Iat DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1700 of 2643

5A2 – 110IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

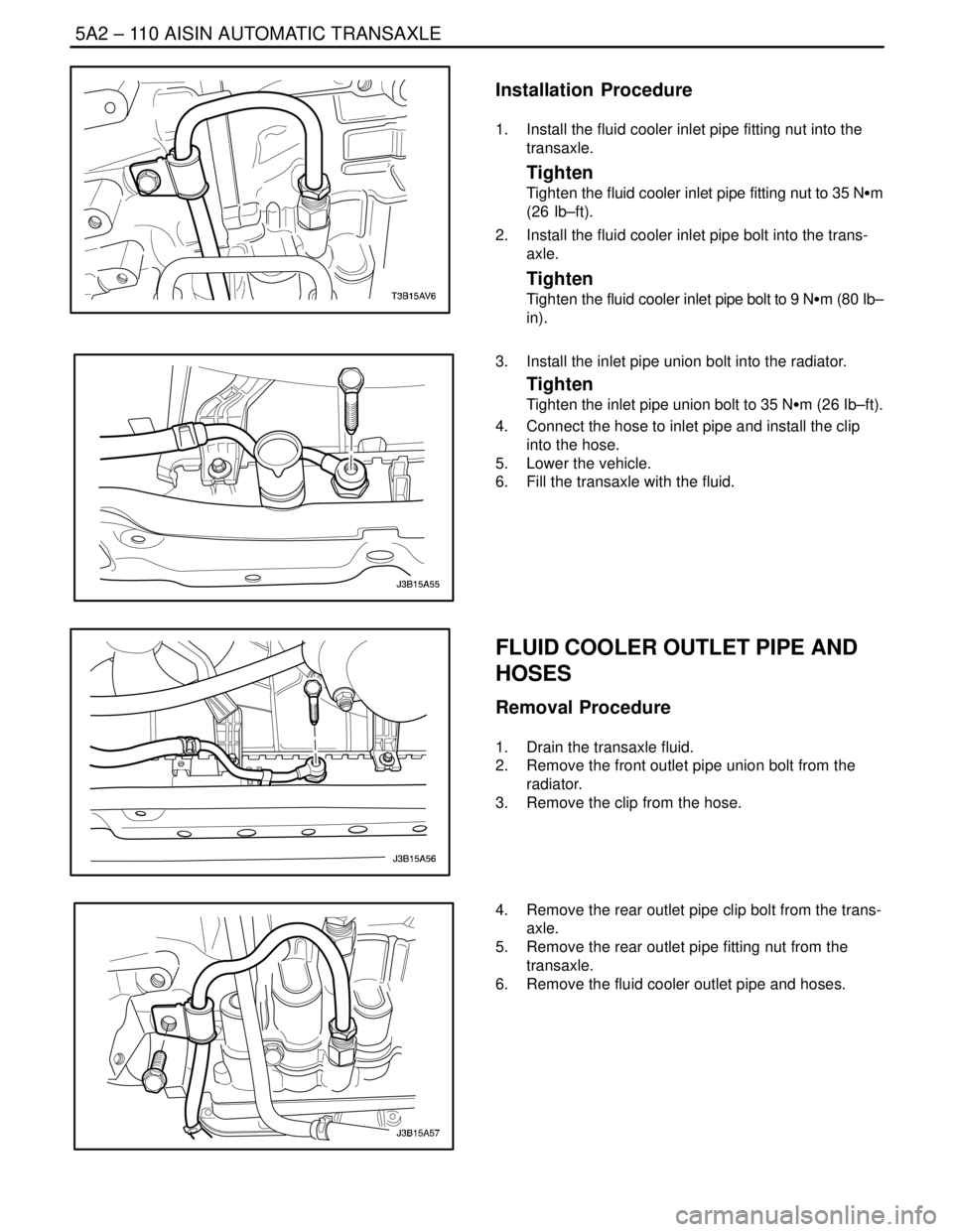

Installation Procedure

1. Install the fluid cooler inlet pipe fitting nut into the

transaxle.

Tighten

Tighten the fluid cooler inlet pipe fitting nut to 35 NSm

(26 Ib–ft).

2. Install the fluid cooler inlet pipe bolt into the trans-

axle.

Tighten

Tighten the fluid cooler inlet pipe bolt to 9 NSm (80 Ib–

in).

3. Install the inlet pipe union bolt into the radiator.

Tighten

Tighten the inlet pipe union bolt to 35 NSm (26 Ib–ft).

4. Connect the hose to inlet pipe and install the clip

into the hose.

5. Lower the vehicle.

6. Fill the transaxle with the fluid.

FLUID COOLER OUTLET PIPE AND

HOSES

Removal Procedure

1. Drain the transaxle fluid.

2. Remove the front outlet pipe union bolt from the

radiator.

3. Remove the clip from the hose.

4. Remove the rear outlet pipe clip bolt from the trans-

axle.

5. Remove the rear outlet pipe fitting nut from the

transaxle.

6. Remove the fluid cooler outlet pipe and hoses.

Page 1773 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 183

DAEWOO V–121 BL4

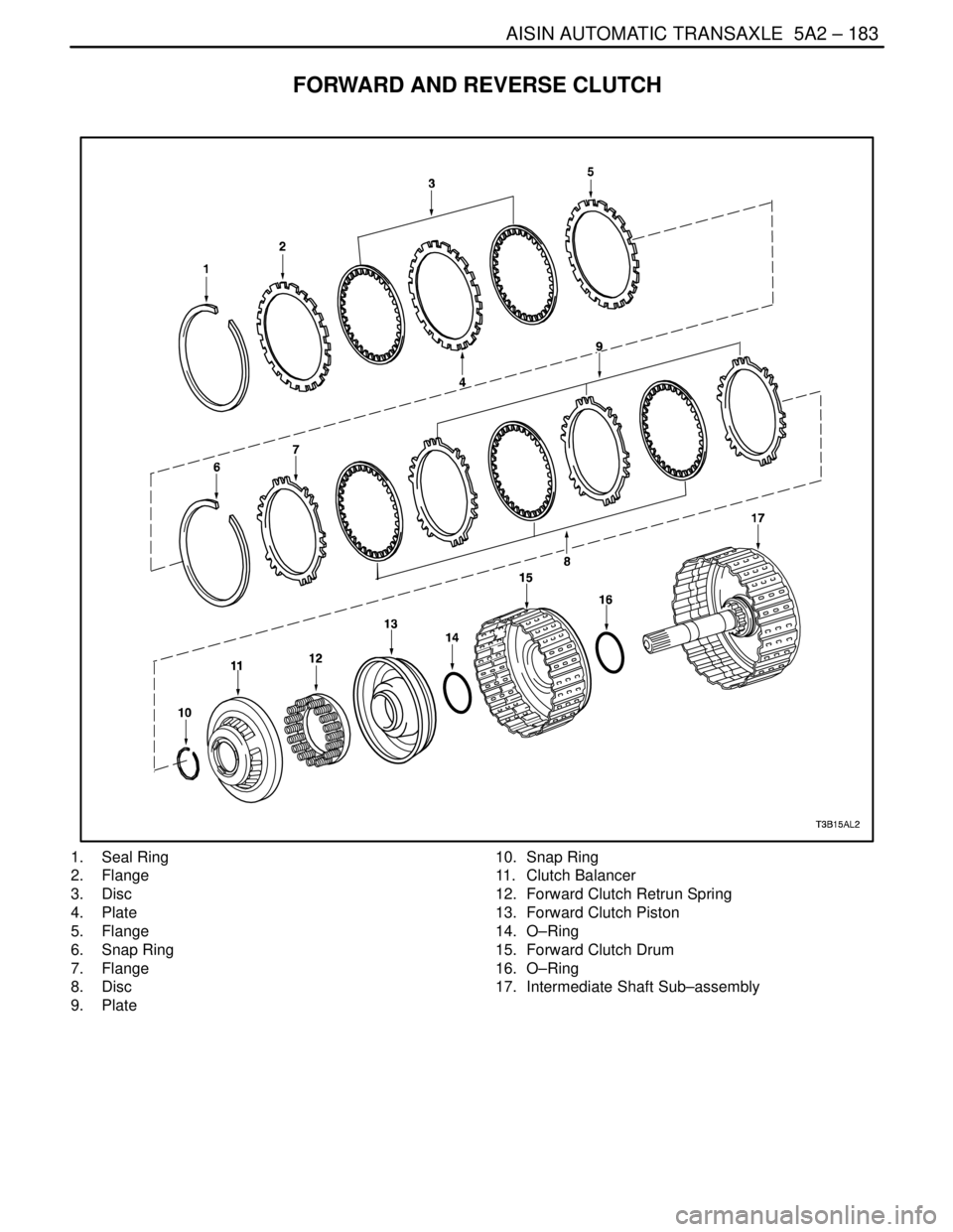

FORWARD AND REVERSE CLUTCH

1. Seal Ring

2. Flange

3. Disc

4. Plate

5. Flange

6. Snap Ring

7. Flange

8. Disc

9. Plate10. Snap Ring

11. Clutch Balancer

12. Forward Clutch Retrun Spring

13. Forward Clutch Piston

14. O–Ring

15. Forward Clutch Drum

16. O–Ring

17. Intermediate Shaft Sub–assembly

Page 1777 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 187

DAEWOO V–121 BL4

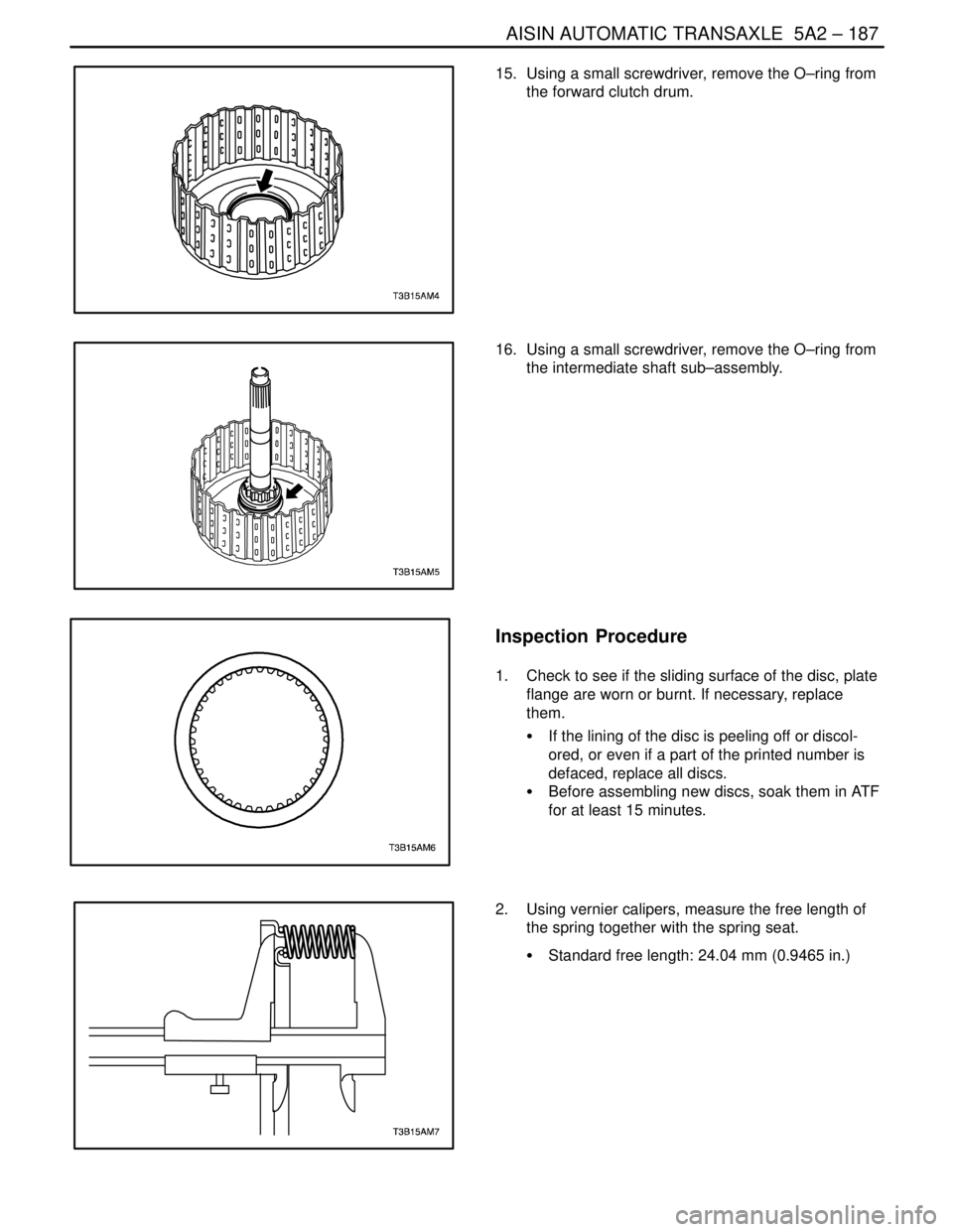

15. Using a small screwdriver, remove the O–ring from

the forward clutch drum.

16. Using a small screwdriver, remove the O–ring from

the intermediate shaft sub–assembly.

Inspection Procedure

1. Check to see if the sliding surface of the disc, plate

flange are worn or burnt. If necessary, replace

them.

S If the lining of the disc is peeling off or discol-

ored, or even if a part of the printed number is

defaced, replace all discs.

S Before assembling new discs, soak them in ATF

for at least 15 minutes.

2. Using vernier calipers, measure the free length of

the spring together with the spring seat.

S Standard free length: 24.04 mm (0.9465 in.)

Page 1778 of 2643

5A2 – 188IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

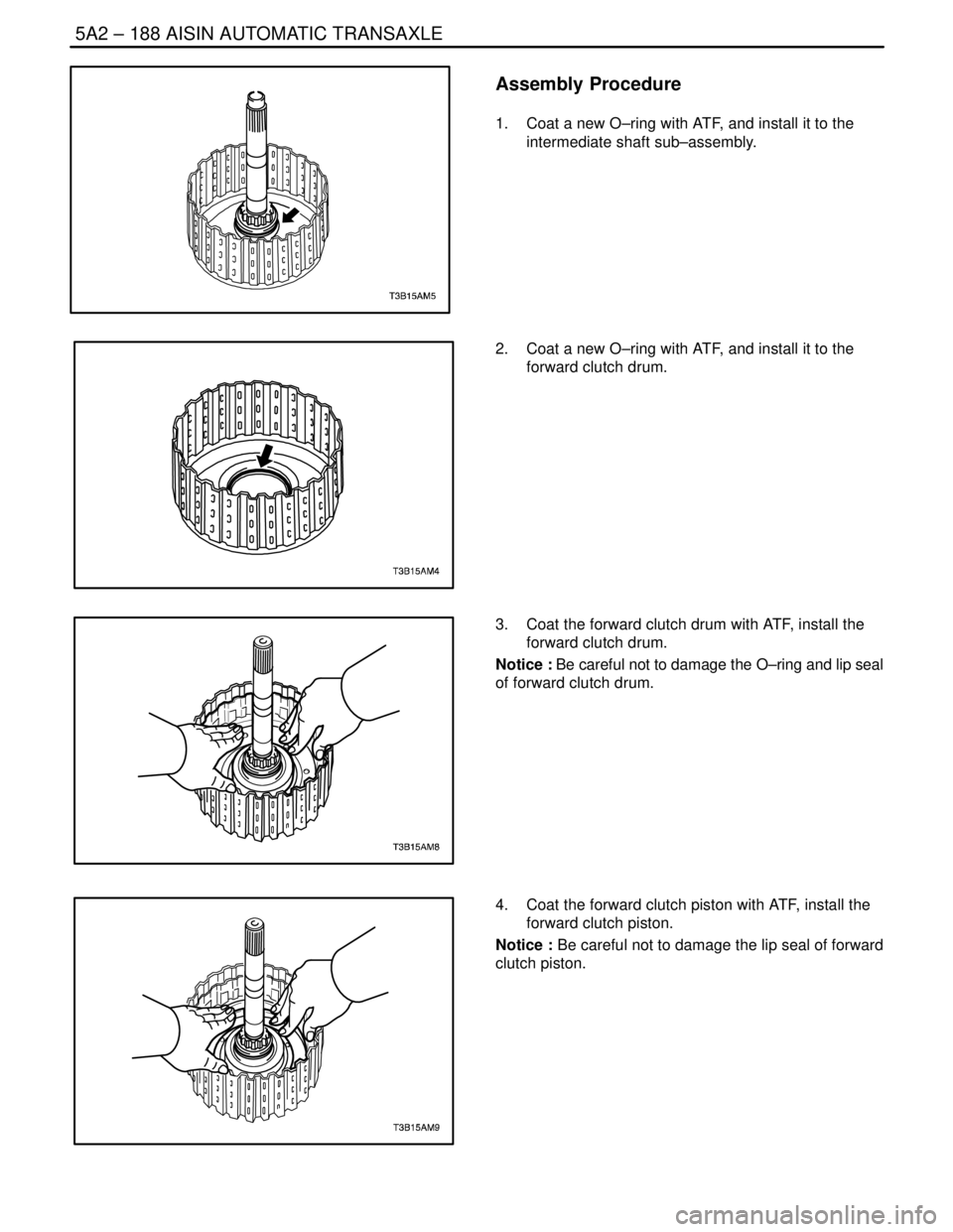

Assembly Procedure

1. Coat a new O–ring with ATF, and install it to the

intermediate shaft sub–assembly.

2. Coat a new O–ring with ATF, and install it to the

forward clutch drum.

3. Coat the forward clutch drum with ATF, install the

forward clutch drum.

Notice : Be careful not to damage the O–ring and lip seal

of forward clutch drum.

4. Coat the forward clutch piston with ATF, install the

forward clutch piston.

Notice : Be careful not to damage the lip seal of forward

clutch piston.

Page 1813 of 2643

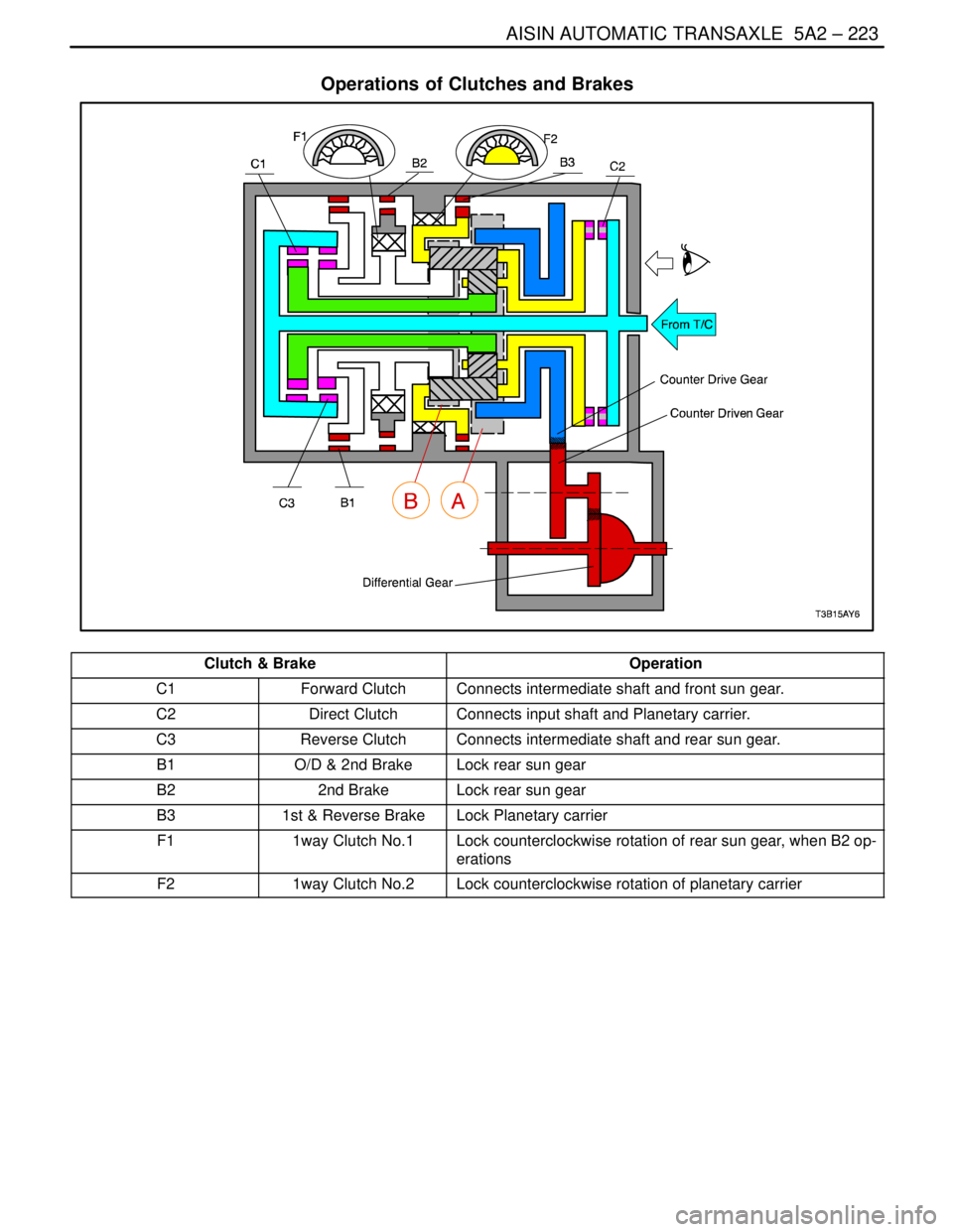

AISIN AUTOMATIC TRANSAXLE 5A2 – 223

DAEWOO V–121 BL4

Operations of Clutches and Brakes

Clutch & BrakeOperation

C1Forward ClutchConnects intermediate shaft and front sun gear.

C2Direct ClutchConnects input shaft and Planetary carrier.

C3Reverse ClutchConnects intermediate shaft and rear sun gear.

B1O/D & 2nd BrakeLock rear sun gear

B22nd BrakeLock rear sun gear

B31st & Reverse BrakeLock Planetary carrier

F11way Clutch No.1Lock counterclockwise rotation of rear sun gear, when B2 op-

erations

F21way Clutch No.2Lock counterclockwise rotation of planetary carrier

Page 1834 of 2643

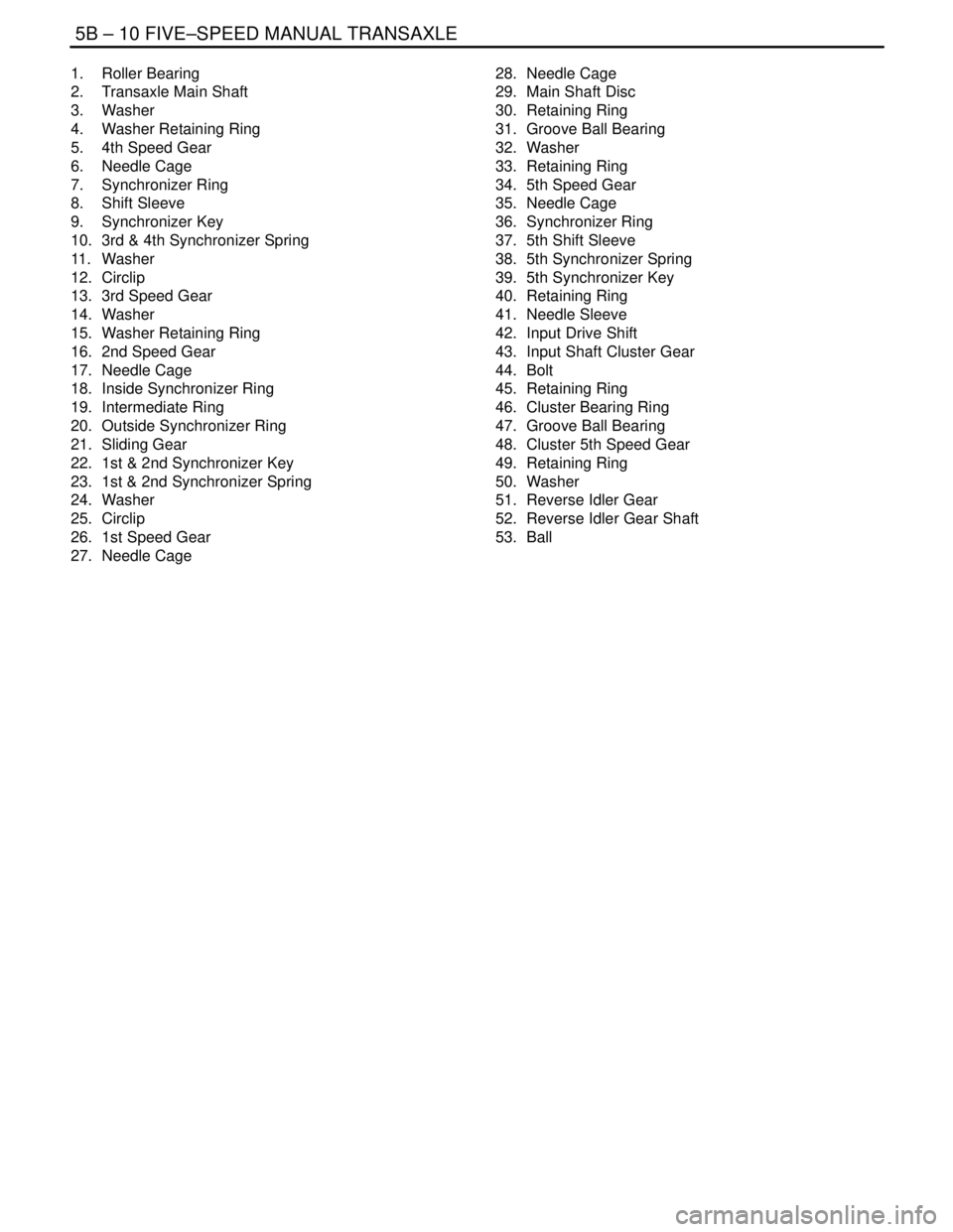

5B – 10IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

1. Roller Bearing

2. Transaxle Main Shaft

3. Washer

4. Washer Retaining Ring

5. 4th Speed Gear

6. Needle Cage

7. Synchronizer Ring

8. Shift Sleeve

9. Synchronizer Key

10. 3rd & 4th Synchronizer Spring

11. Washer

12. Circlip

13. 3rd Speed Gear

14. Washer

15. Washer Retaining Ring

16. 2nd Speed Gear

17. Needle Cage

18. Inside Synchronizer Ring

19. Intermediate Ring

20. Outside Synchronizer Ring

21. Sliding Gear

22. 1st & 2nd Synchronizer Key

23. 1st & 2nd Synchronizer Spring

24. Washer

25. Circlip

26. 1st Speed Gear

27. Needle Cage28. Needle Cage

29. Main Shaft Disc

30. Retaining Ring

31. Groove Ball Bearing

32. Washer

33. Retaining Ring

34. 5th Speed Gear

35. Needle Cage

36. Synchronizer Ring

37. 5th Shift Sleeve

38. 5th Synchronizer Spring

39. 5th Synchronizer Key

40. Retaining Ring

41. Needle Sleeve

42. Input Drive Shift

43. Input Shaft Cluster Gear

44. Bolt

45. Retaining Ring

46. Cluster Bearing Ring

47. Groove Ball Bearing

48. Cluster 5th Speed Gear

49. Retaining Ring

50. Washer

51. Reverse Idler Gear

52. Reverse Idler Gear Shaft

53. Ball

Page 1851 of 2643

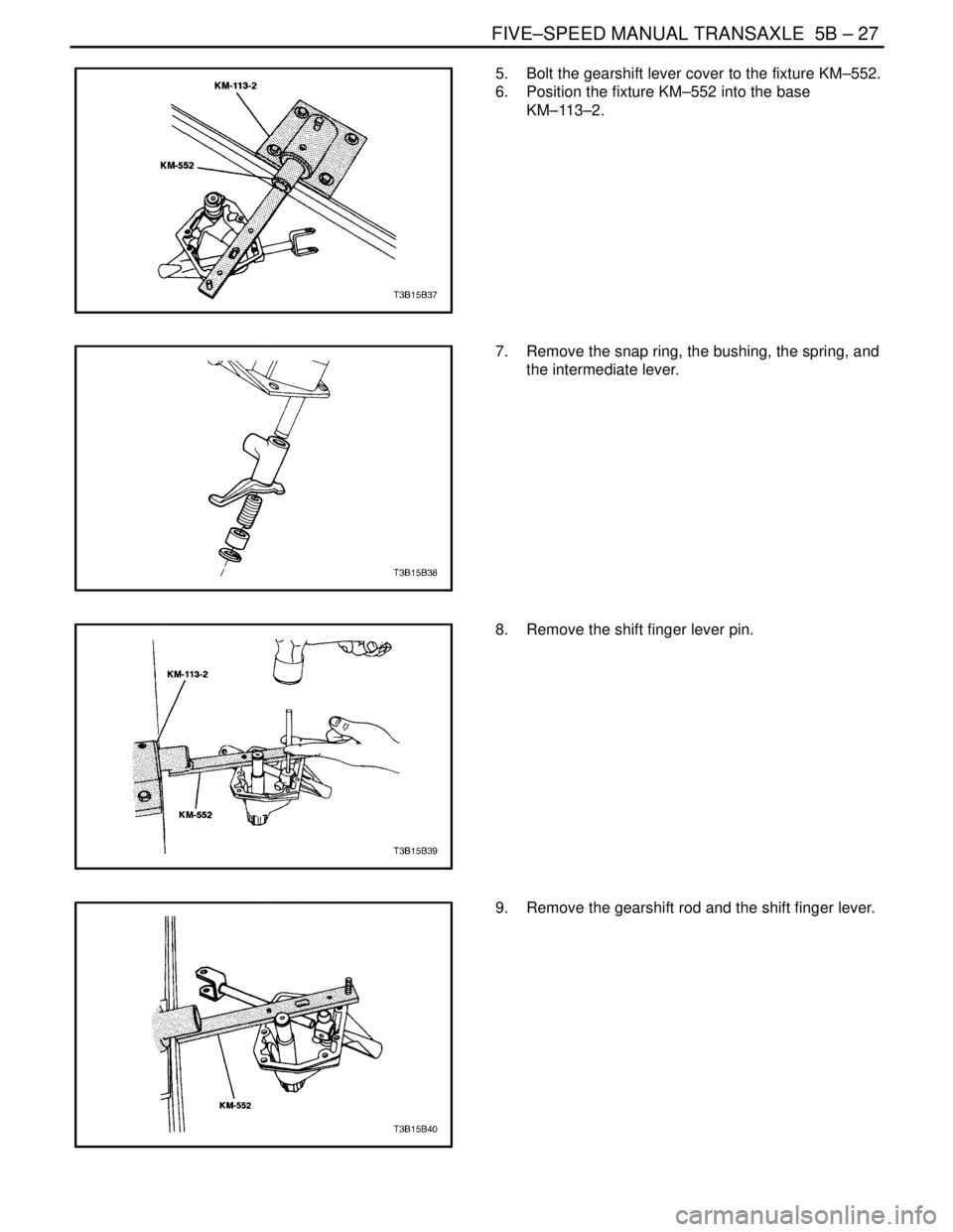

FIVE–SPEED MANUAL TRANSAXLE 5B – 27

DAEWOO V–121 BL4

5. Bolt the gearshift lever cover to the fixture KM–552.

6. Position the fixture KM–552 into the base

KM–113–2.

7. Remove the snap ring, the bushing, the spring, and

the intermediate lever.

8. Remove the shift finger lever pin.

9. Remove the gearshift rod and the shift finger lever.

Page 1886 of 2643

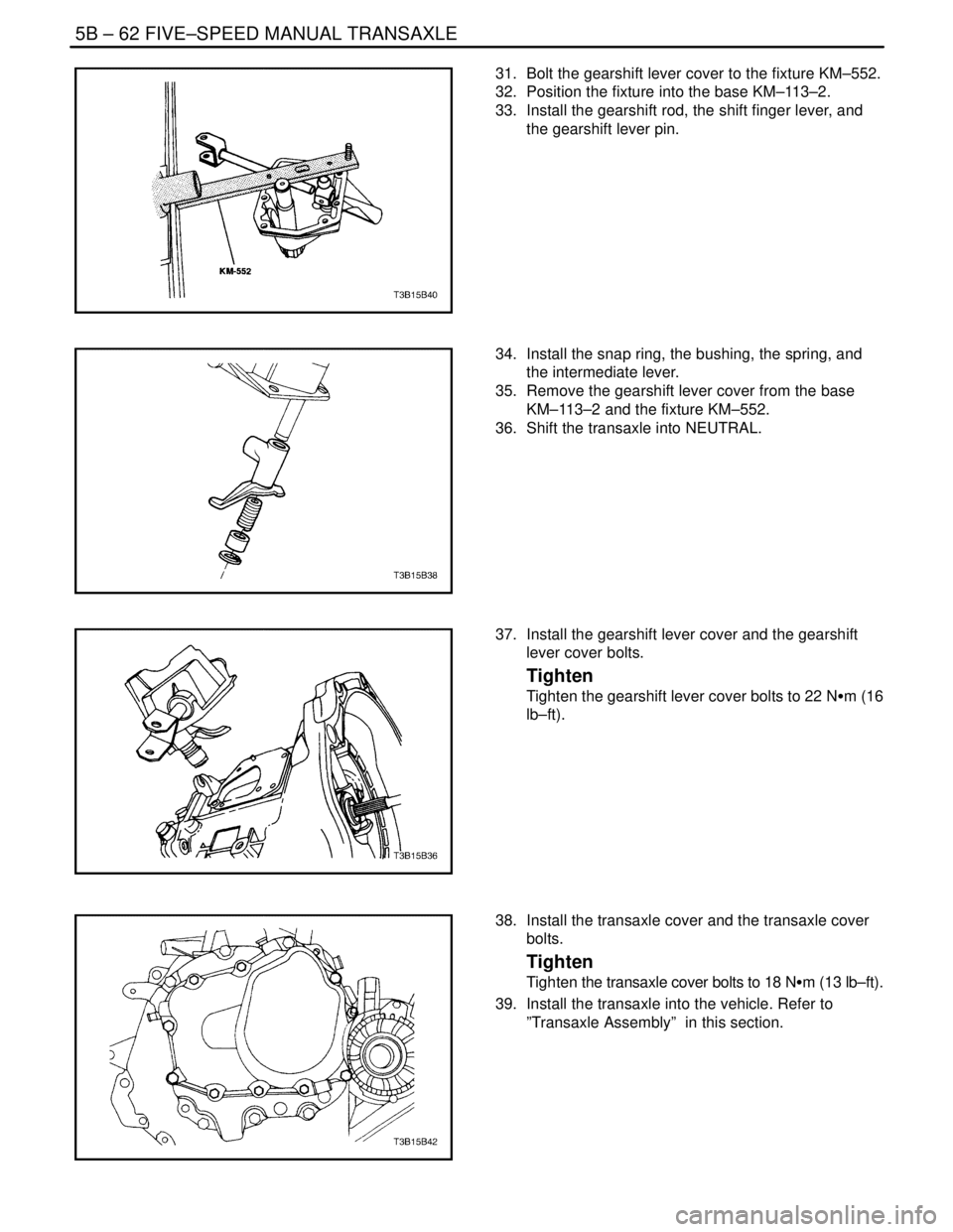

5B – 62IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

31. Bolt the gearshift lever cover to the fixture KM–552.

32. Position the fixture into the base KM–113–2.

33. Install the gearshift rod, the shift finger lever, and

the gearshift lever pin.

34. Install the snap ring, the bushing, the spring, and

the intermediate lever.

35. Remove the gearshift lever cover from the base

KM–113–2 and the fixture KM–552.

36. Shift the transaxle into NEUTRAL.

37. Install the gearshift lever cover and the gearshift

lever cover bolts.

Tighten

Tighten the gearshift lever cover bolts to 22 NSm (16

lb–ft).

38. Install the transaxle cover and the transaxle cover

bolts.

Tighten

Tighten the transaxle cover bolts to 18 NSm (13 lb–ft).

39. Install the transaxle into the vehicle. Refer to

”Transaxle Assembly” in this section.

Page 1903 of 2643

6A – 2IPOWER STEERING SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

KM–354–B Pressure Test Gauge Kit

Check the fluid pressure as follows to determine whether

the trouble is in the pump or the gear unit.

Test Procedure

1. Check the power steering fluid level and the power

steering pump belt tension. Refer to ”Checking and

Adding Fluid” in this section and Section 6B, Power

Steering Pump.

2. Disconnect the high pressure line at the pump. Use

a small container to catch any fluid.

3. Connect the hose of the pressure test gauge kit

KM–354–B to the power steering pressure hose

from the power steering pump.

4. Place the gear selector lever in PARK (automatic

transaxle–equipped vehicles) or NEUTRAL (manual

transaxle–equipped vehicles). Set the parking

brake.

5. Open the gauge valve fully.

6. Start the engine and let it idle.

7. Turn the steering wheel from lock to lock several

times to warm the fluid to operating temperature.

8. Increase the engine speed to 1,500 rpm.

Notice : The power steering pump could be damaged if

the valve is fully closed for more than 5 seconds.

9. Close the gauge valve fully, and read the pressure.

The pump pressure with the valve closed should be

between 8,330 kPa to 8,820 kPa (1,208 psi to

1,279 psi). With electronic variable orifice, the pres-

sure should be between 8,500 kPa to 8,960 kPa

(1,233 psi to 1,299 psi).

10. Immediately open the gauge valve fully.

11. Turn the steering wheel all the way to the left and

the right. If the pressure is within the specified lim-

its, the problem is not in the pump. Check the pow-

er steering gear for leaks.

POWER STEERING SYSTEM LEAK

TEST

General Procedure

Inspect the following:

S The fluid reservoir for overfill.

S Fluid for aeration and overflow.

S The hoses for loose connections.

S The torsion bar, stub shaft and adjuster seals for

leaks.

S The component sealing surfaces for damage.

Important : Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the point

at which the system is leaking. When service is required,

clean the leak area upon disassembly, replace the leaking

seal, check the component sealing surfaces for damage

and reset the torque bolt to specifications, where required.

External Leak Check

The purpose of this procedure is to pinpoint the location of

the leak. In some cases, the leak can be easily located, but

seepage–type leaks may be harder to find. To locate seep-

age leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary. Refer

to ”Checking and Adding Fluid” in this section.

Notice : Do not hold the steering wheel at a stop for any

length of time as this can damage the power steering

pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1907 of 2643

6A – 6IPOWER STEERING SYSTEM

DAEWOO V–121 BL4

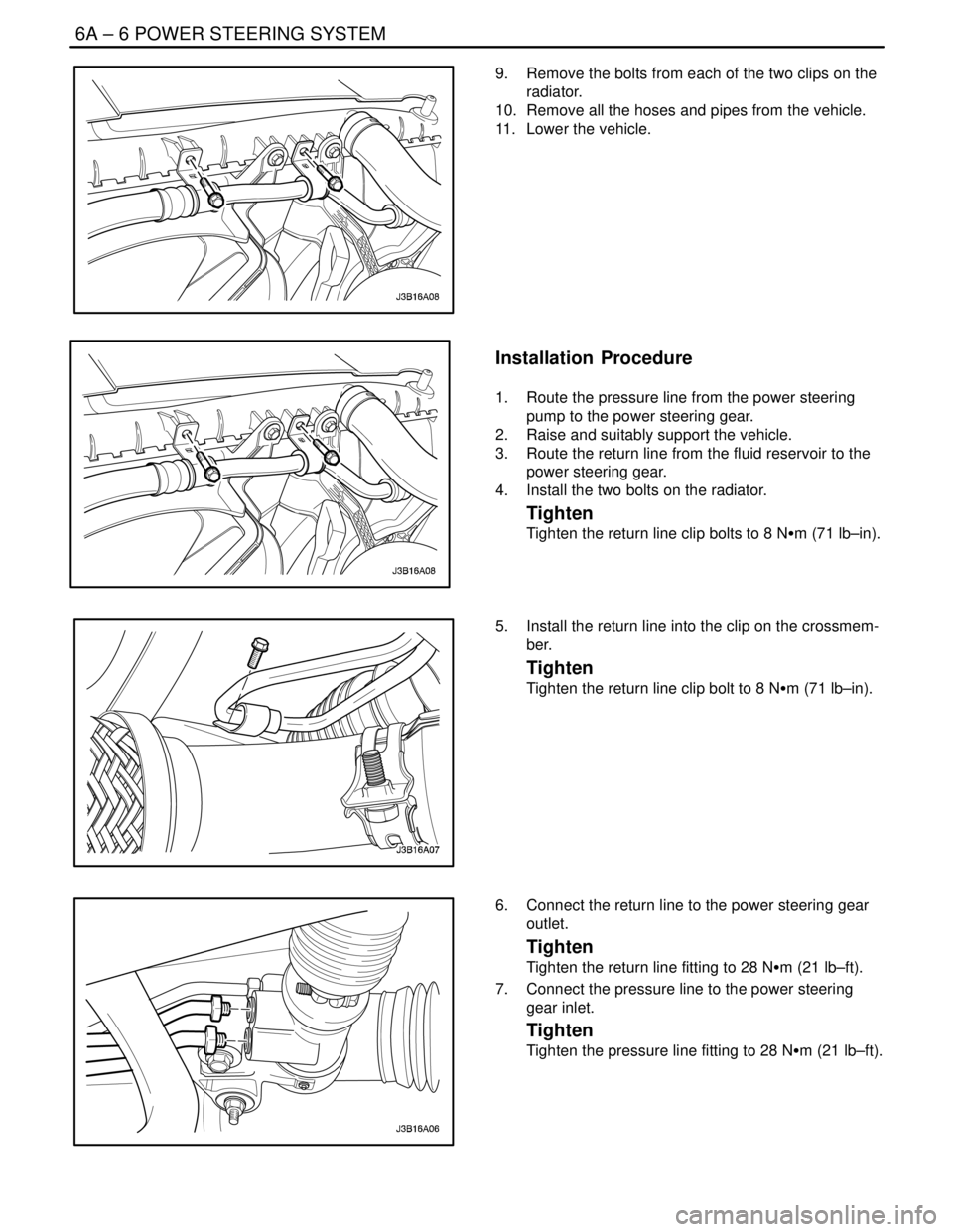

9. Remove the bolts from each of the two clips on the

radiator.

10. Remove all the hoses and pipes from the vehicle.

11. Lower the vehicle.

Installation Procedure

1. Route the pressure line from the power steering

pump to the power steering gear.

2. Raise and suitably support the vehicle.

3. Route the return line from the fluid reservoir to the

power steering gear.

4. Install the two bolts on the radiator.

Tighten

Tighten the return line clip bolts to 8 NSm (71 lb–in).

5. Install the return line into the clip on the crossmem-

ber.

Tighten

Tighten the return line clip bolt to 8 NSm (71 lb–in).

6. Connect the return line to the power steering gear

outlet.

Tighten

Tighten the return line fitting to 28 NSm (21 lb–ft).

7. Connect the pressure line to the power steering

gear inlet.

Tighten

Tighten the pressure line fitting to 28 NSm (21 lb–ft).