DAEWOO LACETTI 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2531 of 2643

NUBIRA/LACETTIWELDING AND TOOLS 3–5

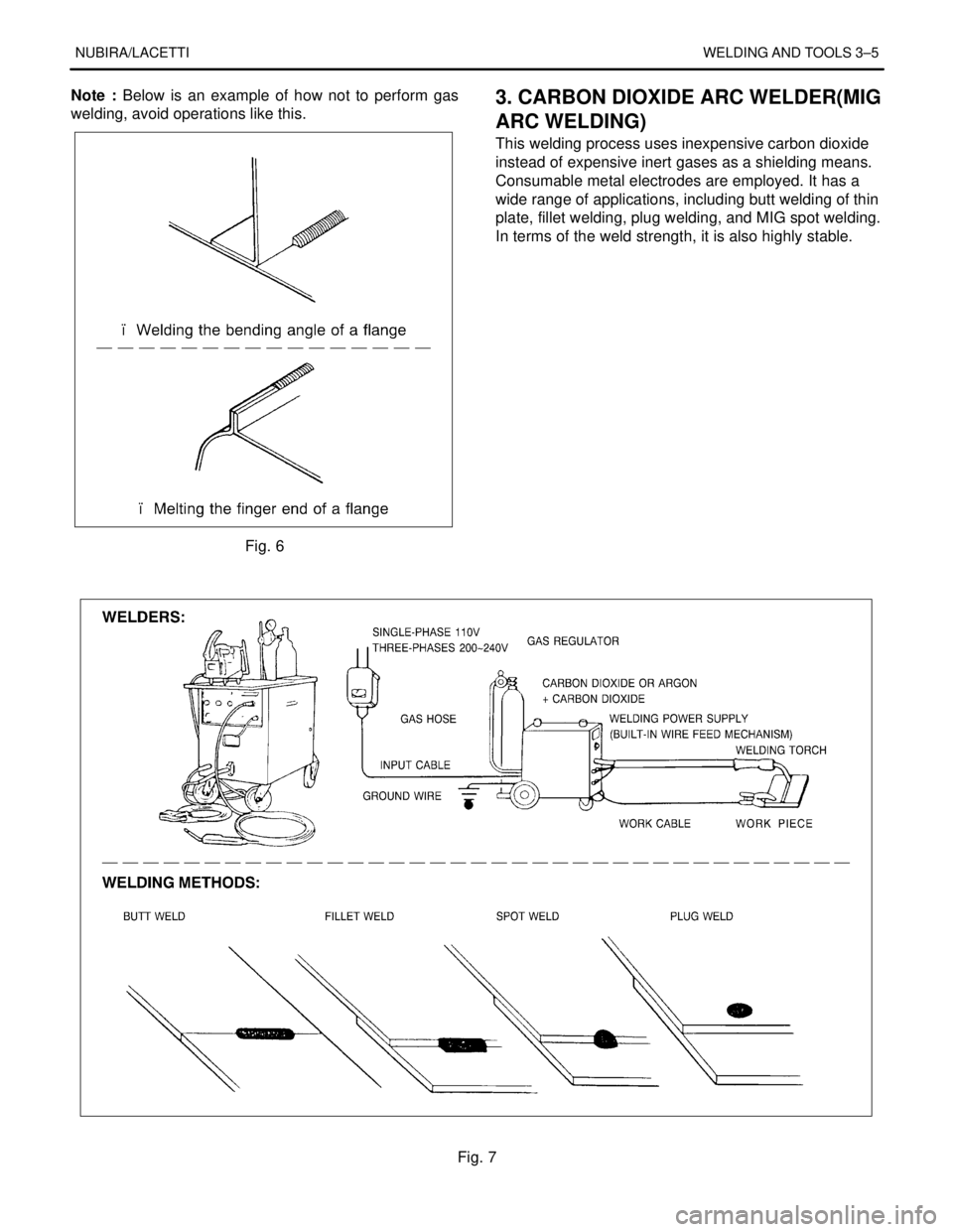

Note : Below is an example of how not to perform gas

welding, avoid operations like this.

Fig. 6

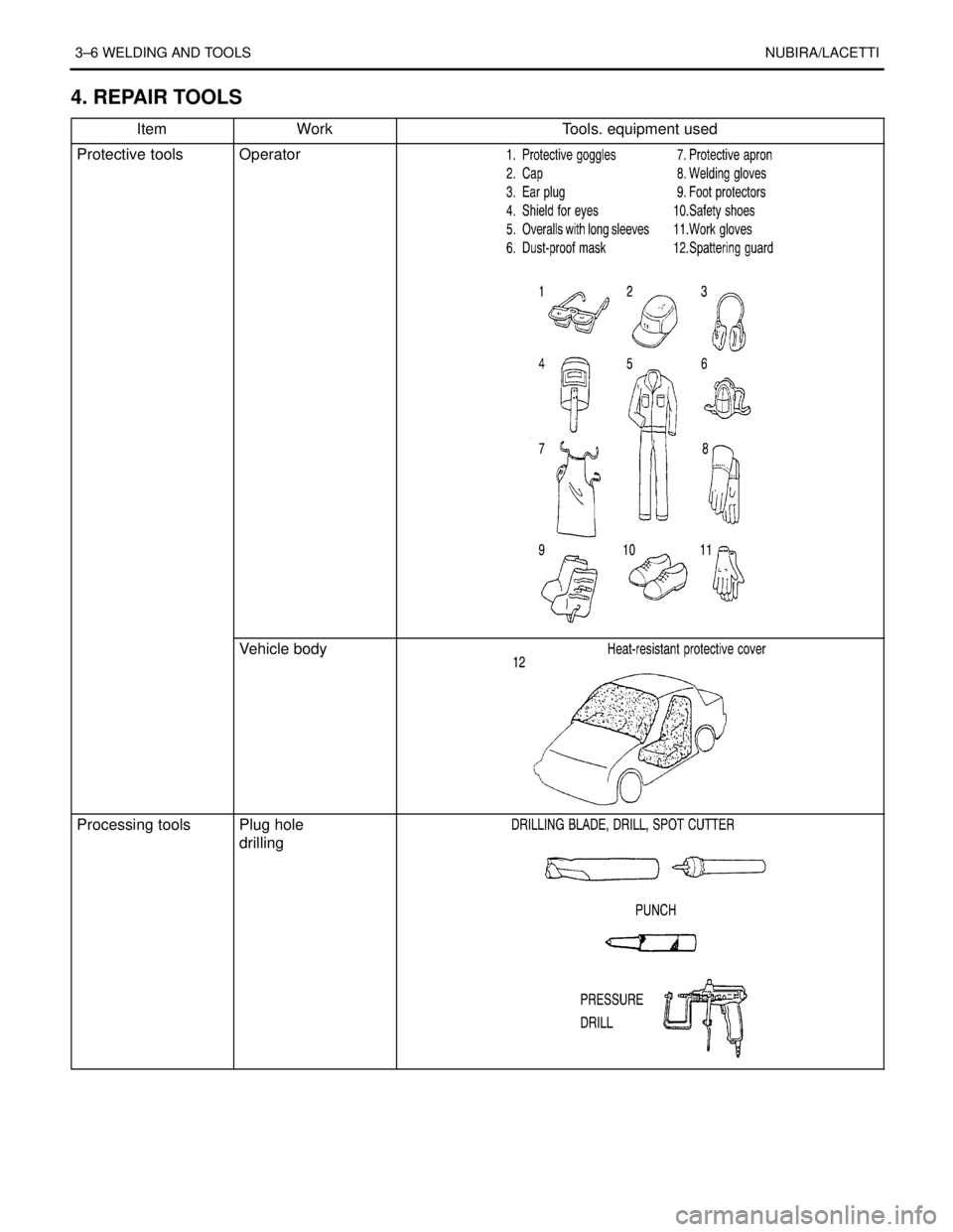

3. CARBON DIOXIDE ARC WELDER(MIG

ARC WELDING)

This welding process uses inexpensive carbon dioxide

instead of expensive inert gases as a shielding means.

Consumable metal electrodes are employed. It has a

wide range of applications, including butt welding of thin

plate, fillet welding, plug welding, and MIG spot welding.

In terms of the weld strength, it is also highly stable.

Fig. 7

Page 2532 of 2643

3–6 WELDING AND TOOLSNUBIRA/LACETTI

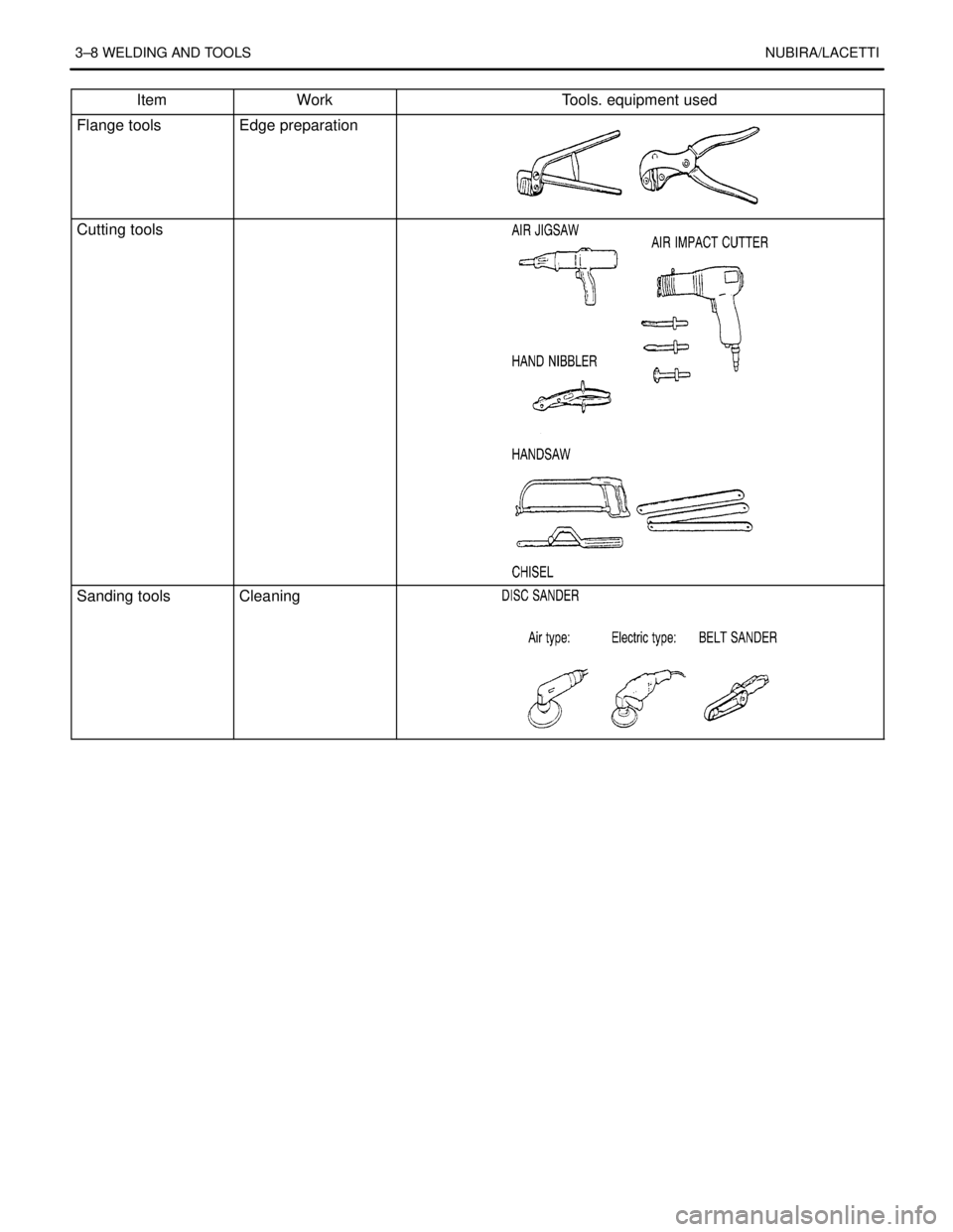

4. REPAIR TOOLS

ItemWorkTools. equipment used

Protective toolsOperator

Vehicle body

Processing toolsPlug hole

drilling

Page 2533 of 2643

NUBIRA/LACETTIWELDING AND TOOLS 3–7

Item Tools. equipment usedWork

Fixing toolsBase metal fixing

Shaping toolsSkin panel shaping

Body, frame shaping

Measuring toolsMeasuring

Page 2534 of 2643

3–8 WELDING AND TOOLSNUBIRA/LACETTI

Item Tools. equipment usedWork

Flange toolsEdge preparation

Cutting tools.

Sanding toolsCleaning

Page 2535 of 2643

NUBIRA/LACETTIFRONT 4–1

SECTION 4

FRONT

CONTENTS

1. FRONT PANEL 4 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.GENERAL DESCRIPTION4–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.REPAIR PROCEDURE4–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. FRONT WHEELHOUSE 4 – 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.GENERAL DESCRIPTION4–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.REPAIR PROCEDURE4–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. FRONT LONGITUDINAL 4 – 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.GENERAL DESCRIPTION4–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.REPAIR PROCEDURE4–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. FRONT PILLAR 4 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.GENERAL DESCRIPTION4–14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.REPAIR PROCEDURE4–15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2536 of 2643

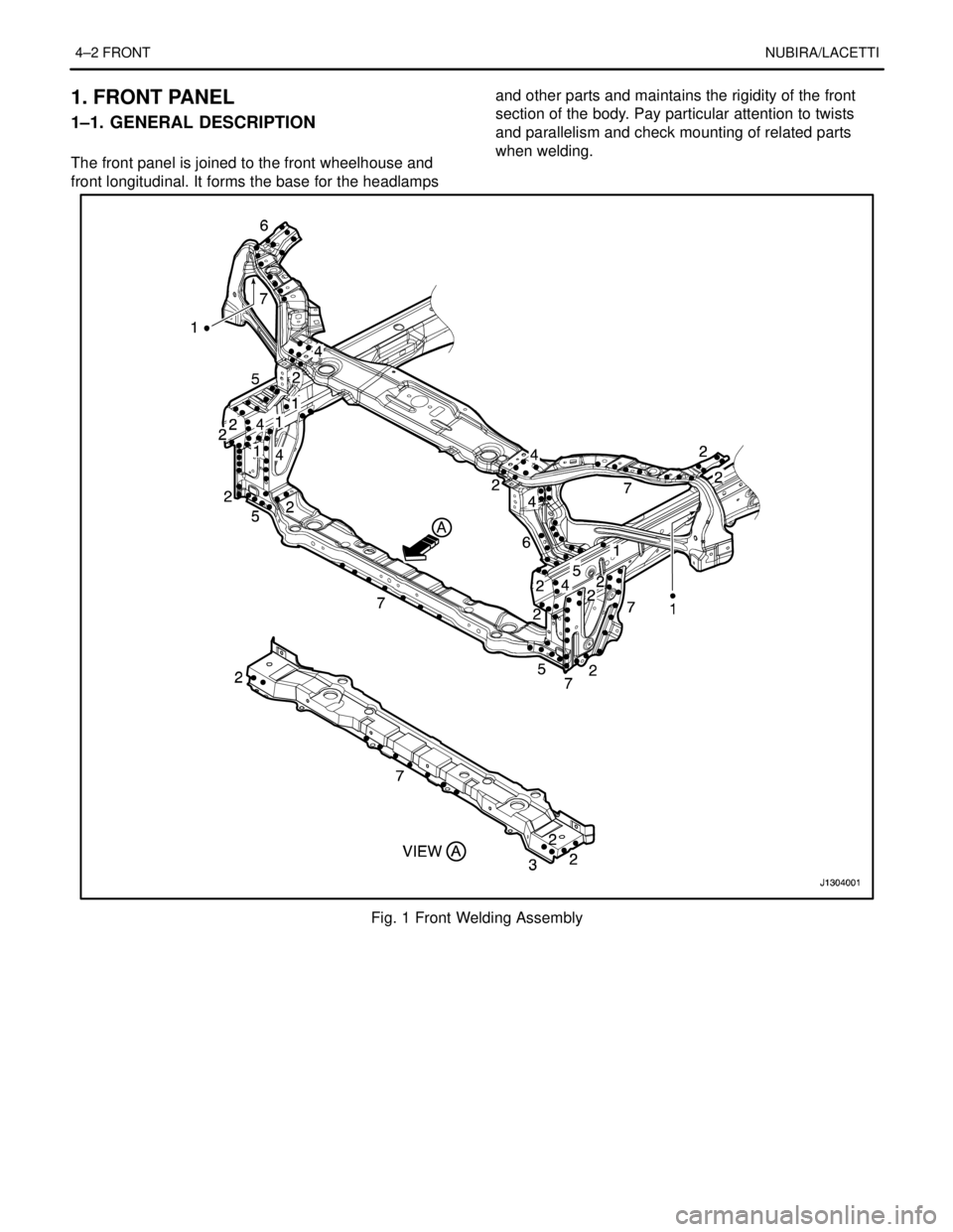

4–2 FRONTNUBIRA/LACETTI

1. FRONT PANEL

1–1. GENERAL DESCRIPTION

.

The front panel is joined to the front wheelhouse and

front longitudinal. It forms the base for the headlampsand other parts and maintains the rigidity of the front

section of the body. Pay particular attention to twists

and parallelism and check mounting of related parts

when welding.

.

Fig. 1 Front Welding Assembly

Page 2537 of 2643

NUBIRA/LACETTIFRONT 4–3

1–2. REPAIR PROCEDURE

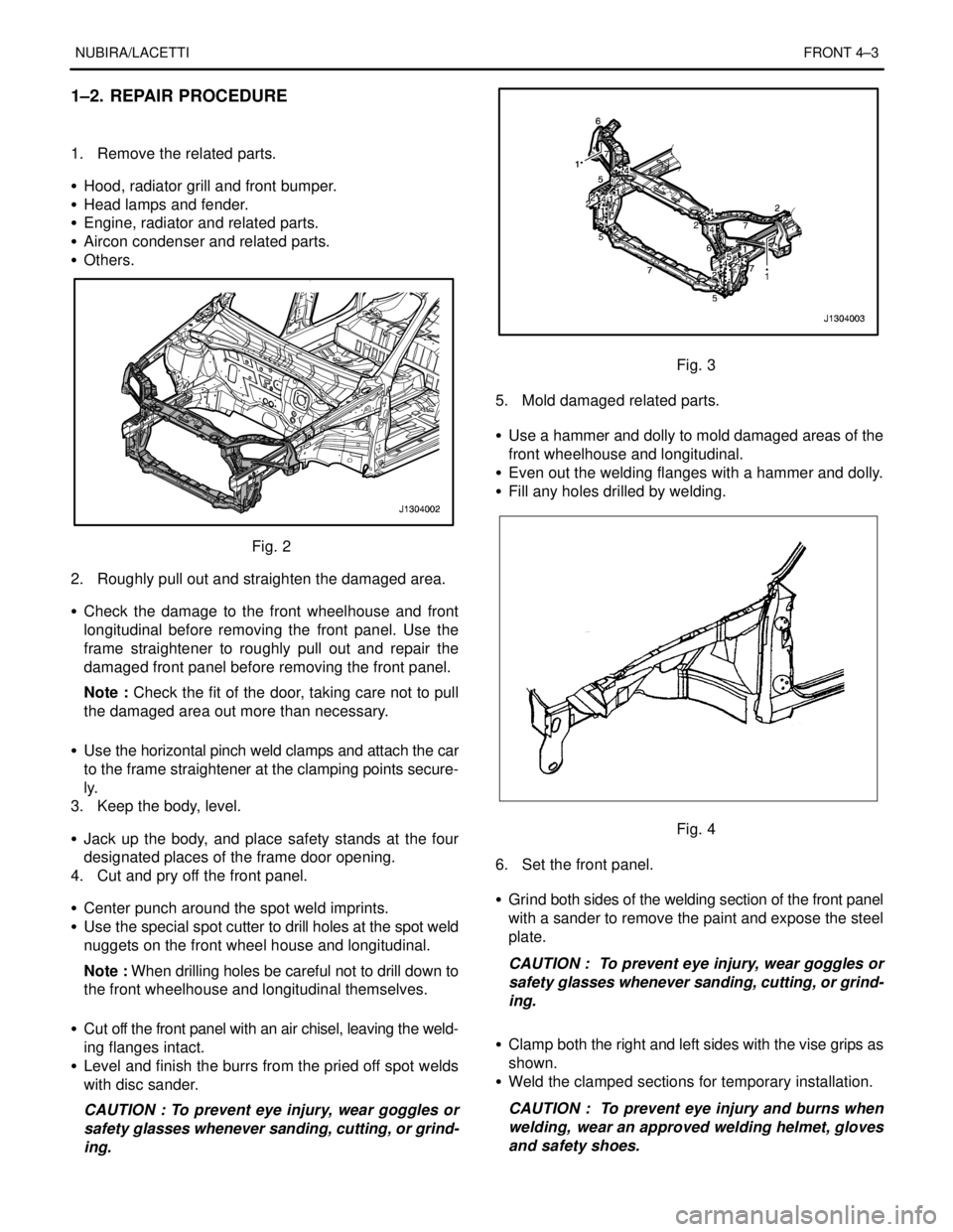

1. Remove the related parts.

S Hood, radiator grill and front bumper.

S Head lamps and fender.

S Engine, radiator and related parts.

S Aircon condenser and related parts.

S Others.

Fig. 2

2. Roughly pull out and straighten the damaged area.

S Check the damage to the front wheelhouse and front

longitudinal before removing the front panel. Use the

frame straightener to roughly pull out and repair the

damaged front panel before removing the front panel.

Note : Check the fit of the door, taking care not to pull

the damaged area out more than necessary.

S Use the horizontal pinch weld clamps and attach the car

to the frame straightener at the clamping points secure-

ly.

3. Keep the body, level.

S Jack up the body, and place safety stands at the four

designated places of the frame door opening.

4. Cut and pry off the front panel.

S Center punch around the spot weld imprints.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the front wheel house and longitudinal.

Note : When drilling holes be careful not to drill down to

the front wheelhouse and longitudinal themselves.

S Cut off the front panel with an air chisel, leaving the weld-

ing flanges intact.

S Level and finish the burrs from the pried off spot welds

with disc sander.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

Fig. 3

5. Mold damaged related parts.

S Use a hammer and dolly to mold damaged areas of the

front wheelhouse and longitudinal.

S Even out the welding flanges with a hammer and dolly.

S Fill any holes drilled by welding.

Fig. 4

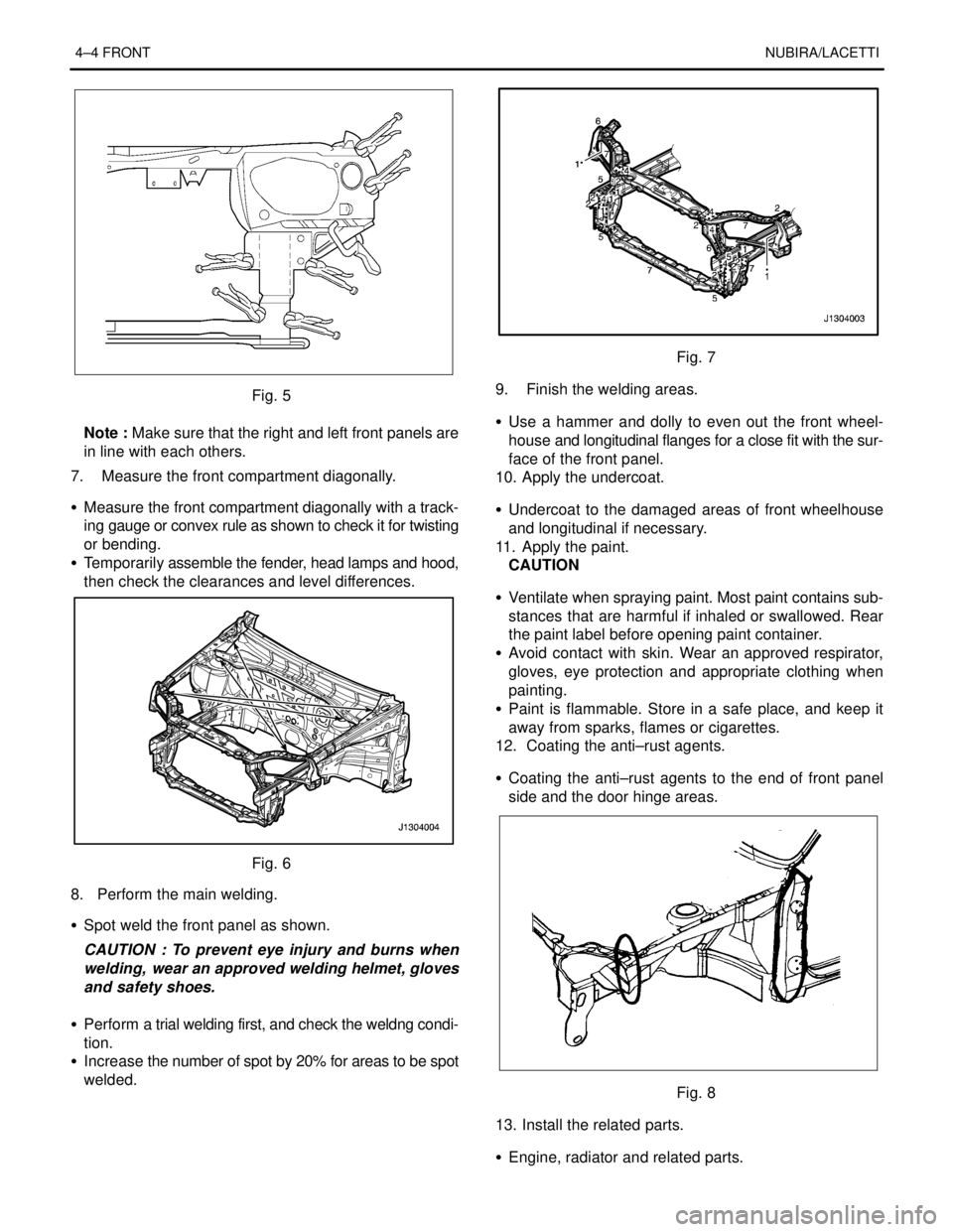

6. Set the front panel.

S Grind both sides of the welding section of the front panel

with a sander to remove the paint and expose the steel

plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Clamp both the right and left sides with the vise grips as

shown.

S Weld the clamped sections for temporary installation.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

Page 2538 of 2643

4–4 FRONTNUBIRA/LACETTI

Fig. 5

Note : Make sure that the right and left front panels are

in line with each others.

7. Measure the front compartment diagonally.

S Measure the front compartment diagonally with a track-

ing gauge or convex rule as shown to check it for twisting

or bending.

S Temporarily assemble the fender, head lamps and hood,

then check the clearances and level differences.

Fig. 6

8. Perform the main welding.

S Spot weld the front panel as shown.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Perform a trial welding first, and check the weldng condi-

tion.

S Increase the number of spot by 20% for areas to be spot

welded.

Fig. 7

9. Finish the welding areas.

S Use a hammer and dolly to even out the front wheel-

house and longitudinal flanges for a close fit with the sur-

face of the front panel.

10. Apply the undercoat.

S Undercoat to the damaged areas of front wheelhouse

and longitudinal if necessary.

11. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Rear

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

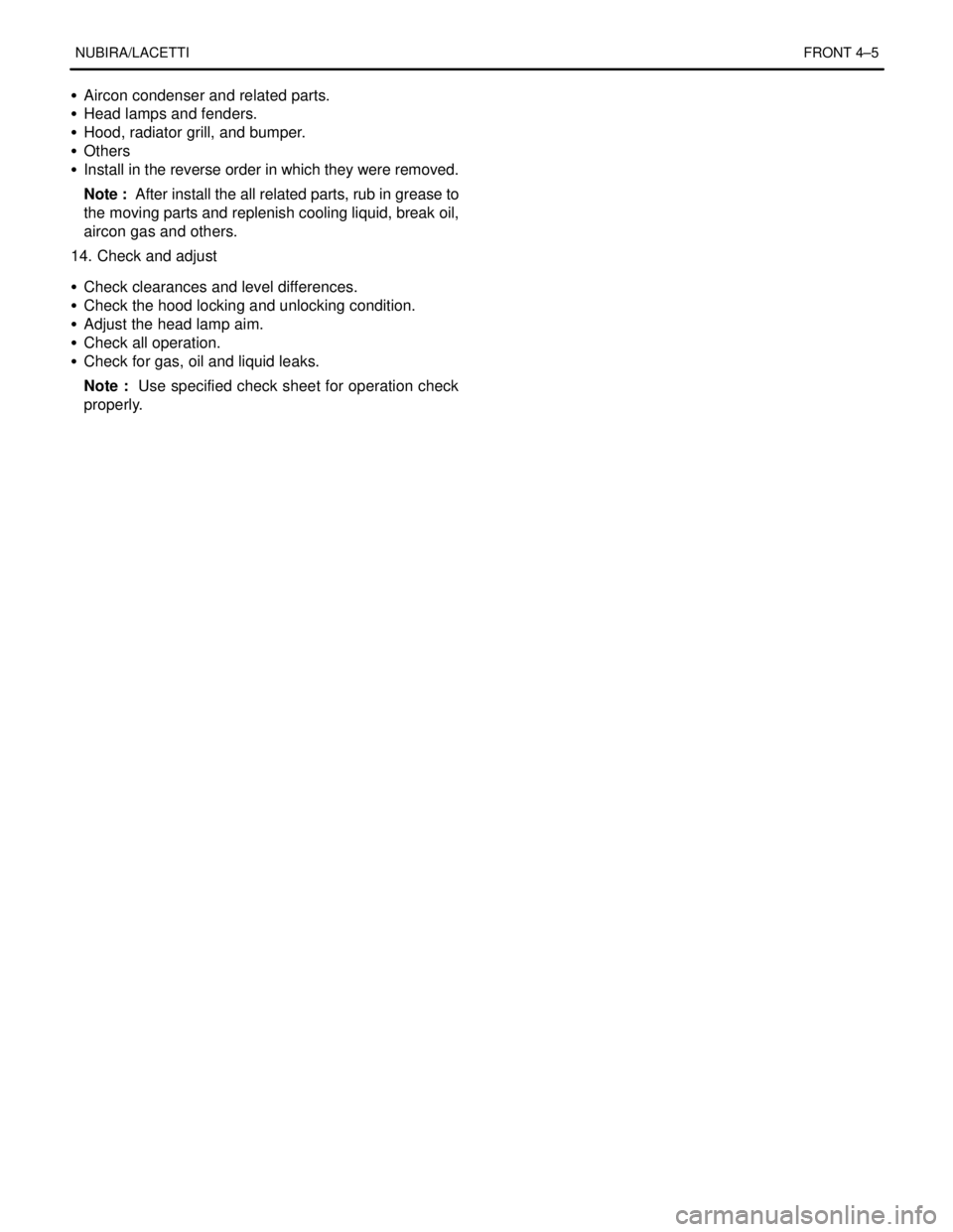

12. Coating the anti–rust agents.

S Coating the anti–rust agents to the end of front panel

side and the door hinge areas.

Fig. 8

13. Install the related parts.

S Engine, radiator and related parts.

Page 2539 of 2643

NUBIRA/LACETTIFRONT 4–5

S Aircon condenser and related parts.

S Head lamps and fenders.

S Hood, radiator grill, and bumper.

S Others

S Install in the reverse order in which they were removed.

Note : After install the all related parts, rub in grease to

the moving parts and replenish cooling liquid, break oil,

aircon gas and others.

14. Check and adjust

S Check clearances and level differences.

S Check the hood locking and unlocking condition.

S Adjust the head lamp aim.

S Check all operation.

S Check for gas, oil and liquid leaks.

Note : Use specified check sheet for operation check

properly.

Page 2540 of 2643

4–6 FRONTNUBIRA/LACETTI

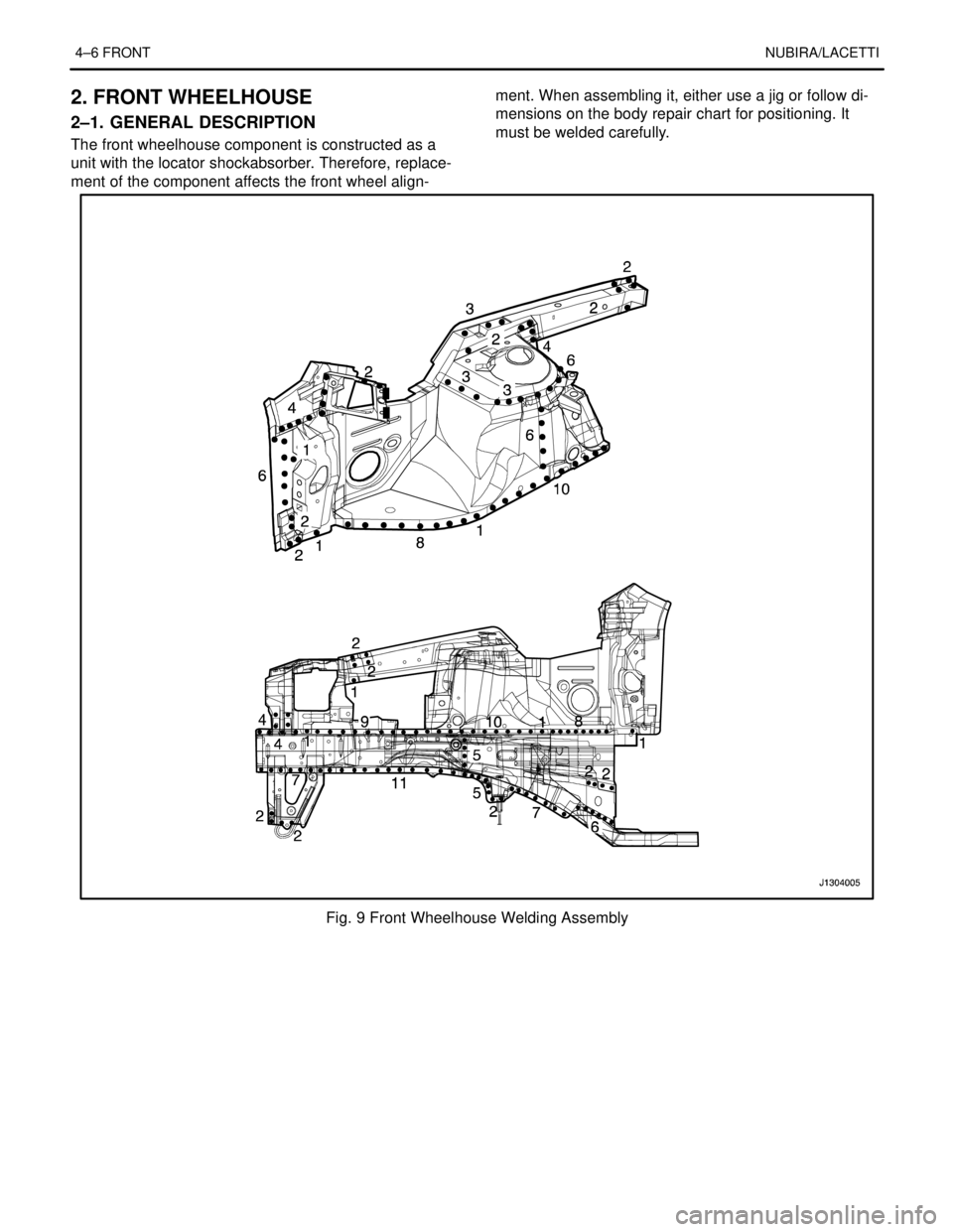

2. FRONT WHEELHOUSE

2–1. GENERAL DESCRIPTION

The front wheelhouse component is constructed as a

unit with the locator shockabsorber. Therefore, replace-

ment of the component affects the front wheel align-ment. When assembling it, either use a jig or follow di-

mensions on the body repair chart for positioning. It

must be welded carefully.

Fig. 9 Front Wheelhouse Welding Assembly