DAEWOO LACETTI 2004 Service Repair Manual

LACETTI 2004

DAEWOO

DAEWOO

https://www.carmanualsonline.info/img/54/56877/w960_56877-0.png

DAEWOO LACETTI 2004 Service Repair Manual

Trending: oxygen sensor, air suspension, manual transaxle oil, door lock, panel cluster warning light, fuel, Steering gear

Page 2511 of 2643

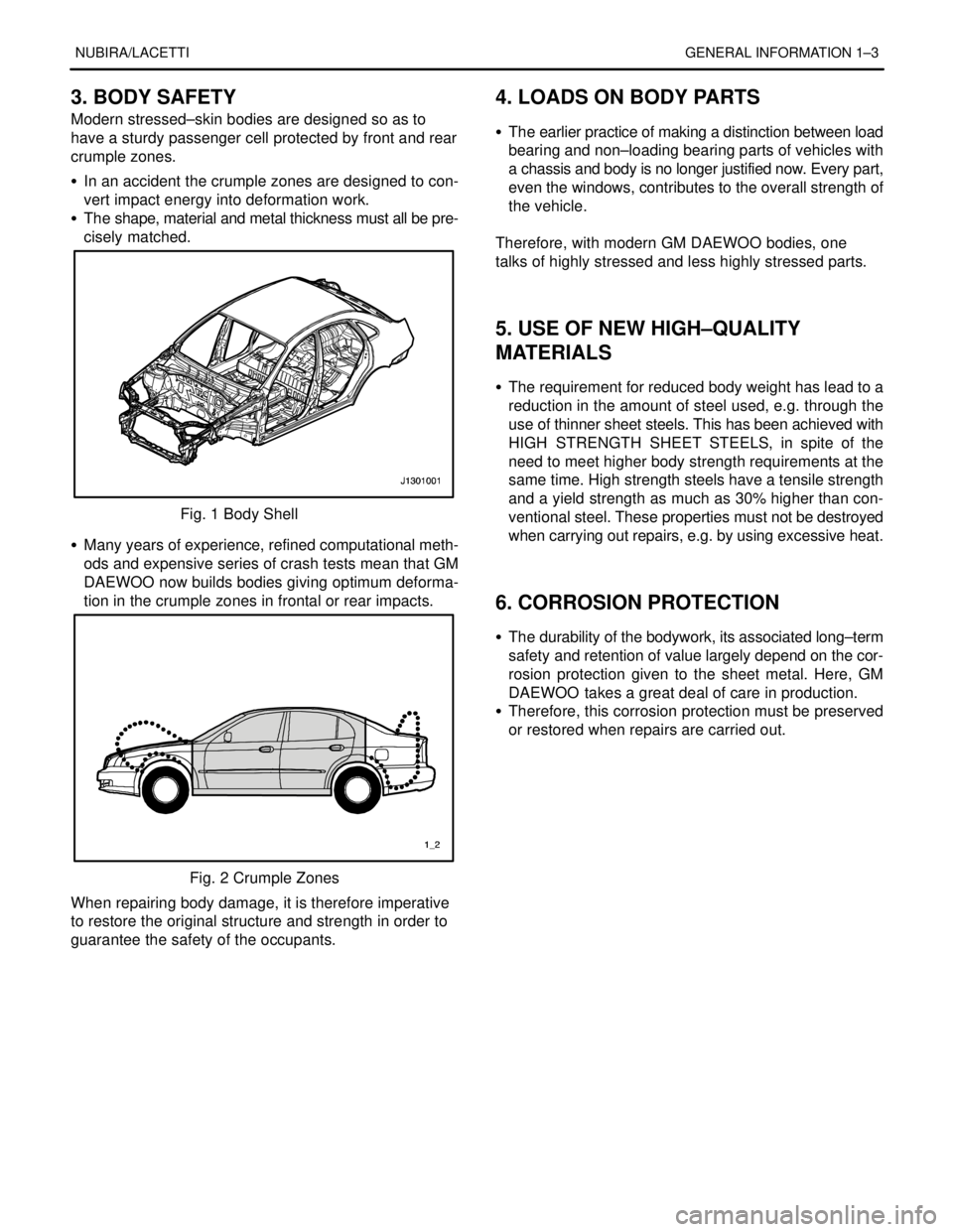

NUBIRA/LACETTIGENERAL INFORMATION 1–3

3. BODY SAFETY

Modern stressed–skin bodies are designed so as to

have a sturdy passenger cell protected by front and rear

crumple zones.

S In an accident the crumple zones are designed to con-

vert impact energy into deformation work.

S The shape, material and metal thickness must all be pre-

cisely matched.

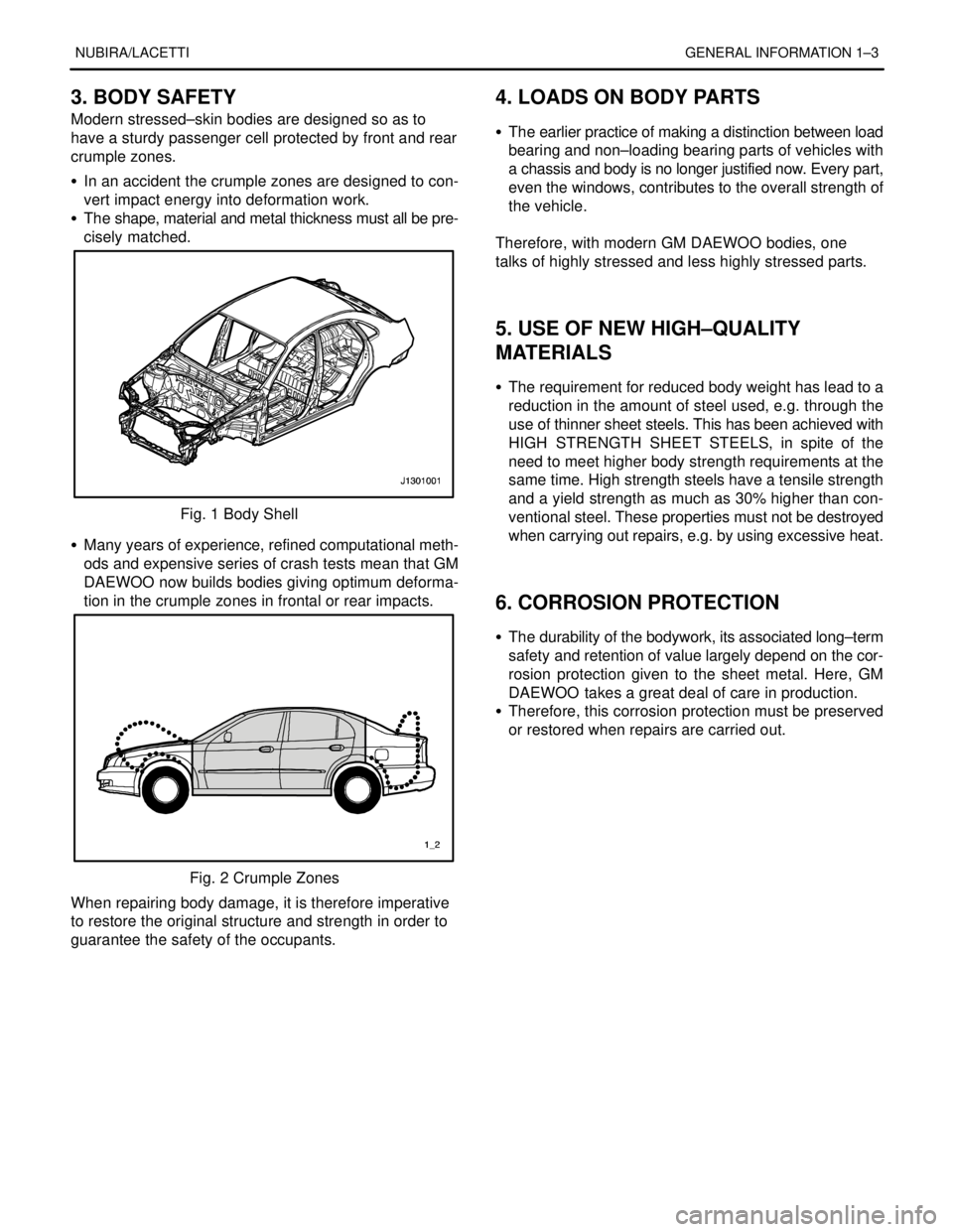

Fig. 1 Body Shell

S Many years of experience, refined computational meth-

ods and expensive series of crash tests mean that GM

DAEWOO now builds bodies giving optimum deforma-

tion in the crumple zones in frontal or rear impacts.

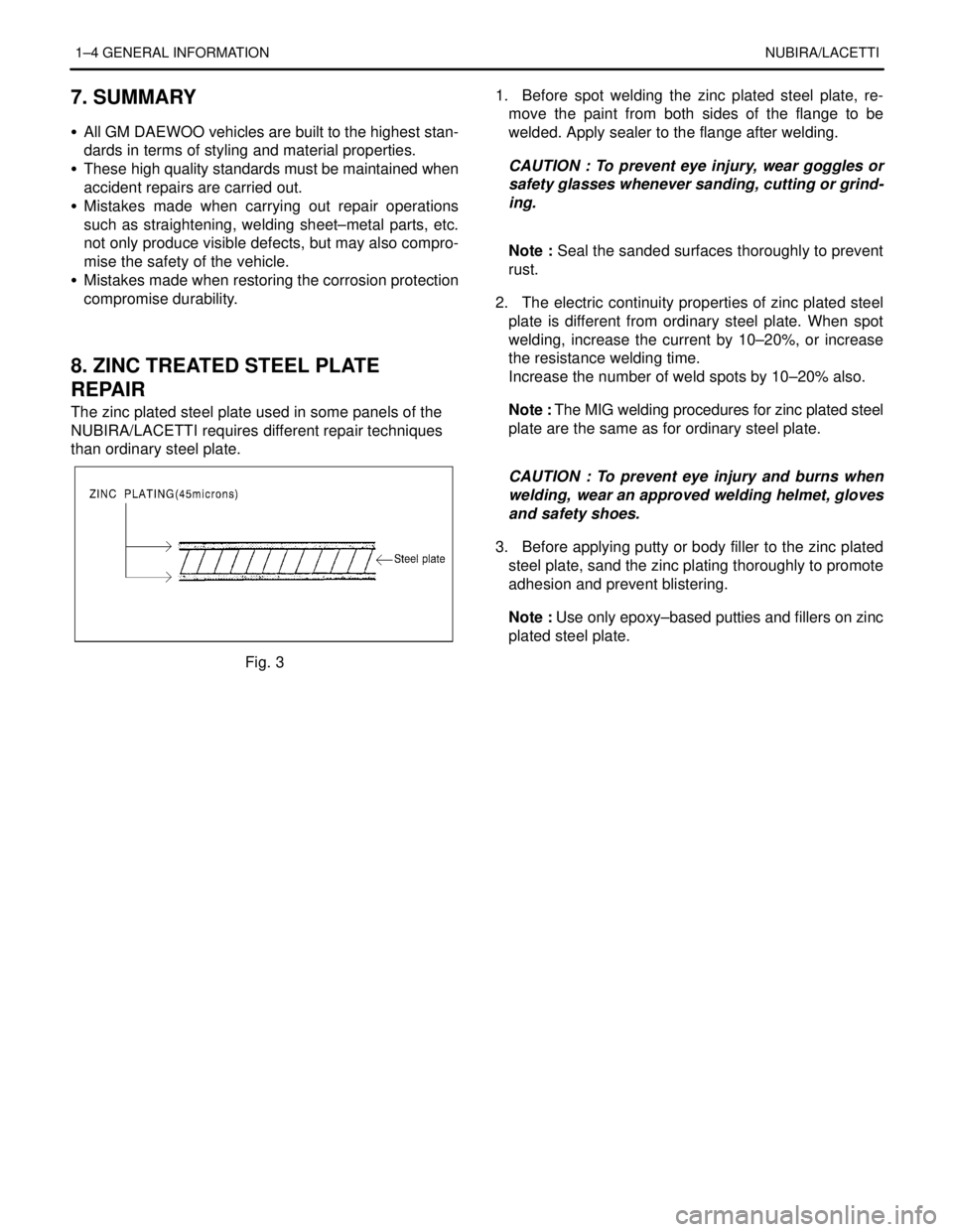

Fig. 2 Crumple Zones

When repairing body damage, it is therefore imperative

to restore the original structure and strength in order to

guarantee the safety of the occupants.

4. LOADS ON BODY PARTS

S The earlier practice of making a distinction between load

bearing and non–loading bearing parts of vehicles with

a chassis and body is no longer justified now. Every part,

even the windows, contributes to the overall strength of

the vehicle.

.

Therefore, with modern GM DAEWOO bodies, one

talks of highly stressed and less highly stressed parts.

.

.

5. USE OF NEW HIGH–QUALITY

MATERIALS

S The requirement for reduced body weight has lead to a

reduction in the amount of steel used, e.g. through the

use of thinner sheet steels. This has been achieved with

HIGH STRENGTH SHEET STEELS, in spite of the

need to meet higher body strength requirements at the

same time. High strength steels have a tensile strength

and a yield strength as much as 30% higher than con-

ventional steel. These properties must not be destroyed

when carrying out repairs, e.g. by using excessive heat.

.

.

6. CORROSION PROTECTION

S The durability of the bodywork, its associated long–term

safety and retention of value largely depend on the cor-

rosion protection given to the sheet metal. Here, GM

DAEWOO takes a great deal of care in production.

S Therefore, this corrosion protection must be preserved

or restored when repairs are carried out.

Page 2512 of 2643

1–4 GENERAL INFORMATIONNUBIRA/LACETTI

7. SUMMARY

S All GM DAEWOO vehicles are built to the highest stan-

dards in terms of styling and material properties.

S These high quality standards must be maintained when

accident repairs are carried out.

S Mistakes made when carrying out repair operations

such as straightening, welding sheet–metal parts, etc.

not only produce visible defects, but may also compro-

mise the safety of the vehicle.

S Mistakes made when restoring the corrosion protection

compromise durability.

.

.

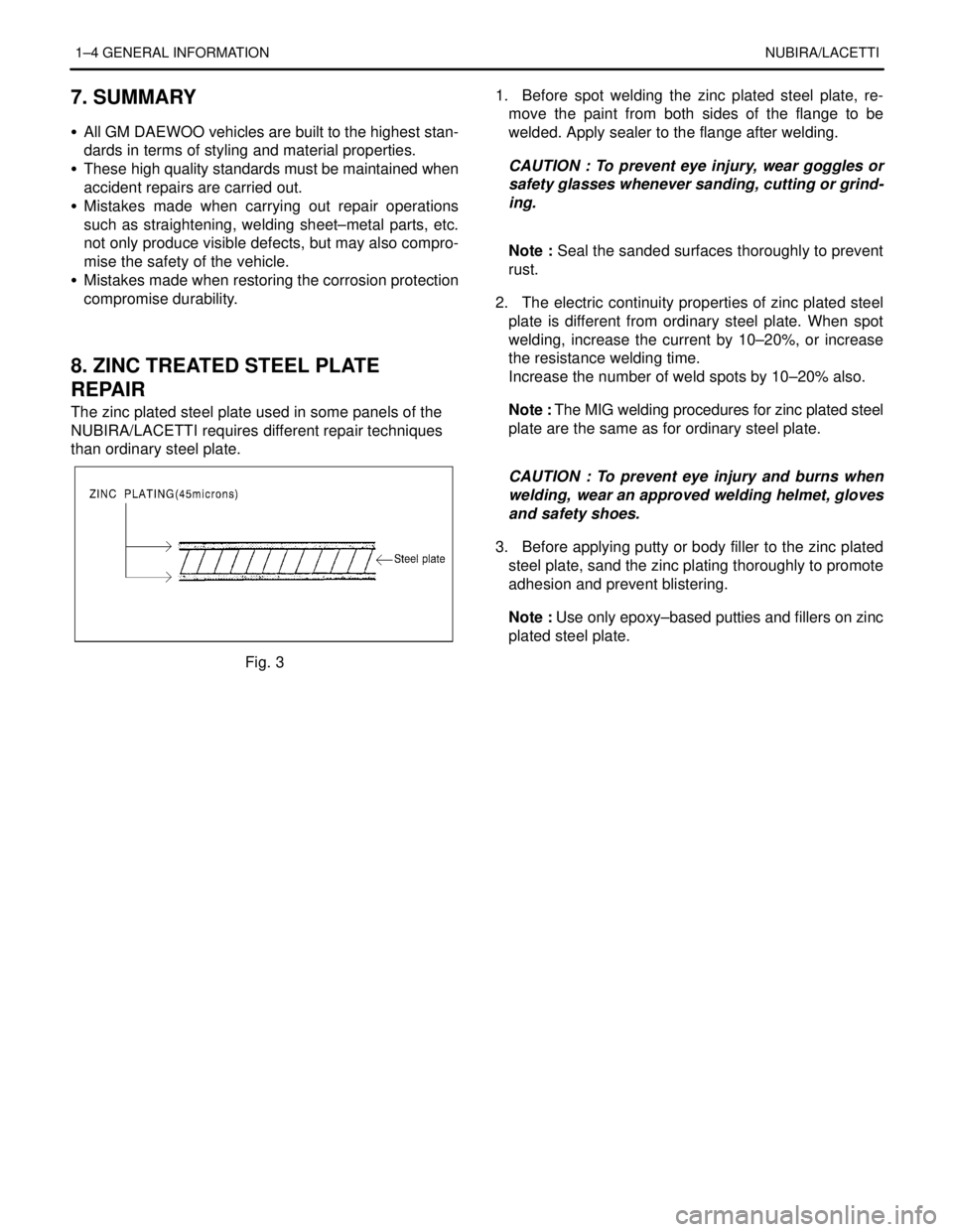

8. ZINC TREATED STEEL PLATE

REPAIR

The zinc plated steel plate used in some panels of the

NUBIRA/LACETTI requires different repair techniques

than ordinary steel plate.

Fig. 31. Before spot welding the zinc plated steel plate, re-

move the paint from both sides of the flange to be

welded. Apply sealer to the flange after welding.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting or grind-

ing.

Note : Seal the sanded surfaces thoroughly to prevent

rust.

2. The electric continuity properties of zinc plated steel

plate is different from ordinary steel plate. When spot

welding, increase the current by 10–20%, or increase

the resistance welding time.

Increase the number of weld spots by 10–20% also.

Note : The MIG welding procedures for zinc plated steel

plate are the same as for ordinary steel plate.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

3. Before applying putty or body filler to the zinc plated

steel plate, sand the zinc plating thoroughly to promote

adhesion and prevent blistering.

Note : Use only epoxy–based putties and fillers on zinc

plated steel plate.

Page 2513 of 2643

NUBIRA/LACETTIGENERAL INFORMATION 1–5

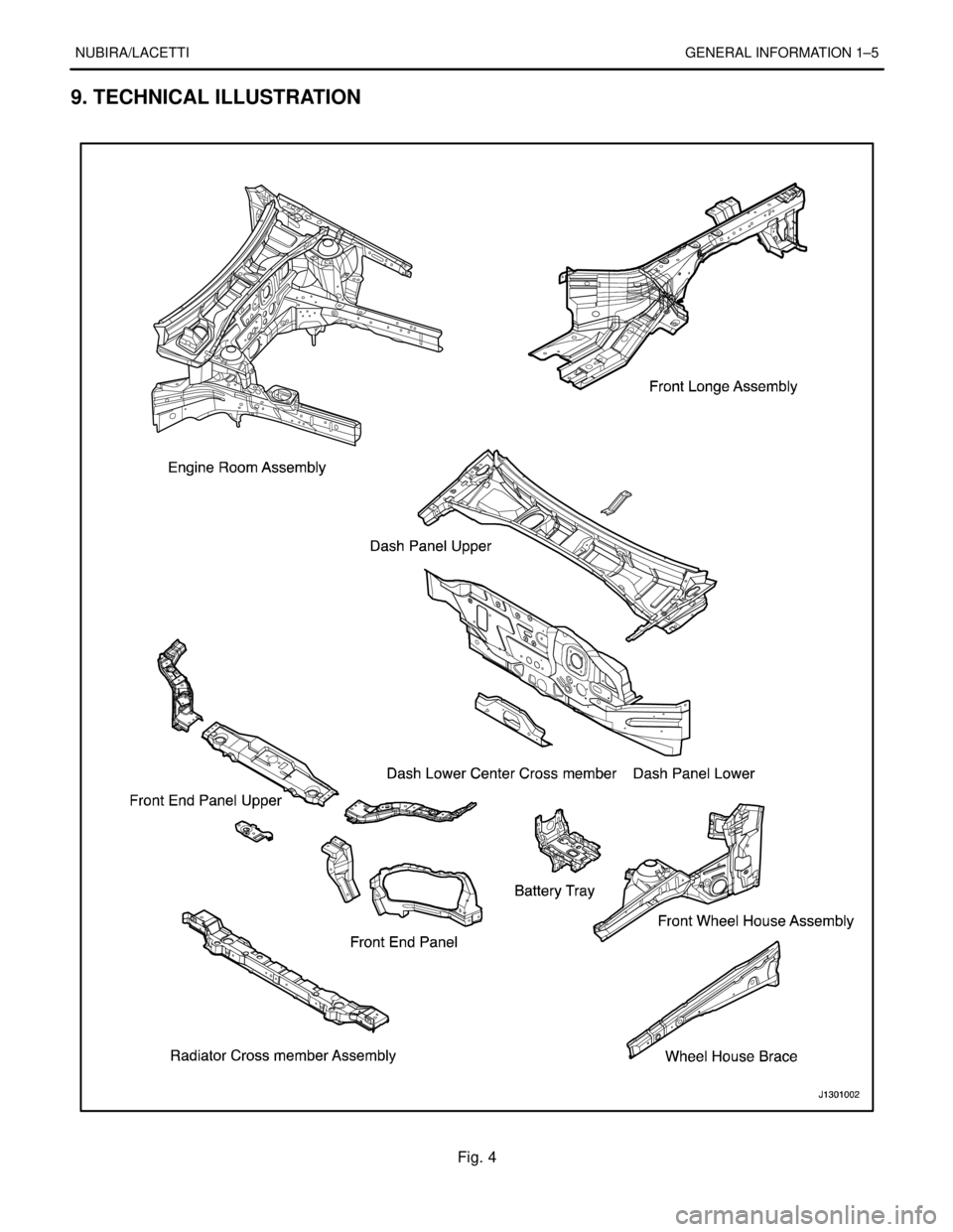

9. TECHNICAL ILLUSTRATION

Fig. 4

Page 2514 of 2643

1–6 GENERAL INFORMATIONNUBIRA/LACETTI

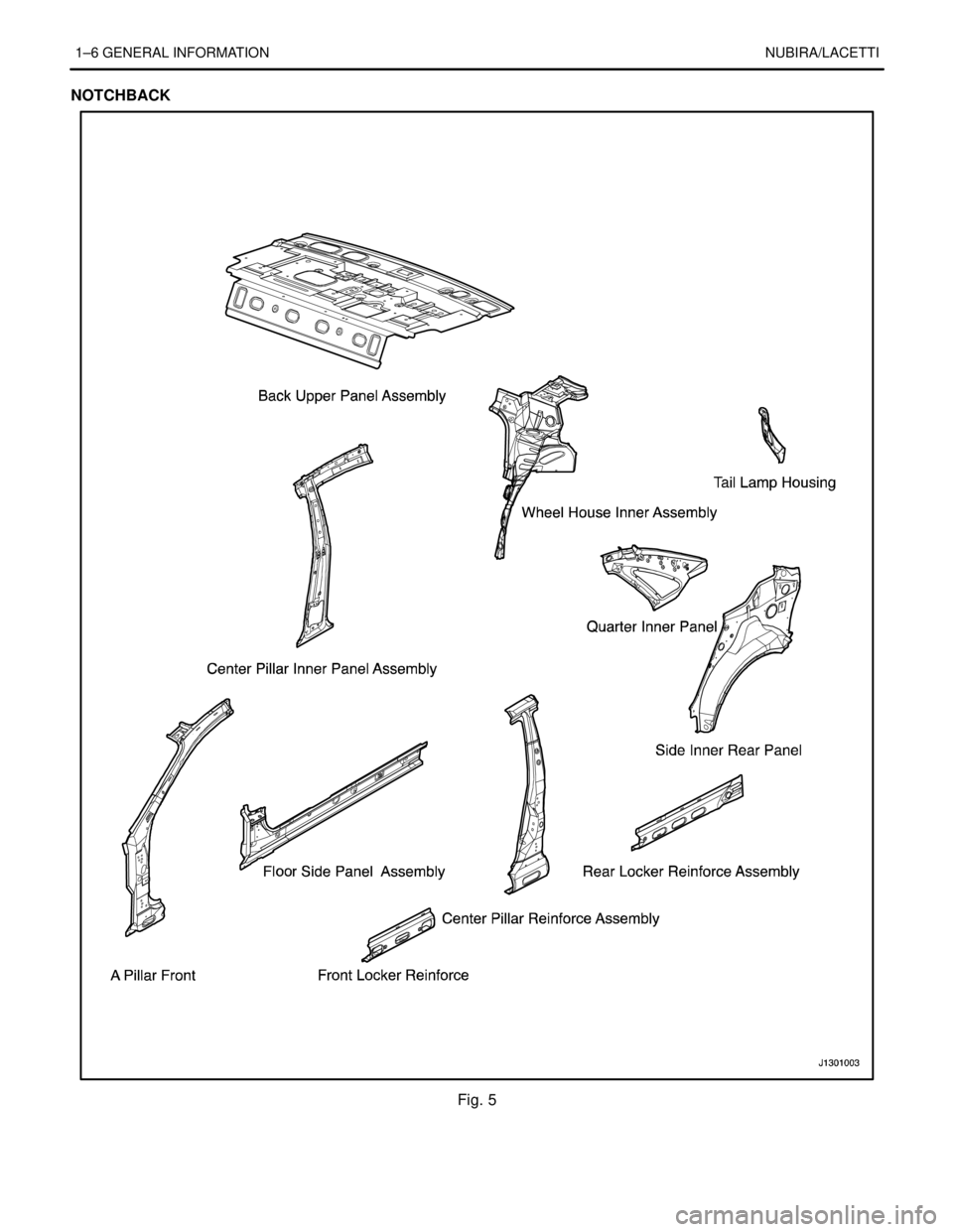

NOTCHBACK

Fig. 5

Page 2515 of 2643

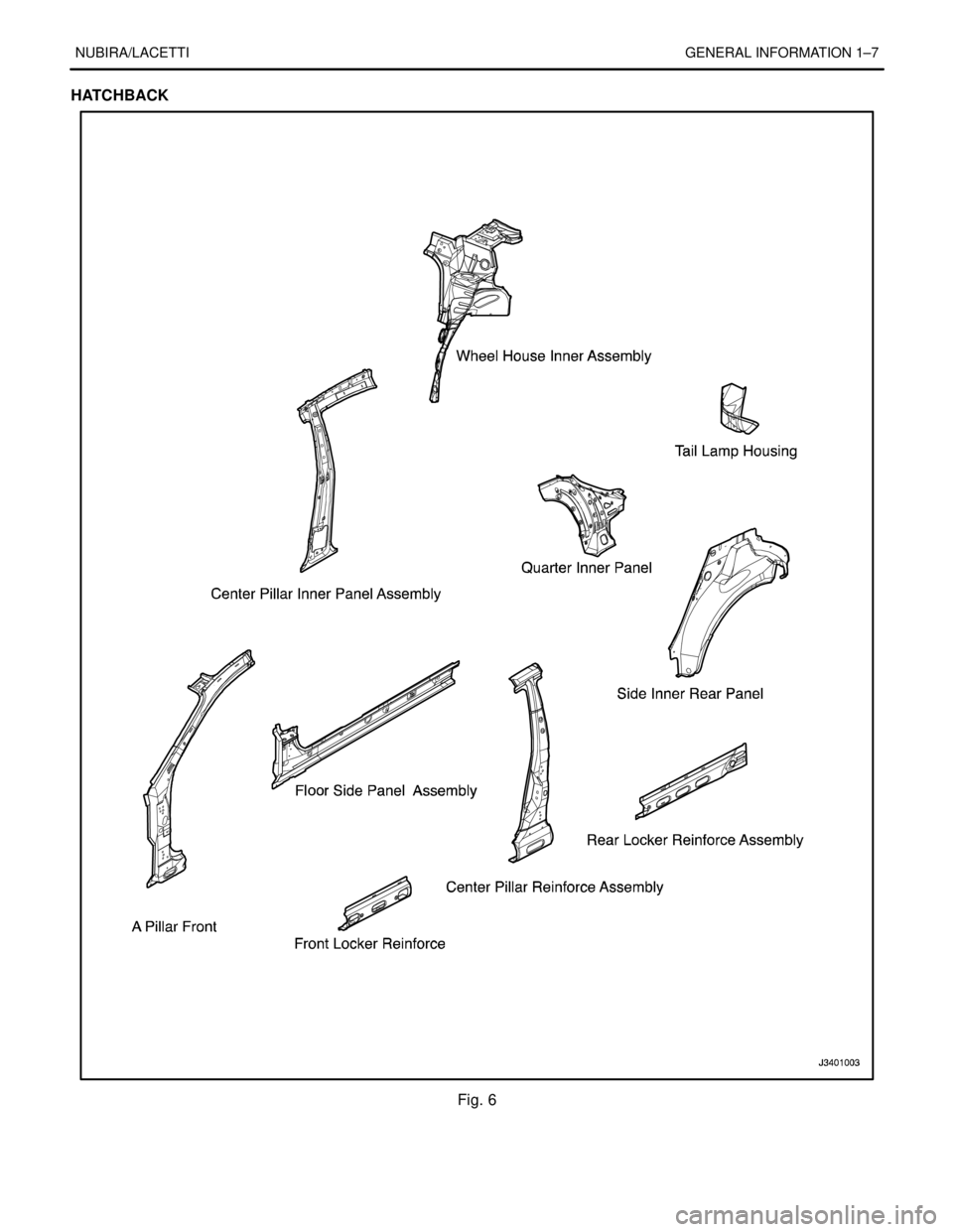

NUBIRA/LACETTIGENERAL INFORMATION 1–7

HATCHBACK

Fig. 6

Page 2516 of 2643

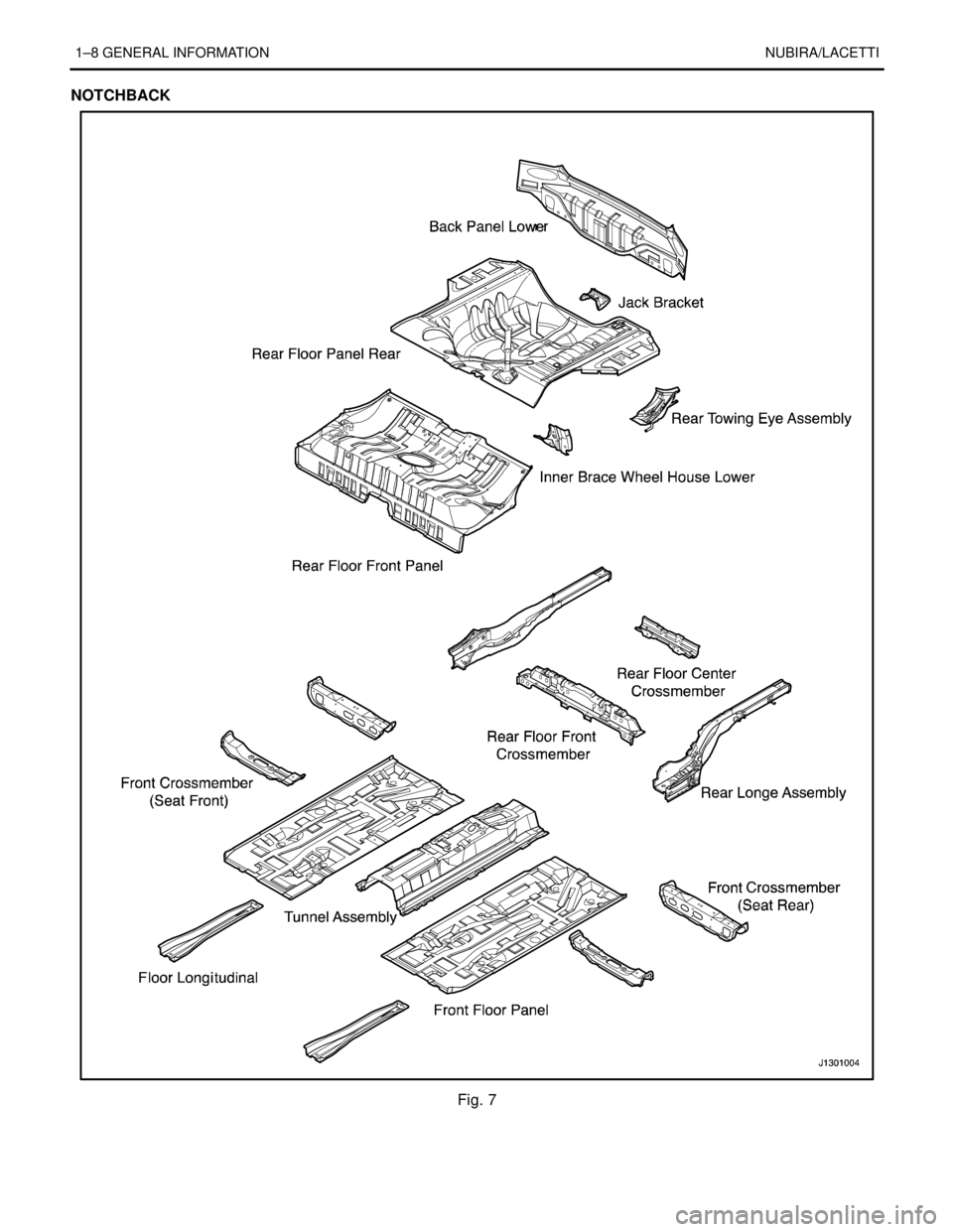

1–8 GENERAL INFORMATIONNUBIRA/LACETTI

NOTCHBACK

Fig. 7

Page 2517 of 2643

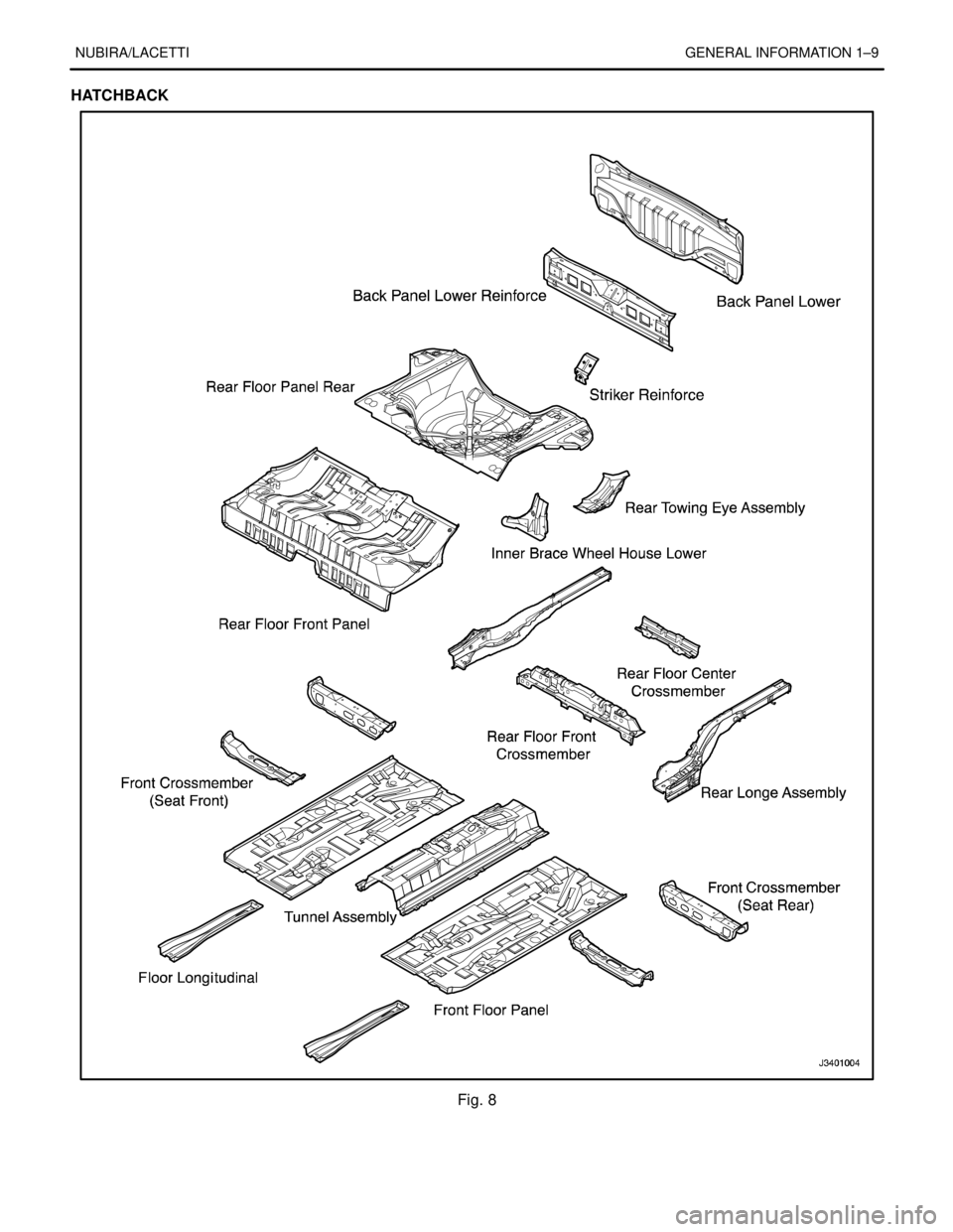

NUBIRA/LACETTIGENERAL INFORMATION 1–9

HATCHBACK

Fig. 8

Page 2518 of 2643

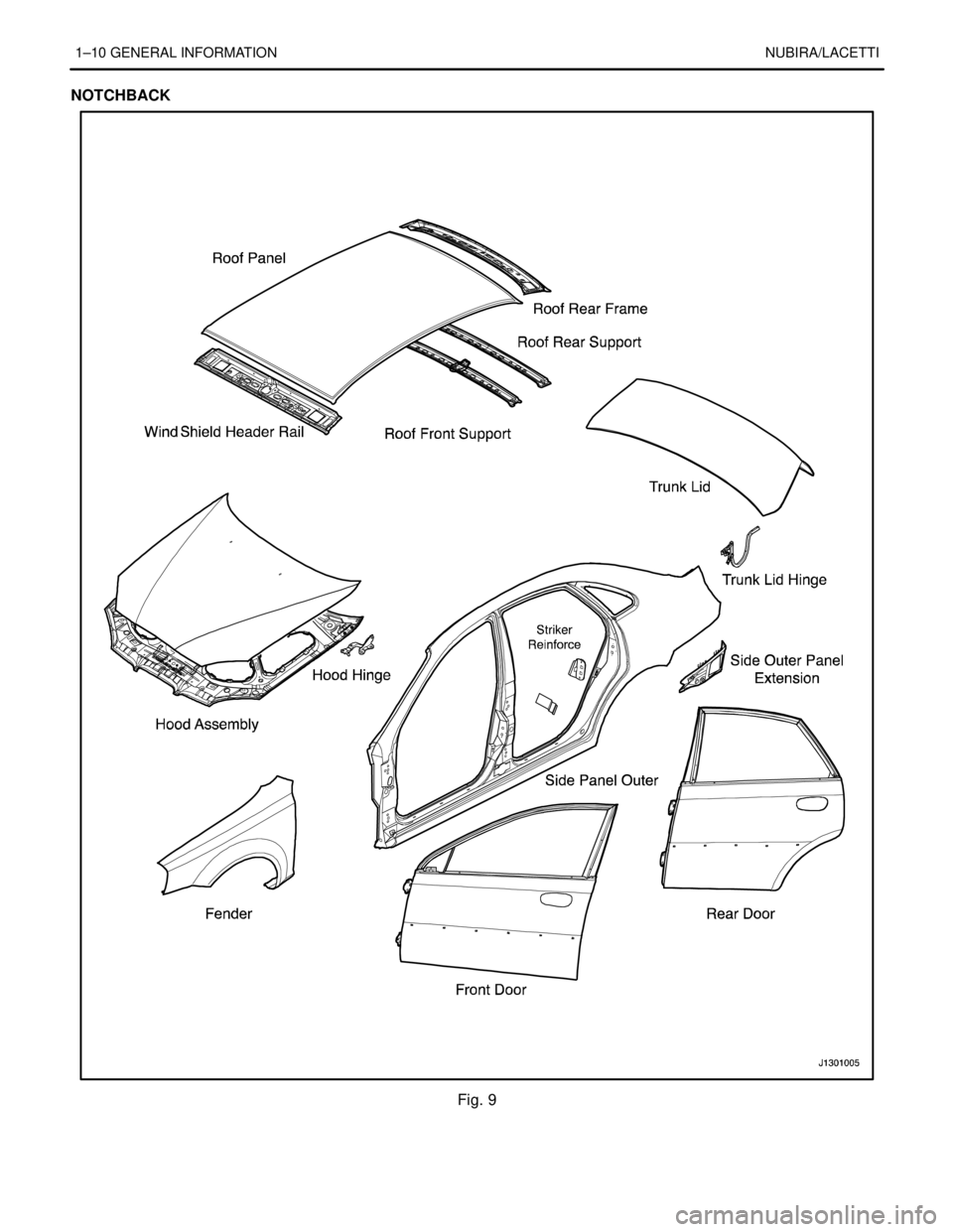

1–10 GENERAL INFORMATIONNUBIRA/LACETTI

NOTCHBACK

Fig. 9

Page 2519 of 2643

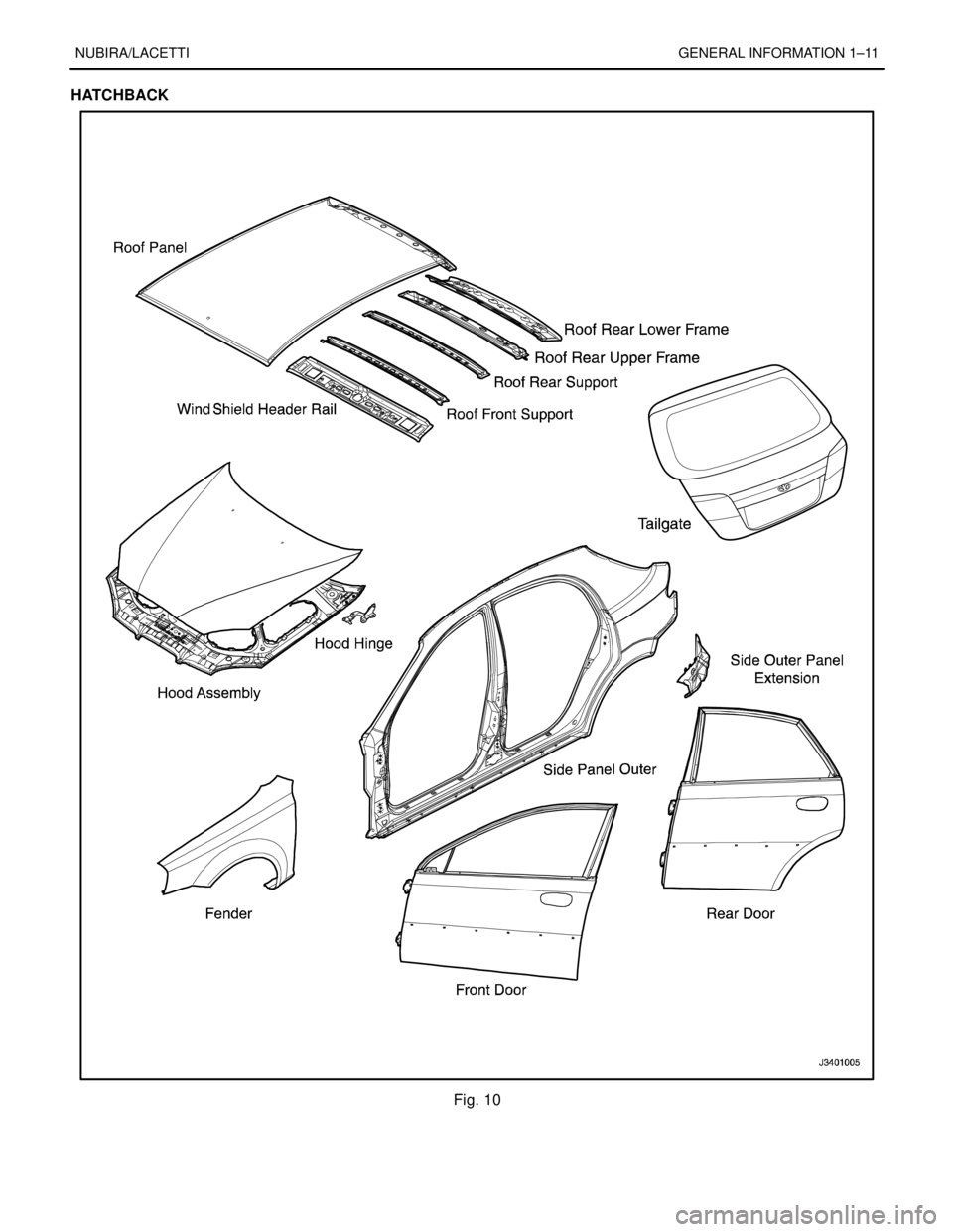

NUBIRA/LACETTIGENERAL INFORMATION 1–11

HATCHBACK

Fig. 10

Page 2520 of 2643

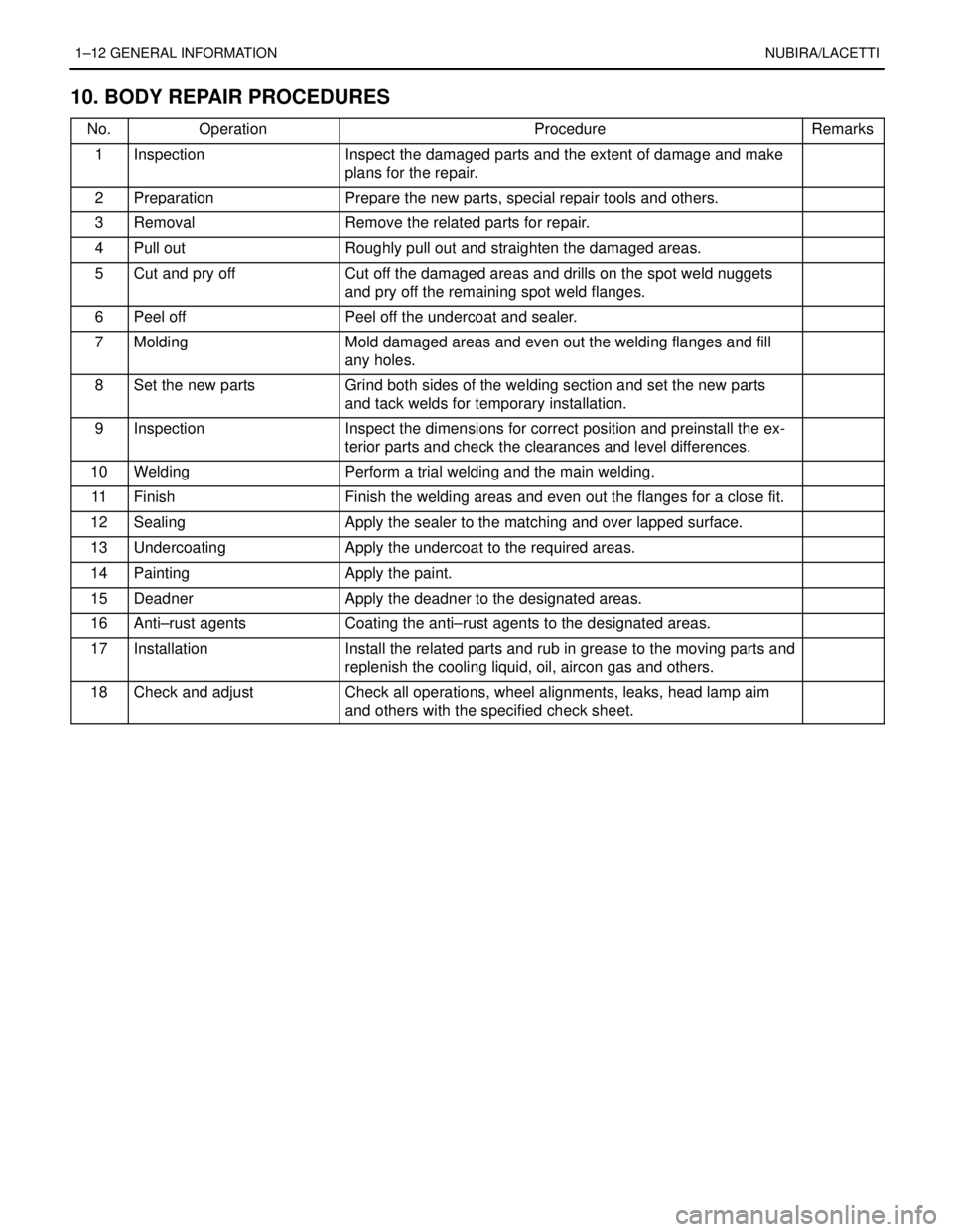

1–12 GENERAL INFORMATIONNUBIRA/LACETTI

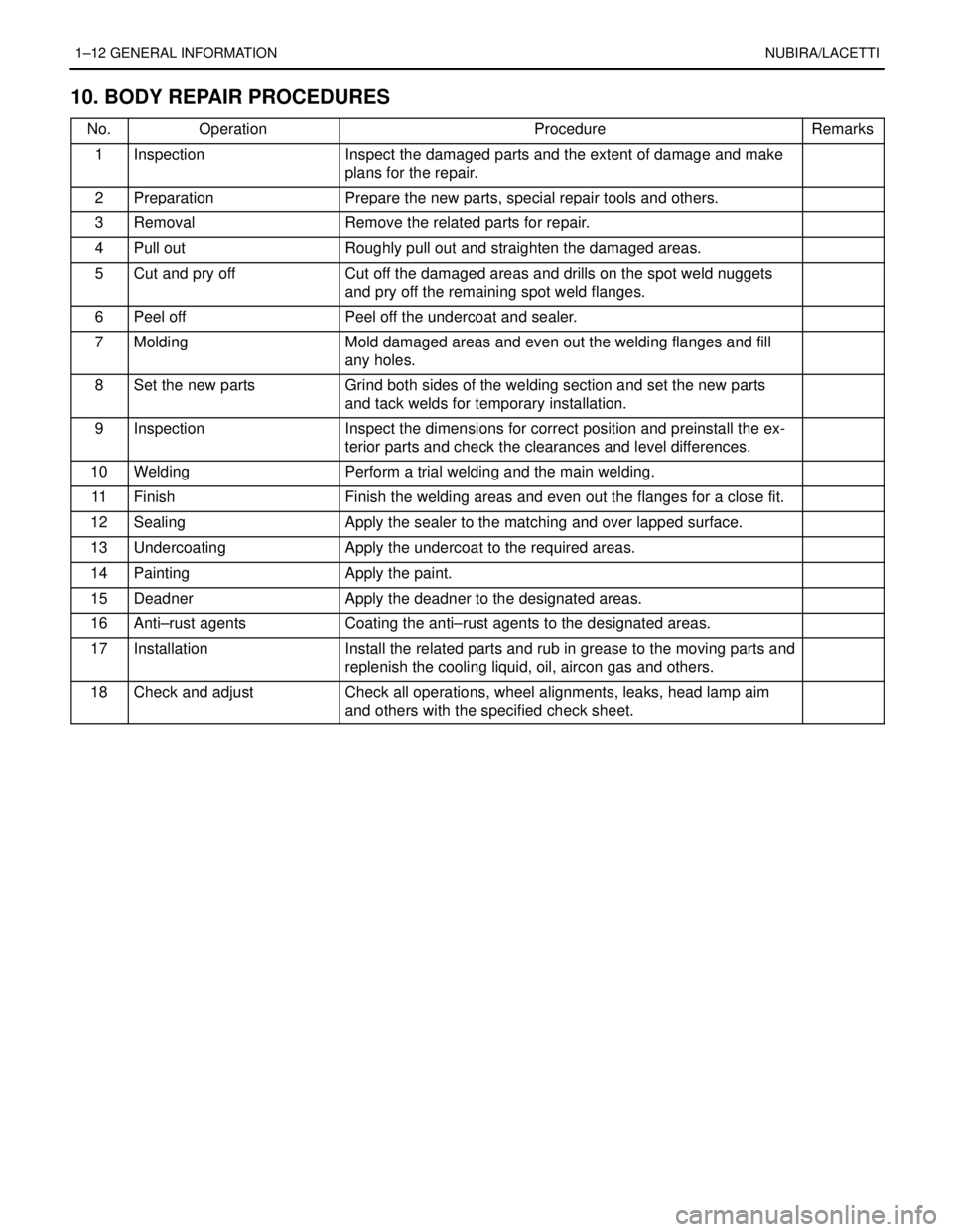

10. BODY REPAIR PROCEDURES

No.OperationProcedureRemarks

1InspectionInspect the damaged parts and the extent of damage and make

plans for the repair..

2PreparationPrepare the new parts, special repair tools and others..

3RemovalRemove the related parts for repair..

4Pull outRoughly pull out and straighten the damaged areas..

5Cut and pry offCut off the damaged areas and drills on the spot weld nuggets

and pry off the remaining spot weld flanges..

6Peel offPeel off the undercoat and sealer..

7MoldingMold damaged areas and even out the welding flanges and fill

any holes..

8Set the new partsGrind both sides of the welding section and set the new parts

and tack welds for temporary installation..

9InspectionInspect the dimensions for correct position and preinstall the ex-

terior parts and check the clearances and level differences..

10WeldingPerform a trial welding and the main welding..

11FinishFinish the welding areas and even out the flanges for a close fit..

12SealingApply the sealer to the matching and over lapped surface..

13UndercoatingApply the undercoat to the required areas..

14PaintingApply the paint..

15DeadnerApply the deadner to the designated areas..

16Anti–rust agentsCoating the anti–rust agents to the designated areas..

17InstallationInstall the related parts and rub in grease to the moving parts and

replenish the cooling liquid, oil, aircon gas and others..

18Check and adjustCheck all operations, wheel alignments, leaks, head lamp aim

and others with the specified check sheet..

Trending: window motor, mirror controls, Gear, mirror, lock, wheel, interior fuse box