driver DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1997 of 2643

HEATING AND VENTILATION SYSTEM 7A – 23

DAEWOO V–121 BL4

Tighten

Tighten the heater/air distributor case assembly

screws to 4 NSm (35 lb–in).

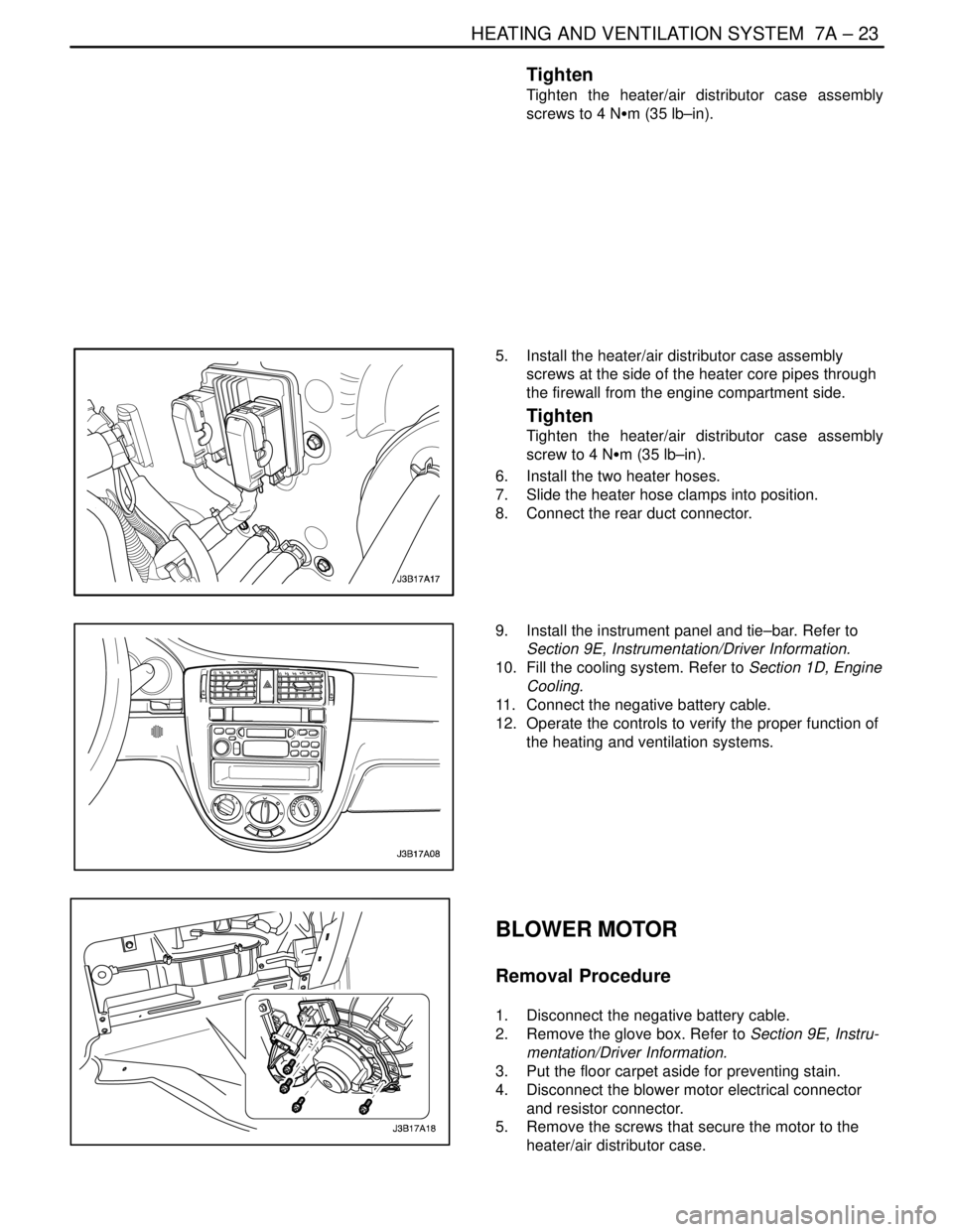

5. Install the heater/air distributor case assembly

screws at the side of the heater core pipes through

the firewall from the engine compartment side.

Tighten

Tighten the heater/air distributor case assembly

screw to 4 NSm (35 lb–in).

6. Install the two heater hoses.

7. Slide the heater hose clamps into position.

8. Connect the rear duct connector.

9. Install the instrument panel and tie–bar. Refer to

Section 9E, Instrumentation/Driver Information.

10. Fill the cooling system. Refer to Section 1D, Engine

Cooling.

11. Connect the negative battery cable.

12. Operate the controls to verify the proper function of

the heating and ventilation systems.

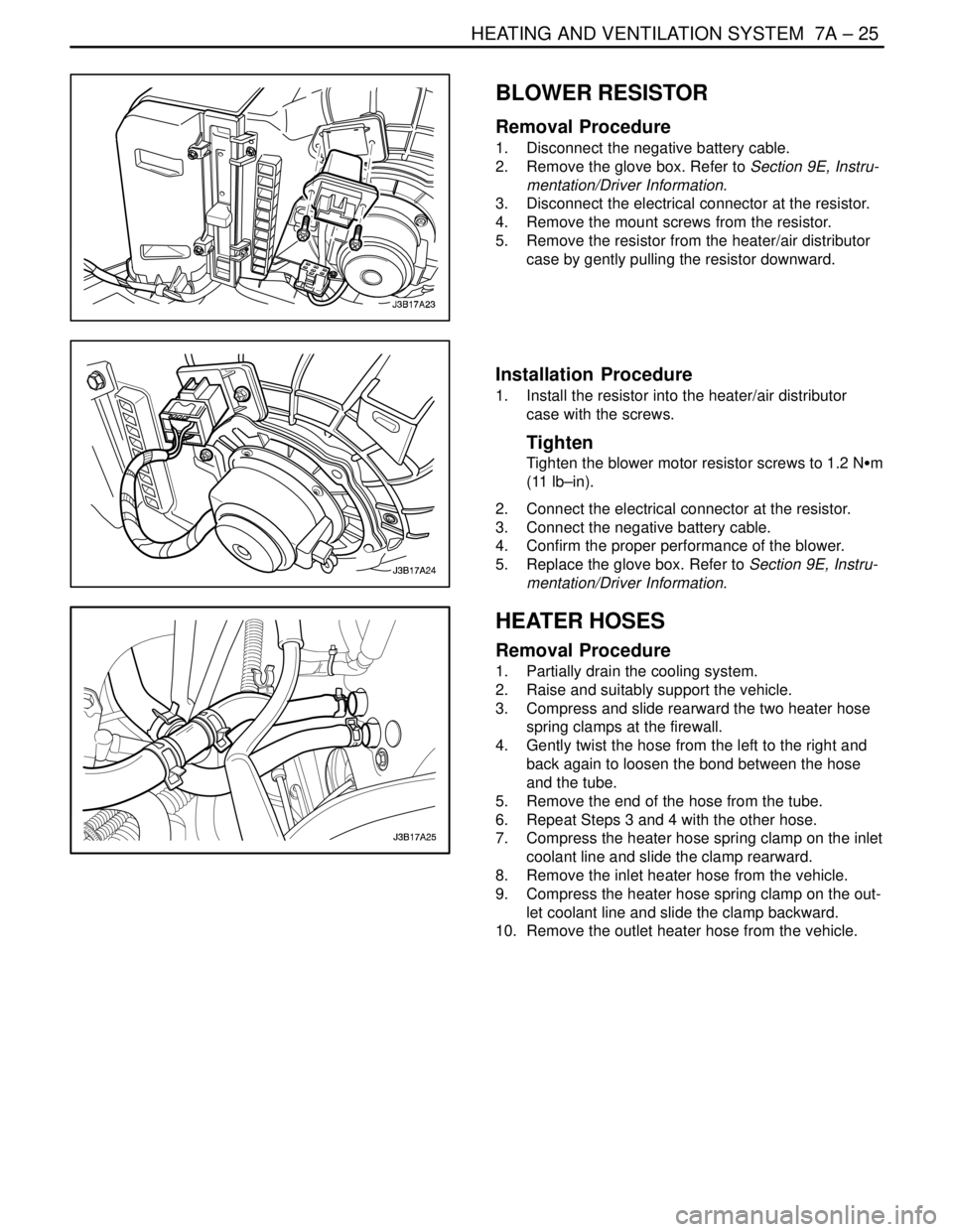

BLOWER MOTOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Put the floor carpet aside for preventing stain.

4. Disconnect the blower motor electrical connector

and resistor connector.

5. Remove the screws that secure the motor to the

heater/air distributor case.

Page 1998 of 2643

7A – 24IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

6. Remove the motor, the seal, and the shock mount

pads from the heater/air distributor case by gently

pulling the motor straight down and out.

Installation Procedure

1. Install the blower motor and the seal with the shock

mount pads in the heater/air distributor case. Hold

the blower motor in position.

2. Install the screws to secure the blower motor to the

heater/air distributor case.

Tighten

Tighten the blower motor retaining screws to 1.2 NSm

(11 lb–in).

3. Connect the blower motor electrical connector and

resistor connector.

4. Connect the negative battery cable.

5. Confirm that the blower motor operates properly.

6. Replace the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

HIGH–BLOWER RELAY

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box housing. Refer to Section

9E, Instrumentation/Driver Information.

3. Separate the connector from the bracket.

4. Disconnect the relay from the connector.

Installation Procedure

1. Connect the relay to the connector.

2. Insert the connector to the bracket.

3. Install the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

Page 1999 of 2643

HEATING AND VENTILATION SYSTEM 7A – 25

DAEWOO V–121 BL4

BLOWER RESISTOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Disconnect the electrical connector at the resistor.

4. Remove the mount screws from the resistor.

5. Remove the resistor from the heater/air distributor

case by gently pulling the resistor downward.

Installation Procedure

1. Install the resistor into the heater/air distributor

case with the screws.

Tighten

Tighten the blower motor resistor screws to 1.2 NSm

(11 lb–in).

2. Connect the electrical connector at the resistor.

3. Connect the negative battery cable.

4. Confirm the proper performance of the blower.

5. Replace the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

HEATER HOSES

Removal Procedure

1. Partially drain the cooling system.

2. Raise and suitably support the vehicle.

3. Compress and slide rearward the two heater hose

spring clamps at the firewall.

4. Gently twist the hose from the left to the right and

back again to loosen the bond between the hose

and the tube.

5. Remove the end of the hose from the tube.

6. Repeat Steps 3 and 4 with the other hose.

7. Compress the heater hose spring clamp on the inlet

coolant line and slide the clamp rearward.

8. Remove the inlet heater hose from the vehicle.

9. Compress the heater hose spring clamp on the out-

let coolant line and slide the clamp backward.

10. Remove the outlet heater hose from the vehicle.

Page 2005 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 3

DAEWOO V–121 BL4

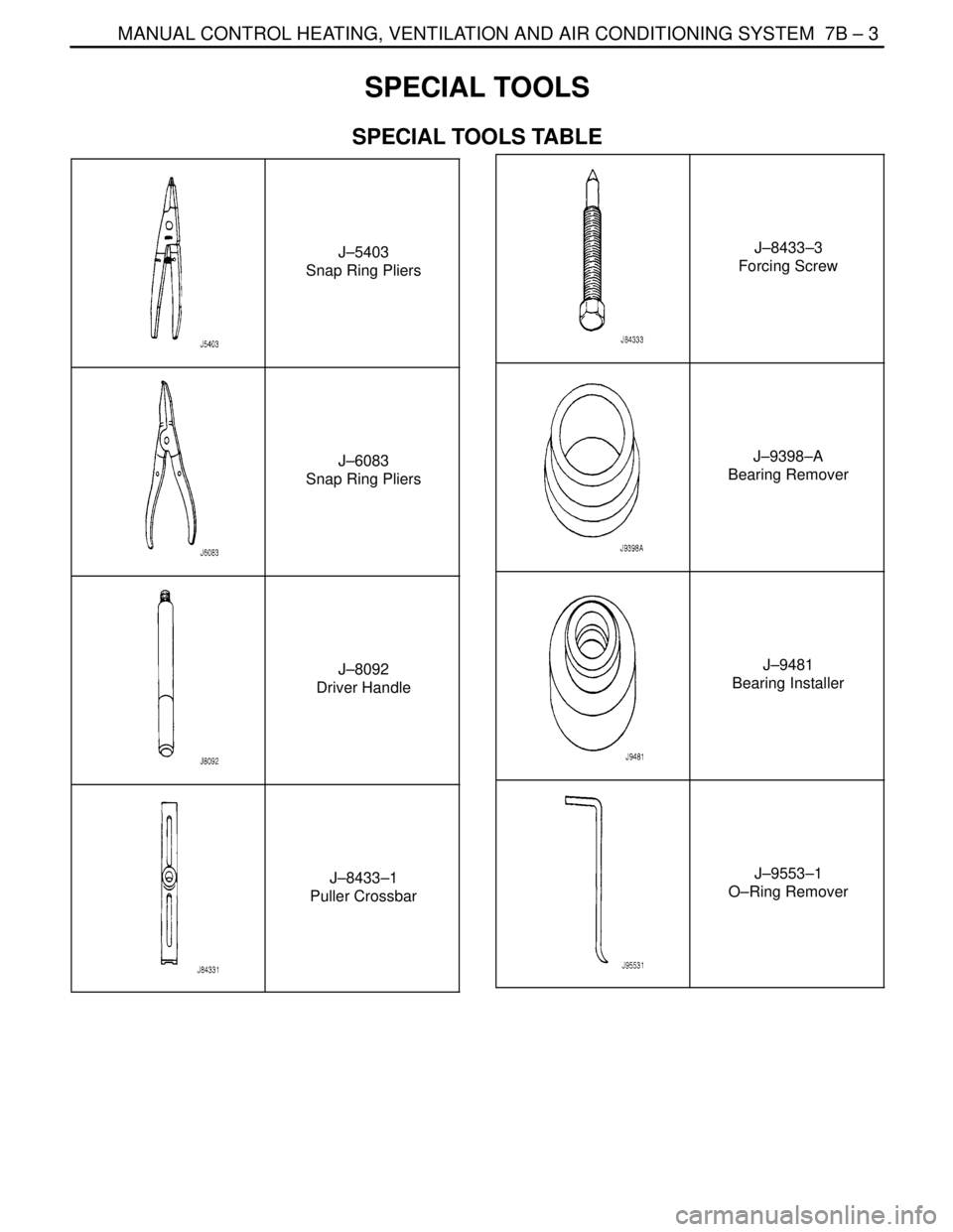

SPECIAL TOOLS

SPECIAL TOOLS TABLE

J–5403

Snap Ring Pliers

J–6083

Snap Ring Pliers

J–8092

Driver Handle

J–8433–1

Puller Crossbar

J–8433–3

Forcing Screw

J–9398–A

Bearing Remover

J–9481

Bearing Installer

J–9553–1

O–Ring Remover

Page 2016 of 2643

7B – 14IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

151. Record the low– and the high–side pressures

after the A/C system has been operating for 5

minutes or more with the engine cooling fan

ON.

2. Locate the intersection of the low– and the high

side pressures. Refer to ”Low– and High–Side

Pressure Relationship Chart” in this section.

Do the low– and the high–side pressures intersect

in the white area of the chart?–System OKGo to Step 16

16Check the high– and the low–side pressures.

Do the low– and the high–side pressures intersect

in the grey area of the chart?–Go to Step 17Go to Step 20

17Feel the liquid pipe between the condenser and the

expansion valve.

Is the pipe cold?–Go to Step 18Go to Step 19

181. Examine the condenser for any restriction of

the airflow.

2. Check the cooling fans for proper operation.

3. Remove the restriction or repair the fans, as

required.

Is the pipe temperature normal now?At least 7°C

(12°F) below

ambient air

temperatureGo to Step 13–

191. Recover, evacuate, and recharge the A/C sys-

tem.

2. Check the A/C system for leaks.

Is the system free from leaks?–Go to Step 13–

20Observe the readings on the pressure gauges.

Are the A/C compressor high– and the low–side

pressures within the specified value of each other?207 kPa

(30 psi)Go to Step 21Go to Step 26

211. Run the engine at 3,000 rpm.

2. Set the A/C controls to the following positions:

S The A/C switch to the ON.

S The fresh air control switch to fresh air.

S The blower motor to 4.

S The temperature to full cold.

3. Close all of the vehicle’s windows and doors.

4. Turn the A/C switch ON and OFF every 20

seconds for 3 minutes.

Are the A/C compressor high– and the low–side

pressures within the specified value of each other?207 kPa

(30 psi)Go to Step 22Go to Step 13

22Observe the pressure rise on both gauges and the

temperatures of both the compressor suction pipe

and the discharge pipe.

Is the pressure rise on both gauges slow and the

suction pipe warm with the discharge pipe very hot?–Go to Step 25Go to Step 23

231. Turn the ignition switch to LOCK.

2. Make sure the compressor clutch is disen-

gaged.

3. Attempt to turn the clutch driver (not the

pulley).

Can you turn the clutch driver freely by hand?–Go to Step 25Go to Step 24

Page 2027 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 25

DAEWOO V–121 BL4

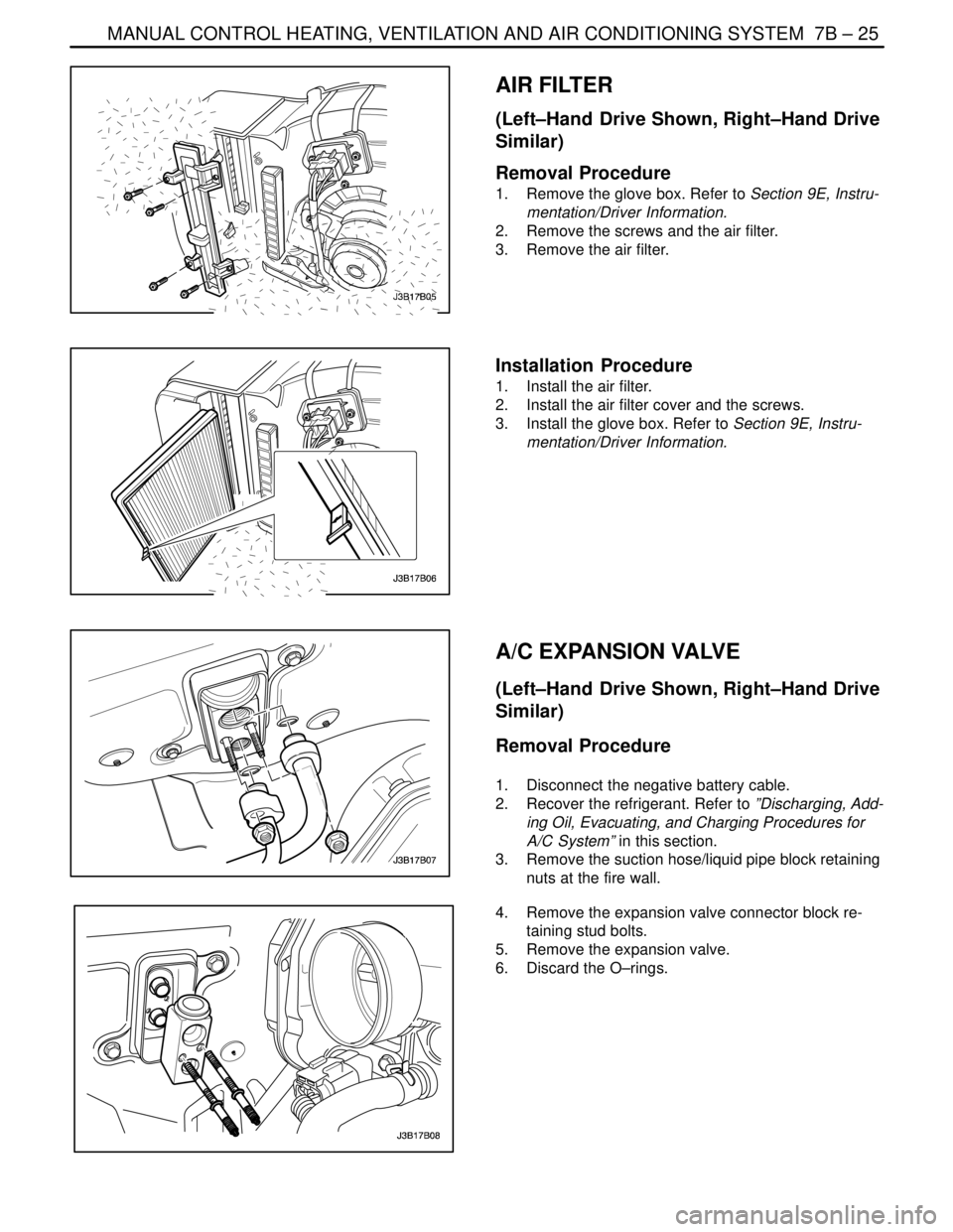

AIR FILTER

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

2. Remove the screws and the air filter.

3. Remove the air filter.

Installation Procedure

1. Install the air filter.

2. Install the air filter cover and the screws.

3. Install the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

A/C EXPANSION VALVE

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Recover the refrigerant. Refer to ”Discharging, Add-

ing Oil, Evacuating, and Charging Procedures for

A/C System” in this section.

3. Remove the suction hose/liquid pipe block retaining

nuts at the fire wall.

4. Remove the expansion valve connector block re-

taining stud bolts.

5. Remove the expansion valve.

6. Discard the O–rings.

Page 2042 of 2643

7B – 40IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

11. Remove the compressor from the bench vise and

remove the J–34992 compressor holding fixture

from the compressor.

12. Install the compressor. Refer to ”Compressor” in

this section.

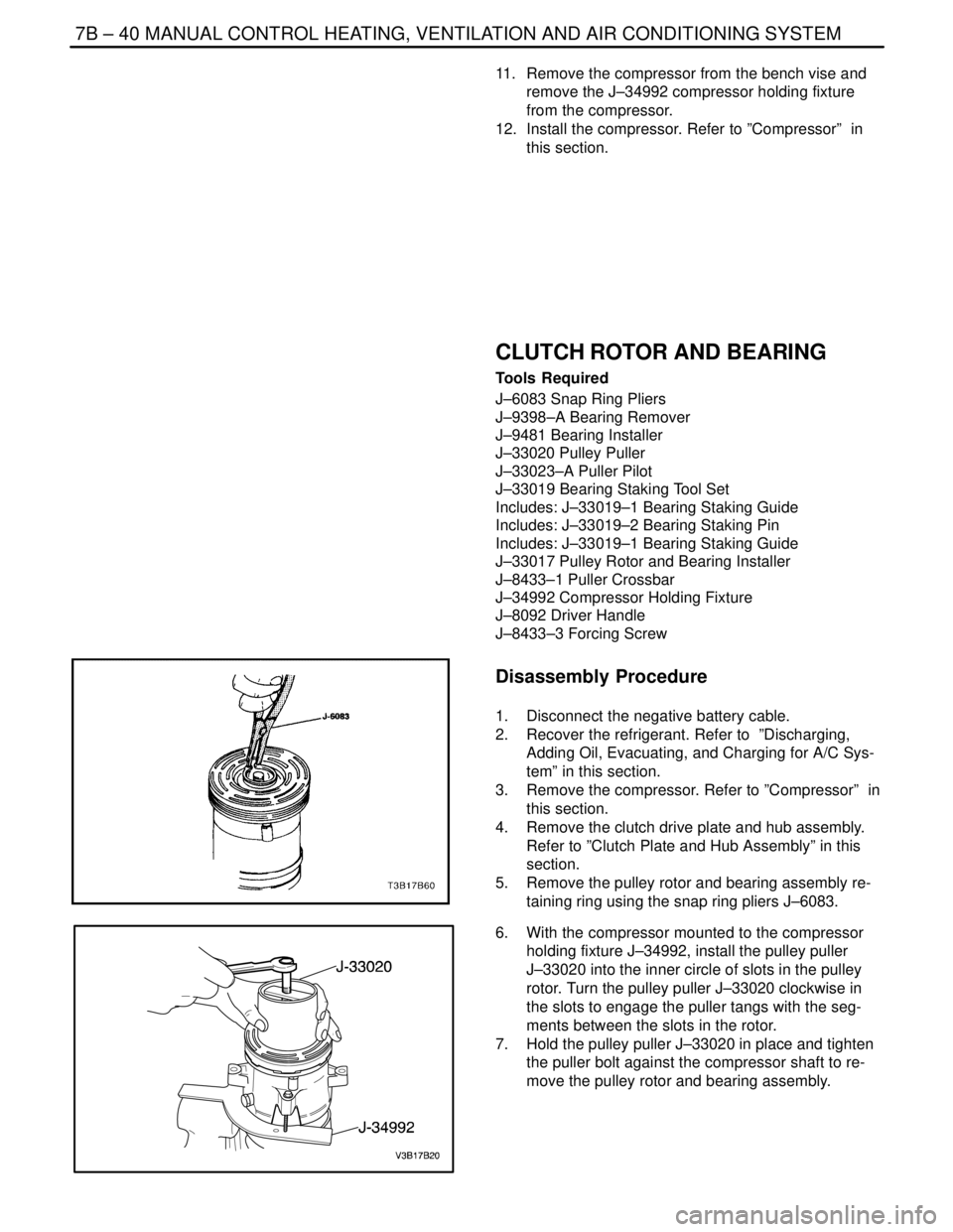

CLUTCH ROTOR AND BEARING

Tools Required

J–6083 Snap Ring Pliers

J–9398–A Bearing Remover

J–9481 Bearing Installer

J–33020 Pulley Puller

J–33023–A Puller Pilot

J–33019 Bearing Staking Tool Set

Includes: J–33019–1 Bearing Staking Guide

Includes: J–33019–2 Bearing Staking Pin

Includes: J–33019–1 Bearing Staking Guide

J–33017 Pulley Rotor and Bearing Installer

J–8433–1 Puller Crossbar

J–34992 Compressor Holding Fixture

J–8092 Driver Handle

J–8433–3 Forcing Screw

Disassembly Procedure

1. Disconnect the negative battery cable.

2. Recover the refrigerant. Refer to ”Discharging,

Adding Oil, Evacuating, and Charging for A/C Sys-

tem” in this section.

3. Remove the compressor. Refer to ”Compressor” in

this section.

4. Remove the clutch drive plate and hub assembly.

Refer to ”Clutch Plate and Hub Assembly” in this

section.

5. Remove the pulley rotor and bearing assembly re-

taining ring using the snap ring pliers J–6083.

6. With the compressor mounted to the compressor

holding fixture J–34992, install the pulley puller

J–33020 into the inner circle of slots in the pulley

rotor. Turn the pulley puller J–33020 clockwise in

the slots to engage the puller tangs with the seg-

ments between the slots in the rotor.

7. Hold the pulley puller J–33020 in place and tighten

the puller bolt against the compressor shaft to re-

move the pulley rotor and bearing assembly.

Page 2043 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 41

DAEWOO V–121 BL4

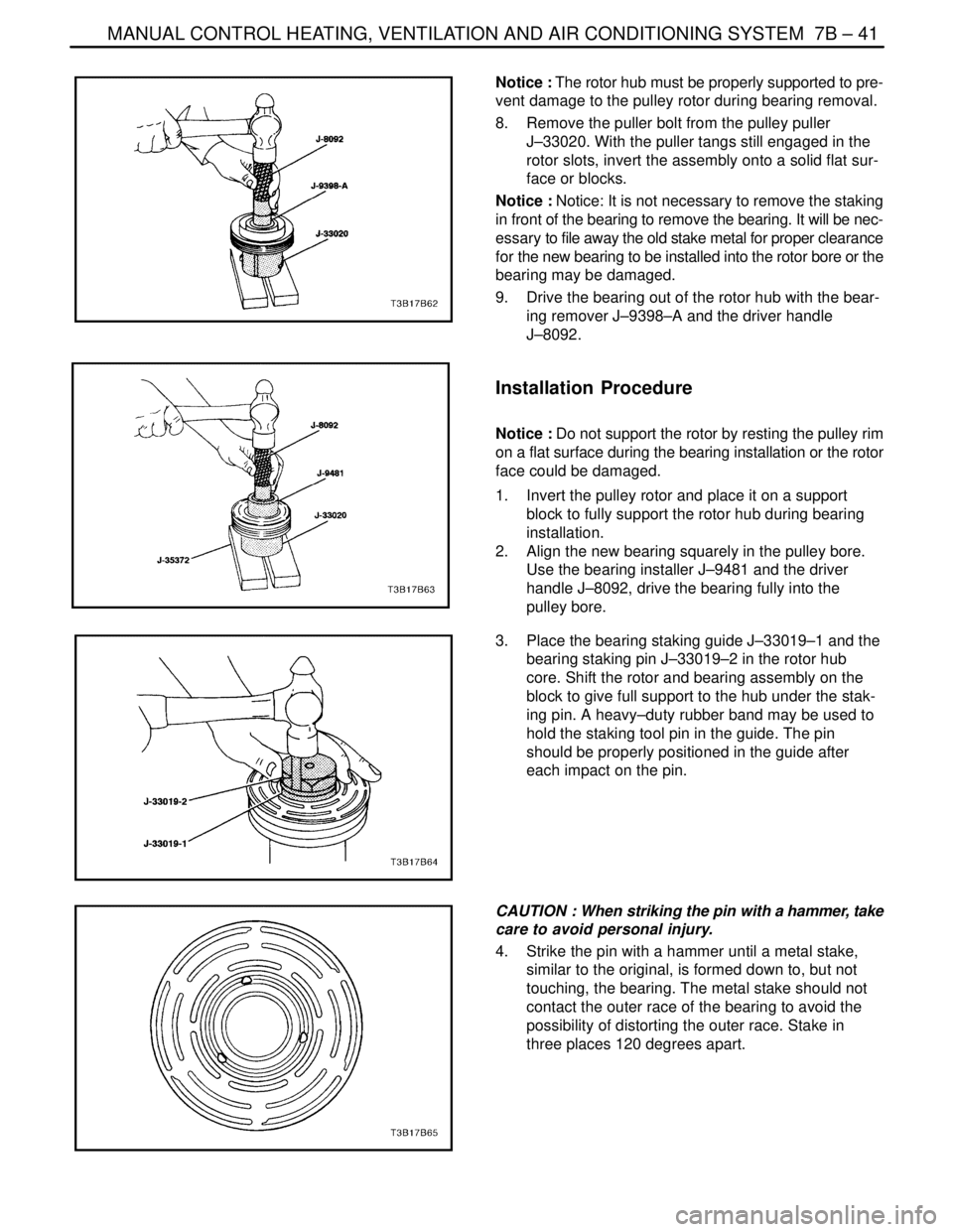

Notice : The rotor hub must be properly supported to pre-

vent damage to the pulley rotor during bearing removal.

8. Remove the puller bolt from the pulley puller

J–33020. With the puller tangs still engaged in the

rotor slots, invert the assembly onto a solid flat sur-

face or blocks.

Notice : Notice: It is not necessary to remove the staking

in front of the bearing to remove the bearing. It will be nec-

essary to file away the old stake metal for proper clearance

for the new bearing to be installed into the rotor bore or the

bearing may be damaged.

9. Drive the bearing out of the rotor hub with the bear-

ing remover J–9398–A and the driver handle

J–8092.

Installation Procedure

Notice : Do not support the rotor by resting the pulley rim

on a flat surface during the bearing installation or the rotor

face could be damaged.

1. Invert the pulley rotor and place it on a support

block to fully support the rotor hub during bearing

installation.

2. Align the new bearing squarely in the pulley bore.

Use the bearing installer J–9481 and the driver

handle J–8092, drive the bearing fully into the

pulley bore.

3. Place the bearing staking guide J–33019–1 and the

bearing staking pin J–33019–2 in the rotor hub

core. Shift the rotor and bearing assembly on the

block to give full support to the hub under the stak-

ing pin. A heavy–duty rubber band may be used to

hold the staking tool pin in the guide. The pin

should be properly positioned in the guide after

each impact on the pin.

CAUTION : When striking the pin with a hammer, take

care to avoid personal injury.

4. Strike the pin with a hammer until a metal stake,

similar to the original, is formed down to, but not

touching, the bearing. The metal stake should not

contact the outer race of the bearing to avoid the

possibility of distorting the outer race. Stake in

three places 120 degrees apart.

Page 2062 of 2643

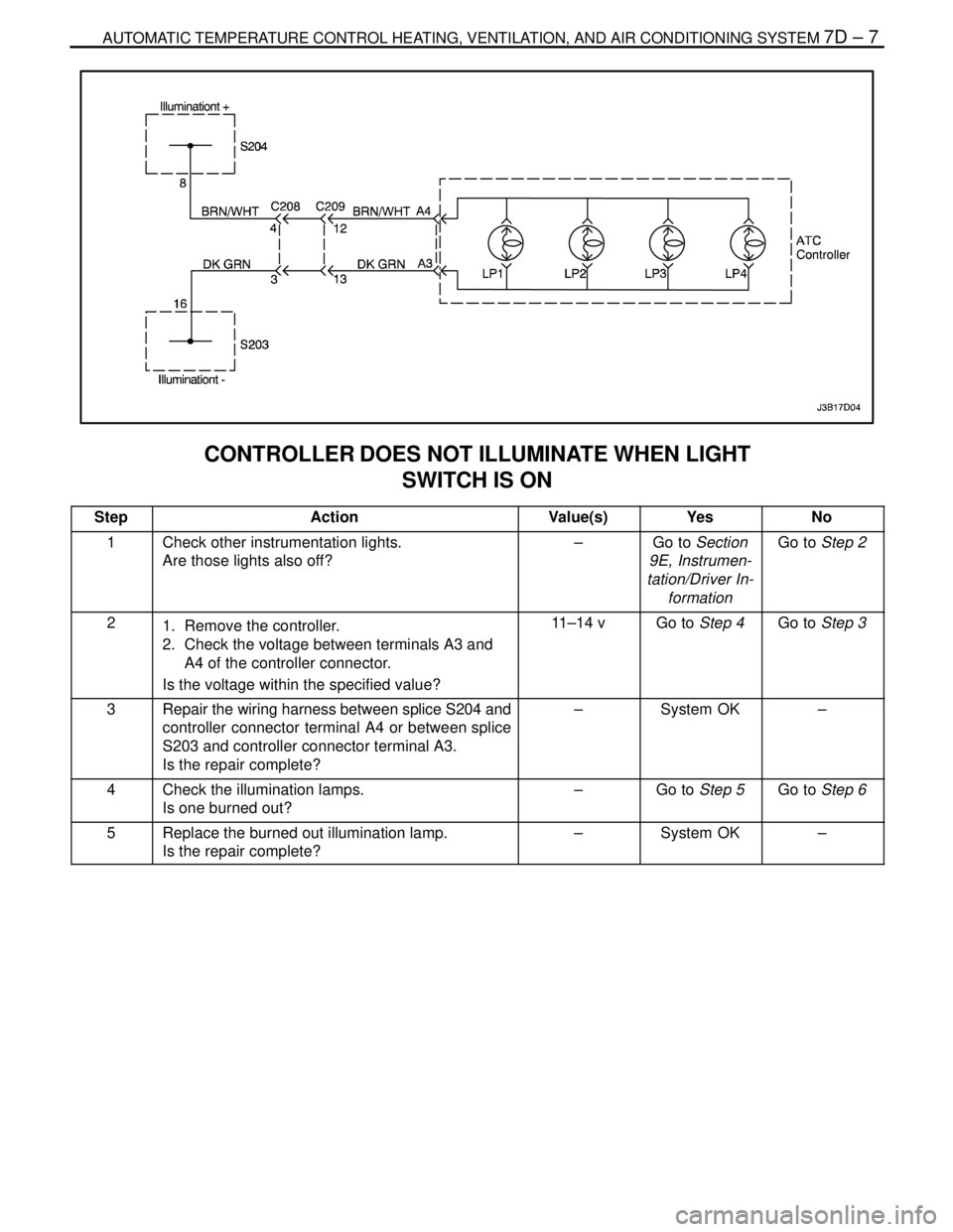

AUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 7

DAEWOO V–121 BL4

CONTROLLER DOES NOT ILLUMINATE WHEN LIGHT

SWITCH IS ON

StepActionValue(s)YesNo

1Check other instrumentation lights.

Are those lights also off?–Go to Section

9E, Instrumen-

tation/Driver In-

formationGo to Step 2

21. Remove the controller.

2. Check the voltage between terminals A3 and

A4 of the controller connector.

Is the voltage within the specified value?11–14 vGo to Step 4Go to Step 3

3Repair the wiring harness between splice S204 and

controller connector terminal A4 or between splice

S203 and controller connector terminal A3.

Is the repair complete?–System OK–

4Check the illumination lamps.

Is one burned out?–Go to Step 5Go to Step 6

5Replace the burned out illumination lamp.

Is the repair complete?–System OK–

Page 2088 of 2643

IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 33

DAEWOO V–121 BL4

SERVICEABLE COMPONENTS

COMMON HVAC COMPONENTS

Those components used in non–automatic systems are

covered in other sections of this manual.

Refer to Section 7A, Heating and Ventilation System for

the following procedures:

S Blower Motor.

S Heater Hoses.

S Blower Resistor.

S High–Blower Relay.

S Heater/Air Distributor Case Assembly (A/C Mod-

ule).

S Heater Core.

Refer to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System, for the following proce-

dures:

S A/C Pressure Transducer.

S A/C Compressor Relay.

S Air Filter.

S A/C Expansion Valve.

S A/C High–Pressure Pipe Line.

S Evaporator Core.

S A/C Suction Hose Assembly.

S A/C Discharge Hose–Compressor to Condenser.

S Compressor.

S Condenser.

S Receiver–Dryer.

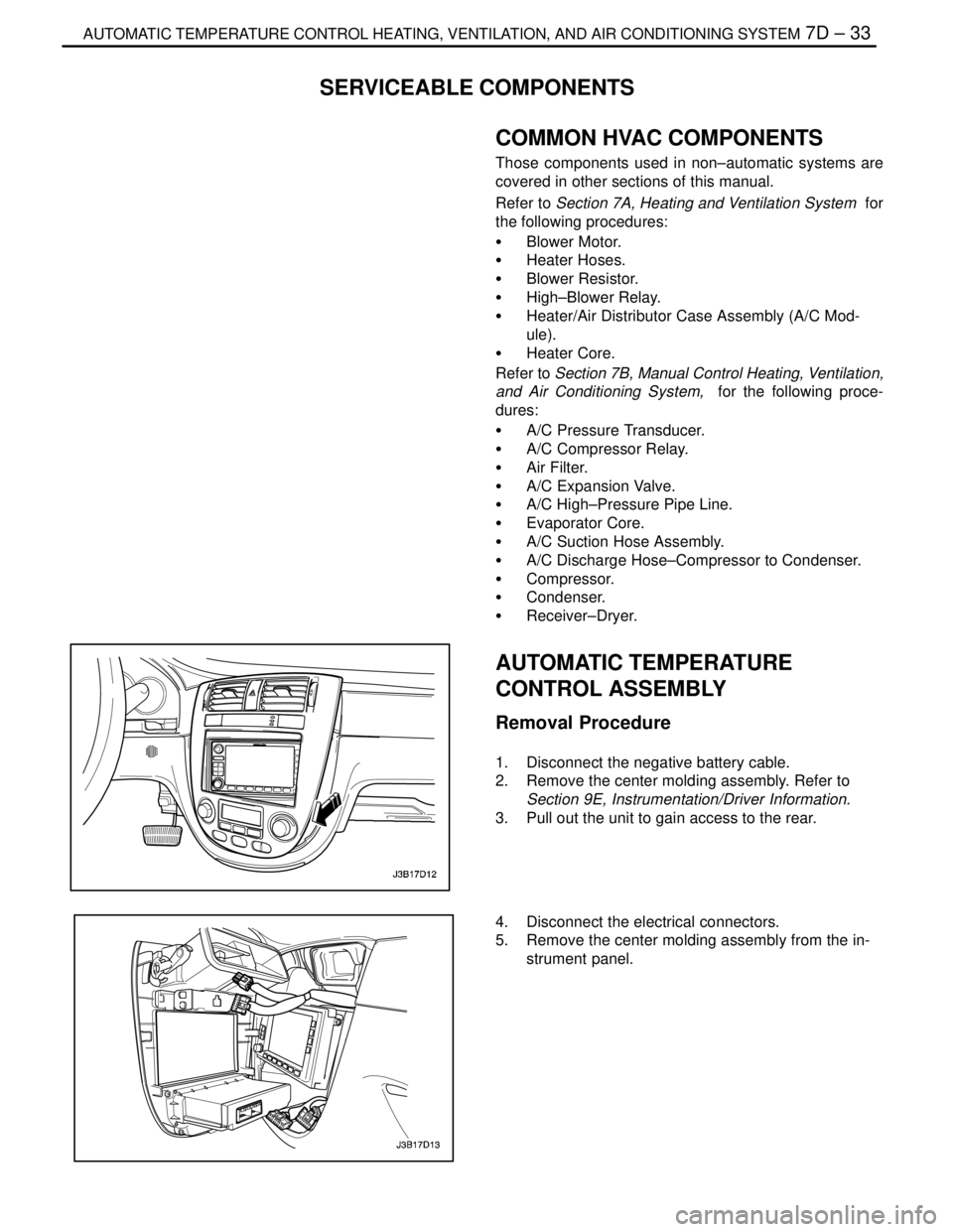

AUTOMATIC TEMPERATURE

CONTROL ASSEMBLY

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the center molding assembly. Refer to

Section 9E, Instrumentation/Driver Information.

3. Pull out the unit to gain access to the rear.

4. Disconnect the electrical connectors.

5. Remove the center molding assembly from the in-

strument panel.