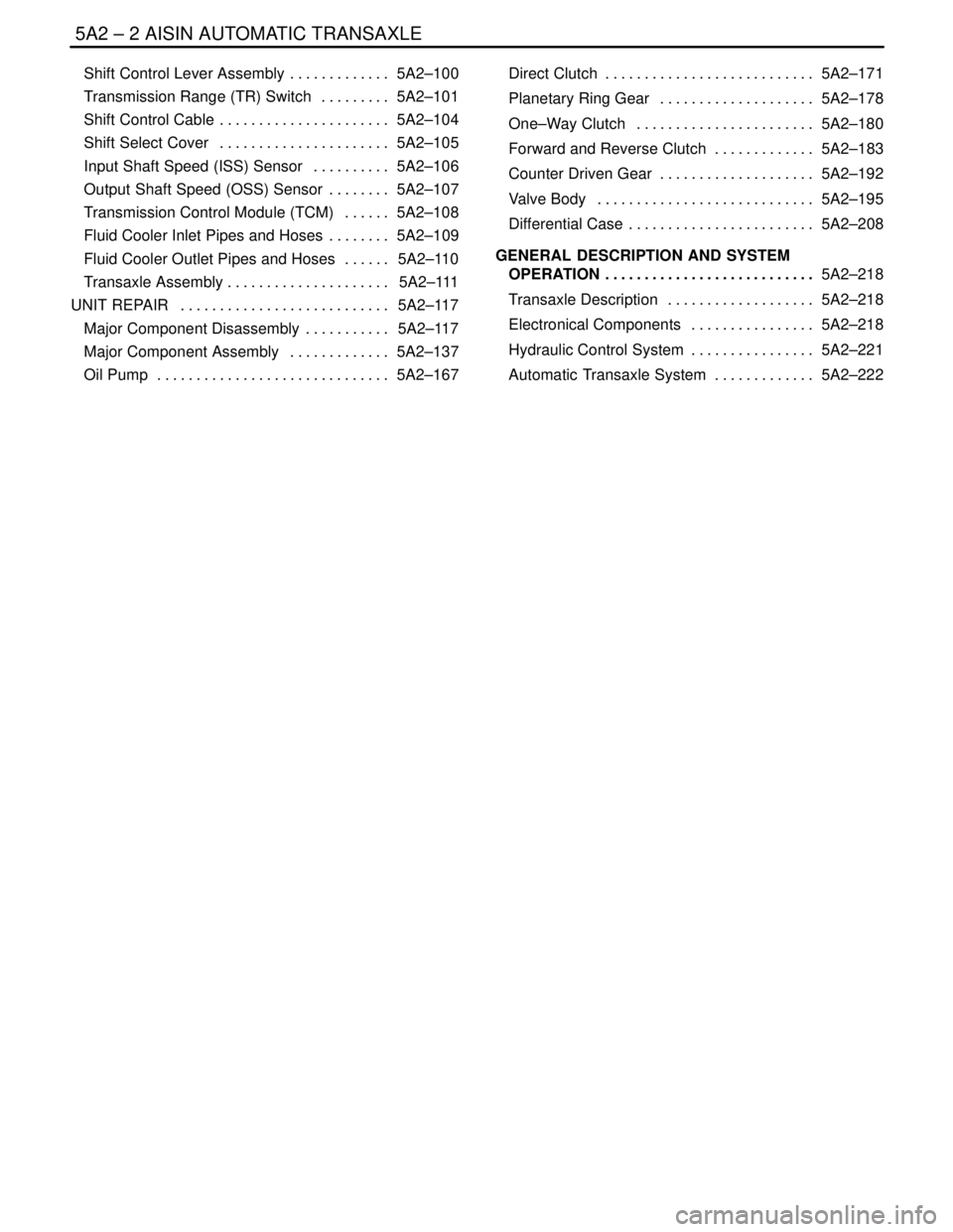

Shift Control Lever Assembly 5A2–100. . . . . . . . . . . . .

Transmission Range (TR) Switch 5A2–101. . . . . . . . .

Shift Control Cable 5A2–104. . . . . . . . . . . . . . . . . . . . . .

Shift Select Cover 5A2–105. . . . . . . . . . . . . . . . . . . . . .

Input Shaft Speed (ISS) Sensor 5A2–106. . . . . . . . . .

Output Shaft Speed (OSS) Sensor 5A2–107. . . . . . . .

Transmission Control Module (TCM) 5A2–108. . . . . .

Fluid Cooler Inlet Pipes and Hoses 5A2–109. . . . . . . .

Fluid Cooler Outlet Pipes and Hoses 5A2–110. . . . . .

Transaxle Assembly 5A2–111. . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 5A2–117. . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Component Disassembly 5A2–117. . . . . . . . . . .

Major Component Assembly 5A2–137. . . . . . . . . . . . .

Oil Pump 5A2–167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direct Clutch 5A2–171. . . . . . . . . . . . . . . . . . . . . . . . . . .

Planetary Ring Gear 5A2–178. . . . . . . . . . . . . . . . . . . .

One–Way Clutch 5A2–180. . . . . . . . . . . . . . . . . . . . . . .

Forward and Reverse Clutch 5A2–183. . . . . . . . . . . . .

Counter Driven Gear 5A2–192. . . . . . . . . . . . . . . . . . . .

Valve Body 5A2–195. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Case 5A2–208. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION5A2–218 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle Description 5A2–218. . . . . . . . . . . . . . . . . . .

Electronical Components 5A2–218. . . . . . . . . . . . . . . .

Hydraulic Control System 5A2–221. . . . . . . . . . . . . . . .

Automatic Transaxle System 5A2–222. . . . . . . . . . . . .