Iat DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2199 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 95

DAEWOO V–121 BL4

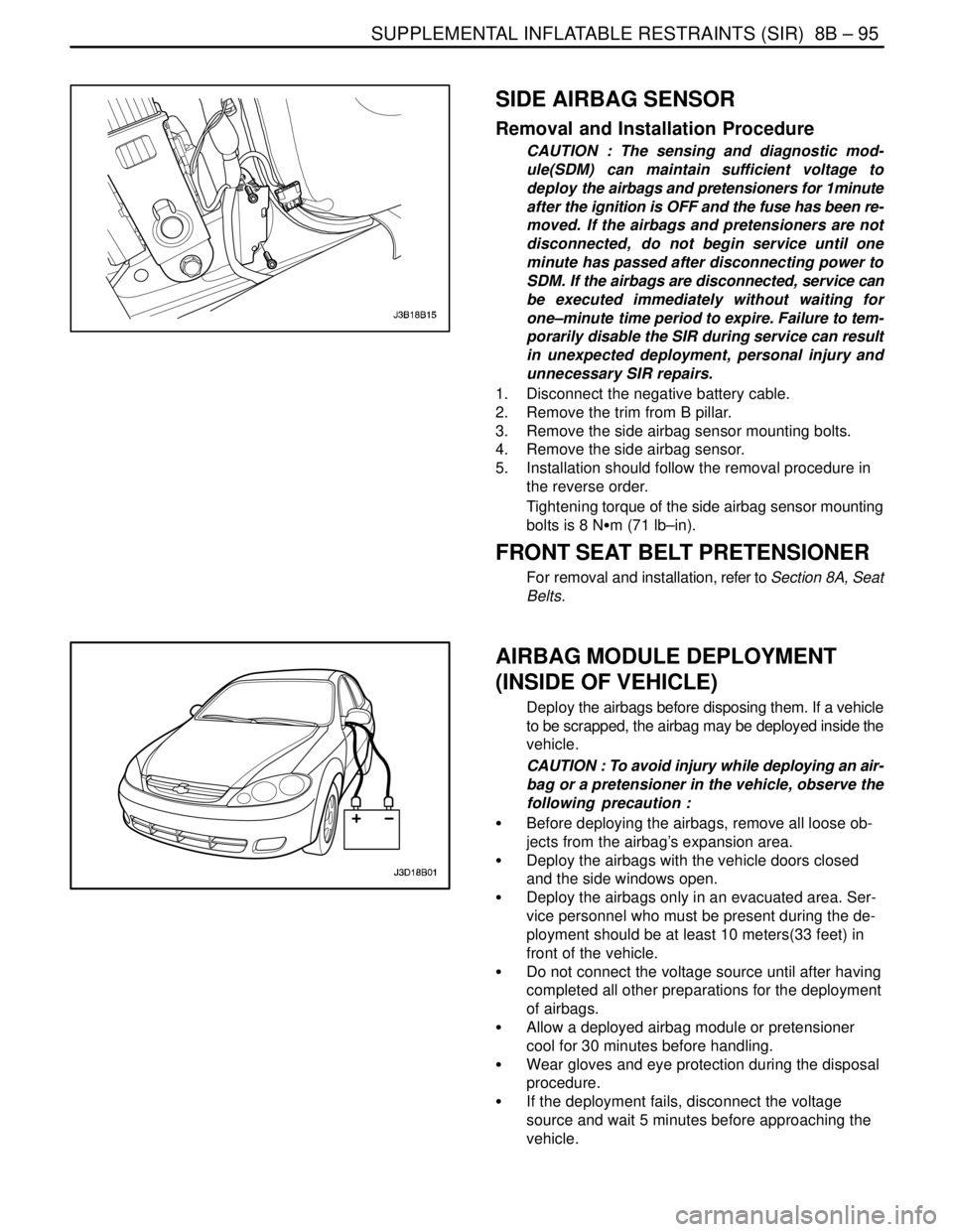

SIDE AIRBAG SENSOR

Removal and Installation Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1minute

after the ignition is OFF and the fuse has been re-

moved. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be executed immediately without waiting for

one–minute time period to expire. Failure to tem-

porarily disable the SIR during service can result

in unexpected deployment, personal injury and

unnecessary SIR repairs.

1. Disconnect the negative battery cable.

2. Remove the trim from B pillar.

3. Remove the side airbag sensor mounting bolts.

4. Remove the side airbag sensor.

5. Installation should follow the removal procedure in

the reverse order.

Tightening torque of the side airbag sensor mounting

bolts is 8 NSm (71 lb–in).

FRONT SEAT BELT PRETENSIONER

For removal and installation, refer to Section 8A, Seat

Belts.

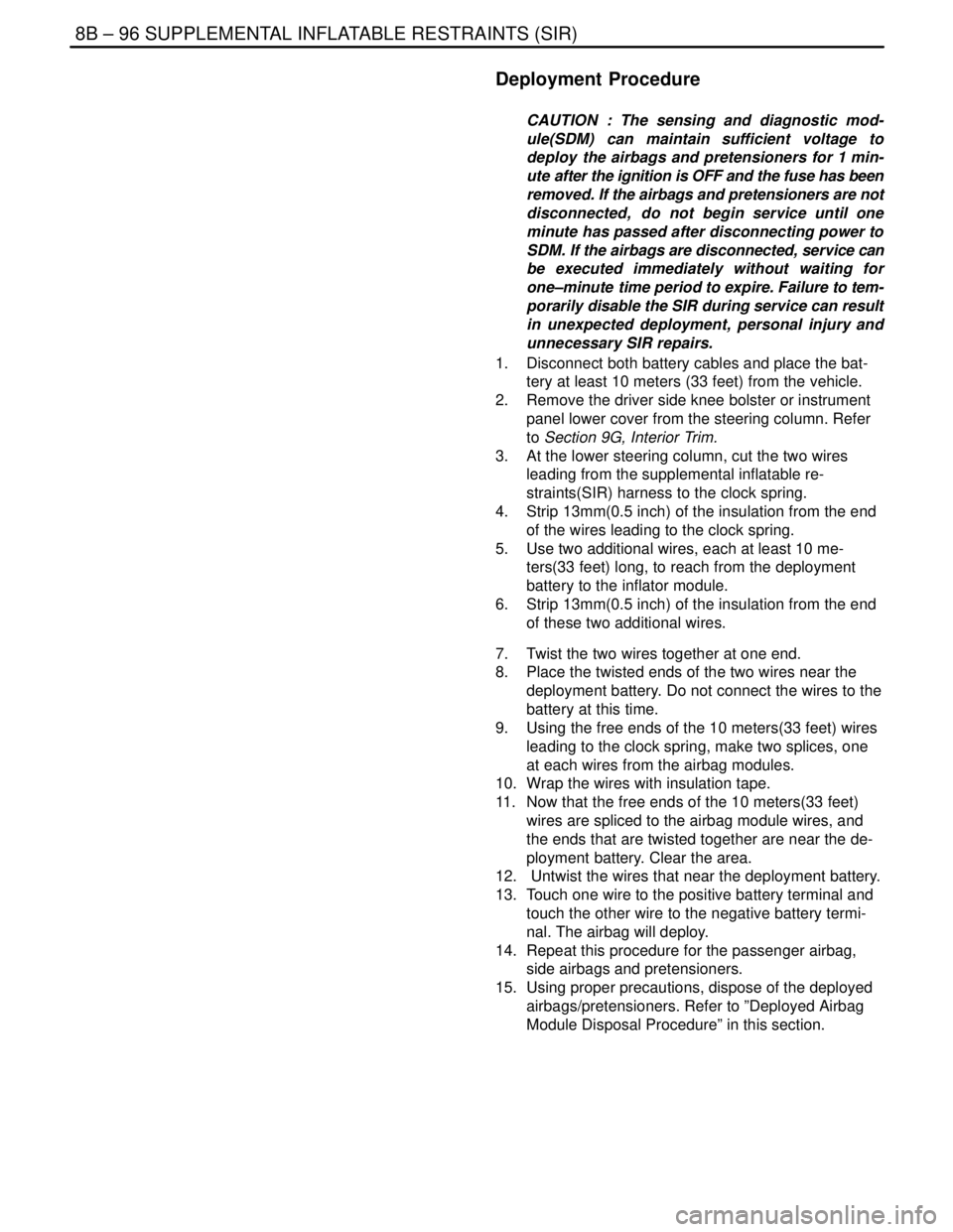

AIRBAG MODULE DEPLOYMENT

(INSIDE OF VEHICLE)

Deploy the airbags before disposing them. If a vehicle

to be scrapped, the airbag may be deployed inside the

vehicle.

CAUTION : To avoid injury while deploying an air-

bag or a pretensioner in the vehicle, observe the

following precaution :

S Before deploying the airbags, remove all loose ob-

jects from the airbag’s expansion area.

S Deploy the airbags with the vehicle doors closed

and the side windows open.

S Deploy the airbags only in an evacuated area. Ser-

vice personnel who must be present during the de-

ployment should be at least 10 meters(33 feet) in

front of the vehicle.

S Do not connect the voltage source until after having

completed all other preparations for the deployment

of airbags.

S Allow a deployed airbag module or pretensioner

cool for 30 minutes before handling.

S Wear gloves and eye protection during the disposal

procedure.

S If the deployment fails, disconnect the voltage

source and wait 5 minutes before approaching the

vehicle.

Page 2200 of 2643

8B – 96ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

Deployment Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be executed immediately without waiting for

one–minute time period to expire. Failure to tem-

porarily disable the SIR during service can result

in unexpected deployment, personal injury and

unnecessary SIR repairs.

1. Disconnect both battery cables and place the bat-

tery at least 10 meters (33 feet) from the vehicle.

2. Remove the driver side knee bolster or instrument

panel lower cover from the steering column. Refer

to Section 9G, Interior Trim.

3. At the lower steering column, cut the two wires

leading from the supplemental inflatable re-

straints(SIR) harness to the clock spring.

4. Strip 13mm(0.5 inch) of the insulation from the end

of the wires leading to the clock spring.

5. Use two additional wires, each at least 10 me-

ters(33 feet) long, to reach from the deployment

battery to the inflator module.

6. Strip 13mm(0.5 inch) of the insulation from the end

of these two additional wires.

7. Twist the two wires together at one end.

8. Place the twisted ends of the two wires near the

deployment battery. Do not connect the wires to the

battery at this time.

9. Using the free ends of the 10 meters(33 feet) wires

leading to the clock spring, make two splices, one

at each wires from the airbag modules.

10. Wrap the wires with insulation tape.

11. Now that the free ends of the 10 meters(33 feet)

wires are spliced to the airbag module wires, and

the ends that are twisted together are near the de-

ployment battery. Clear the area.

12. Untwist the wires that near the deployment battery.

13. Touch one wire to the positive battery terminal and

touch the other wire to the negative battery termi-

nal. The airbag will deploy.

14. Repeat this procedure for the passenger airbag,

side airbags and pretensioners.

15. Using proper precautions, dispose of the deployed

airbags/pretensioners. Refer to ”Deployed Airbag

Module Disposal Procedure” in this section.

Page 2207 of 2643

SECTION : 9A

BODY WIRING SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SCHEMATIC AND ROUTING DIAGRAMS9A–1 . . . . .

Wire Color Chart 9A–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Schematic 9A–3. . . . . . . . . . . . . . .

Fuse Block Locator (Engine) 9A–12. . . . . . . . . . . . . . .

Fuse Block Locator (Passenger Compartment) 9A–12

Fuse Chart 9A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front Harness Routing 9A–15. . . . . . . . . . . . . . . . . . . .

Rear Harness Routing 9A–16. . . . . . . . . . . . . . . . . . . . .

Hatchback Rear Harness Routing 9A–17. . . . . . . . . . .

Floor Harness Routing 9A–18. . . . . . . . . . . . . . . . . . . .

Instrument Harness Routing 9A–19. . . . . . . . . . . . . . . .

Door Harness Routing 9A–20. . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS

WIRE COLOR CHART

Wire ColorAbbreviation On Schematic

GreenDK GRN

Light GreenLT GRN

BlueDK BLU

BrownBRN

OrangeORN

YellowYEL

GreyGRY

Sky BlueLT BLU

RedRED

BlackBLK

PinkPNK

WhiteWHT

PurplePPL

Page 2208 of 2643

9A – 2IBODY WIRING SYSTEM

DAEWOO V–121 BL4

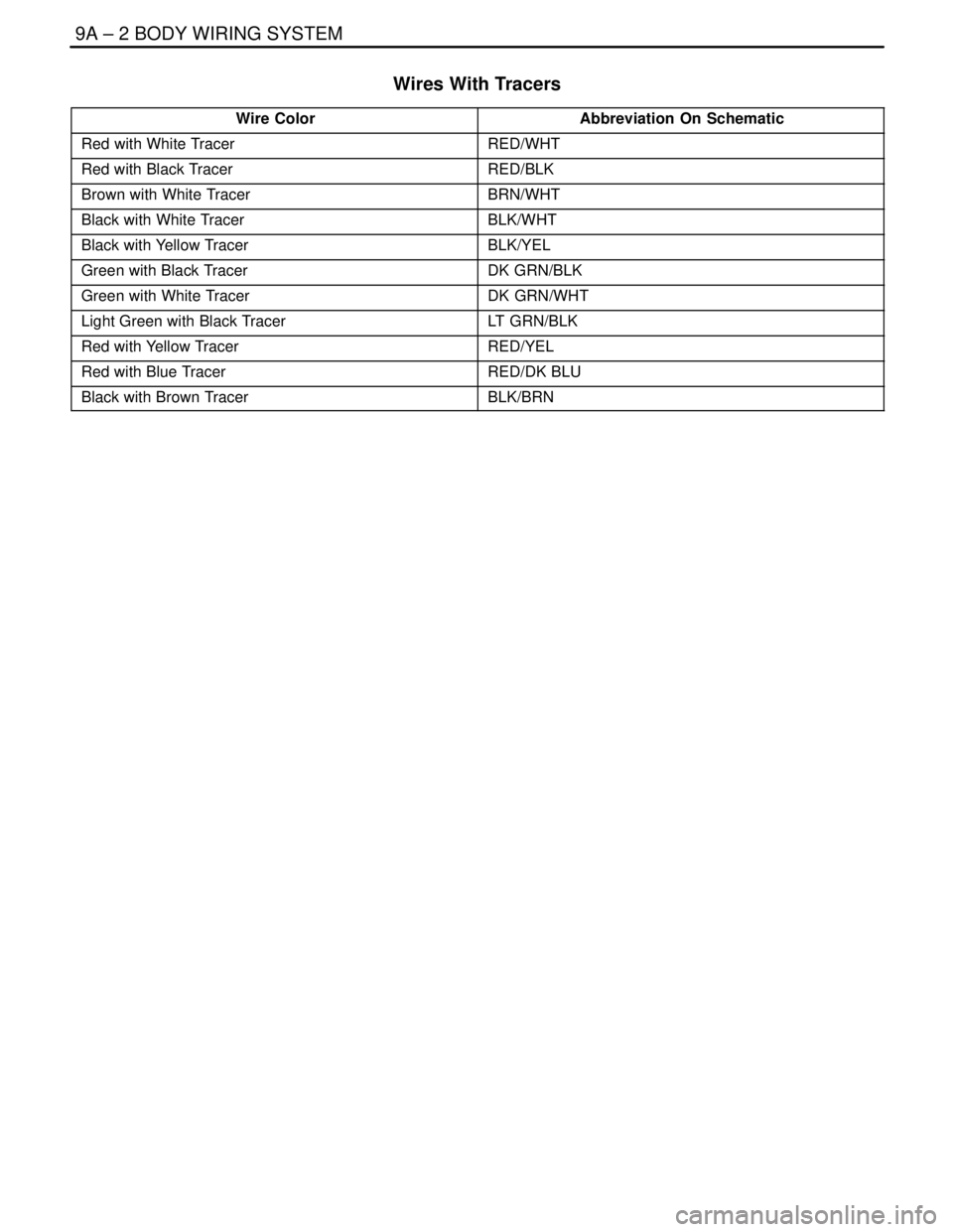

Wires With Tracers

Wire ColorAbbreviation On Schematic

Red with White TracerRED/WHT

Red with Black TracerRED/BLK

Brown with White TracerBRN/WHT

Black with White TracerBLK/WHT

Black with Yellow TracerBLK/YEL

Green with Black TracerDK GRN/BLK

Green with White TracerDK GRN/WHT

Light Green with Black TracerLT GRN/BLK

Red with Yellow TracerRED/YEL

Red with Blue TracerRED/DK BLU

Black with Brown TracerBLK/BRN

Page 2277 of 2643

9C – 4IHORN(S)

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

HORN(S)

The horns are located under the hood. They are attached

near the radiator at the front of the vehicle. The horns are

actuated by pressing the steering wheel pad, which

grounds the horns’ electrical circuit.

Page 2374 of 2643

9I – 6IWATERLEAKS

DAEWOO V–121 BL4

8. Allow the primer to dry for 5 minutes.

9. Apply the adhesive over the leak and for a distance

of 75 to 100 mm (3 to 4 inches) on both sides of the

leak.

10. Immediately after applying the adhesive, use a flat

stick or a similar tool to work the adhesive into the

leak area and into the joint between the original ma-

terial and the vehicle body in order to ensure a wa-

tertight seal.

11. Spray warm or hot water over the repaired area in

order to determine if the leak was repaired. Do not

run a heavy stream of water directly on the freshly

applied adhesive.

12. Install the trim strip lace if it was removed.

13. Install the garnish molding if it was removed.

14. Install the reveal molding.

Important : After the completion of any waterleak repair,

retest the area using the watertest stands. Do not use

localized testing procedures on the newly–repaired areas,

as the repair material may dislodge under abnormal pres-

sure.

Page 2442 of 2643

9P – 22IDOORS

DAEWOO V–121 BL4

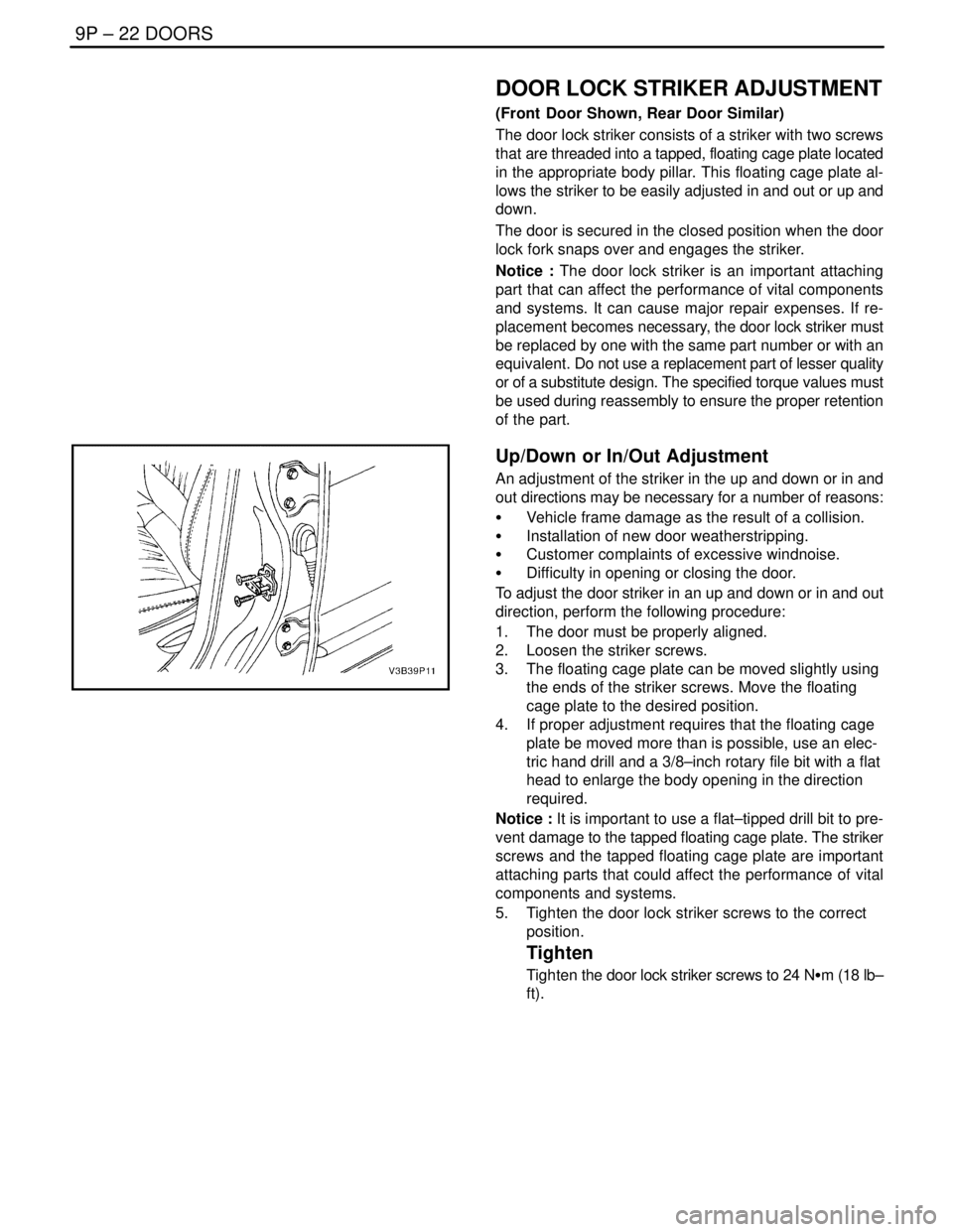

DOOR LOCK STRIKER ADJUSTMENT

(Front Door Shown, Rear Door Similar)

The door lock striker consists of a striker with two screws

that are threaded into a tapped, floating cage plate located

in the appropriate body pillar. This floating cage plate al-

lows the striker to be easily adjusted in and out or up and

down.

The door is secured in the closed position when the door

lock fork snaps over and engages the striker.

Notice : The door lock striker is an important attaching

part that can affect the performance of vital components

and systems. It can cause major repair expenses. If re-

placement becomes necessary, the door lock striker must

be replaced by one with the same part number or with an

equivalent. Do not use a replacement part of lesser quality

or of a substitute design. The specified torque values must

be used during reassembly to ensure the proper retention

of the part.

Up/Down or In/Out Adjustment

An adjustment of the striker in the up and down or in and

out directions may be necessary for a number of reasons:

S Vehicle frame damage as the result of a collision.

S Installation of new door weatherstripping.

S Customer complaints of excessive windnoise.

S Difficulty in opening or closing the door.

To adjust the door striker in an up and down or in and out

direction, perform the following procedure:

1. The door must be properly aligned.

2. Loosen the striker screws.

3. The floating cage plate can be moved slightly using

the ends of the striker screws. Move the floating

cage plate to the desired position.

4. If proper adjustment requires that the floating cage

plate be moved more than is possible, use an elec-

tric hand drill and a 3/8–inch rotary file bit with a flat

head to enlarge the body opening in the direction

required.

Notice : It is important to use a flat–tipped drill bit to pre-

vent damage to the tapped floating cage plate. The striker

screws and the tapped floating cage plate are important

attaching parts that could affect the performance of vital

components and systems.

5. Tighten the door lock striker screws to the correct

position.

Tighten

Tighten the door lock striker screws to 24 NSm (18 lb–

ft).

Page 2462 of 2643

SECTION : 9R

BODY FRONT END

TABLE OF CONTENTS

SPECIFICATIONS9R–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9R–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9R–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9R–2. . . . . . . . . . . . . . . . . . . . .

Lubrication 9R–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fasteners 9R–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anticorrosion Materials 9R–2. . . . . . . . . . . . . . . . . . . . .

Front End Sealing 9R–2. . . . . . . . . . . . . . . . . . . . . . . . .

Cowl Vent Grille 9R–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood 9R–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hood Hinges 9R–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Prop Rod 9R–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Secondary Latch 9R–4. . . . . . . . . . . . . . . . . . . . .

Hood Latch Release Cable 9R–5. . . . . . . . . . . . . . . . . .

Notchback Radiator Grille 9R–5. . . . . . . . . . . . . . . . . . .

Hatchback Radiator Grille 9R–6. . . . . . . . . . . . . . . . . . .

Front Wheel Well Splash Shield 9R–6. . . . . . . . . . . . .

Fender 9R–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9R–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Body Front End 9R–10. . . . . . . . . . . . . . . . . . . . . . . . . .

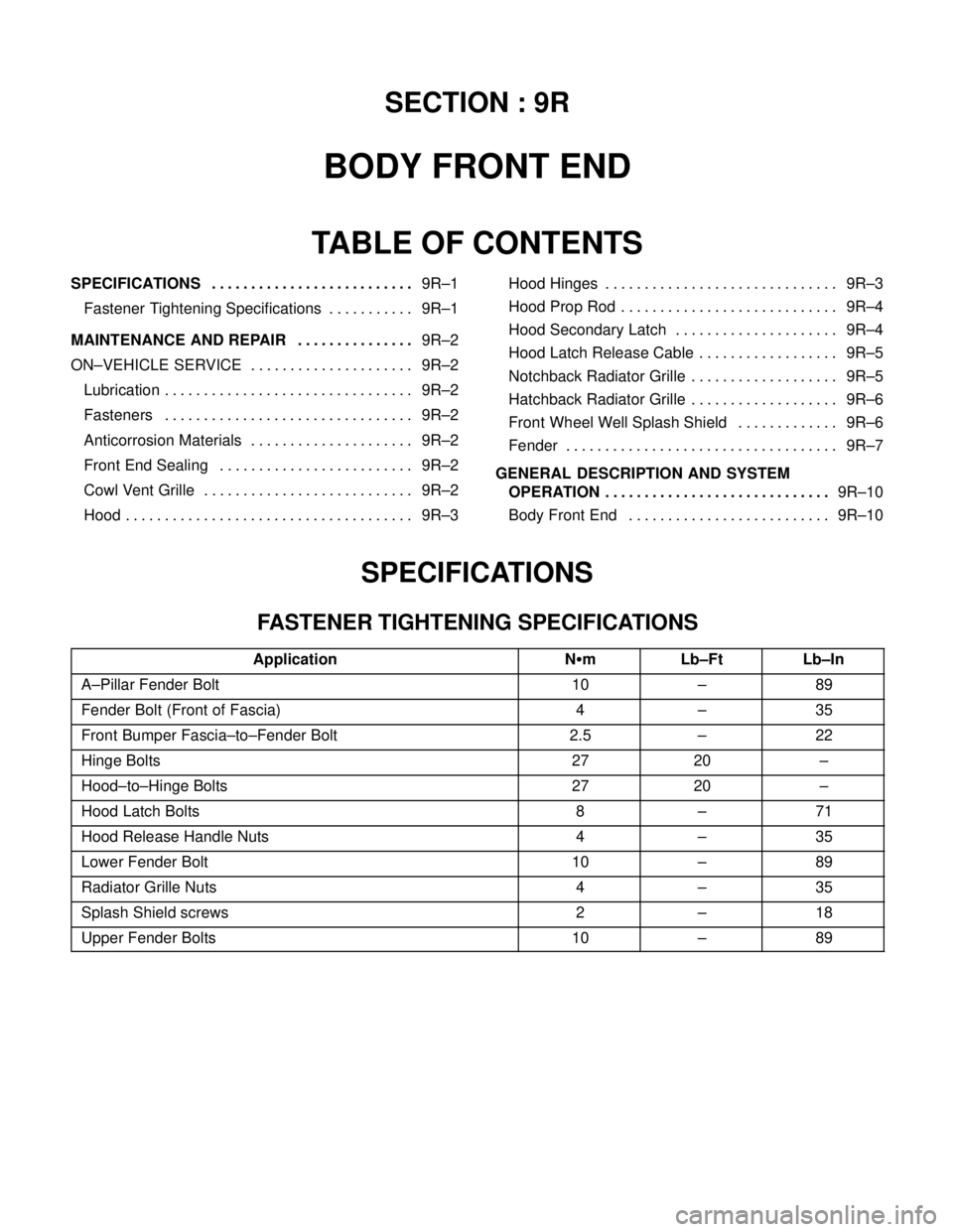

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

A–Pillar Fender Bolt10–89

Fender Bolt (Front of Fascia)4–35

Front Bumper Fascia–to–Fender Bolt2.5–22

Hinge Bolts2720–

Hood–to–Hinge Bolts2720–

Hood Latch Bolts8–71

Hood Release Handle Nuts4–35

Lower Fender Bolt10–89

Radiator Grille Nuts4–35

Splash Shield screws2–18

Upper Fender Bolts10–89

Page 2465 of 2643

9R – 4IBODY FRONT END

DAEWOO V–121 BL4

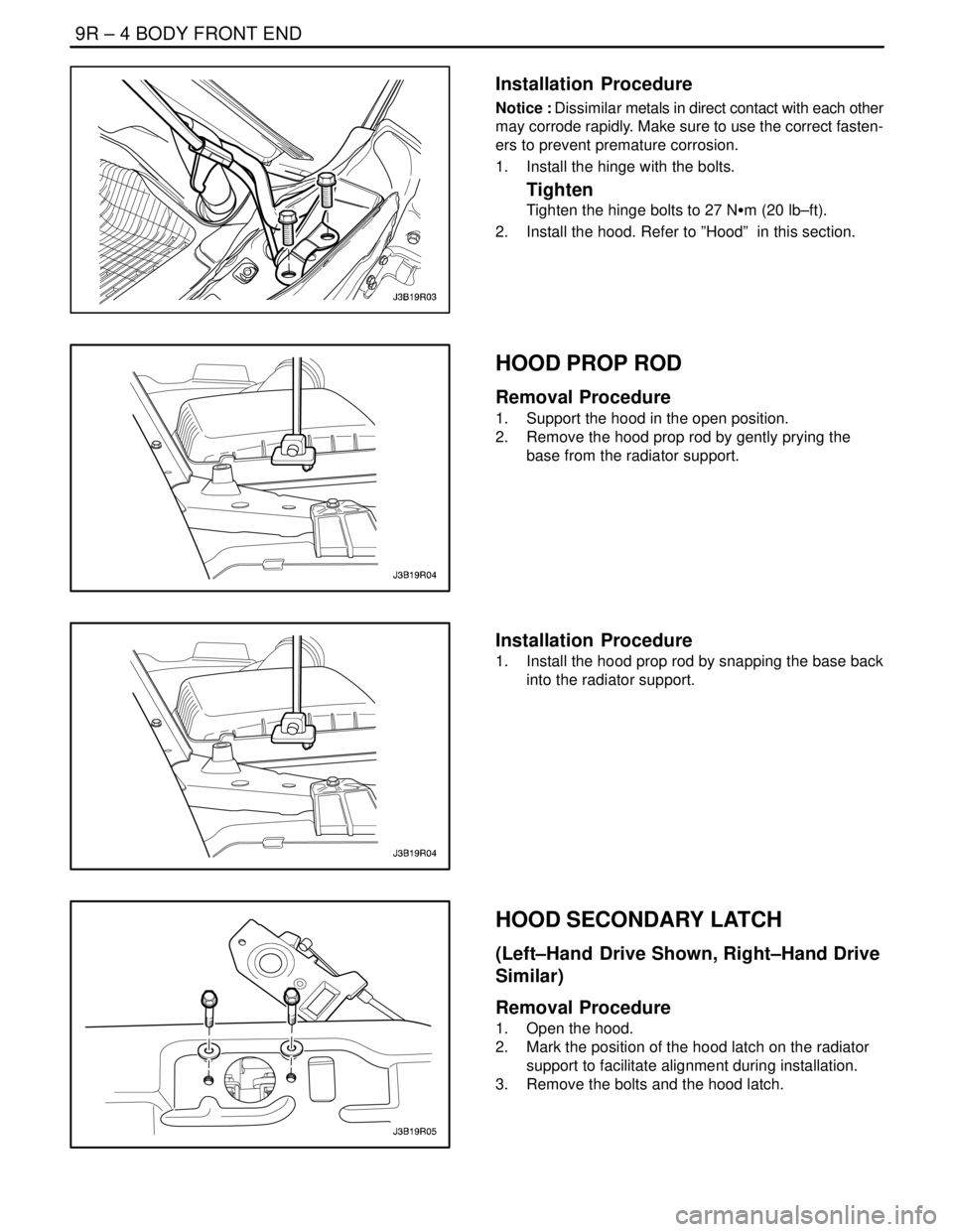

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the hinge with the bolts.

Tighten

Tighten the hinge bolts to 27 NSm (20 lb–ft).

2. Install the hood. Refer to ”Hood” in this section.

HOOD PROP ROD

Removal Procedure

1. Support the hood in the open position.

2. Remove the hood prop rod by gently prying the

base from the radiator support.

Installation Procedure

1. Install the hood prop rod by snapping the base back

into the radiator support.

HOOD SECONDARY LATCH

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Open the hood.

2. Mark the position of the hood latch on the radiator

support to facilitate alignment during installation.

3. Remove the bolts and the hood latch.

Page 2466 of 2643

BODY FRONT END 9R – 5

DAEWOO V–121 BL4

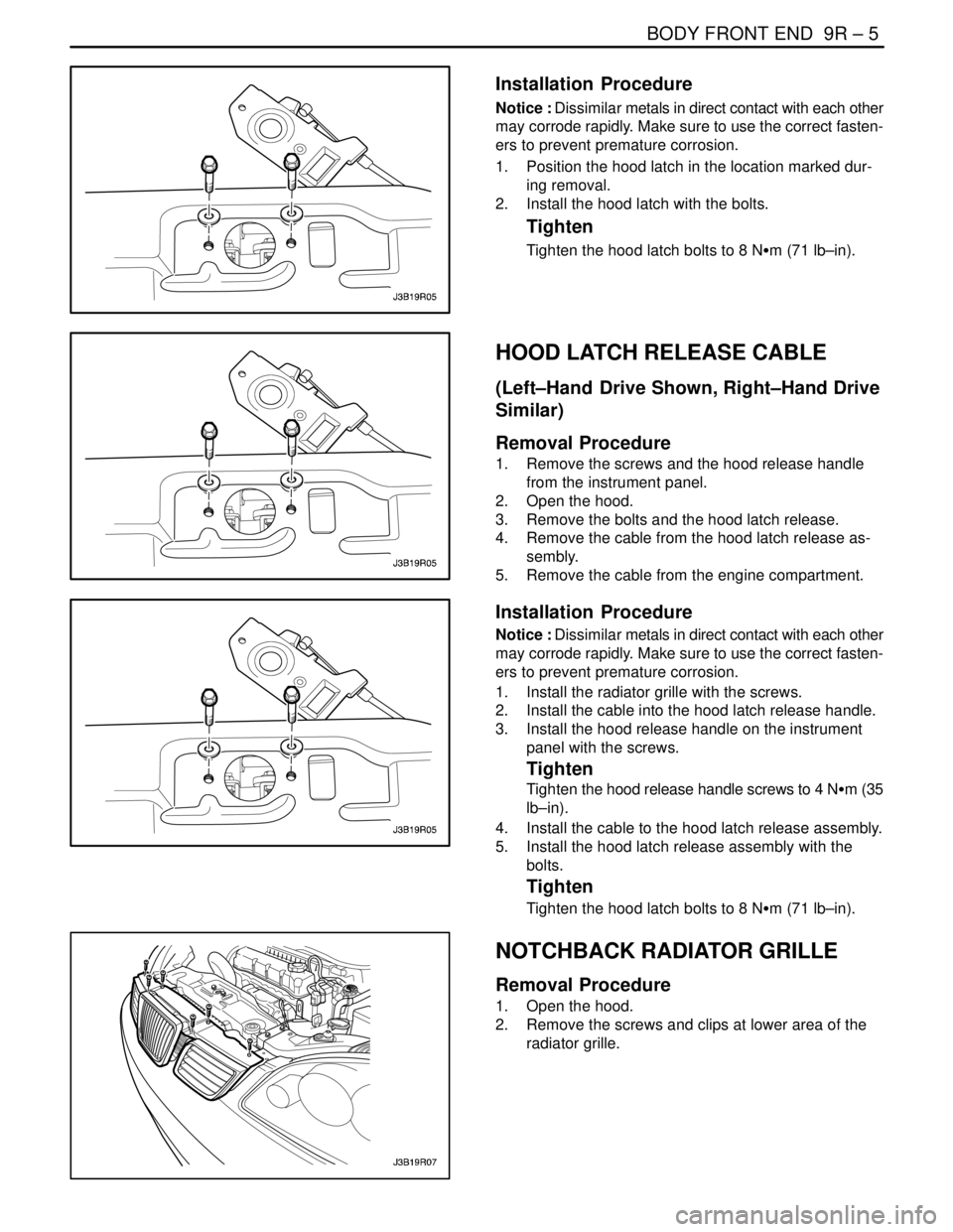

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Position the hood latch in the location marked dur-

ing removal.

2. Install the hood latch with the bolts.

Tighten

Tighten the hood latch bolts to 8 NSm (71 lb–in).

HOOD LATCH RELEASE CABLE

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Remove the screws and the hood release handle

from the instrument panel.

2. Open the hood.

3. Remove the bolts and the hood latch release.

4. Remove the cable from the hood latch release as-

sembly.

5. Remove the cable from the engine compartment.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the radiator grille with the screws.

2. Install the cable into the hood latch release handle.

3. Install the hood release handle on the instrument

panel with the screws.

Tighten

Tighten the hood release handle screws to 4 NSm (35

lb–in).

4. Install the cable to the hood latch release assembly.

5. Install the hood latch release assembly with the

bolts.

Tighten

Tighten the hood latch bolts to 8 NSm (71 lb–in).

NOTCHBACK RADIATOR GRILLE

Removal Procedure

1. Open the hood.

2. Remove the screws and clips at lower area of the

radiator grille.