DAEWOO LACETTI 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2291 of 2643

9D – 14IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

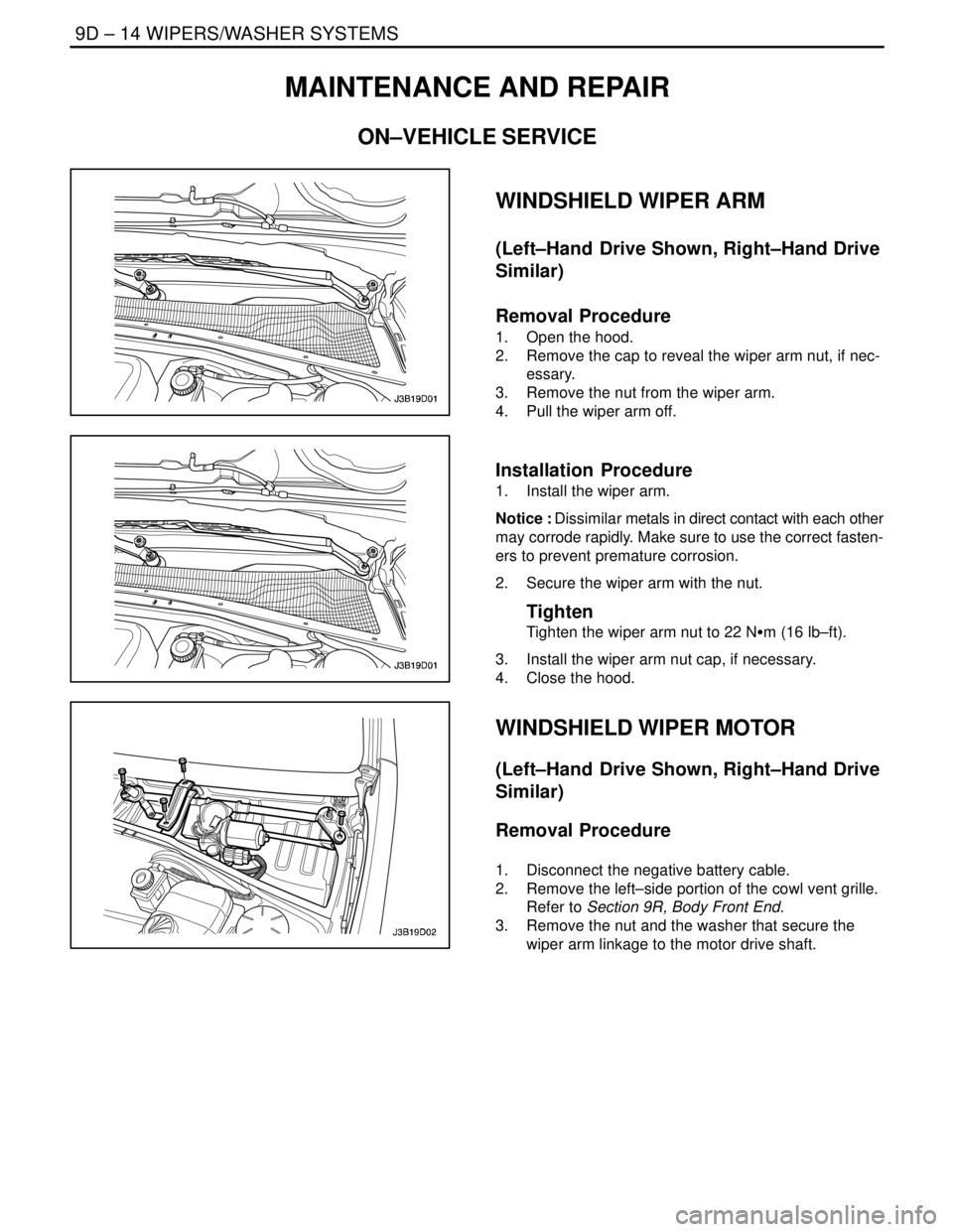

WINDSHIELD WIPER ARM

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Open the hood.

2. Remove the cap to reveal the wiper arm nut, if nec-

essary.

3. Remove the nut from the wiper arm.

4. Pull the wiper arm off.

Installation Procedure

1. Install the wiper arm.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Secure the wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 22 NSm (16 lb–ft).

3. Install the wiper arm nut cap, if necessary.

4. Close the hood.

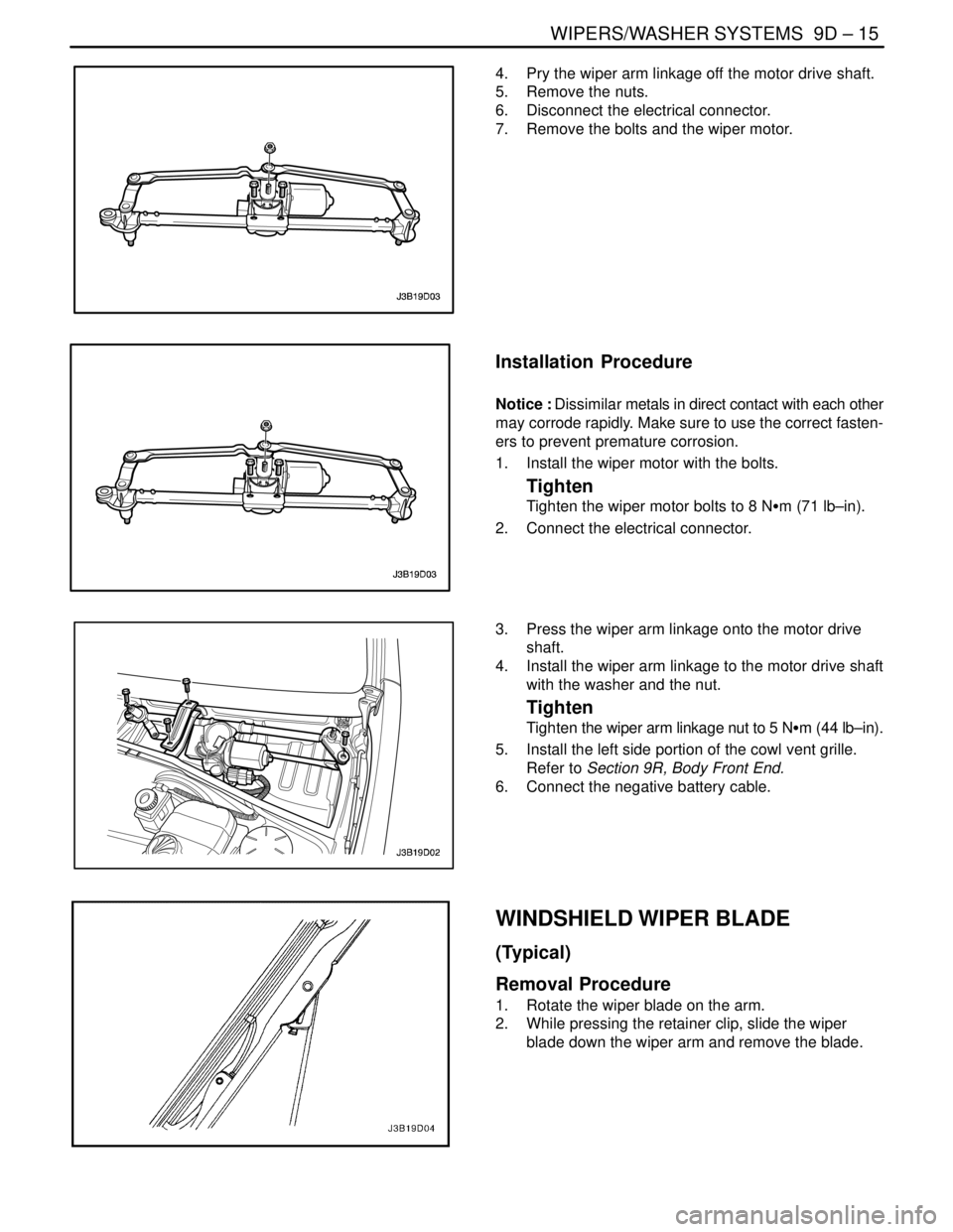

WINDSHIELD WIPER MOTOR

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the left–side portion of the cowl vent grille.

Refer to Section 9R, Body Front End.

3. Remove the nut and the washer that secure the

wiper arm linkage to the motor drive shaft.

Page 2292 of 2643

WIPERS/WASHER SYSTEMS 9D – 15

DAEWOO V–121 BL4

4. Pry the wiper arm linkage off the motor drive shaft.

5. Remove the nuts.

6. Disconnect the electrical connector.

7. Remove the bolts and the wiper motor.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 8 NSm (71 lb–in).

2. Connect the electrical connector.

3. Press the wiper arm linkage onto the motor drive

shaft.

4. Install the wiper arm linkage to the motor drive shaft

with the washer and the nut.

Tighten

Tighten the wiper arm linkage nut to 5 NSm (44 lb–in).

5. Install the left side portion of the cowl vent grille.

Refer to Section 9R, Body Front End.

6. Connect the negative battery cable.

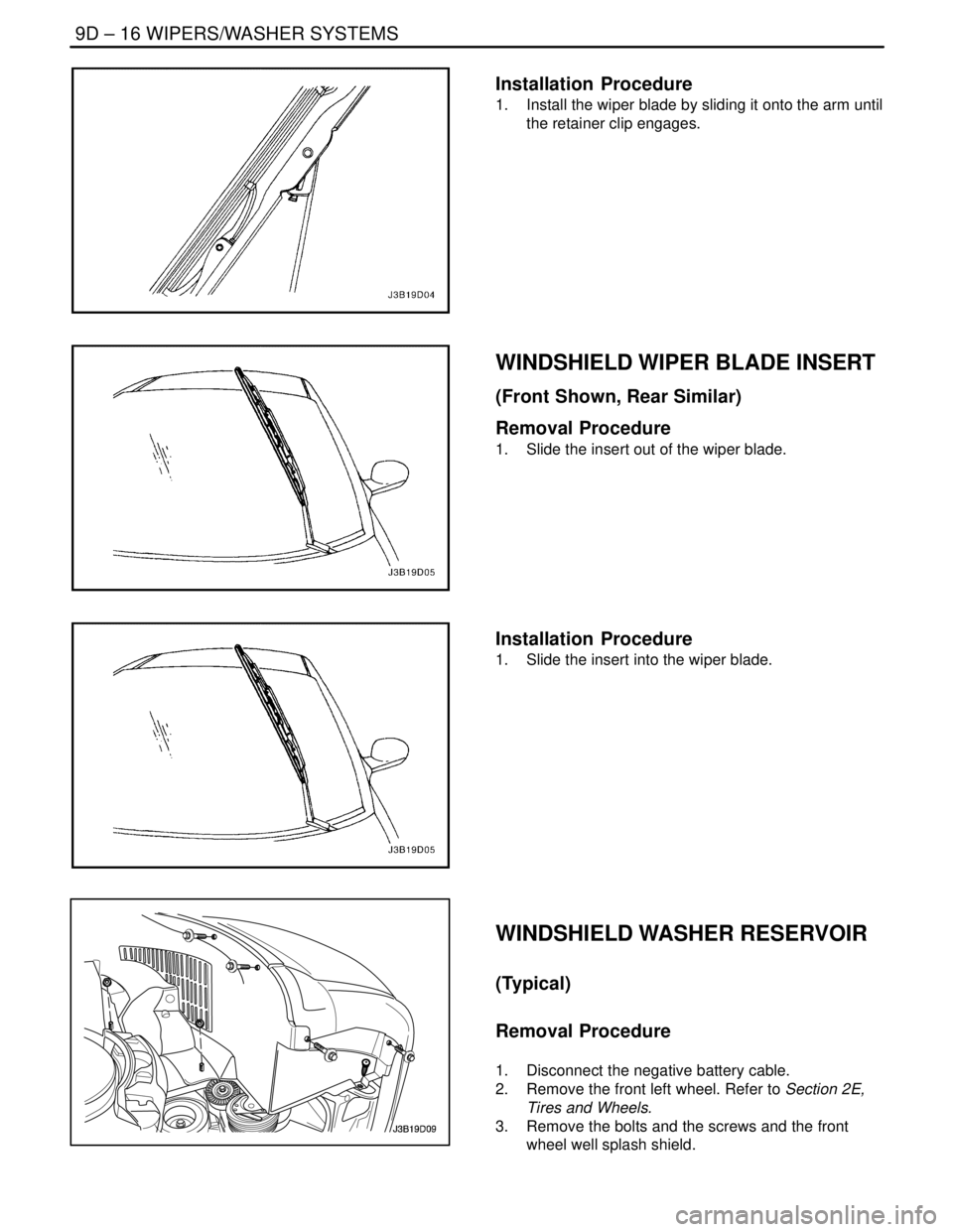

WINDSHIELD WIPER BLADE

(Typical)

Removal Procedure

1. Rotate the wiper blade on the arm.

2. While pressing the retainer clip, slide the wiper

blade down the wiper arm and remove the blade.

Page 2293 of 2643

9D – 16IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

Installation Procedure

1. Install the wiper blade by sliding it onto the arm until

the retainer clip engages.

WINDSHIELD WIPER BLADE INSERT

(Front Shown, Rear Similar)

Removal Procedure

1. Slide the insert out of the wiper blade.

Installation Procedure

1. Slide the insert into the wiper blade.

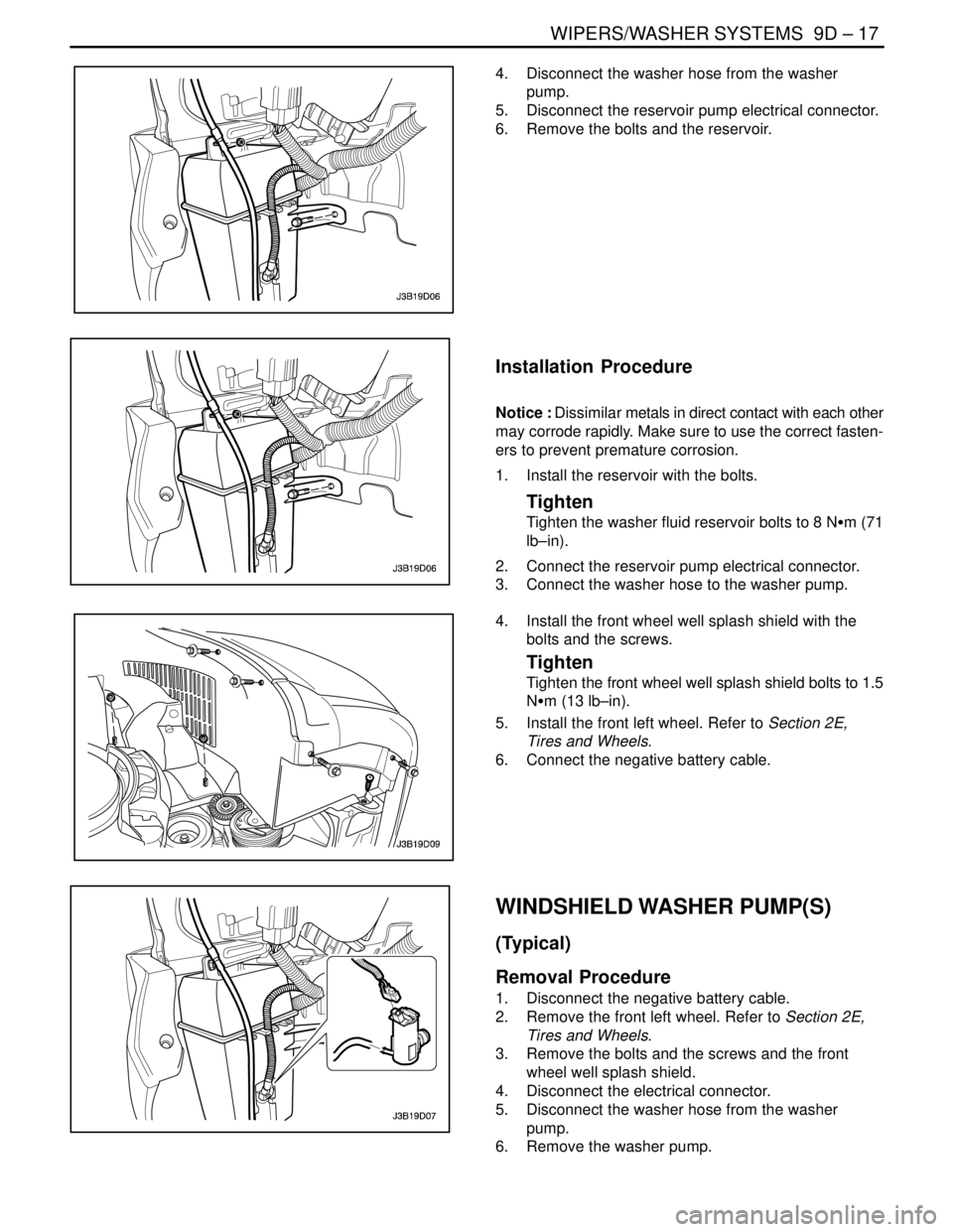

WINDSHIELD WASHER RESERVOIR

(Typical)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

3. Remove the bolts and the screws and the front

wheel well splash shield.

Page 2294 of 2643

WIPERS/WASHER SYSTEMS 9D – 17

DAEWOO V–121 BL4

4. Disconnect the washer hose from the washer

pump.

5. Disconnect the reservoir pump electrical connector.

6. Remove the bolts and the reservoir.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the reservoir with the bolts.

Tighten

Tighten the washer fluid reservoir bolts to 8 NSm (71

lb–in).

2. Connect the reservoir pump electrical connector.

3. Connect the washer hose to the washer pump.

4. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the front wheel well splash shield bolts to 1.5

NSm (13 lb–in).

5. Install the front left wheel. Refer to Section 2E,

Tires and Wheels.

6. Connect the negative battery cable.

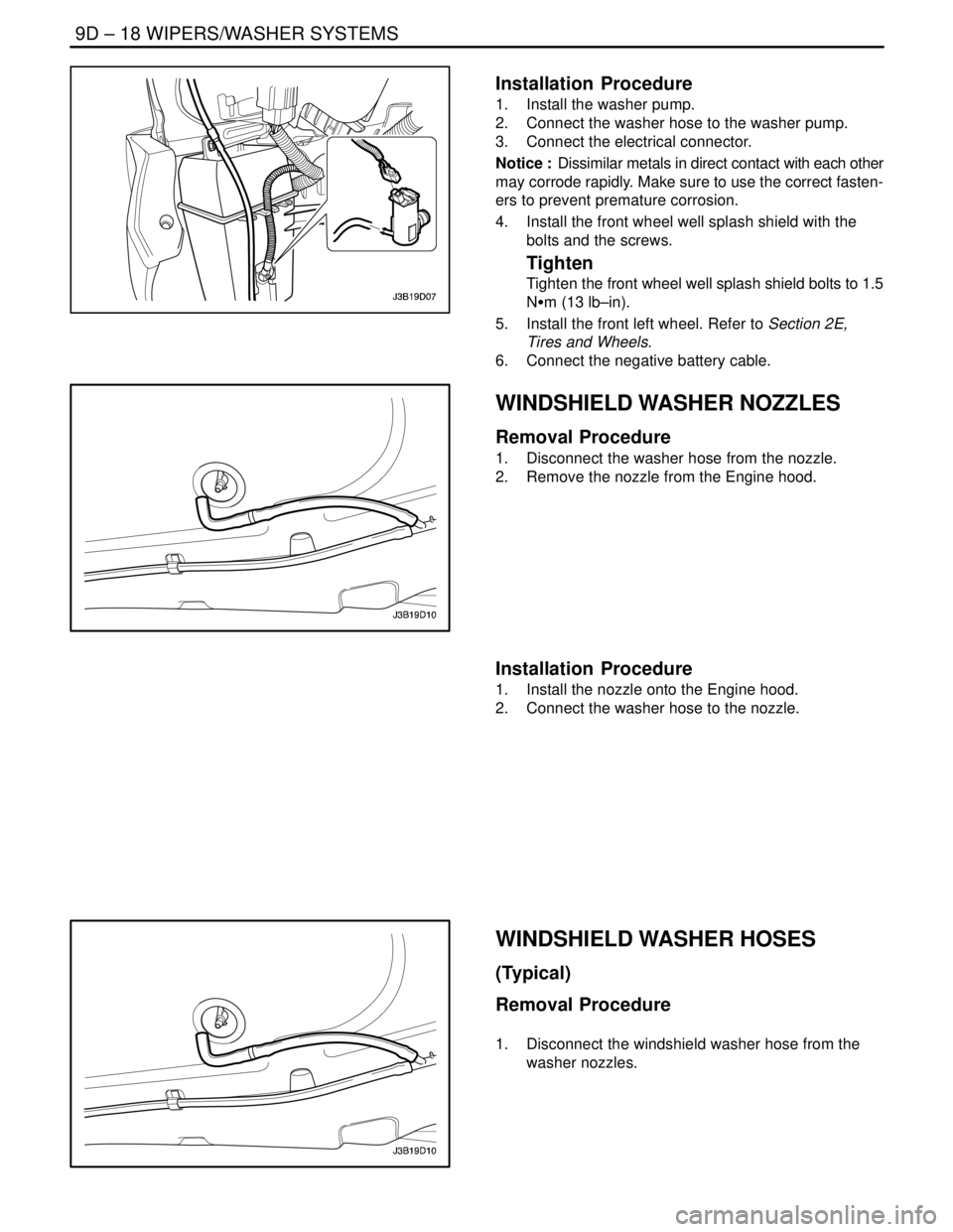

WINDSHIELD WASHER PUMP(S)

(Typical)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

3. Remove the bolts and the screws and the front

wheel well splash shield.

4. Disconnect the electrical connector.

5. Disconnect the washer hose from the washer

pump.

6. Remove the washer pump.

Page 2295 of 2643

9D – 18IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

Installation Procedure

1. Install the washer pump.

2. Connect the washer hose to the washer pump.

3. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

4. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the front wheel well splash shield bolts to 1.5

NSm (13 lb–in).

5. Install the front left wheel. Refer to Section 2E,

Tires and Wheels.

6. Connect the negative battery cable.

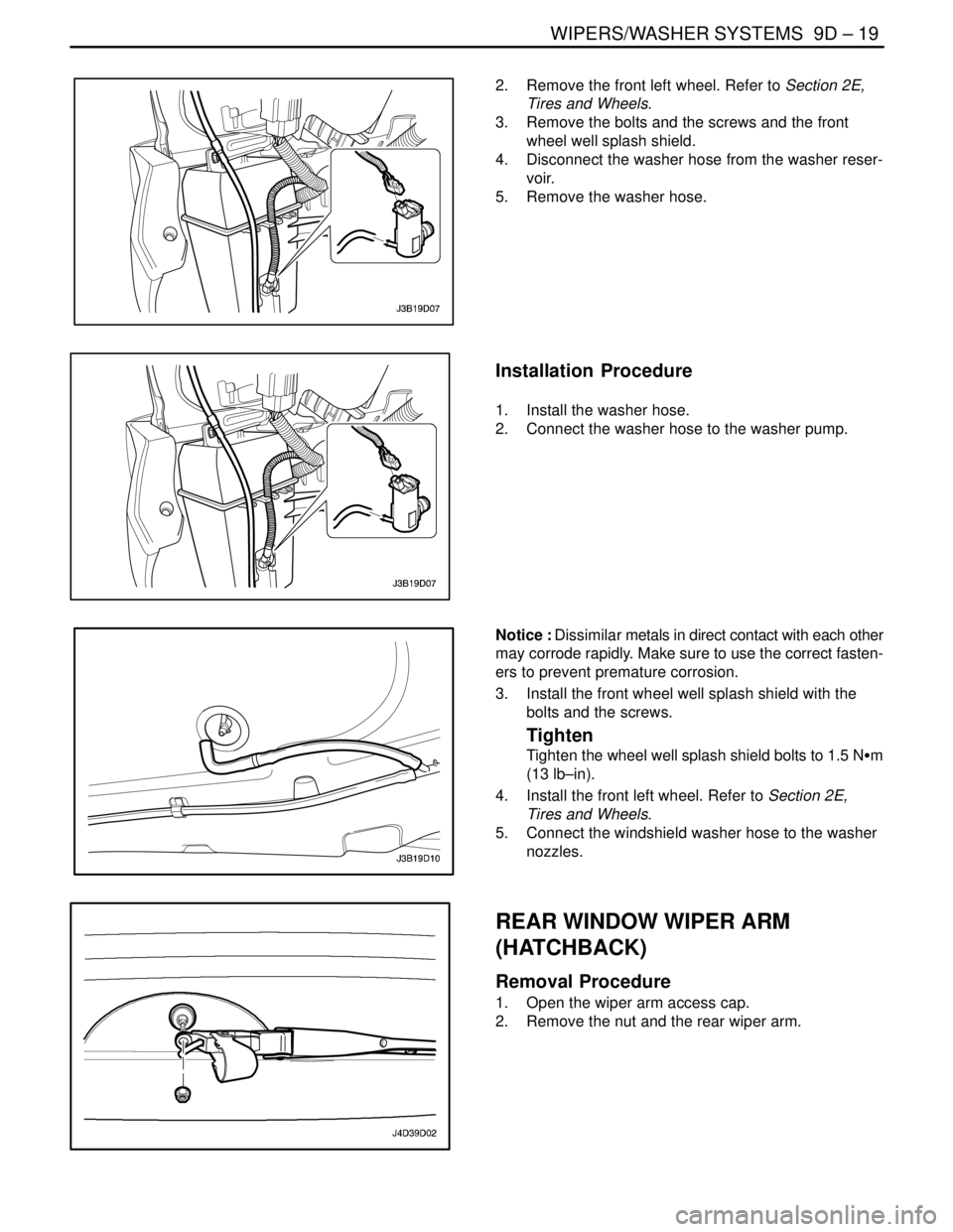

WINDSHIELD WASHER NOZZLES

Removal Procedure

1. Disconnect the washer hose from the nozzle.

2. Remove the nozzle from the Engine hood.

Installation Procedure

1. Install the nozzle onto the Engine hood.

2. Connect the washer hose to the nozzle.

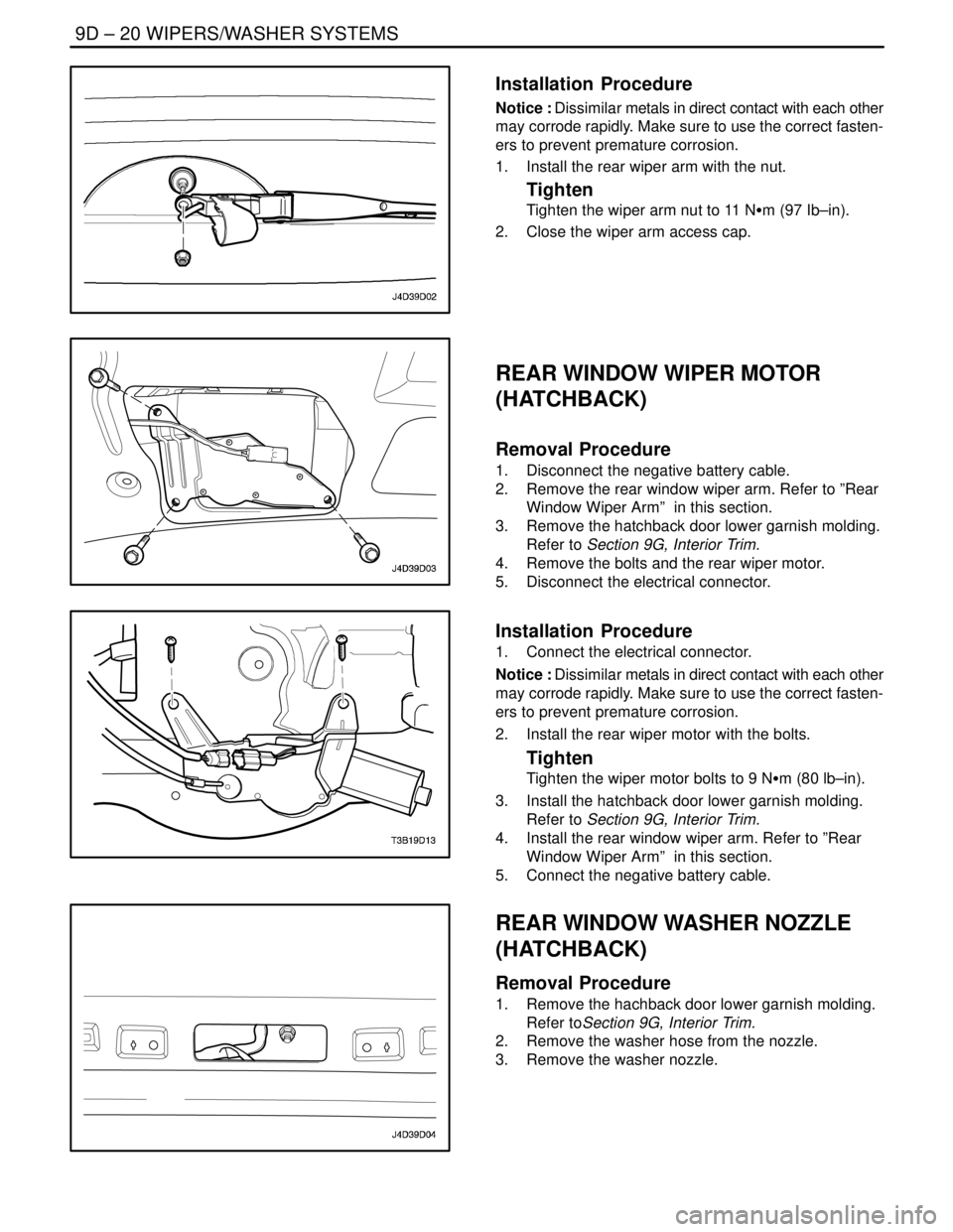

WINDSHIELD WASHER HOSES

(Typical)

Removal Procedure

1. Disconnect the windshield washer hose from the

washer nozzles.

Page 2296 of 2643

WIPERS/WASHER SYSTEMS 9D – 19

DAEWOO V–121 BL4

2. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

3. Remove the bolts and the screws and the front

wheel well splash shield.

4. Disconnect the washer hose from the washer reser-

voir.

5. Remove the washer hose.

Installation Procedure

1. Install the washer hose.

2. Connect the washer hose to the washer pump.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

3. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the wheel well splash shield bolts to 1.5 NSm

(13 lb–in).

4. Install the front left wheel. Refer to Section 2E,

Tires and Wheels.

5. Connect the windshield washer hose to the washer

nozzles.

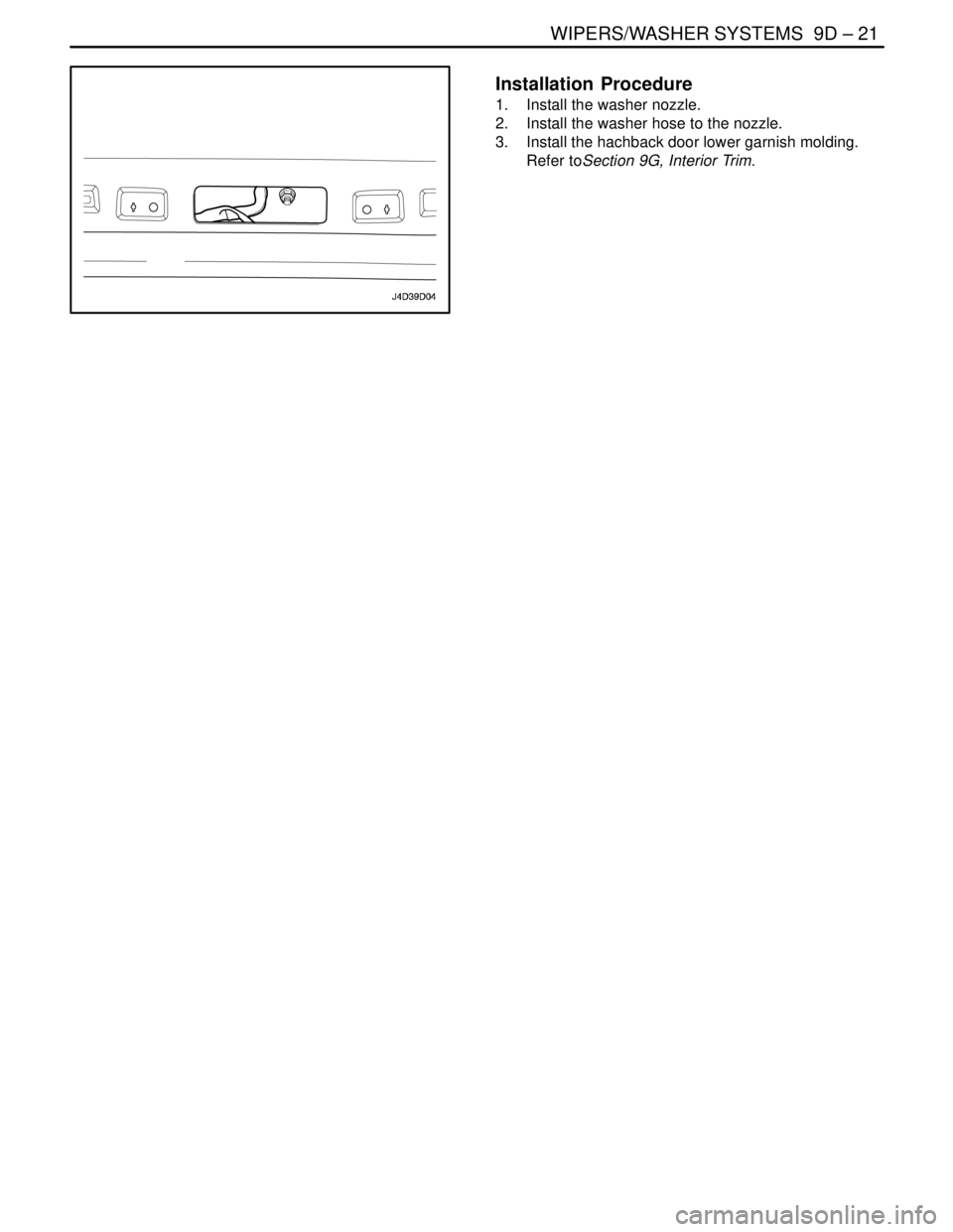

REAR WINDOW WIPER ARM

(HATCHBACK)

Removal Procedure

1. Open the wiper arm access cap.

2. Remove the nut and the rear wiper arm.

Page 2297 of 2643

9D – 20IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the rear wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 11 NSm (97 Ib–in).

2. Close the wiper arm access cap.

REAR WINDOW WIPER MOTOR

(HATCHBACK)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

3. Remove the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Remove the bolts and the rear wiper motor.

5. Disconnect the electrical connector.

Installation Procedure

1. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the rear wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 9 NSm (80 lb–in).

3. Install the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Install the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

5. Connect the negative battery cable.

REAR WINDOW WASHER NOZZLE

(HATCHBACK)

Removal Procedure

1. Remove the hachback door lower garnish molding.

Refer toSection 9G, Interior Trim.

2. Remove the washer hose from the nozzle.

3. Remove the washer nozzle.

Page 2298 of 2643

WIPERS/WASHER SYSTEMS 9D – 21

DAEWOO V–121 BL4

Installation Procedure

1. Install the washer nozzle.

2. Install the washer hose to the nozzle.

3. Install the hachback door lower garnish molding.

Refer toSection 9G, Interior Trim.

Page 2299 of 2643

9D – 22IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

WINDSHIELD WIPER SYSTEM

The windshield wiper system consists of a wiper motor, a

linkage, a wiper arm and a blade, and a wiper/washer

switch. The windshield wiper circuit incorporates a self–

parking device which consists of a worm gear and a cam

plate in order to keep the circuit engaged temporarily when

the switch is turned off. The wiper system is driven by a

permanent magnet–type motor. The windshield wiper mo-

tor is mounted on the dash panel and is directly connected

to the windshield wiper linkage.

The windshield wiper motor has two speeds, LO and HI,

and also has intermittent wiper capability. The wiper

switch is an integral part of the wiper/washer switch. Wind-

shield wiper operation is actuated through the lever on the

right side of the steering column.

WINDSHIELD WASHER SYSTEM

The windshield washer system is equipped with a washerfluid reservoir, a washer fluid pump, hoses, nozzles, and

a wiper/washer switch. The windshield washer reservoir

is mounted behind the front left wheel well splash shield.

Attached to the reservoir is a washer pump, which pumps

fluid through the hoses to the two nozzles mounted on the

hood. The washer switch is an integral part of the wiper/

washer switch. Windshield washer operation is actuated

through the lever on the right side of the steering column.

REAR WINDOW WIPER/WASHER

SYSTEM

The rear window wiper system consists of a wiper motor,

a wiper arm, and a blade. The rear window wiper motor is

located inside the hatchback/tailgate door and is directly

connected to the rear window wiper. The rear window

washer system is equipped with a separate washer fluid

pump and hose. The hatchback has a hatch–mounted

rear window washer nozzle and on the wagon, the washer

nozzle is incorporated into the rear wiper motor. The rear

window washer reservoir is mounted behind the front left

wheel well splash shield. Attached to the reservoir is a

washer pump, which pumps fluid through a hose to the

rear washer nozzle.

Page 2300 of 2643

SECTION : 9E

INSTRUMENTATION/DRIVER INFORMATION

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9E–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9E–2. . . . . . . . . . .

Instrument Cluster Indicator Lamps

Specifications 9E–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9E–3 . . . . .

Instrument Cluster Circuit (1 of 2) 9E–3. . . . . . . . . . . .

Instrument Cluster Circuit (2 of 2) 9E–4. . . . . . . . . . . .

Cigar Lighter And Extra Power Jack Circuit 9E–5. . . .

DIAGNOSIS9E–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigar Lighter 9E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Clock 9E–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Illumination 9E–9. . . . . . . . . . . . . . . .

Speedometer 9E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge 9E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Gauge 9E–11. . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–12. . . . . . . . .

Chime Module 9E–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chime Module 9E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9E–18 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9E–18. . . . . . . . . . . . . . . . . . . .

Center Molding 9E–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Trim Panel 9E–18. . . . . . . . . . . . . .

Garnish Molding 9E–19. . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray 9E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cigar Lighter 9E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glove Box 9E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notchback Deposit Box 9E–21. . . . . . . . . . . . . . . . . . . .

Notchback Digital Clock 9E–21. . . . . . . . . . . . . . . . . . .

Hatchback Digital Clock 9E–22. . . . . . . . . . . . . . . . . . .

Instrument Cluster 9E–23. . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Dimmer/Headlamp

Leveling Switch 9E–23. . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–24. . . . . . . . .

Instrument Panel 9E–24. . . . . . . . . . . . . . . . . . . . . . . . .

Chime Module 9E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9E–30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigar Lighter 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Vents 9E–30. . . . . . . . . . . . . . . . . . . .

Glove Box 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Clock 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster 9E–30. . . . . . . . . . . . . . . . . . . . . . . .

Speedometer/Odometer/Trip Odometer 9E–30. . . . . .

Fuel Gauge 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Gauge 9E–30. . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–30. . . . . . . . .

Chime Module 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .