DAEWOO LACETTI 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 211 of 2643

1D – 16IENGINE COOLING

DAEWOO V–121 BL4

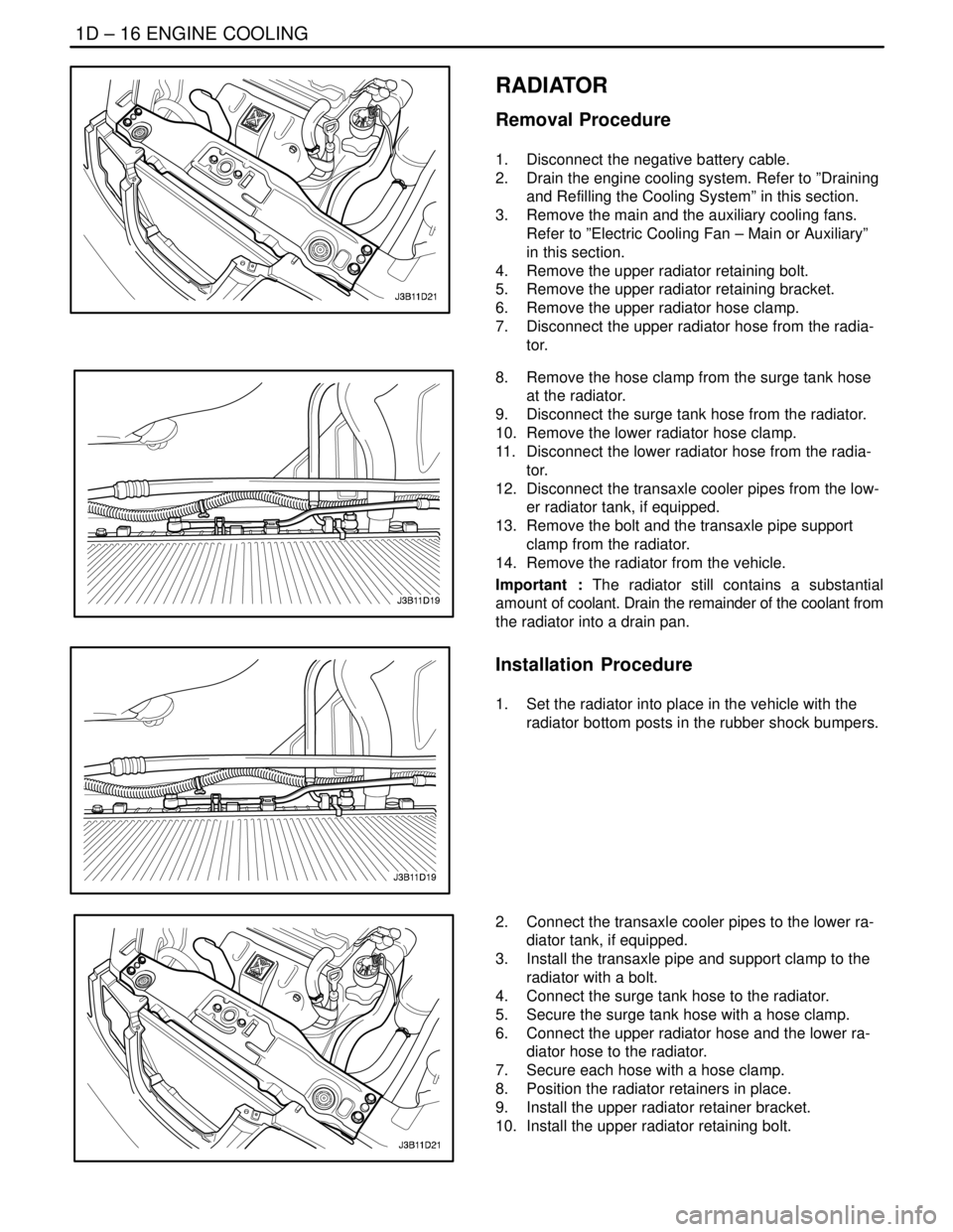

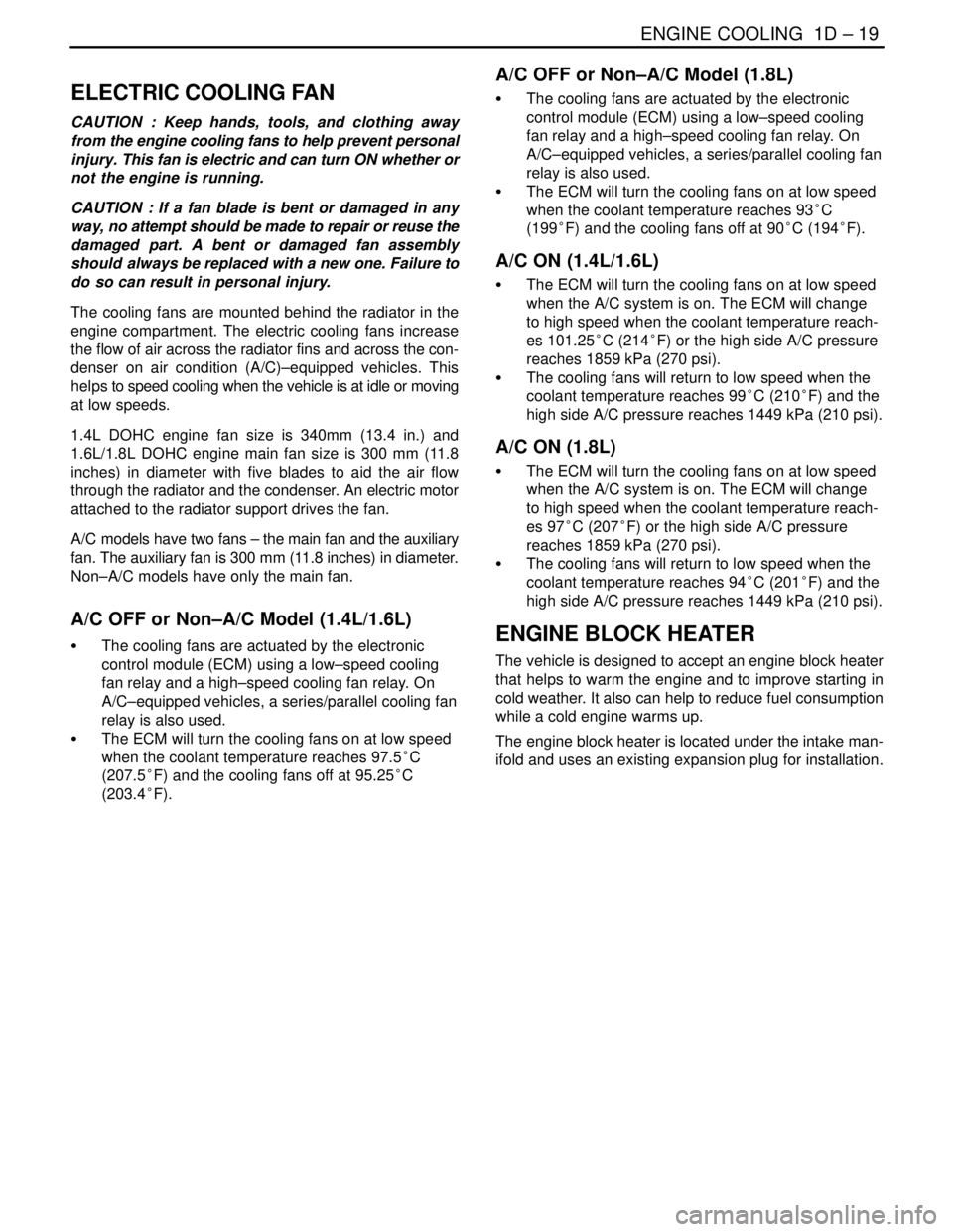

RADIATOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

3. Remove the main and the auxiliary cooling fans.

Refer to ”Electric Cooling Fan – Main or Auxiliary”

in this section.

4. Remove the upper radiator retaining bolt.

5. Remove the upper radiator retaining bracket.

6. Remove the upper radiator hose clamp.

7. Disconnect the upper radiator hose from the radia-

tor.

8. Remove the hose clamp from the surge tank hose

at the radiator.

9. Disconnect the surge tank hose from the radiator.

10. Remove the lower radiator hose clamp.

11. Disconnect the lower radiator hose from the radia-

tor.

12. Disconnect the transaxle cooler pipes from the low-

er radiator tank, if equipped.

13. Remove the bolt and the transaxle pipe support

clamp from the radiator.

14. Remove the radiator from the vehicle.

Important : The radiator still contains a substantial

amount of coolant. Drain the remainder of the coolant from

the radiator into a drain pan.

Installation Procedure

1. Set the radiator into place in the vehicle with the

radiator bottom posts in the rubber shock bumpers.

2. Connect the transaxle cooler pipes to the lower ra-

diator tank, if equipped.

3. Install the transaxle pipe and support clamp to the

radiator with a bolt.

4. Connect the surge tank hose to the radiator.

5. Secure the surge tank hose with a hose clamp.

6. Connect the upper radiator hose and the lower ra-

diator hose to the radiator.

7. Secure each hose with a hose clamp.

8. Position the radiator retainers in place.

9. Install the upper radiator retainer bracket.

10. Install the upper radiator retaining bolt.

Page 212 of 2643

ENGINE COOLING 1D – 17

DAEWOO V–121 BL4

11. Install the main and the auxiliary cooling fans. Refer

to ”Electric Cooling Fan – Main or Auxiliary” in this

section.

12. Refill the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

13. Connect the negative battery cable.

Tighten

Tighten the radiator retaining bolt to 8 NSm (71 lb–in).

Page 213 of 2643

1D – 18IENGINE COOLING

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL DESCRIPTION

The cooling system maintains the engine temperature at

an efficient level during all engine operating conditions.

When the engine is cold, the cooling system cools the en-

gine slowly or not at all. This slow cooling of the engine al-

lows the engine to warm up quickly.

The cooling system includes a radiator and recovery sub-

system, cooling fans, a thermostat and housing, a coolant

pump, and a coolant pump drive belt. The timing belt

drives the coolant pump.

All components must function properly in order for the

cooling system to operate. The coolant pump draws the

coolant from the radiator. The coolant then circulates

through water jackets in the engine block, the intake man-

ifold, and the cylinder head. When the coolant reaches the

operating temperature of the thermostat, the thermostat

opens. The coolant then goes back to the radiator where

it cools.

This system directs some coolant through the hoses to the

heater core. This provides for heating and defrosting. The

surge tank is connected to the radiator to recover the cool-

ant displaced by expansion from the high temperatures.

The surge tank maintains the correct coolant level.

The cooling system for this vehicle has no radiator cap or

filler neck. The coolant is added to the cooling system

through the surge tank.

RADIATOR

This vehicle has a lightweight tube–and–fin aluminum ra-

diator. Plastic tanks are mounted on the right and the left

sides of the radiator core.

On vehicles equipped with automatic transaxles, the

transaxle fluid cooler lines run through the left radiator

tank. A radiator drain cock is on this radiator.

To drain the cooling system, open the drain cock.

SURGE TANK

The surge tank is a transparent plastic reservoir, similar to

the windshield washer reservoir.

The surge tank is connected to the radiator by a hose and

to the engine cooling system by another hose. As the ve-

hicle is driven, the engine coolant heats and expands. The

portion of the engine coolant displaced by this expansion

flows from the radiator and the engine into the surge tank.

The air trapped in the radiator and the engine is degassed

into the surge tank.When the engine stops, the engine coolant cools and con-

tracts. The displaced engine coolant is then drawn back

into the radiator and the engine. This keeps the radiator

filled with the coolant to the desired level at all times and

increases the cooling efficiency.

Maintain the coolant level between the MIN and the MAX

marks on the surge tank when the system is cold.

WATER PUMP

The belt–driven centrifugal water pump consists of an im-

peller, a drive shaft, and a belt pulley. The water pump is

mounted on the front of the transverse–mounted engine,

and is driven by the timing belt.

The impeller is supported by a completely sealed bearing.

The water pump is serviced as an assembly and, there-

fore, cannot be disassembled.

THERMOSTAT

A wax pellet–type thermostat controls the flow of the en-

gine coolant through the engine cooling system. The ther-

mostat is mounted in the thermostat housing to the front

of the cylinder head.

The thermostat stops the flow of the engine coolant from

the engine to the radiator in order to provide faster warm–

up, and to regulate the coolant temperature. The thermo-

stat remains closed while the engine coolant is cold, pre-

venting circulation of the engine coolant through the

radiator. At this point, the engine coolant is allowed to cir-

culate only throughout the heater core to warm it quickly

and evenly.

As the engine warms, the thermostat opens. This allows

the engine coolant to flow through the radiator, where the

heat is dissipated through the radiator. This opening and

closing of the thermostat permits enough engine coolant

to enter the radiator to keep the engine within proper en-

gine temperature operating limits.

The wax pellet in the thermostat is hermetically sealed in

a metal case. The wax element of the thermostat expands

when it is heated and contracts when it is cooled.

As the vehicle is driven and the engine warms, the engine

coolant temperature increases. When the engine coolant

reaches a specified temperature, the wax pellet element

in the thermostat expands and exerts pressure against the

metal case, forcing the valve open. This allows the engine

coolant to flow through the engine cooling system and cool

the engine.

As the wax pellet cools, the contraction allows a spring to

close the valve.

The thermostat begins to open at 87°C (189°F) and is fully

open at 102°C (216°F). The thermostat closes at 86°C

(187°F).

Page 214 of 2643

ENGINE COOLING 1D – 19

DAEWOO V–121 BL4

ELECTRIC COOLING FAN

CAUTION : Keep hands, tools, and clothing away

from the engine cooling fans to help prevent personal

injury. This fan is electric and can turn ON whether or

not the engine is running.

CAUTION : If a fan blade is bent or damaged in any

way, no attempt should be made to repair or reuse the

damaged part. A bent or damaged fan assembly

should always be replaced with a new one. Failure to

do so can result in personal injury.

The cooling fans are mounted behind the radiator in the

engine compartment. The electric cooling fans increase

the flow of air across the radiator fins and across the con-

denser on air condition (A/C)–equipped vehicles. This

helps to speed cooling when the vehicle is at idle or moving

at low speeds.

1.4L DOHC engine fan size is 340mm (13.4 in.) and

1.6L/1.8L DOHC engine main fan size is 300 mm (11.8

inches) in diameter with five blades to aid the air flow

through the radiator and the condenser. An electric motor

attached to the radiator support drives the fan.

A/C models have two fans – the main fan and the auxiliary

fan. The auxiliary fan is 300 mm (11.8 inches) in diameter.

Non–A/C models have only the main fan.

A/C OFF or Non–A/C Model (1.4L/1.6L)

S The cooling fans are actuated by the electronic

control module (ECM) using a low–speed cooling

fan relay and a high–speed cooling fan relay. On

A/C–equipped vehicles, a series/parallel cooling fan

relay is also used.

S The ECM will turn the cooling fans on at low speed

when the coolant temperature reaches 97.5°C

(207.5°F) and the cooling fans off at 95.25°C

(203.4°F).

A/C OFF or Non–A/C Model (1.8L)

S The cooling fans are actuated by the electronic

control module (ECM) using a low–speed cooling

fan relay and a high–speed cooling fan relay. On

A/C–equipped vehicles, a series/parallel cooling fan

relay is also used.

S The ECM will turn the cooling fans on at low speed

when the coolant temperature reaches 93°C

(199°F) and the cooling fans off at 90°C (194°F).

A/C ON (1.4L/1.6L)

S The ECM will turn the cooling fans on at low speed

when the A/C system is on. The ECM will change

to high speed when the coolant temperature reach-

es 101.25°C (214°F) or the high side A/C pressure

reaches 1859 kPa (270 psi).

S The cooling fans will return to low speed when the

coolant temperature reaches 99°C (210°F) and the

high side A/C pressure reaches 1449 kPa (210 psi).

A/C ON (1.8L)

S The ECM will turn the cooling fans on at low speed

when the A/C system is on. The ECM will change

to high speed when the coolant temperature reach-

es 97°C (207°F) or the high side A/C pressure

reaches 1859 kPa (270 psi).

S The cooling fans will return to low speed when the

coolant temperature reaches 94°C (201°F) and the

high side A/C pressure reaches 1449 kPa (210 psi).

ENGINE BLOCK HEATER

The vehicle is designed to accept an engine block heater

that helps to warm the engine and to improve starting in

cold weather. It also can help to reduce fuel consumption

while a cold engine warms up.

The engine block heater is located under the intake man-

ifold and uses an existing expansion plug for installation.

Page 215 of 2643

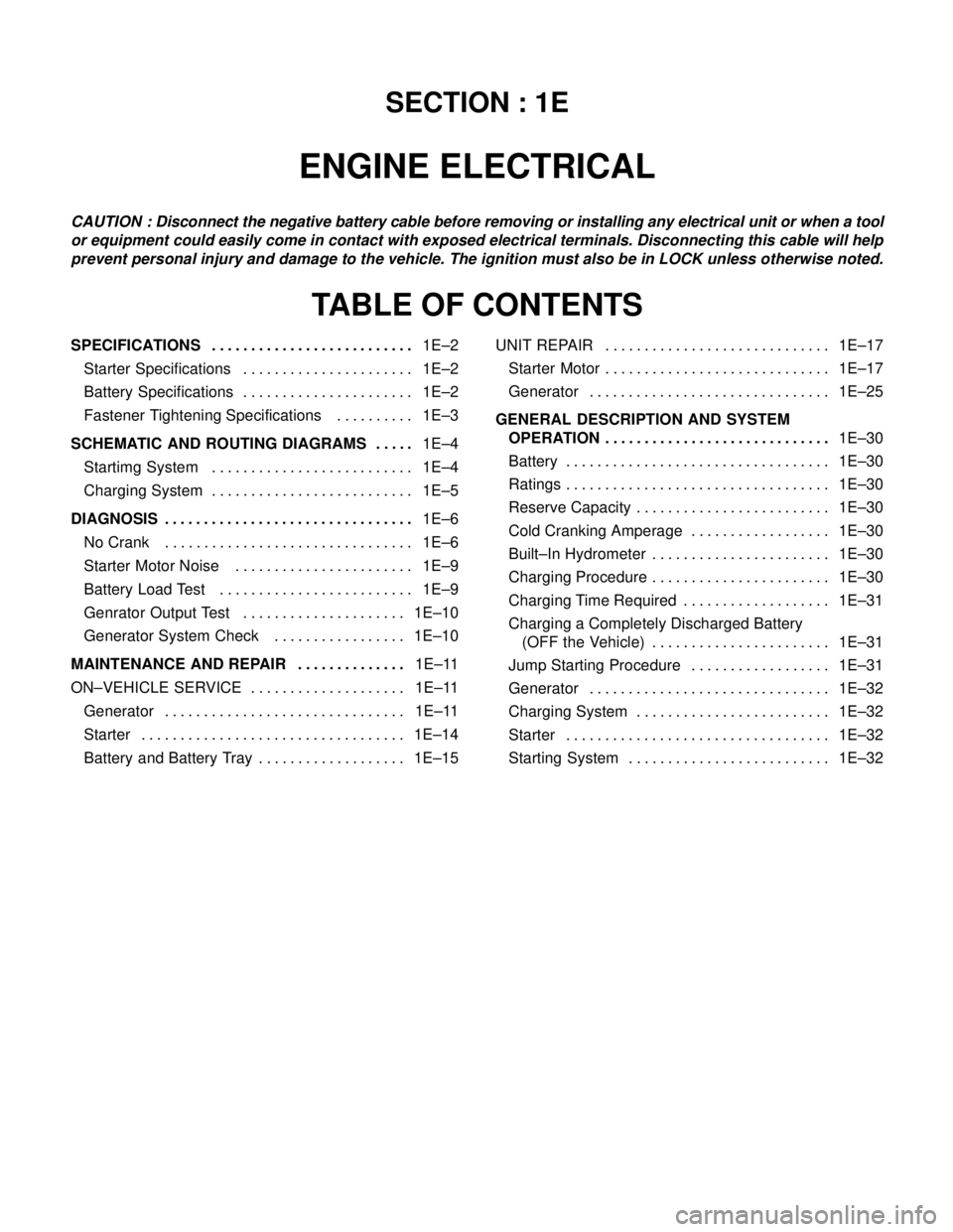

SECTION : 1E

ENGINE ELECTRICAL

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS1E–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Specifications 1E–2. . . . . . . . . . . . . . . . . . . . . .

Battery Specifications 1E–2. . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 1E–3. . . . . . . . . .

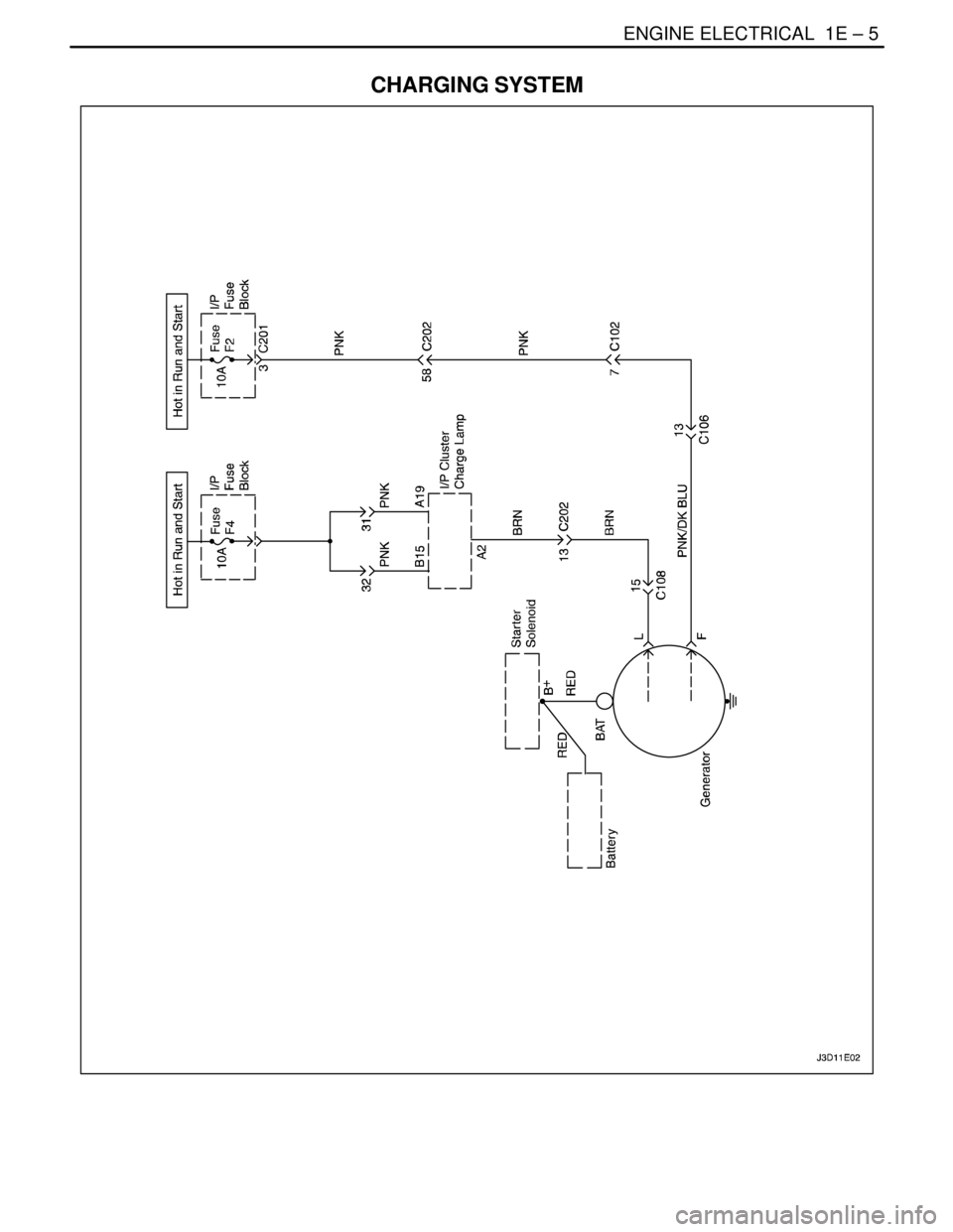

SCHEMATIC AND ROUTING DIAGRAMS1E–4 . . . . .

Startimg System 1E–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System 1E–5. . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS1E–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Crank 1E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Motor Noise 1E–9. . . . . . . . . . . . . . . . . . . . . . .

Battery Load Test 1E–9. . . . . . . . . . . . . . . . . . . . . . . . .

Genrator Output Test 1E–10. . . . . . . . . . . . . . . . . . . . .

Generator System Check 1E–10. . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR1E–11 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 1E–11. . . . . . . . . . . . . . . . . . . .

Generator 1E–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter 1E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery and Battery Tray 1E–15. . . . . . . . . . . . . . . . . . . UNIT REPAIR 1E–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Motor 1E–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator 1E–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION1E–30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 1E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratings 1E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reserve Capacity 1E–30. . . . . . . . . . . . . . . . . . . . . . . . .

Cold Cranking Amperage 1E–30. . . . . . . . . . . . . . . . . .

Built–In Hydrometer 1E–30. . . . . . . . . . . . . . . . . . . . . . .

Charging Procedure 1E–30. . . . . . . . . . . . . . . . . . . . . . .

Charging Time Required 1E–31. . . . . . . . . . . . . . . . . . .

Charging a Completely Discharged Battery

(OFF the Vehicle) 1E–31. . . . . . . . . . . . . . . . . . . . . . .

Jump Starting Procedure 1E–31. . . . . . . . . . . . . . . . . .

Generator 1E–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System 1E–32. . . . . . . . . . . . . . . . . . . . . . . . .

Starter 1E–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting System 1E–32. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 216 of 2643

1E – 2IENGINE ELECTRICAL

DAEWOO V–121 BL4

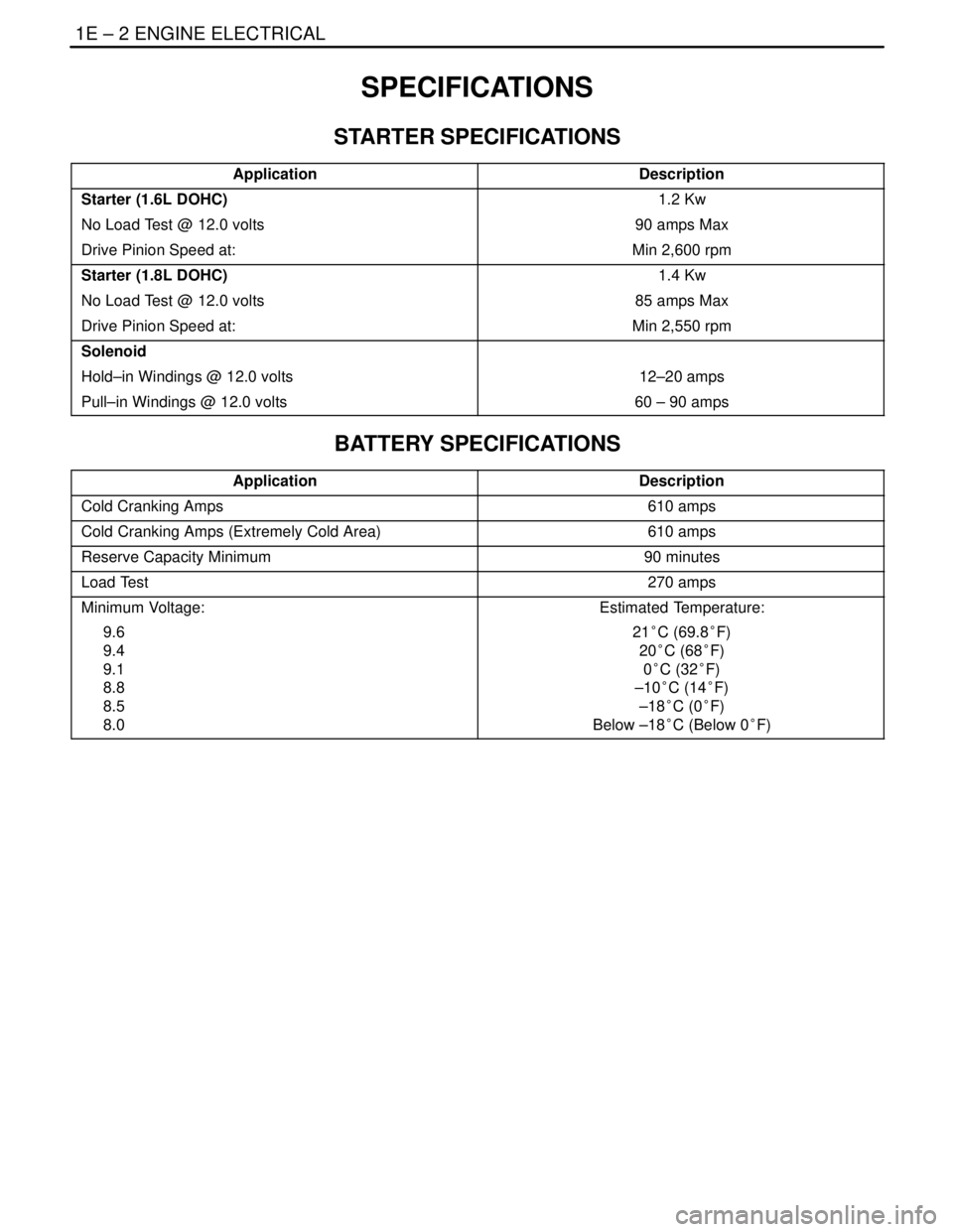

SPECIFICATIONS

STARTER SPECIFICATIONS

ApplicationDescription

Starter (1.6L DOHC)1.2 Kw

No Load Test @ 12.0 volts90 amps Max

Drive Pinion Speed at:Min 2,600 rpm

Starter (1.8L DOHC)1.4 Kw

No Load Test @ 12.0 volts85 amps Max

Drive Pinion Speed at:Min 2,550 rpm

Solenoid

Hold–in Windings @ 12.0 volts12–20 amps

Pull–in Windings @ 12.0 volts60 – 90 amps

BATTERY SPECIFICATIONS

ApplicationDescription

Cold Cranking Amps610 amps

Cold Cranking Amps (Extremely Cold Area)610 amps

Reserve Capacity Minimum90 minutes

Load Test270 amps

Minimum Voltage:

9.6

9.4

9.1

8.8

8.5

8.0Estimated Temperature:

21°C (69.8°F)

20°C (68°F)

0°C (32°F)

–10°C (14°F)

–18°C (0°F)

Below –18°C (Below 0°F)

Page 217 of 2643

ENGINE ELECTRICAL 1E – 3

DAEWOO V–121 BL4

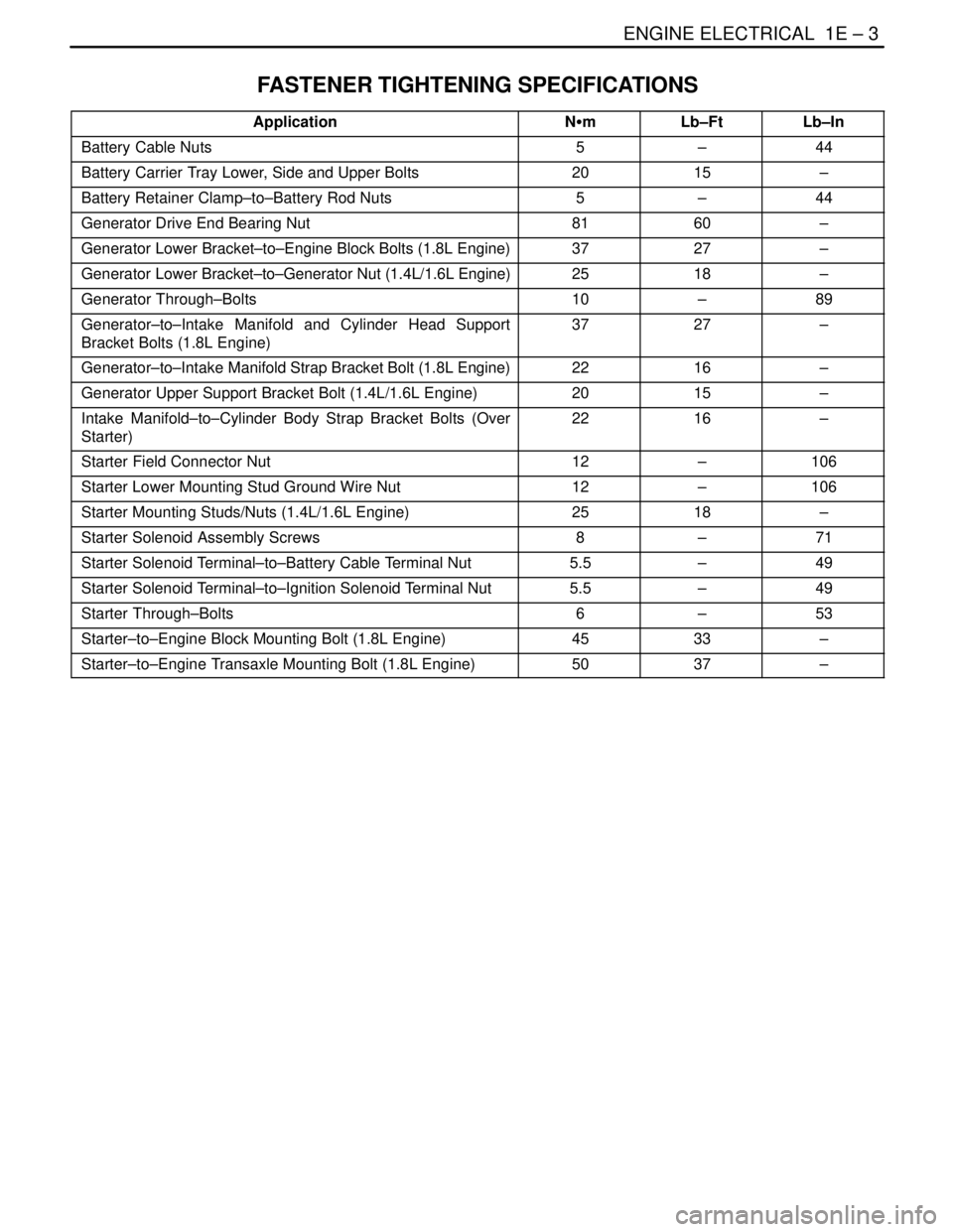

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Battery Cable Nuts5–44

Battery Carrier Tray Lower, Side and Upper Bolts2015–

Battery Retainer Clamp–to–Battery Rod Nuts5–44

Generator Drive End Bearing Nut8160–

Generator Lower Bracket–to–Engine Block Bolts (1.8L Engine)3727–

Generator Lower Bracket–to–Generator Nut (1.4L/1.6L Engine)2518–

Generator Through–Bolts10–89

Generator–to–Intake Manifold and Cylinder Head Support

Bracket Bolts (1.8L Engine)3727–

Generator–to–Intake Manifold Strap Bracket Bolt (1.8L Engine)2216–

Generator Upper Support Bracket Bolt (1.4L/1.6L Engine)2015–

Intake Manifold–to–Cylinder Body Strap Bracket Bolts (Over

Starter)2216–

Starter Field Connector Nut12–106

Starter Lower Mounting Stud Ground Wire Nut12–106

Starter Mounting Studs/Nuts (1.4L/1.6L Engine)2518–

Starter Solenoid Assembly Screws8–71

Starter Solenoid Terminal–to–Battery Cable Terminal Nut5.5–49

Starter Solenoid Terminal–to–Ignition Solenoid Terminal Nut5.5–49

Starter Through–Bolts6–53

Starter–to–Engine Block Mounting Bolt (1.8L Engine)4533–

Starter–to–Engine Transaxle Mounting Bolt (1.8L Engine)5037–

Page 218 of 2643

1E – 4IENGINE ELECTRICAL

DAEWOO V–121 BL4

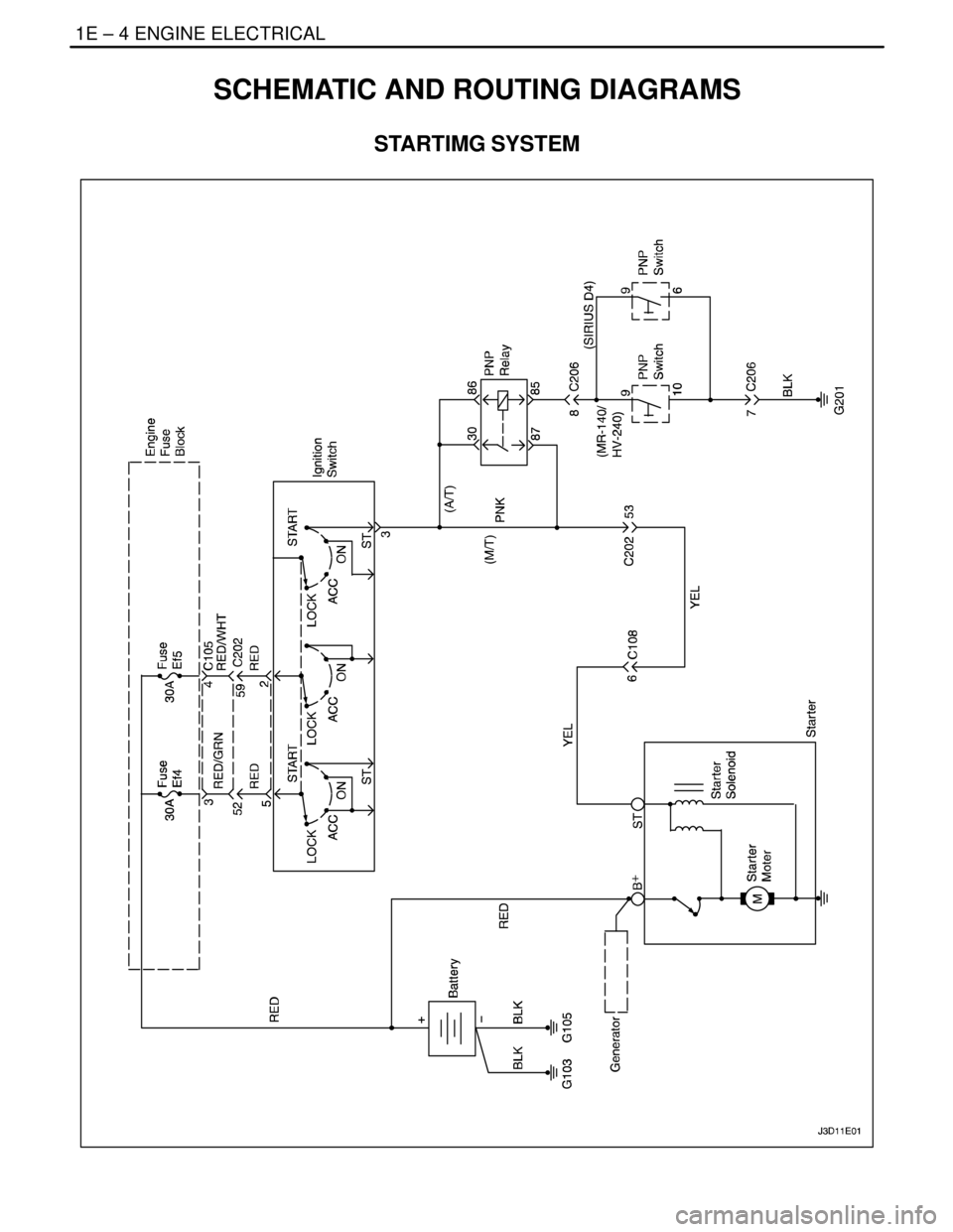

SCHEMATIC AND ROUTING DIAGRAMS

STARTIMG SYSTEM

Page 219 of 2643

ENGINE ELECTRICAL 1E – 5

DAEWOO V–121 BL4

CHARGING SYSTEM

Page 220 of 2643

1E – 6IENGINE ELECTRICAL

DAEWOO V–121 BL4

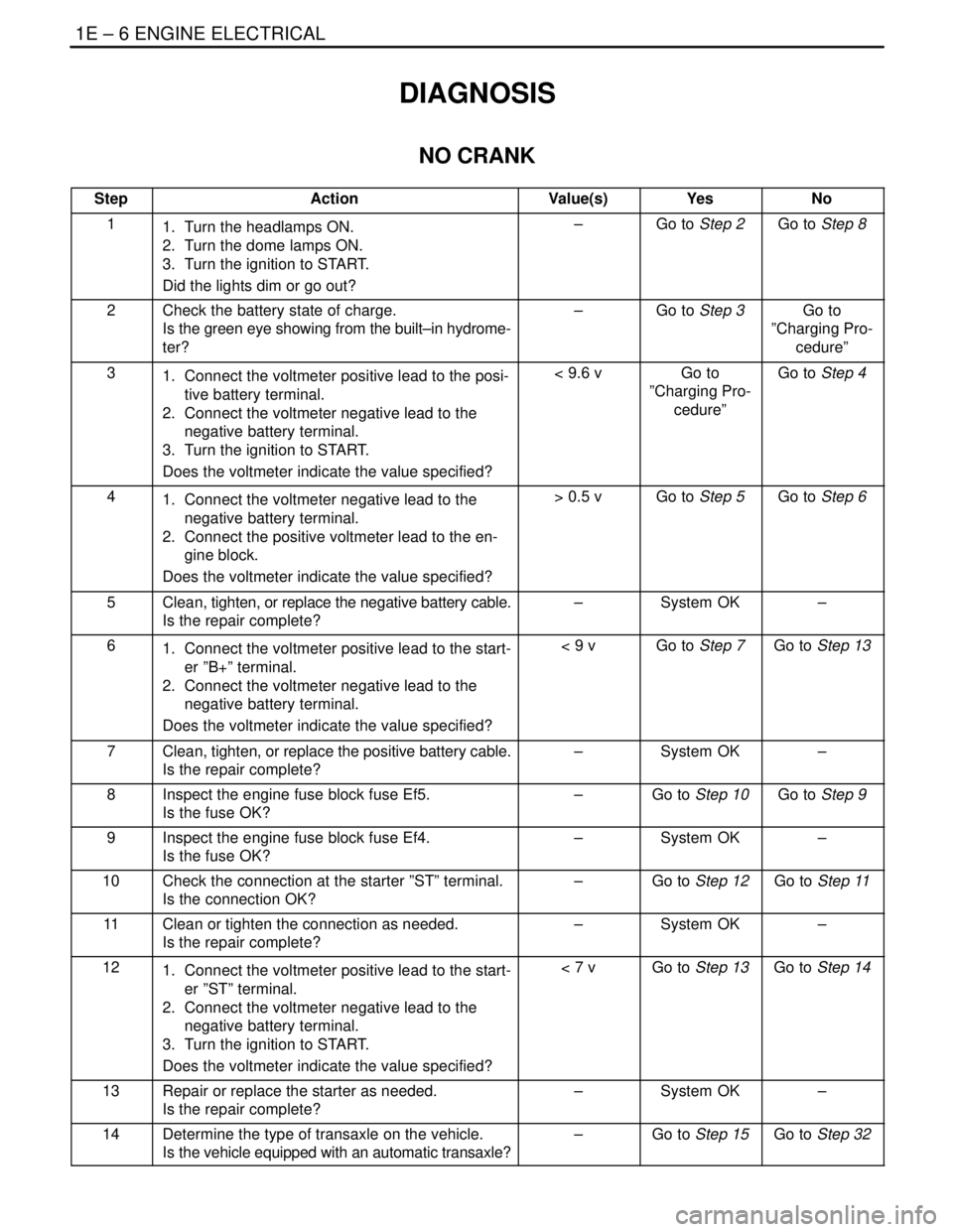

DIAGNOSIS

NO CRANK

StepActionValue(s)YesNo

11. Turn the headlamps ON.

2. Turn the dome lamps ON.

3. Turn the ignition to START.

Did the lights dim or go out?–Go to Step 2Go to Step 8

2Check the battery state of charge.

Is the green eye showing from the built–in hydrome-

ter?–Go to Step 3Go to

”Charging Pro-

cedure”

31. Connect the voltmeter positive lead to the posi-

tive battery terminal.

2. Connect the voltmeter negative lead to the

negative battery terminal.

3. Turn the ignition to START.

Does the voltmeter indicate the value specified?< 9.6 vGo to

”Charging Pro-

cedure”Go to Step 4

41. Connect the voltmeter negative lead to the

negative battery terminal.

2. Connect the positive voltmeter lead to the en-

gine block.

Does the voltmeter indicate the value specified?> 0.5 vGo to Step 5Go to Step 6

5Clean, tighten, or replace the negative battery cable.

Is the repair complete?–System OK–

61. Connect the voltmeter positive lead to the start-

er ”B+” terminal.

2. Connect the voltmeter negative lead to the

negative battery terminal.

Does the voltmeter indicate the value specified?< 9 vGo to Step 7Go to Step 13

7Clean, tighten, or replace the positive battery cable.

Is the repair complete?–System OK–

8Inspect the engine fuse block fuse Ef5.

Is the fuse OK?–Go to Step 10Go to Step 9

9Inspect the engine fuse block fuse Ef4.

Is the fuse OK?–System OK–

10Check the connection at the starter ”ST” terminal.

Is the connection OK?–Go to Step 12Go to Step 11

11Clean or tighten the connection as needed.

Is the repair complete?–System OK–

121. Connect the voltmeter positive lead to the start-

er ”ST” terminal.

2. Connect the voltmeter negative lead to the

negative battery terminal.

3. Turn the ignition to START.

Does the voltmeter indicate the value specified?< 7 vGo to Step 13Go to Step 14

13Repair or replace the starter as needed.

Is the repair complete?–System OK–

14Determine the type of transaxle on the vehicle.

Is the vehicle equipped with an automatic transaxle?–Go to Step 15Go to Step 32